Page 1

Manual F-20-TF-L

June 2008

Revision 1

www.dwyer-inst.com

MODEL TFP-LI

MODEL TFM-LI

MODEL TFP-LP

MODEL TFM-LP

Flow Sensors and Flow Meters For Liquids

Installat

ion Manual & Operating Instructions

READ THIS MANUAL COMPLETELY BEFORE ATTEMPTING TO CONNECT

OR OPERATE YOU R FLOW SENSOR. FAILURE TO DO SO MAY RESULT

IN INJURY TO YOU OR D

AMAGE TO THE FLOW SENSOR.

Page 2

T A B L E O F C O N T E N T S

A. Introduction ......................................................................................... 3

B. Installation ........................................................................................... 5

C. Operation .......................................................................................... 13

D. Maintenance And Product Care ............................................................ 19

E. Specifications ..................................................................................... 21

F. Dimensions ...................................................................................

..... 23

G. Connector Pin And Wire Color Cross Reference ..................................... 27

H. Tr

ouble Shooting Guide ...................................................................... 28

I. Warr

anty ........................................................................................... 30

J

. Contacting Dwyer ............................................................................... 30

1. Unpacking .................................................................................................. 3

2. Product Overview And Principle Of Operation .............................................. 3

1. General Considerations .............................................................................. 5

2. Mounting The Flow Sensor Or Flow Meter .................................................. 6

3. Tubing Connections .................................................................................... 7

4. Electrical Connections ................................................................................. 8

a) Overview ........................................................................................... 9

b) Connecting A Cable Assembly ................................................................. 9

c) Electrical Connections – Voltage Output Units (TFP-LI & TFM-LI Series) ..... 10

d) Electrical Connections – Units With Both Voltage & Pulse Outputs

(TFP-LP & TFM-LP Series) ......................................................................... 11

e) Using a 0-5VDC Output Power Adapter Package .................................... 12

1. Start-Up ................................................................................................... 13

2. Entrapped Air or Gas ................................................................................ 13

3. Flow Readings .......................................................................................... 13

a) 0-5VDC Analog Outputs ....................................................................... 14

b) Pulse Outputs ..................................................................................... 14

c) Units with an Integral Display ................................................................. 14

4. Operating at Flow Rates Outside the Calibrated Flow Range ....................... 15

a) Flows Above the Maximum Rated Flow ................................................... 15

b) Flows Below the Minimum Rated Flow .................................................... 16

5. Zero Adjustments ...................................................................................... 16

6. Recalibration ............................................................................................ 16

7. Calibrating Units for different Liquids ......................................................... 19

1. General .................................................................................................... 19

2. Cleaning and Flushing .............................................................................. 20

3. Returning Units For Repair Or Recalibration ............................................... 20

F-20-TF-L, pg. 2 of 30

Page 3

A. Introduction

1. Unpacking

All sensors are suitably packaged to prevent damage during shipping. If

external damage is noted upon receipt of the package, please contact

shipping company

to the device once it has left the manufacturing premises.

Open the package from the top, taking care not to cut too deeply into the

package. Remove all the documentation and contents. Take care to remove

all the items and check them against the packing slip. The products should

also be checked for any concealed shipping damage. If any shortages or

damage is noted, please contact the shipping company and/or Dwyer

Instruments to resolve the problem.

Sensor, Calibration Certificate & Instruction Manual

the

immediately. Dwyer Instruments is not liable for damage

Typical Contents of Box

(Model TFP-LP shown, other models similar).

2. Product Overview and Principle of Operation

CAUTION: Take care not to

drop

your sensor or subject it to

sudden impact. Read the installation section of this manual before

providing power or tubing connections to the unit. Any damage

caused by improper installation or careless handling will not be

repaired under warranty (see limited warranty on page 30 for

more details).

TF Series Flow Meters and Flow Sensors for liquids are capable of

measuring flows as low as 13-100 ml/min or as high as 1.0-10.0 l/min.

Highly repeatable results are achieved using a patented Pelton Turbine

F-20-TF-L, pg. 3 of 30

Page 4

Wheel flow sensor design. This proven design minimizes zero drift while

maintaining fast response and linear outputs with virtually no maintenance.

Patented technology measures flow using a miniature turbine wheel similar

in size to a U.S. dime (16 mm diameter, 0.75 mm thick). The micro-turbine

wheel is supported on a very small sapphire shaft that is held in position by

two sapphire bearings. The micro-turbine assembly is so light that it virtually

floats in the liquid. This relieves force on the bearings and almost eliminates

wear.

As flow passes through the flow sensor, a precision machined nozzle directs

the fluid onto the very small teeth of the micro-turbine wheel. This causes the

wheel to spin at a speed proportional to the flow rate.

The micro-turbine wheel has alternating white and black sections evenly

spaced on one side of the wheel. An infrared light beam is directed onto the

wheel. As the wheel rotates the infrared beam is reflected off each white

section. The reflected beam is detected by a phototransistor that converts the

reflections into electrical pulses. As the wheel spins faster the pulse rate

increases. Processing circuitry provides analog and/or pulse output that are

linearly proportional to the flow rate

When the wheel stops (under zero flow conditions), no pulses are

generated. Consequently, zero drift is not possible and zero adjustments are

never required.

Every unit is supplied with a calibration certificate detailing the results

obtained during calibration. Units are calibrated using deionized water as

the reference media. Flowing liquids with different specific gravities or

viscosities may affect the calibration.

F-20-TF-L, pg. 4 of 30

Page 5

B. Installation

CAUTION: Do not flow any gas through a liquid flow sensor.

