Page 1

Bulletin T-TE-SNW

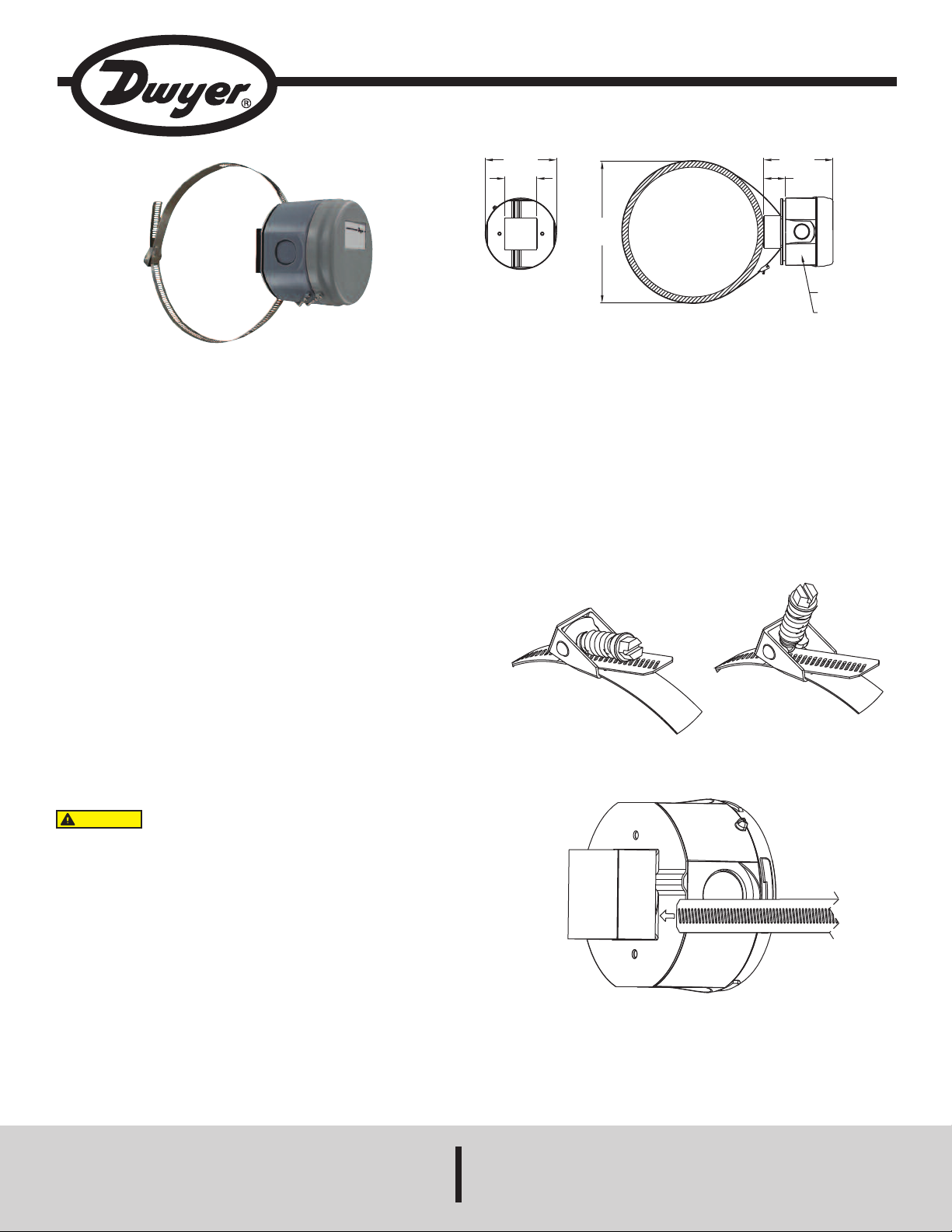

3-1/4

[82.38]

1 [25.97]

2 X PG11

KNOCKOUTS

2 X PG16

KNOCKOUTS

FITS 2

TO 6˝ PIPE

1-1/2

[38.10]

3

-3/8

[

84.86]

IN LOCKED POSITION

IN ADJUSTABLE POSITION

INSERT INTO SLOT UNDER FOAM

Series TE-SNW Weather Resistant Surface Temperature Sensor

Specifications - Installation and Operating Instructions

The Series TE-SNW Surface Temperature Sensor non-intrusively

measures the process temperature in hot and cold water loops in

buildings. An adjustable metal strap can tightly fit around 2 through 6˝

pipe sizes, allowing the surface area of the copper plate on the sensor

to make good contact with the pipe surface. In order to work with most

common building controllers, the output of the sensor can be chosen

from 6 different RTD and Thermistor curves. Additional features include

a quarter turn twist off cap that is chained to the housing to prevent it

from getting lost, and multiple knockout locations and sizes to reduce

installation time.

