Page 1

Bulletin L-TFLS2

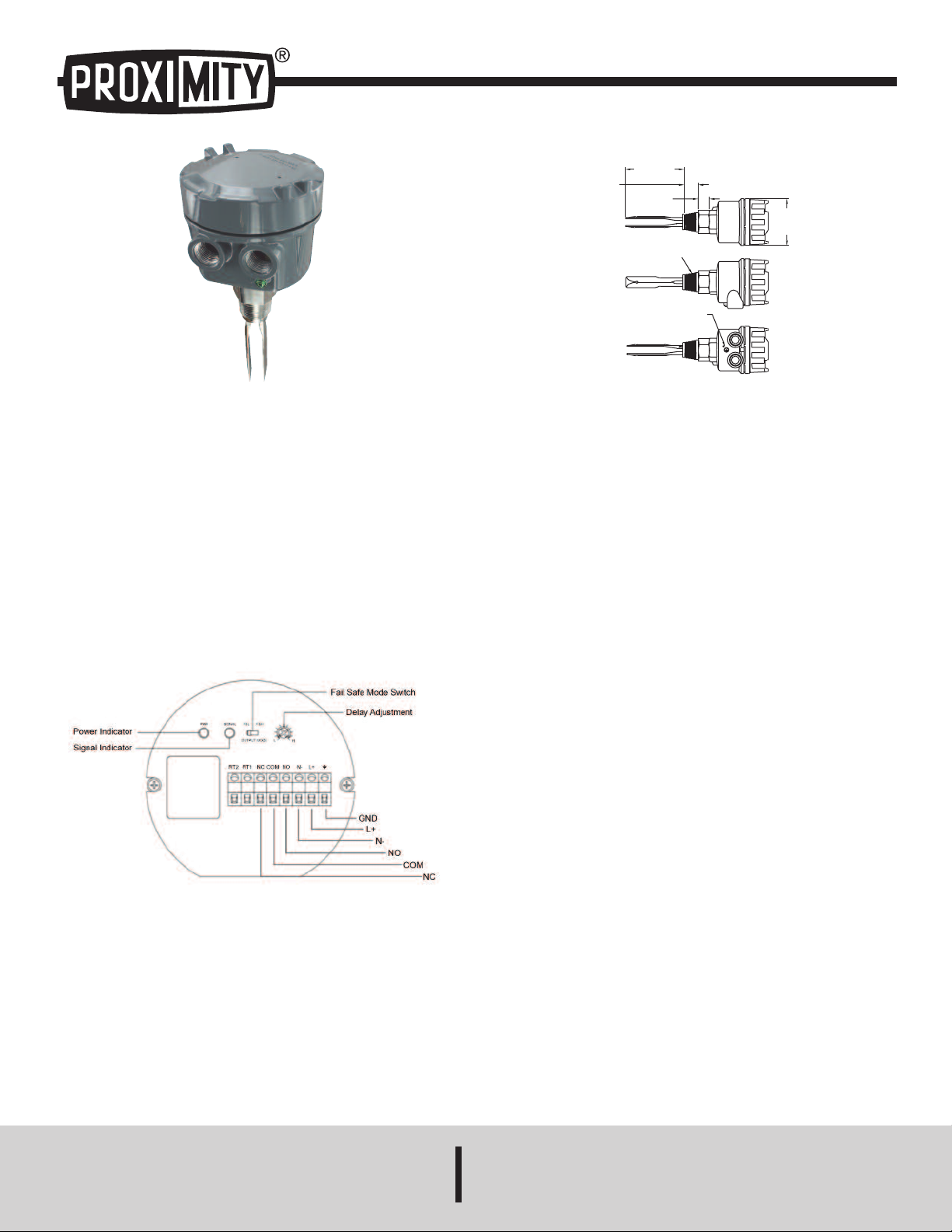

GROUND

1

˝ NPT

3

-5/16

[

84.00]

4-9/64

[105.00]

63/64

[25.06]

25/32

[19.99]

Model TFLS2 Compact Tuning Fork Level Switch

Specifications - Installation and Operating Instructions

he Model TFLS2 Compact Tuning Fork Level Switch is an ideal choice for level

T

control of powders and liquids. The TFLS2 incorporates a piezoelectric crystal that

vibrates the fork at its natural frequency. When the fork comes in contact with a

material, the vibration is dampened and the switch changes state. As the fork

becomes free of material, the switch changes back to its normal state. Featured in

he TFLS2 is user selectable fail-safe operation of the contacts. The unit is not

t

ffected by vibration from conveying systems, motors, or the movement of

a

aterial. Its compact size allows for mounting in places a larger tuning fork level

m

switch may not fit, providing great versatility.