This may damage the micro-turbine assembly and void the

warranty. Do not exceed the pressure, temperature or power

operating ranges detailed in the Specifications section of this

manual. Dwyer Instruments shall not be liable for any damage or

injury caused by incorrect operation of their products.

1. General Considerations

It is recommended that a safety shut-off valve be installed upstream of

(before) the sensor.

All wetted parts should be checked for compatibility with the liquid to be

used. If there are any incompatibilities e.g. highly corrosive liquid, then the

unit may be damaged or fail prematurely. Such damage will not be

repaired under warranty.

Units should be installed in a clean, dry environment with an ambient

temperature that is as stable as possible. Avoid areas with strong magnetic

fields, strong air flows or excessive vibration.

If the liquid to be used may contain particles larger than 25 microns then a

filter (25 microns or less) should be installed upstream of (before) the unit.

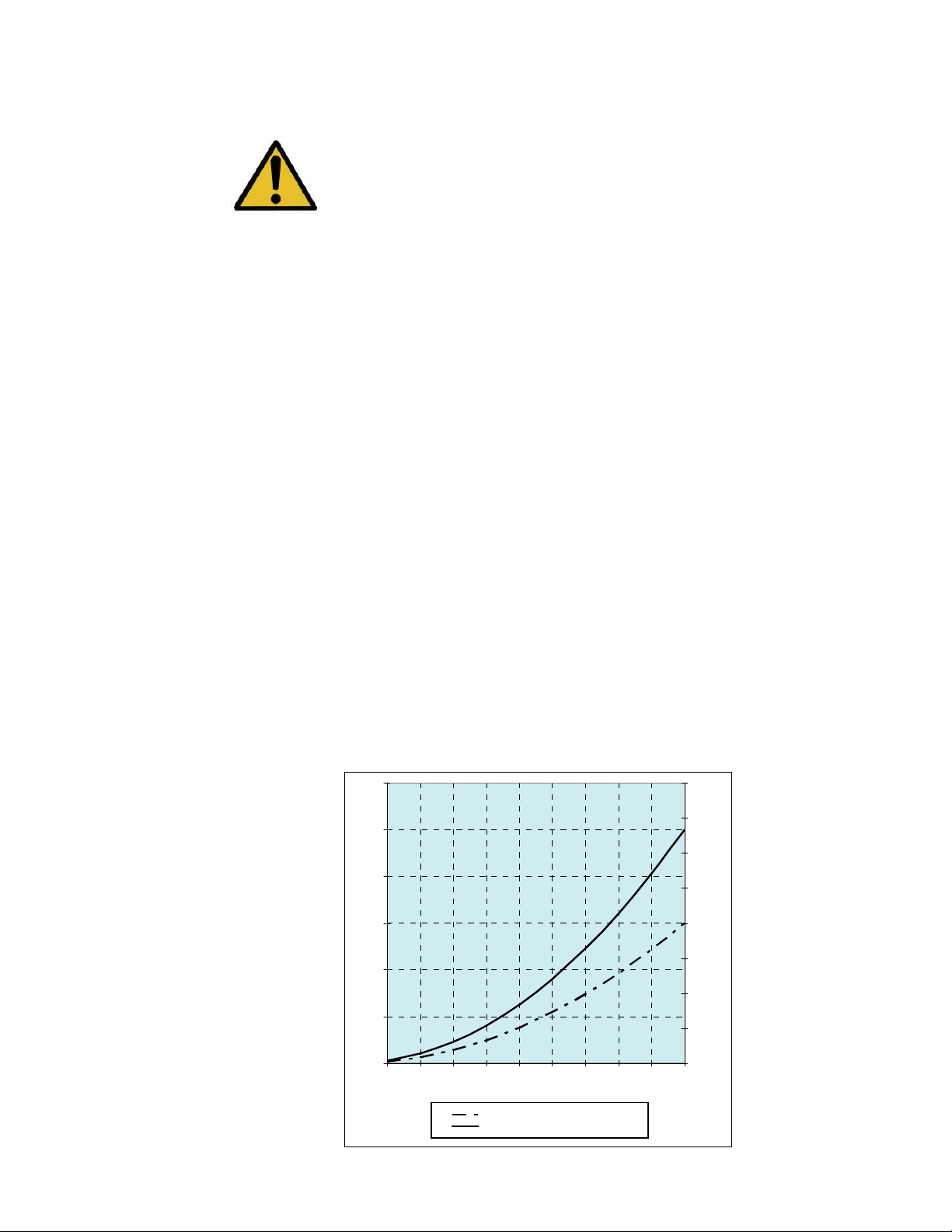

The required differential press (or pressure drop across the unit) decreases

exponentially with decreases in flow rate.

Pressure Drop vs. Percentage of the Full Scale

Rated Flow (may vary ±10% of indicated psid)

12

0.8

10

8

6

Delta P psid

4

2

0

10 20 30 40 50 60 70 80 90 100

% o f rate d flow

100-1000 ml/min Units

All Other Ranges

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

Delta P Bar

F-20-TF-L, pg. 5 of 30

Page 6

To calculate the pressure drop at a certain flow rate use the formula

PD = (YourFlow / MaxFlow)2 x PDmax

PD = Pressure drop at YourFlow.

YourFLow = flow rate (ml/min or l/min)

MaxFlow = 100% rated flow for the sensor (in same units as YourFlow)

max = Pressure drop at 100% rated flow (see chart above)

PD

If the pressure available for the flow sensor is BELOW the pressure drop at

the required flow then flow through the unit will not be possible.

For example: You have a sensor with a 50-500ml/min flow range and want

to know the pressure drop (or minimum differential pressure required) at

300ml/min. According to the chart above, the pressure drop at 100% of

flow is approx 10psi. Using the formula above:

PD = (300 / 500)2 x 10 = 3.6 psid

Therefore, at 300ml/min the minimum required differential pressure for this

unit is 3.6 psid. This means that if the available pressure is below 3.6psid

then flow through the unit may not be possible.