INSTALLATION

1. Knock out the preferred conduit entrance and attach either a conduit

fitting or cable gland.

2. Remove the protective film from the copper plate and the stainless

steel mounting plate.

3. Uncoil strap by lifting the screw head up like shown in Figure 1 and

pressing on the end of the strap.

4. Slide the open end of the strap through the gap in the stainless steel

mounting plate underneath the foam block opposite the copper plate, as

shown in Figure 2.

5. Add a small amount of thermal transfer paste to the copper plate.

6. Wrap the strap around the pipe and insert the open end into the strap

fastener.

7. Pull the open end of the strap until the copper plate is flush against

the pipe.

8. Lower the screw head to lock the strap in place as shown in Figure 1.

9. Use a flat head screw driver to tighten the strap.

CAUTION

10. Remove the cover.

11. Connect wires to the terminal block.

12. Close the lid tightly to protect against water ingress.

Do not over tighten the strap to the pipe as it could cause

damage to the sensor.

SPECIFICATIONS

Accuracy:

Thermistor Temperature Sensor: ±0.2°C @ 25°C

(±-0.36°F @ 77°F);

RTD Temperature Sensor: DIN Class A ±0.15°C @ 0°C

(±0.28°F @ 32°F).

Temperature Limits: Operating: -32 to 240°F (-35.5 to 115.5°C).

Sensor Curves: See resistance vs temperature table.

Housing Material: Meets UL 94 V-0 polycarbonate plastic, NEMA 3R.

Weight: 7 oz.

Figure 1

Make sure all connections are in accordance with the job wiring diagram

and in accordance with national and local electrical codes. Use 18 to 20

AWG twisted pair or shielded copper conductors only.