The Model TFLS2 is easy to use with no calibration required and no mechanical

moving parts means no routine maintenance. The TFLS2 is not affected by the

dielectric constant of the sensed material, making it superior to a comparable

capacitance level switch for applications where the dielectric constant is low, more

than one material is being used in the single vessel, and when material moisture

content can change. The level switch is also great for applications when the bulk

density is too low for a rotating paddle level switch, making it the ideal choice for

low density bulk solids and liquids.

SPECIFICATIONS

ervice: Dry powders compatible with wetted materials. Can detect bulk materials

S

ubmerged in liquid.

s

ensitivity: Minimum bulk solid density: 4.4 lb/ft

S

in (10 mm).

Wetted Materials: 316 L SS.

Temperature Limits:

Ambient: -40 to 140°F (-40 to 60°C);

rocess: -40 to 266°F (-40 to 130°C).

P

Pressure Limit: 600 psi (40 bar).

Power Requirement: 20 to 250 VAC, 50/60 Hz.

Power Consumption: 10 VA.

Enclosure: Aluminum, painted.

Enclosure Rating: IP65.

Switch Type: SPDT.

Electrical Rating: 5 A @ 250 VAC.

Electric Connections: Screw terminals.

Conduit Connection: 2 x 1/2˝ female NPT.

Process Connections: 1˝ male NPT.

Weight: 2.4 lb (1.09 kg).

Indication Lights: Internal: Green and red LED’s.

Sensing Delay: 0 to 6 seconds.

3

70 g/l), maximum particle size 0.4

(

All of the wiring should use the 18 AWG standard isolation cable, and it is

compulsory to keep out dust in the housing to avoid electric short. To prevent water

or moisture penetrating into the housing, please rotate the screw cover in the

clockwise direction and make sure it is tightly locked.

FAIL SAFE MODE

1. Confirm the vessel is empty before calibration.

2. The default configuration of OUTPUT MODE is FSH (High Level Fail Safe).

3. Two ranges (L and H) for different material specific gravity. Factory value is L.

The user can change the range for different specific material; L for high specific

gravity material (like steel and rock) and H for low specific gravity material (like

milk powder, Styrofoam, and plastic).