Pressure drop through a system is cumulative. If the total pressure drop

across all the components in a system exceeds the minimum pressure

available then flow will not be possible.

For example: A system has a pressure of 30-40psi. There are several

components and the sum of their pressure drops at the required flow rate is

32psid. If the system is operating at 30psi flow would not be possible as the

total of the pressure drops would be greater than the pressure available.

The system will only operate if the system pressure is above 32psi.

If there is any possibility that there may be bubbles or entrapped gas in the

system then the outlet tubing should be elevated above the inlet port. This

will enable any gas that may become entrapped in the unit to escape (see

section C2 for details of how to remove entrapped air or gas).

2. Mounting the Flow Sensor or Flow Meter.

The TF Series of Flow Sensors and Flow Meters have no particular

installation requirements so may be mounted in any convenient position.

It is recommended that units be fixed to a suitable substrate with #4 screws

using the two mounting holes provided.

F-20-TF-L, pg. 6 of 30

Page 7

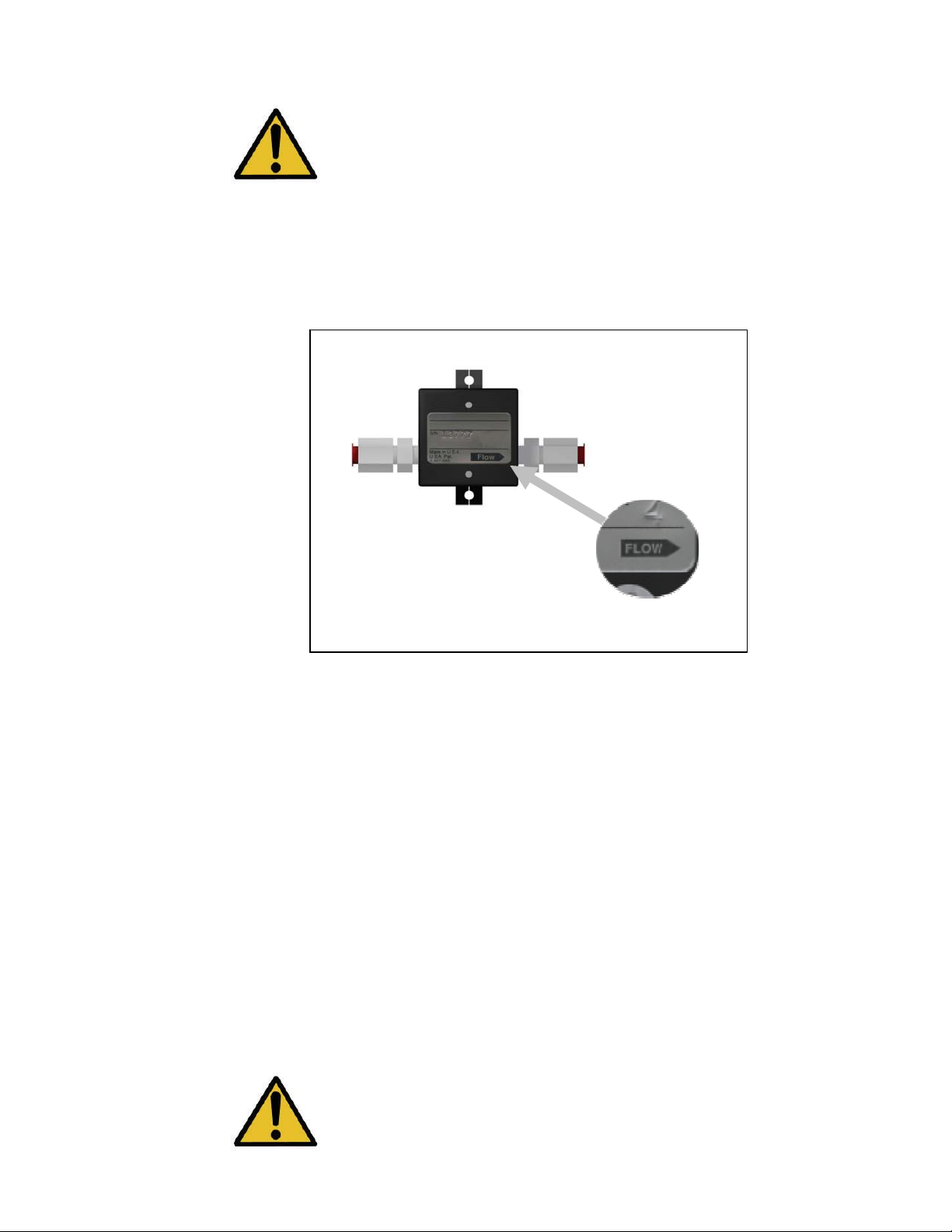

Mounting The Sensor

(Mounting hardware not included with sensor)

3. Tubing Connections

CAUTION: DO NOT FLOW ANY GAS THROUGH A LIQUID

FLOW SENSOR OR FLOW METER. THIS WILL DAMAGE THE

MICRO-TURBINE ASSEMBLY AND VOID THE WARRANTY.

All tubing must be clean and without crimps, burrs or scratches.

Only use the fittings factory installed on the unit. If the fittings are removed

the calibration of the unit may be effected and leaking may occur. If

different fittings are required please contact Dwyer Customer Service for

assistance.

When connecting the sensor to the tubing a wrench should be used to stop

the fitting rotating in the sensor body. Take care not to over tighten the

fittings or leaking may occur.

