Page 1

Bulletin L-33

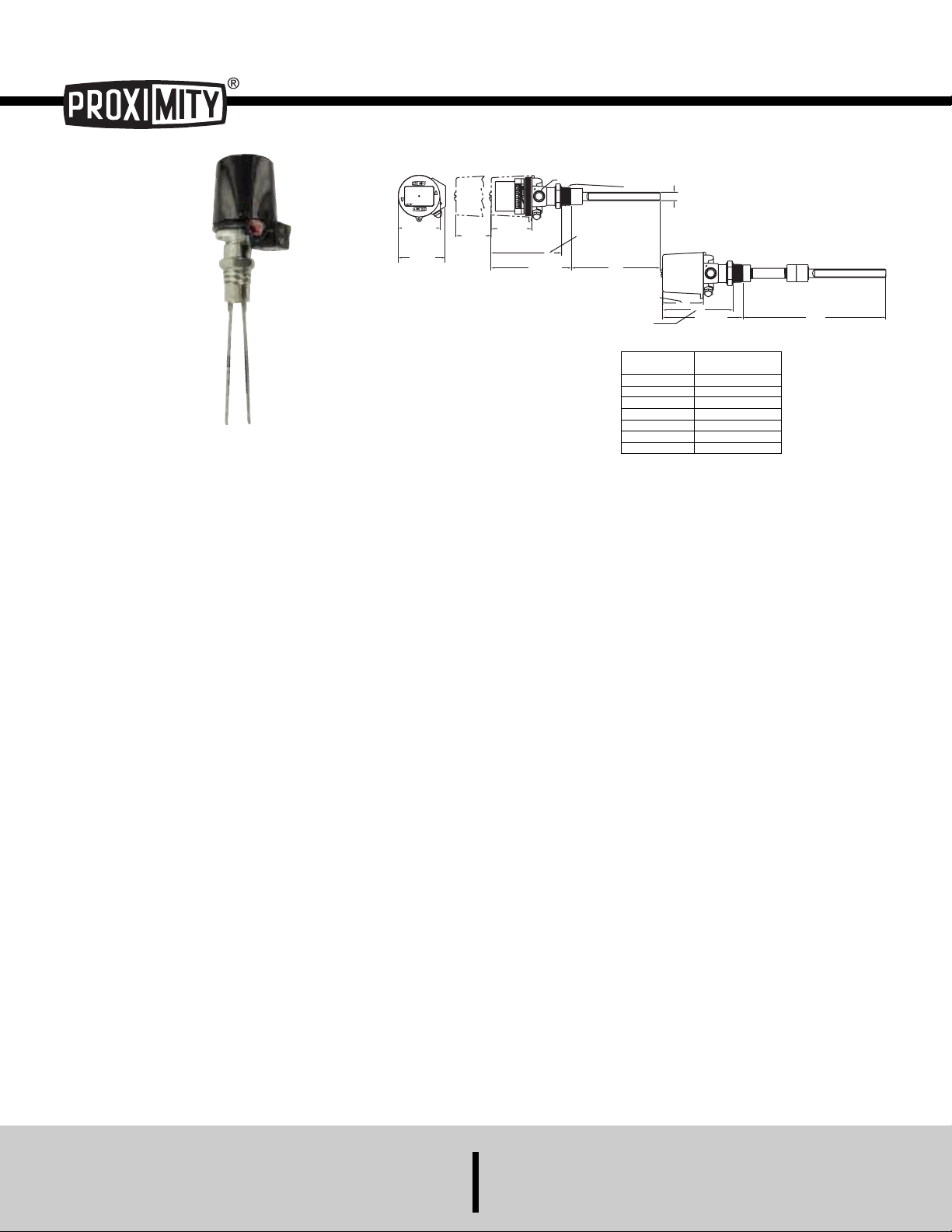

3/4 CONDUIT

CONNECTION

1

-1/2 NPT

7/8

[22.23]

W/ EXTENSION

NO EXTENSION

“

A”

4

-7/32

[107.14]

7-5/16

[

185.74]

8-5/16

[211.14]

“

A”

