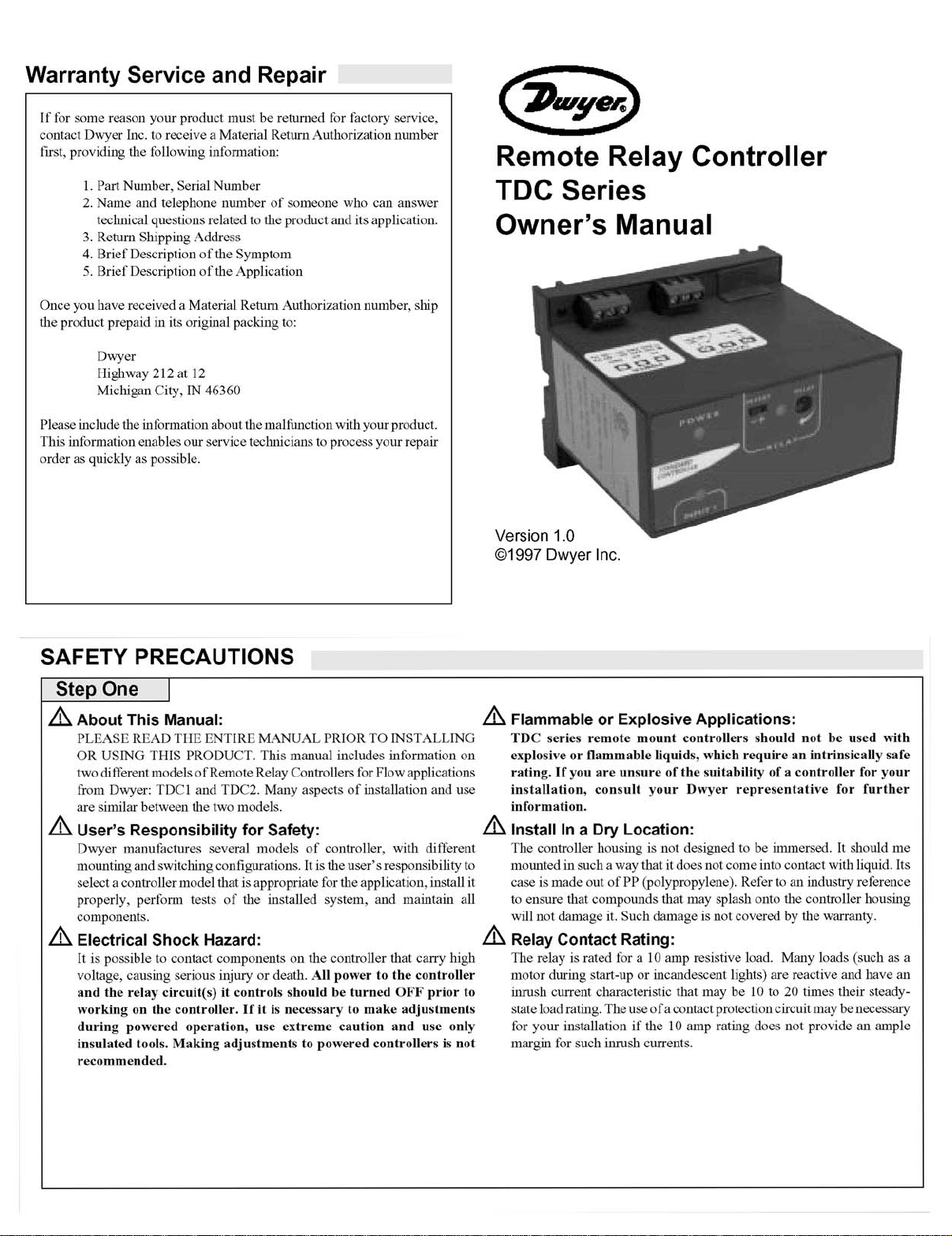

Page 1

Page 2

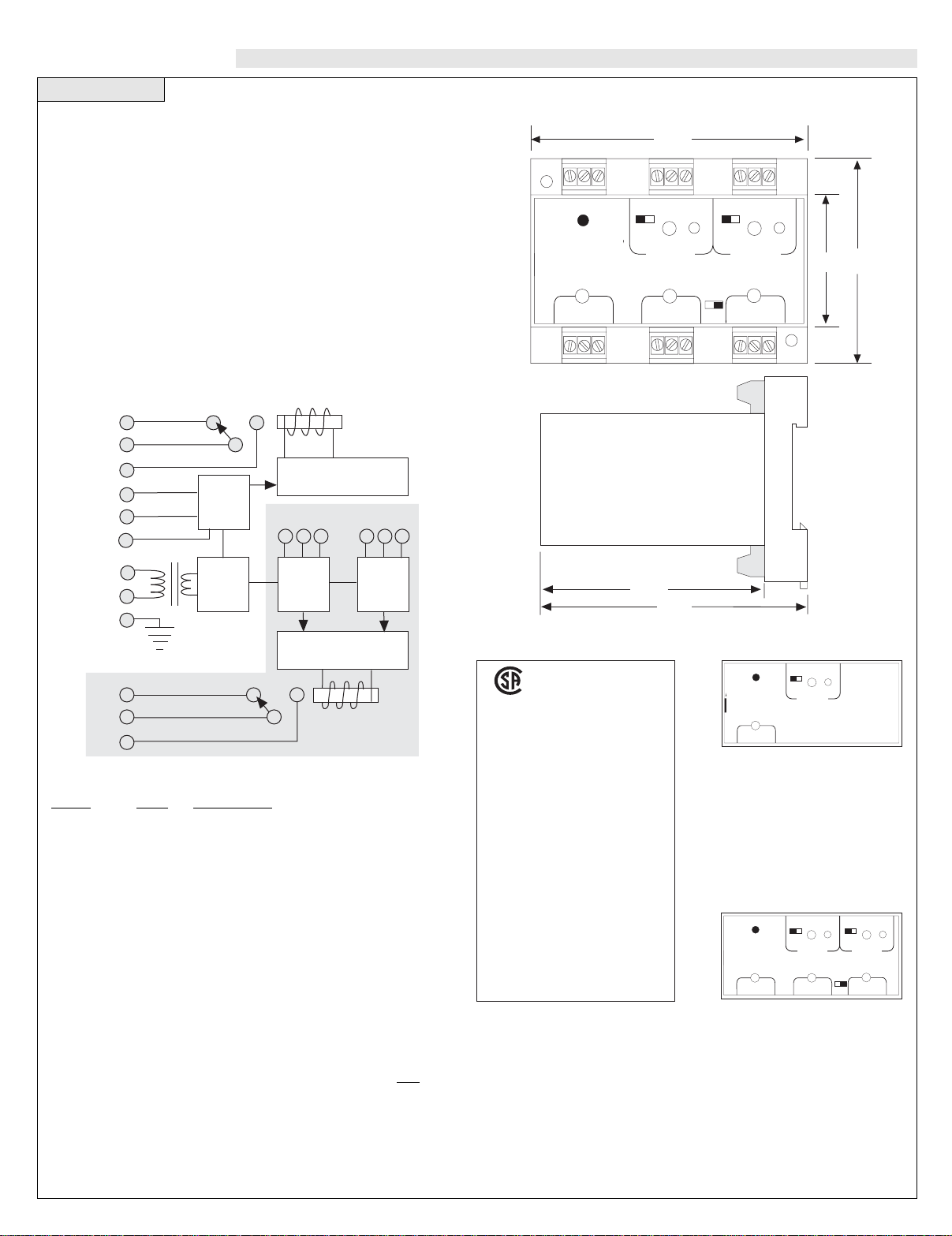

SPECIFICATIONS

Step Two

Supply voltage: 120 / 240 VAC, 50 - 60 Hz.

Consumption: 5 Watt

Sensor supply: 13.5 VDC @ 100 mA

Relay type: TDC1: (1) SPDT

TDC2: (1) SPDT, (1) Latched SPDT

Relay load: 250 VAC, 10A, 1/2 hp.

Relay mode: Selectable, NO or NC

Time delay: 0 to 60 seconds

LED indication: Sensor, relay & power status

Fail safety: Power fail-safe

Temperature range: F: -40 to 158

C: -40 to 70

Enclosure rating: Panel or 35 mm DIN Rail

(EN 50 022)

Enclosure material: Polypropylene (U.L. 94 VO)

Certificate number: LR 79326-3 (CSA/NRTL)

Functional Diagram

NC

C

NO

(+)

(-)

Sensor

Input

1

S

Latch / Invert Logic

Time Delay

Relay

("Relay 1"

in LC82)

+ - S+ - S

Dimensions

POWER

INPUT1 INPUT2A INPUT2B

3.9"

INVERT INVERT DELAYDELAY

—

+

RELAY 1

LATCH

ONOFF

—

+

RELAY 2

1.8"

2.7"

AC

AC

Power

Supply

Sensor

Input

A*

Sensor

Input

B*

GND

Latch / Invert Logic

Time Delay

NC

C

NO

Relay

("Relay 2" in LC82)

Part Number Information:

Part # Mat'l Description

TDC1 PP Flow/No-Flow Controller

TDC2 PP Dual Flow/No-Flow Controller

Make a Fail-Safe System:

Design a fail-safe system that accommodates the possibility of relay or

power failure. If power is cut off to the controller, it will de-energize the

relay. Make sure that the de-energized state of the relay is the safe state in