Connecting and tightening the Fittings

F-20-TF-L, pg. 7 of 30

Page 8

CAUTION: DO NOT over tighten the fittings into the sensor

body. Excessive force may damage the sensor body and will

NOT be repaired under warranty.

The flow direction for the unit is clearly marked on the label. Do not reverse

the flow direction or the unit will not function.

Close Up of Label Showing Flow Directions

(All models similar)

For the best results, precautions should be taken to minimize the amount of

turbulence in the flow stream. Avoid valves, fittings, curves in the tube, and

changes in the internal diameter or any other restrictions close to the inlet of

the sensor. The tubing ID should be as large as possible and preferably not

smaller than the ID of the fittings installed on the sensor.

For 0.2-2.0 L/min units a 10 cm straight length of tube before the sensor is

recommended. For higher flow range units (0.5-5.0 L/min and 1.0-10.0

L/min), a 20 cm straight length of tubing before the sensor is recommended.

If this is not possible it is recommended that straight lengths between all

connections on the inlet side of the sensor are as long as possible and 90

degree fittings (with a large enough ID) are used instead of curves in the

tubing.

4. Electrical Connections

CAUTION: Incorrect wiring may cause severe damage to the

unit. Applying an AC voltage (115VAC or 230VAC) directly to

the unit will cause damage. Read the following instructions

carefully before making any connections.

F-20-TF-L, pg. 8 of 30

Page 9

a) Overview

The TFP-LP and TFM-LP series provide a 0-5VDC and pulse output

proportional to the flow rate. This output may be connected to a display,

data acquisition system or voltmeter.

The TFP-LI and TFM-LI feature an integral display that provides a local flow

reading. These units also have a 0-5VDC analog output available. If

required, this may be connected to another display, data acquisition system

or voltmeter.

A stable D.C. power supply is required to operate the unit. The voltage and

current requirements depend on the configuration of the unit. Full details

may be found in the Specifications section of this manual.

Connecting wires should be as short as possible to avoid voltage drops.

Twisted 2 pair conductor cable should be used if the length of the power

wires is to be longer than 1 meter.

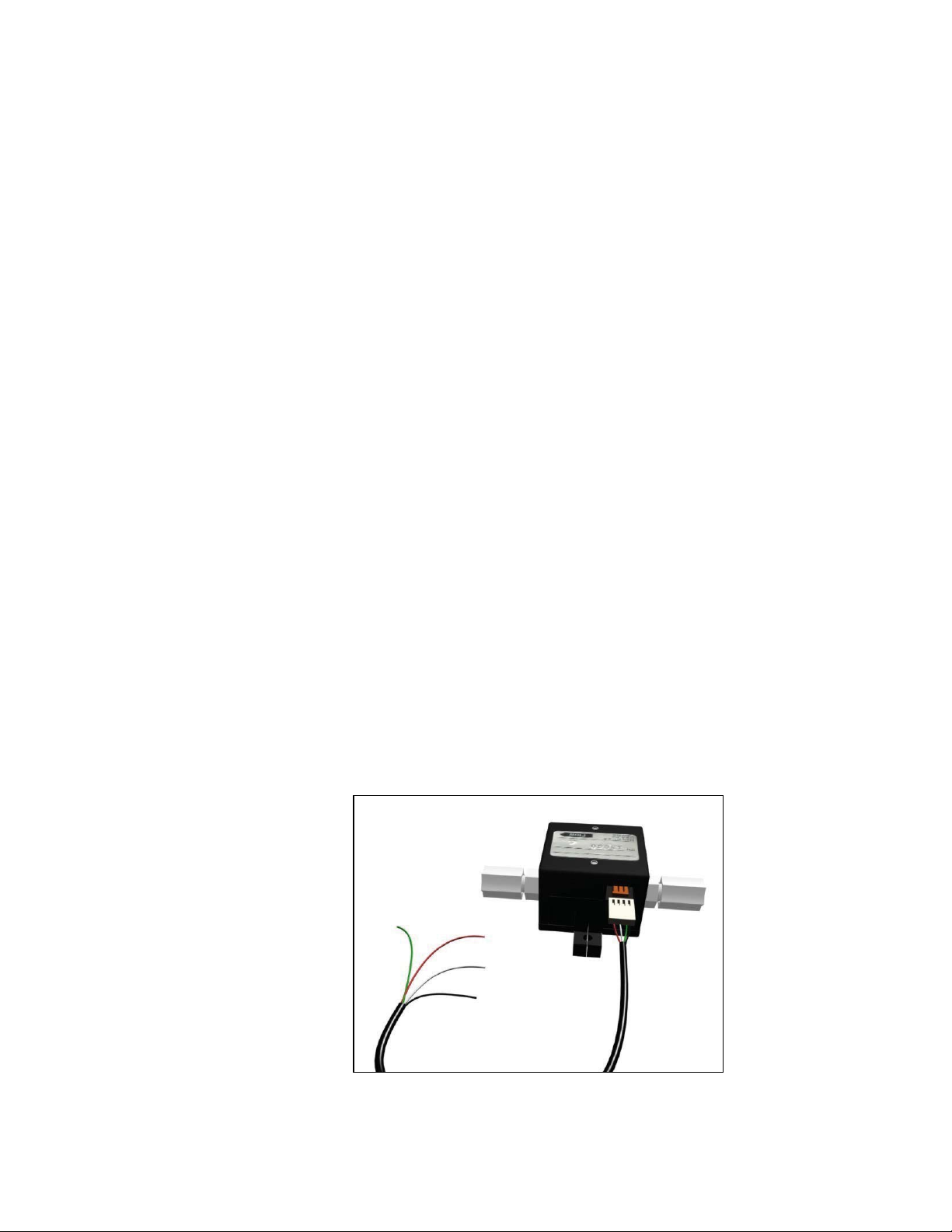

Units are supplied with an integral 4 pin connector. Connections to the unit

are made using a mating cable assembly or power adapter package as

detailed in the following sections (parts 4.b to 4.e of this manual). A

connector pin and wire color cross reference may also be found in

Appendix G (Page 27) of this manual.

b) Connecting the Cable Assembly

The connector on the end of the cable assembly should be pushed into the

mating socket on the sensor taking care to ensure that it is the correct way

up.