Ø4-7/16

[112.73]

4

-7/8

[

123.83]

3

-5/8

[

92.08]

C

OVER

R

EMOVAL

4

-7/32

[

107.14]

8

-5/16

[

211.48]

7

-5/16

[

185.64]

SERIES

TFLS

TUNING FORK LEVEL SWITCH

MOD TFLSSERIAL:

Series TFLS Tuning Fork Level Switch

Specifications – Perfect for Sensing Low Bulk Density or Low Dielectric Materials

Series TFLS tuning fork level switch is ideal for level control of

powders and fine grained solids, especially those with a low bulk

density. Featured in the TFLS is user-selectable fail-safe

operation of the contacts. Unit is not affected by vibration from

conveying systems, motors, or the movement of material. It can

be mounted in any position and is available with factory built

extensions for mounting on the top of the storage vessel.

Series TFLS is easy to use with no calibration required and with

no mechanical moving parts there is no routine maintenance

required. The TFLS is unaffected by the dielectric constant of the

sensed material making it superior to a capacitance level switch

for applications where the dielectric constant is too low, where

there is more than one material being used in one vessel, and

when material moisture content can change. The level switch is

also good for applications when the bulk density is too low for a

rotating paddle level switch. It can also detect granular material

submerged in liquids of low viscosity, for example sand, gravel, or

polyester chips in water.

FEATURES

• No Calibration Required

• Vibrating Fork Design: Great for low bulk density and low

dielectric constant products. Will detect products down to 1.8

lb/cu ft (30 g/l).

• Universal Power Supply: One model works from 90 to 265 VAC

and 24 VDC.

• Adjustable Sensitivity: Can be set to ignore lighter bulk density

products and only detect heavier products, such as sand in

water.

• Status Indication: External LED status indicator, and internal

indicators for normal and alarm status.

• Failsafe Setting: Output switch can be set for Normally Open or

Normally Closed condition on loss of power.

• Time Delay: Prevent false alarms from material surges.

EXTENSION

LENGTH

NONE

6 IN

12 IN

8 IN

1

24 IN

36 IN

48 IN

DIM

“A”

9-1/4 (234.95)

15-1/4 (387.35)

21-1/4 (539.75)

7-1/4 (692.15)

2

33-1/4 (844.55)

45-1/4 (1149.35)

57-1/4 (1454.15)

SPECIFICATIONS

Service: Dry powder or bulk materials compatible with wetted

materials. Can detect bulk materials submerged in liquid.

Sensitivity: Minimum bulk density of 1.8 lb/ft

3

(30 g/l), maximum

particle size 0.4 in (10 mm).

Wetted Materials: 316 SS.

Temperature Limits: Ambient: -4 to 140˚F (-20 to 60˚C);

Process: -4 to 176˚F (-20 to 80˚C).

Pressure Limit: 145 psig (10 bar).

Power Requirement: 90 to 265 VAC, 50/60 Hz; 24 VDC.

Power Consumption: 4 VA.

Enclosure: Aluminum, powder coated.

Enclosure Rating: Weatherproof, NEMA 4X.

Switch Type: SPDT.

Electrical Rating: 5A @ 230 VAC.

Electric Connections: Screw terminals.

Conduit Connection: 3/4˝ female NPT.

Process Connection: 1-1/2˝ male NPT.

Weight: 5.5 lb (2.5 kg).

Indication Lights: External: red LED; Internal: green and red

LED’s.

Sensing Delay: (Maximum) covered probe: 2 seconds;

uncovered probe: 3 to 7 seconds.

Time Delay: Separate settings for covering and uncovering the

probe. Adjustable from 2 to 20 seconds.