Figure 2

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

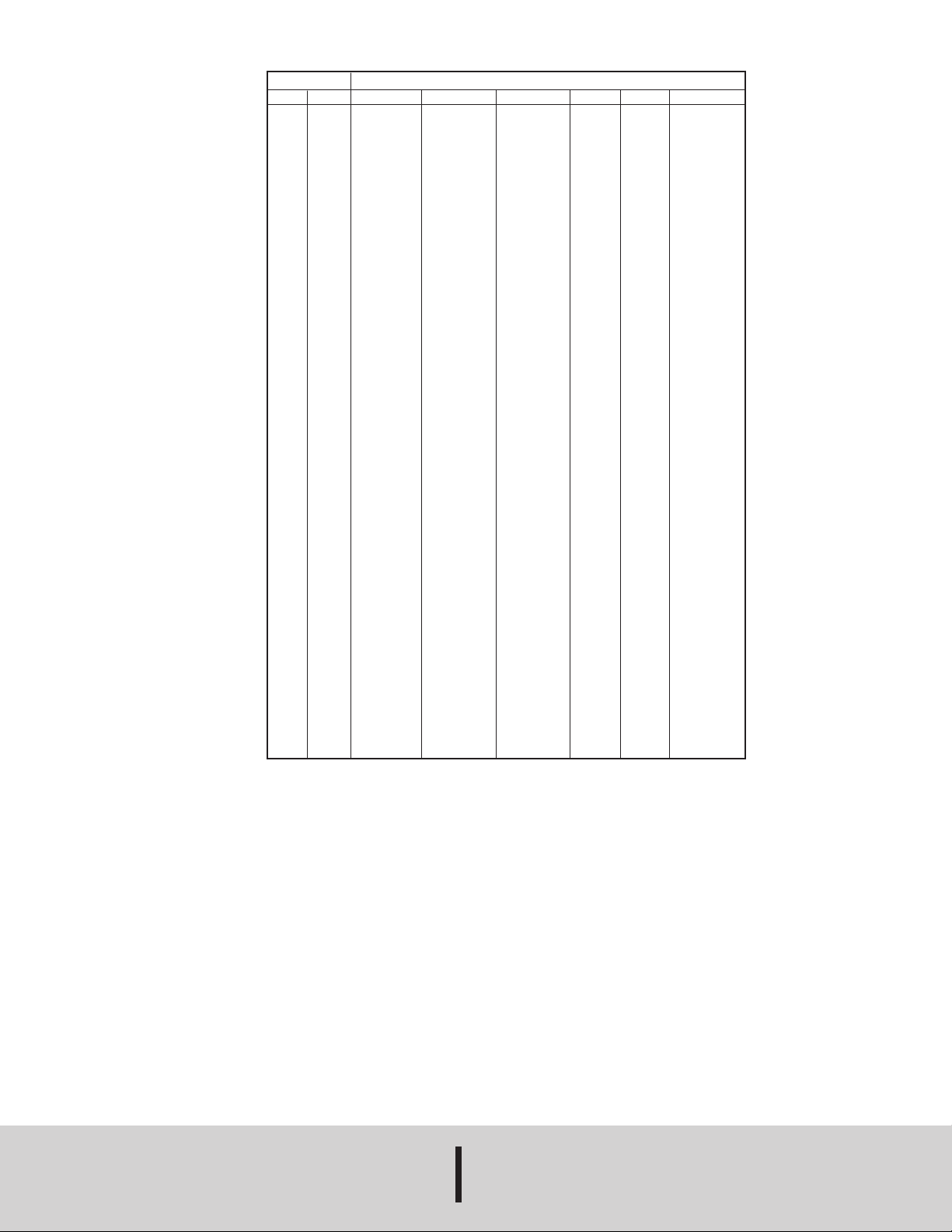

Resistance vs Temperature Table

Temperature

°C

°F

-55

-67.0

-50

-58.0

-45

-49.0

-40

-40.0

-35

-31.0

-30

-22.0

-25

-13.0

-20

-4.0

-15

5.0

-10

14.0

-5

23.0

0

32.0

5

41.0

10

50.0

15

59.0

20

68.0

25

77.0

30

86.0

35

95.0

40

104.0

45

113.0

50

122.0

55

131.0

60

140.0

65

149.0

70

158.0

75

167.0

80

176.0

85

185.0

90

194.0

95

203.0

100

212.0

105

221.0

110

230.0

115

239.0

120

248.0

125

257.0

130

266.0

135

275.0

140

284.0

145

293.0

150

302.0

A

607800.00

441200.00

323600.00

239700.00

179200.00

135200.00

102900.00

78910.00

61020.00

47540.00

37310.00

29490.00

23460.00

18780.00

15130.00

12260.00

10000.00

8194.00

6752.00

5592.00

4655.00

3893.00

3271.00

2760.00

2339.00

1990.00

1700.00

1458.00

1255.00

1084.00

939.30

816.80

712.60

623.60

547.30

481.80

425.30

376.40

334.00

297.20

265.10

237.00

Resistance Curves (Ω)

B

963849.00

670166.00

471985.00

336479.00

242681.00

176974.00

130421.00

97081.00

72957.00

55329.00

42327.00

32650.00

25392.00

19901.00

15712.00

12493.00

10000.00

8057.00

6531.00

5326.00

4368.00

3602.00

2986.00

2488.00

2083.00

1752.00

1480.00

1255.00

1070.00

915.50

786.60

678.60

587.60

510.60

445.30

389.60

341.90

301.00

265.80

235.30

208.90

186.10

C

289154.70

201049.80

141595.50

100943.70

72804.30

53092.20

39126.30

29124.30

21887.10

16598.70

12698.10

9795.00

7617.60

5970.30

4713.60

3747.90

3000.00

2417.10

1959.30

1597.80

1310.40

1080.60

895.80

746.40

624.90

525.60

444.00

376.50

321.00

274.65

235.98

203.58

176.28

153.18

133.59

116.88

102.57

90.30

79.74

70.59

62.67

55.83

D

78.32

80.31

82.29

84.27

86.25

88.22

90.19

92.16

94.12

96.09

98.04

100.00

101.95

103.90

105.85

107.79

109.74

111.67

113.61

115.54

117.47

119.40

121.32

123.24

125.16

127.08

128.99

130.90

132.80

134.71

136.61

138.51

140.40

142.29

144.18

146.07

147.95

149.83

151.71

153.58

155.46

157.33

E

783.2

803.1

822.9

842.7

862.5

882.2

901.9

921.6

941.2

960.9

980.4

1000.0

1019.5

1039.0

1058.5

1077.9

1097.4

1116.7

1136.1

1155.4

1174.7

1194.0

1213.2

1232.4

1251.6

1270.8

1289.9

1309.0

1328.0

1347.1

1366.1

1385.1

1404.0

1422.9

1441.8

1460.7

1479.5

1498.3

1517.1

1535.8

1554.6

1573.3

F

2394000.00

1646200.00

1145800.00

806800.00

574400.00

413400.00

300400.00

220600.00

163500.00

122280.00

92240.00

70160.00

53780.00

41560.00

32340.00

25360.00

20000.00

15892.00

12704.00

10216.00

8264.00

6722.00

5498.00

4520.00

3734.00

3100.00

2586.00

2166.00

1822.60

1540.00

1306.40

1112.60

951.00

815.80

702.20

606.40

525.60

N/A

N/A

N/A

N/A

N/A

MAINTENANCE/REPAIR

Upon final installation of the Series TE-SNW no routine maintenance is required. The

Series TE-SNW is not field serviceable and should be returned if repair is needed. Field

repair should not be attempted and may void warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on our website. Contact

customer service to receive a Return Goods Authorization number before shipping the

product back for repair. Be sure to include a brief description of the problem plus any

additional application notes.

©Copyright 2013 Dwyer Instruments, Inc. Printed in U.S.A. 5/13 FR# 08-444084-00

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...