Connecting the Cable Assembly

(All models similar)

Electrical Connections are made to the cable assembly as detailed in the

following sections.

F-20-TF-L, pg. 9 of 30

Page 10

c) Electrical Connections – Voltage Output Units (TFP-LI &

TFM-LI Series)

The cable assembly should be connected to the sensor as detailed in section

4(b) above. Power should not be applied to the sensor until all the

connections have been made and checked. Electrical connections should be

made as follows:

Wiring Schematic For Voltage Output Units.

The RED wire should be connected to the Positive of the power source.

The BLACK wire should be connected to the Negative ( Ground ) of the

power source.

The WHITE wire provides the signal output and should be connected to the

positive terminal of the display, data acquisition system or voltmeter with an

impedance of greater than 2500Ω (Ohms).

The GREEN wire (if present) is NOT used

CAUTION: Avoid high voltage static discharges to any of the

connections. Do not short the input/output signal wires or allow

them to contact the power wires at any time. DAMAGE WILL

RESULT!

F-20-TF-L, pg. 10 of 30

Page 11

d) Electrical Connections –Units with Both Voltage and Pulse

Outputs (TFP-LP & TFM-LP Series)

The cable assembly should be connected to the sensor as detailed in section

4(b) above. Power should not be applied to the sensor until all the

connections have been made and checked.

Wiring Schematic For Voltage and Pulse Output.

The RED wire should be connected to the Positive of the power source.

The BLACK wire should be connected to the Negative ( Ground ) of the

power source.

The WHITE wire provides the signal output and should be connected to the

positive terminal of the display, data acquisition system or voltmeter with an

impedance of greater than 2500Ω (Ohms).

The GREEN wire (“T” option only) is the pulse output and should be

connected to the Positive terminal of the data acquisition system with an

impedance of greater than 10KΩ (Ohms).

The PULSE and VOLTAGE output may be monitored simultaneously.

CAUTION: Avoid high voltage static discharges to any of the

connections. Do not short the input/output signal wires or allow

them to contact the power wires at any time. DAMAGE WILL

RESULT!

F-20-TF-L, pg. 11 of 30

Page 12

e) Using a 0-5VDC Output Power Adapter Package.

An optional 0-5VDC Output Power Adapter Package is available for use

with the TF Series. This consists of a power source (115VAC or 230VAC)

and cable assembly with pig-tail (soldered wire) ends for the signal output.

This should be assembled as shown in the following diagram.

Connecting the Power Adapter to the Flow Sensor

(All other models similar)

Electrical connections to the cable assembly should be made as follows:

YELLOW WIRE: This provides the 0-5VDC signal output and should be

connected to the positive terminal of the display, data acquisition system or

voltmeter with an impedance of greater than 2500Ω (Ohms).

GREEN WIRE: For Pulse output units the green wire provides the pulse

output and should be connected to the positive terminal of the data

acquisition system with an impedance of greater than 10KΩ (Ohms).

WHITE WIRE: This is the signal negative and should be connected to the

negative (ground) terminal of the voltmeter, display or data acquisition

system.

CAUTION: Avoid high voltage static discharges to any of the

connections. Do not short the output signal wires or allow them to

contact the power wires at any time. DAMAGE WILL RESULT!

F-20-TF-L, pg. 12 of 30

Page 13

C. Operation

CAUTION: USE WITH LIQUIDS ONLY. FLOWING GAS OR AIR

THROUGH YOUR FLOW SENSOR WILL DAMAGE THE MICROTURBINE ASSEMBLY. THIS TYPE OF DAMAGE WILL NOT BE

REPAIRED UNDER WARRANTY.

1. Start Up

Before applying power to the unit check all tubing and electrical

connections. Once correct installation is verified switch on the power.

2. Entrapped Air or Gas

There may be a lot of air or gas trapped in your sensor after installation.

This will usually escape the unit when flow (within the range of the unit) is

first started.

CAUTION: The system should be primed with liquid and flow

started gradually. This will prevent trapped air or gas from being

forced through the sensor at a high velocity that may damage the

sensor.

If gas remains entrapped in the unit it may be necessary to elevate the outlet

tubing above the inlet of the sensor. This should enable the trapped gas to

escape the unit. The sensor may be returned to its original position once all

the gas has escaped.

If elevating the outlet tubing does not work, block or pinch the outlet tube

whilst there is flow in the system. After approximately 5 seconds, release the

restriction to allow normal flow. Doing this will build up pressure in the flow

path that when released will help remove the entrapped gas. Repeat this

until the entrapped gas is removed from the unit.

3. Flow Readings

TFP-LP and TFM-LP Series sensors provide a 0-5VDC and pulse output

proportional to the flow rate.

The TFP-LI and TFM-LI Series feature an integral display that provides a local

flow reading and a 0-5VDC analog output.

Each flow sensor is factory calibrated for a specific flow range. The flow

range is shown on the unit’s label and calibration certificate. Units are

calibrated using deionized water as the reference media.