PROXIMITY CONTROLS

A DIVISION OF DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

Bulletin L-33

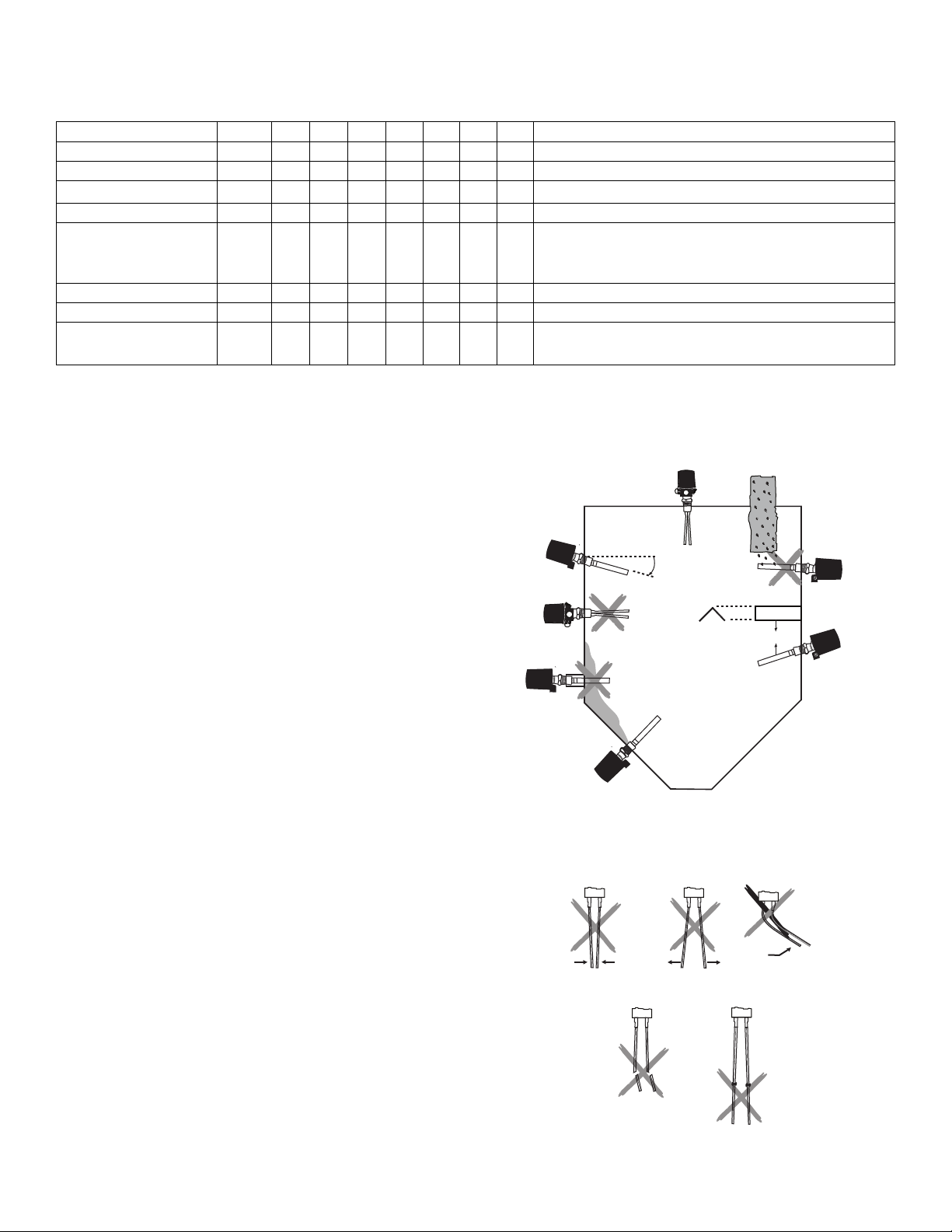

Do Not Bend

Do Not Shorten

or Extend

A

1

2

3

4

5

6

7

page 2

ODEL CHART

M

xample

E

Series

Enclosure

Switch

Power Supply

Probe Type

Process Connection

robe Length

P

Options

TFLS

TFLS

WW1

1

11EC

SR

EC

ES

048

1

MT

TFLS-W11EC1-048-MT

uning Fork Level Switch

T

Weatherproof

SPDT rated 5A @ 120/240 VAC

24 VDC, 90-265 VAC

Standard Rod

Extension Carbon Steel

Extension 316 SS

1

XXX

1-1/2˝ NPT male

Insertion length in inches (Only for probe type E)

MT

M25 conduit connection

SS

316 SS Enclosure

OPERATING PRINCIPLE

The TFLS incorporates a piezoelectric crystal that vibrates the fork

does not extend further than necessary into the vessel (Figure 1,

No. 5).

at its natural frequency, 85 Hz. When the fork comes in contact

with material the vibration is dampened and the switch changes

Figure 1: Installation Guide

state. As the fork becomes free of material the switch changes

back to its normal state.