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

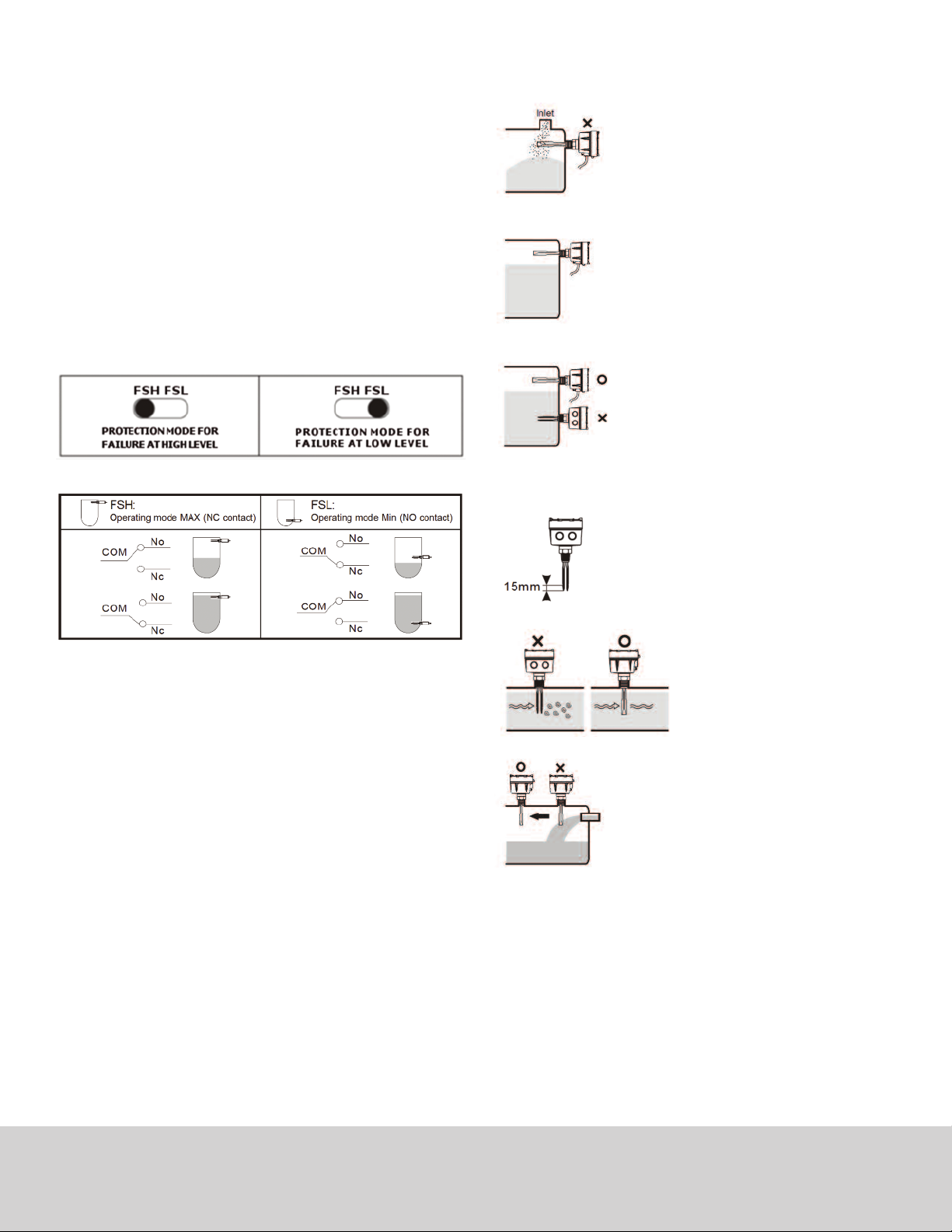

UNCTIONAL DESCRIPTION

F

SH High Level Fail Safe Protection

F

UTPUT MODE is located at FSH. The tuning fork is installed at a high level position.

O

. Relay Contact Output

1

A. Normal Status: SIGNAL light on means that the tuning fork is at normal status.

The sensor probe does not come in contact with the medium and relay NO and

COM are conductive.

. Failure Status: Under the power failure, SIGNAL light off means that the tuning

B

ork locates at the failure status. At the same time, relay NC and COM are

f

onductive. In other words, if the sensor probe contacts with the medium, that

c

eans the medium is higher than the high level.

m

FSL Low Level Fail Safe Protection

OUTPUT MODE is located at FSL. The tuning fork is installed at a low level position.

. Relay Contact Output

1

. Normal Status: SIGNAL light on means that the tuning fork is covered by the

A

edium, and the relay NO and COM contact are conductive.

m

B. Failure Status: Under the power failure, SIGNAL light off means that the tuning fork

locates at the failure status. At the same time, relay NC and COM are conductive.

In other words, if the sensor probe does not come in contact with the medium, that

means the medium is lower than the low level.

NSTALLATION

I

ORIZONTAL INSTALLATION

H

. Do not install near substance inlet.

1

2. Conduit faces downward at installation.

3. The surface of the two fork blades needs to be facing each other horizontally.

ERTICAL INSTALLATION

V

. With high sensitivity, switching point is distanced .59 in (15 mm) away from the tip

1

of fork.

Diagram of Relay Contact Output

2. Opening of the two fork blades is to be as the flow direction.

3. Do not install near the substance inlet.

MAINTENANCE/REPAIR

Upon final installation of the Model TFLS2 no routine maintenance is required. The

Model TFLS2 is not field serviceable and should be returned if repair is needed. Field

repair should not be attempted and may void warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on our website. Contact

customer service to receive a Return Goods Authorization number before shipping the

product back for repair. Be sure to include a brief description of the problem plus any

additional application notes.

©Copyright 2012 Dwyer Instruments, Inc. Printed in U.S.A. 12/12 FR# R4-444006-00 Rev. 3

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...