F-20-TF-L, pg. 13 of 30

Page 14

a) 0-5VDC Analog Outputs

By monitoring the voltage output signal it is possible to determine the flow

rate of the liquid. Units are configured so that an output signal of 5.0VDC is

provided when the maximum flow (i.e. Full Scale flow) is passing through

the unit. The output signal is linear and scalable enabling calculation of flow

rates within the sensor’s range. For example:

For a flow range of 50-500ml/min:

At 500ml/min the output signal would be 5VDC

If the output signal were 3.5VDC then the flow rate would be:

500 ÷ 5 × 3.5 = 350ml/min

If the maximum flow rate is exceeded non-linear and inaccurate readings

will result.

b) Pulse Outputs

By monitoring the Pulse output frequency it is possible to determine the flow

rate of the liquid. The pulse frequency for maximum flow through the unit

(i.e. full scale flow) is detailed on the calibration certificate. This differs from

unit to unit. This output is approximately linear and scalable within the

sensor’s range. For example:

For a flow range of 1.0-10.0l/min:

The calibration certificate gives the following:

At 10.0l/min the pulse output signal is 312Hz

At 5.0l/min the pulse output signal is 150Hz

At 2.0l/min the pulse output signal is 58Hz

If the output signal were 120Hz then the flow rate would be:

5.0 ÷ 150 × 120 = 4.0 l/min (using the closest calibration point)

c) Units With an Integral Display

The TFP-LI and TFM-LI Series feature an integral 3 ˝ digit LCD display. This is

configured to read in ml/min for flow ranges up to 50-500 ml/min and in

l/min for all other flow ranges. The display will only operate if power is

applied to the unit.

F-20-TF-L, pg. 14 of 30

Page 15

Flow readings may be taken directly from the display or by monitoring the

0-5VDC analog output provided by using a cable assembly or power

adapter package (see above).

LCD Flow Display

(TFM-LI Series Shown, other models similar)

4. Operating at Flow Rates Outside the Calibrated Flow Range

CAUTION: If the flow through the unit exceeds 120% of the

maximum rated (full scale) flow the unit may be damaged. This

type of damage will not be repaired under warranty.

Flow measurement is only accurate within the calibrated flow range for the

unit. This is detailed on the calibration certificate. The unit will still operate, to

some degree, outside this flow range.

Results obtained when operating outside the specified range of the unit are

not accurate but may be considered repeatable.

a) Flows Above the Maximum Rated Flow.

If the flow rate is above the maximum rated (or full scale) flow, the unit will

still operate and provide an output signal proportional to the flow rate.

Flows must not exceed 120% of the maximum rated flow or the unit may be

damaged.

F-20-TF-L, pg. 15 of 30

Page 16

b) Flows Below the Minimum Rated Flow.

Signal outputs may be obtained at flow rates below the minimum specified

for your unit. The amount of flow that may be measured below the minimum

specified varies from unit to unit.

5. Zero Adjustments

It is impossible for there to be any zero drift so zero adjustments are never

required.

6. Recalibration

The calibration of the flow sensor may be easily verified using empirical

methods.

It should be noted that the use of empirical methods outside a certified

calibration laboratory is subject to inaccuracy and error. These methods

should only be used to gain an indication of a sensor’s performance. Please

contact Dwyer Customer Service if accurate, certified recalibration is

required.

A typical empirical calibration check may be carried out as follows:

Carefully adjust the flow rate so that the maximum output signal is obtained.

With the flow rate constant, liquid flowing through the unit should be

gathered in a container over a timed interval. The total volume flowed over

the timed period should then be measured using a measuring cylinder. The

actual flow rate (in the same units as the flow sensor calibration certificate)

may then be calculated. The actual maximum flow rate should then be

compared to the specified maximum flow rate to determine the error in

calibration. For example:

For a flow range of 20-200ml/min with a 0-5VDC output:

With a constant flow and constant 5VDC output the actual volume

measured over 30 seconds was 102ml.

Therefore the actual flow rate is:

(102 / 30) x 60 = 204ml/min

The error is therefore 204 – 200 = 4ml/min or 2%

F-20-TF-L, pg. 16 of 30

Page 17

A second empirical check should be made at a flow rate below the

maximum for the unit e.g. at 50% of full scale. The calculated percentage

error at this flow should then be compared to the error at maximum flow. If

there is a big difference in the percentage errors then the flow signal is no

longer linear and the unit may be damaged (consult Dwyer Customer

Service).

Once it has been determined that the linearity is still acceptable and the

error in flow reading at maximum flow has been calculated, there are 3

options:

i.) Minor adjustments to actual calibration of the flow sensor may be made

by turning the gain potentiometer on the side of the unit. For example:

For a unit with a flow range of 13-100ml/min and a

0-5VDC output:

With a constant flow and constant 5VDC output the actual volume

measured over 60 seconds was 103ml.

The correct voltage output for a flow of 103 ml/min is:

(5/100) x 103 = 5.15 V

With the flow at a constant 103 ml/min the gain potentiometer

should be carefully adjusted so that a voltage output reading of

5.15 V is obtained.

If the unit cannot be suitably adjusted please contact Dwyer Customer

Service. Pulse outputs are not adjustable.

Adjusting the Gain Potentiometer Using a Flat Head Screwdriver

(TFP-LP Series shown, other models similar)

F-20-TF-L, pg. 17 of 30

Page 18

ii.) Adjust the scaling endpoints in the display or data acquisition system. For

example:

For a flow range of 50-500ml/min with a 0-5VDC output:

With a constant flow and constant 5VDC output the actual volume

measured over 60 seconds was 405ml.