INSTALLATION

Unpacking

Remove the TFLS from the shipping carton and inspect for

damage. If damage is found, notify the carrier immediately.

Mounting Location

The TFLS is rated for industrial environments with few restrictions,

however certain considerations must be made to ensure for

optimal sensing and extended operational life.

• The process temperature and ambient temperature must be

with- in the specified limits for the instrument.

• It is recommended to use a suitable material to protect and seal

the process threads such as TFE tape.

• Position the tines using a wrench on the hexagonal flats above

the process connection. Do not position by turning the housing.

• The probe must be located away from tank inlets or chutes

where material may fall on the probe during filling or emptying

(Figure 1, No. 2). If this is not possible a baffle may be installed

above the probe to protect it from falling material (Figure 1, No. 3).

The baffle must be installed a minimum of 8” (200 cm), see

Figure 2: Fork Protection

dimension A in Figure 1, above the probe so that material will not

become packed between the probe and the baffle.

• For mounting horizontally install with conduit entry facing down

so condensate does not enter the enclosure.

• For mounting horizontally position the tines vertically, narrow

edges up, so that material flows freely through them. The TFLS is

designed so that if the conduit opening is pointed down the tines

will be in the proper orientation. No. 6 in Figure 1 shows incorrect

mounting, No. 7 correct mounting.

• For mounting horizontally with materials that may stick to the

tines it is recommended to mount the probe angled down so that

material slides off easily (Figure 1, No. 7).

• The tines should not be bent, shortened, lengthened, or altered

in any way (See Figure 2).

• For top mounting the tines can be mounted in any position

(Figure 1, No. 1).

• When using mounting nozzles, make sure the length is proper so

that the tines extend far enough into the vessel to vibrate free of

material buildup on the vessel wall. Also make sure the nozzle

Page 3

Bulletin L-33

age 3

p

iring

W

Warning: Always install or service this device with the power off

and where required install a disconnect lockout.

Caution: For power line connections use NEC Class 1 wiring rated

60°/75°C. Use 12 to 20 AWG copper only for line and load

connections. Strip the wires 1/4˝.

Note: Installation must be made in accordance with National

lectric Code and local codes and regulations. When fishing wire

E

through the conduit connection do not allow the wire to touch or

press on components on the boards. Damage to the circuitry may

result.

The TFLS has a 3/4˝ NPT female conduit connection. The conduit

connection must be made such that condensation is not allowed to

enter the housing. If nonmetallic conduit is used, the protective

ground may be connected to the external ground connection

screw.

Strip 1/4˝ of insulation from wires. Connect the power wires to

terminals 4 and 5 if powered by 24 VDC and terminals 1, 2, and 3

if powered by 90 to 265 VAC. Only one type of power supply may

be used at a time, do not connect both AC and DC power

simultaneously. Connect control lines to the relay contact terminals

6, 7, and 8. See Figure 3 for terminals layout.

ONTROLS AND INDICATORS (See Figure 4)

C

Sensitivity Potentiometer — This control sets the sensitivity for

different types of material.

Time Delay Potentiometers — These controls select the delay

times from 2 to 20 seconds from the detection of a level change to

the output. There is one setting for the probe getting covered by

material and one setting for the probe becoming uncovered by

material.

Dip Switch — This two section switch selects the external LED

tatus and failsafe mode.

s

Normal LED — Green. This LED is illuminated when the unit is

powered and the fork does not sense any material.

Alarm LED — Red. This LED is illuminated when the relay is

powered by the fork sensing material. It is affected by the delay

setting.

External LED — Red. This external LED is illuminated in

conjunction with the fork being covered or uncovered.