Therefore the actual flow rate is:

(405 / 60) x 60 = 405ml/min

The display or data acquisition system may now be configured as

follows:

0 VDC = Zero flow

5VDC = 405ml/min

iii.) Apply the error factor to each flow reading taken. For example:

For a flow range of 0.2-2.0l/min connected to a display:

With a constant flow rate of 2.0 l/min on the display, the actual

volume measured over 20 seconds was 0.7l

Therefore the actual flow rate is:

(0.7 / 20) x 60 = 2.1 l/min

The error is therefore 2.1 – 2.0 = 0.1 l/min or 5%

If the display shows an uncorrected flow rate of 1.4 l/min then :

Corrected flow rate = Uncorrected flow rate + error

Corrected flow rate = 1.4 + 5% = 1.47 l/min

F-20-TF-L, pg. 18 of 30

Page 19

7. Calibrating Units for Different Liquids

The TF Series for liquids will operate with most translucent liquids subject to

compatibility of the wetted parts. Best results are obtained with low viscosity

(less than 10 centistokes) liquids. For information regarding higher viscosity

liquids, contact Dwyer Customer Service.

Units are calibrated with deionized water as the reference media. Using

other liquids will affect the calibration. The amount of calibration error will

depend on the characteristics of the liquid being flowed.

The error in flow reading (or calibration) should be calculated and utilized

as detailed in section 6 above.

D. Maintenance and Product Care

1. General

CAUTION: Do not disassemble your flow meter or flow sensor

for any reason. If the unit appears to be malfunctioning please

contact Dwyer Customer Service.

The TF Series of flow sensors require no periodic maintenance if used within

the recommended specifications.

The next recommended recalibration date is stated on the calibration

certificate supplied with the unit. Please contact Dwyer Customer Service for

further information.

Inlet filters should be periodically checked and cleaned / replaced as

necessary.

Regularly check all electrical and process connections for damage or

deterioration.

If the sensor is to be stored, keep both the inlet and outlet ports sealed.

Do not store a sensor with any chemical other than water (or air) inside it

over an extended period of time. Prolonged exposure to chemicals other

than water may lead to precipitation or corrosion.

F-20-TF-L, pg. 19 of 30

Page 20

2. Cleaning and Flushing

If there is a buildup of deposits or residues from the measured chemicals it

may be necessary to clean

or flush

the unit. This should be done by flowing

clean, particle free water through the unit at a flow rate, pressure and

temperature within the specifications of the unit. If necessary, flow may be

reversed to assist flushing.

Under no circumstances should gas or air be flowed through the unit. This

will cause severe damage.

3. Returning Units for Repair or Recalibration

To return units for repair or recalibration please contact Dwyer Customer

Service. A Return Material Authorization (RMA) Number will then be issued

to enable the unit to be returned. Please note that no returns will be

accepted unless the RMA number is clearly indicated on the outside of all

packages.

Once the unit has been received it will be evaluated and the cost of any

repairs / recalibration determined. Once agreement has been received to

pay for all the necessary work the unit will be processed and returned. No

charges will be made for Warranty Repairs.

Dwyer Customer Service may be contacted as follows:

Mailing address: Dwyer Instruments Inc.

P.O. Box 373, 102 Indiana Hwy. 212

Michigan City, IN 46361

U.S.A.

Phone: U.S.A. (800) 872-9141 or (219) 879-8000

Fax: U.S.A. (219) 872-9057

Email: tech@dwyer-inst.com

Website: www.dwyer-inst.com

F-20-TF-L, pg. 20 of 30

Page 21

E. Specifications

Model TFP-LP Model TFM-LP

Analog Signal Accuracy

(including linearity)

Repeatability ±0.2% Full Scale1

±1.0% Full Scale

1

Pressure Rating

Temperature Rating

100 psig

(6.8 bar)

Operating Range: 5 to 55°C

500 psig

(34.5 bar)

Storage Range: 0 to 70°C

Temperature Sensitivity ±0.2% F.S. 1 or less per °C

Wetted Materials

Ryton

Epoxy

Glass

Sapphire

316 Stainless

®

Ryton

Epoxy

Glass

®

Sapphire

O-Ring Material Viton®

Fitting Material (Standard) Acetal Stainless Steel

Fitting Material Optional

Kynar PVDF

Brass

Stainless Steel

Acetal

Kynar PVDF

Brass

Recommended Filtration 25 microns or less

Compatible Liquids

Low viscosity (ideally <10cS)

Translucent or transparent

Minimum amount of entrapped air or gas

0-5VDC Output Signal

Standard

Minimum 2.5 KΩ load

Pulse Output Signal

7.5VDC peak buffered square wave

Typically 0-400Hz

±3.0% Full Scale accuracy

Typical Power Consumption

12 VDC @ 35 mA

(11.5-15 VDC)

Response Time Typically <1 second for 63% of final value

Reliability 100,000 hours MTBF

Certifications CE Approved

89/336/EEC

(EN 55011 & EN 50082-1)

73/23/EEC Low Voltage Directive

Ratings IP10 (NEMA 1)

Warranty 1 year limited

1. Specifications from 10-100% of rated flow. Linearity is best fit straight line. All calibrations performed

with deionized water unless otherwise stated on calibration certificate

F-20-TF-L, pg. 21 of 30

Page 22

Model TFP-LI Model TFM-LI

Display 3.5 Digit Non Backlit LCD, 0.39” (10mm) high digits

Accuracy (including linearity) ±1.0% Full Scale1

Repeatability ±0.2% Full Scale1

Pressure Rating

Temperature Rating

100 psig

(6.8 bar)

Operating Range: 5 to 55°C

500 psig

(34.5 bar)

Storage Range: 0 to 70°C

Temperature Sensitivity ±0.2% F.S. 1 or less per °C

Wetted Materials

Ryton

Epoxy

Glass

Sapphire

316 Stainless*

®

Ryton

Epoxy

Glass

®

Sapphire

O-Ring Material Viton®

Fitting Material (Standard) Acetal Stainless Steel

Optional Fitting Materials Acetal, Kynar PVDF, brass, or stainless steel

Recommended Filtration 25 microns or less

Compatible Liquids

Low viscosity (ideally <10cS)

Translucent or transparent

Minimum amount of entrapped air or gas

0-5VDC Output Signal

Standard

Minimum 2.5 KΩ load

Typical Power Consumption

12 VDC @ 35 mA

(11.5-15 VDC)

Response Time Typically <1 second for 97% of final value

Reliability 100,000 hours MTBF

Certifications CE Approved

89/336/EEC (EN 55011 & EN 50082-1)

73/23/EEC Low Voltage Directive

Ratings IP10 (NEMA 1)

Warranty 1 year limited

1. Specifications from 10-100% of rated flow. Linearity is best fit straight line. All

calibrations performed with deionized water unless otherwise stated on calibration

certificate

F-20-TF-L, pg. 22 of 30

Page 23

F. Dimensions

ALL DIMENSIONS IN INCHES (MILLIMETERS IN BRACKETS)

Model TFP-LP For Liquids

1/4” Acetal Fittings Shown

F-20-TF-L, pg. 23 of 30

Page 24

Model TFM-LP For Liquids

1/4” Stainless Fittings Shown

F-20-TF-L, pg. 24 of 30

Page 25

Model TFP-LI For Liquids

1/4” Acetal Fittings Shown

F-20-TF-L, pg. 25 of 30

Page 26

Model TFM-LI For Liquids

1/4” Stainless Fittings Shown

F-20-TF-L, pg. 26 of 30

Page 27

G. Connector Pin & Wire Color Cross Reference

End On View of Connector Socket and Connector

Standard Units:

Pin Cable Wire

Color

Voltage

(TFP-LI & TFM-LI)

1 Black Signal & Power

Negative (Ground)

2 White Voltage Output Voltage Output

3 Red Power Positive Power Positive

4 Green Not Used Pulse Output

Unit Output

Voltage & Pulse

(TFP-LP & TFM-LP

Signal & Power

Negative (Ground)

F-20-TF-L, pg. 27 of 30

Page 28

H. Troubleshooting Guide

Symptom Possible Cause Method of Correction

Unit Leaks. Fittings not tight enough.

Sensor assembly cracked.

No output signal or

flow indication.

Flow reading

accuracy is outside

the specification.

No power or low power.

No flow passing through

unit.

Output shorted or

overloaded.

Improper connection.

Moisture on internal

electronics.

Output circuitry damaged.

Liquid not translucent

enough.

Attempting to measure flows

below the specified

minimum for the unit.

Liquid has a different

viscosity and / or specific

gravity than water at 20°C.

Entrapped air or gas.

Mechanical sensor

assembly damaged.

Tighten fittings (see section

B3).

Unit must be returned for

repair (see Section D3).

Apply correct power.

Display or output should

read zero if there is no flow.

Increase the flow rate until a

reading is obtained. (Do not

exceed the specified

maximum flow!).

Check electrical connections

(see section B4).

Check electrical connections

(see section B4) and ensure

connector is correctly

plugged in.

Allow unit to dry out in a

dry environment.

Unit must be returned for

repair (see Section D3).

Contact Dwyer Customer

Service for assistance.

Use higher flow rates.

Calculate the flow reading

error / offset as explained

in section C6/C7.

Remove the entrapped air

(see section C2).

Unit must be returned for

repair (see Section D3).

F-20-TF-L, pg. 28 of 30

Page 29

Symptom Possible Cause Method of Correction

Flow indication is not

linear and output too

low at lower flows

Flow indication

“bounces” or

fluctuates

Flow indication is

fixed at one value

Attempting to measure flows

below the specified

minimum for the unit

Liquid is too viscous

Entrapped air or gas

Mechanical sensor

assembly damaged

Flow is actually fluctuating

Not using the fittings

supplied by the

manuafacturer

Entrapped air or gas

Turbulence in tubing or

sensor

Fluctuating input power

Mechanical sensor

assembly damaged

The maximum rated flow for

the unit is being exceeded.

Output circuits may be

damaged

Use higher flow rates.

Best results are obtained

with liquids that have a

viscosity of 10cS or less.

Contact Dwyer Customer

Service for further

information.

Remove entrapped air (see

section C2).

Unit must be returned for

repair (see Section D3).

Correct flow source to

obtain steady flow.

Use the supplied fittings.

Remove entrapped air (see

section C2).

Straighten the inlet tubing or

lengthen it to at least 6”

(150mm) (see section B3).

Correct the power source or

change to a regulated

supply.

Unit must be returned for

repair (see Section D3).

Reduce the flow.

Unit must be returned for

repair (see Section D3).

F-20-TF-L, pg. 29 of 30

Page 30

I. Warranty

After final installation of the flow meter, no routine maintenance is required. A

periodic check of system calibration is suggested. The series TFP-LP, TFP-LI, TFM-LP

and TFM-LI are not field repairable and should be returned if repair is needed

(field repair should not be attempted and may void the warranty). Be sure to

include a brief description of the problem plus any relevant application notes.

Contact Dwyer Customer Service to receive a return goods authorization

(R.M.A.) number before shipping.

J. Contacting Dwyer

Mailing address: Dwyer Instruments Inc.

P.O. Box 373, 102 Indiana Hwy. 212

Michigan City, IN 46361

U.S.A.

Phone: (800) 872-9141 or (219) 879-8000

Fax: (219) 872-9057

Email: tech@dwyer-inst.com

Website: www.dwyer-inst.com

For repairs and/or return information, please contact Dwyer Customer Service

any of the ways shown above.

F-20-TF-L, pg. 30 of 30

Loading...

Loading...