Figure 4: Switches and LED’s

Normal Status LED

(Green)

Alarm Status LED

(Red)

Failsafe

External LED

Figure 3: Terminals

Probe Covered

Time Delay

Potentiometer

Probe Uncovered

Time Delay

Potentiometer

SETUP AND CALIBRATION

1. Fail Safe Mode Selection: The relay will always be off when the

power fails. In this case the contacts identified as normally open

will be open. The fail safe switch selects whether the normally

open contacts are open or closed when the probe is uncovered.

There are two options for the failsafe condition that are selected by

the RELAY DIP switch (See Figure 4). Selecting MAX will force the

relay contacts to be open when the probe is uncovered and the

NORMAL green LED to be on. Selecting MIN will energize the

relay (closed) when the probe is uncovered and the ALARM red

LED to be on.

2. External LED Selection: The red external LED indicates

material sensing status. There are two options for the LED

condition that are selected by the EXTERNAL INDICATOR DIP

switch (See Figure 4). Selecting MAX will make the LED illuminate

when the probe is uncovered. Selecting MIN will make the LED

illuminate when the probe is covered.

Sensitivity

Page 4

Bulletin L-33

page 4

3. Sensitivity Selection: The sensitivity selection adjusts the fork

sensitivity to material bulk density. The more dense the material,

the lower the sensitivity needed. After installing the probe and

making all electrical connections, set the Fail Safe Selection

switch to the MAX position. Set both the CVD and UNCOVD time

delays to their minimum by rotating them counter-clockwise to the

nd position. Rotate the SENSITIVITY potentiometer counter-

e

clockwise to its end position (See Figure 4). If there is no material

in the tank then the green LED will be illuminated. Fill the tank so

that the fork tines are covered by material. If the green LED turns

off and the red LED turns on then no adjustments are necessary.

If the green LED stays on then rotate the sensitivity potentiometer

clockwise to the point where the green LED goes out and the red

LED comes on. Setting is completed.

4. Time Delay Selection: The time delay is the programmed time

between when the probe senses the presence or absence of

material and when the relay changes state. A time delay is good

for applications that could have false or rapid pulsing of level

indications from sloshing or agitated material. Choose a delay

setting appropriate for the specific application. There are two

potentiometers for adjusting the delay time. The potentiometer

labeled COVD sets the delay time between when the probe is

covered and when the switch changes state. The potentiometer

labeled UNCOVD sets the delay time between when the probe

becomes uncovered and when the switch reverts back to its

normal state (See Figure 4). Adjust the time delay potentiometers

by turning them fully counter-clockwise to their end position. This

setting is no delay. To then set a delay time turn the potentiometer

clockwise to the desired time setting. The delay can be set

anywhere from 2 to 20 seconds.

MAINTENANCE

Upon final installation of the Series TFLS Tuning Fork Level

Switch, no routine maintenance is required. A periodic check of the

system calibration is recommended. The Series TFLS is not field

serviceable and should be returned if repair is needed (field repair

should not be attempted and may void warranty). Be sure to

include a brief description of the problem plus any relevant

application notes. Contact customer service to receive a return

oods authorization number before shipping.

g

TROUBLE SHOOTING

If the instrument fails first check that the wiring connections are

correct and that the set up is correct for the application. Next,

check to see if the tines vibrate when free of material.

Condition

Probe Covered

Red LED Off

Green LED Off

Probe Covered

Red LED On

Green LED Off

Probe Uncovered

Red LED Off

Green LED On

Relay Status

Terminals 6 & 7 Open

Relay De-energized

Terminals 6 & 7 Open

Relay De-energized

Terminals 6 & 7

Closed

Relay Energized

Probable Cause

No power supplied

Voltage too low

Material too light

Material has formed cavities

Vibration of vessel wall at 85 Hz

Heavy material deposit on fork

Fork Damaged

Vibration of vessel wall at 85 Hz

©Copyright 2012 Dwyer Instruments, Inc.

Printed in U.S.A. 5/12

PROXIMITY CONTROLS

A DIVISION OF DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

FR# 85-443478-00 Rev. 1

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...