your process. For example, if controller power is lost, a pump will turn off

if it is connected to the Normally Open side of the relay.

While the internal relay is reliable, over the course of time relay failure is

possible in two modes: under a heavy load the contacts may be “welded”

or stuck into the energized position, or corrosion may build up on a

3.1"

3.6"

TDC1 FaceplateApproval Label

PO WE R

INVERT

®

NRTL-C

Power Supply

LR79326 -3

INPUT1

--

+

RELAY 1

DELAY

120/240 VAC, 50 - 60 Hz

5 Watt

Maximum Relay Rating

250 VAC, 10 A, 1/2 Hp

Refer to the instruction

manual for installation

TDC2 Faceplate

instructions.

contact so that it will not complete the circuit when it should. In critical

applications, redundant backup systems and alarms must be used in

addition to the primary system. Such backup systems should use different

sensor technologies where possible.

While this manual offers some examples and suggestions to help explain

the operation of Dwyer products, such examples are for information only

and are not intended as a complete guide to installing any specific system.

PO WER

INVERT INVERT

--

+

RELAY 1 RELAY 2

INPUT1 INPUT2A

DELAY

DELAY

--

+

LATC H

INPUT2B

ONOFF

Page 3

INSTALLATIONGUIDE TO CONTROLS

Step Three

3

PO WER

1

6

INPUT1 INPUT2A

9

INVERT INVERT

--

+

9

4

7

DELAY

--

+

5

2

RELAY 1 RELAY 2

6

8

LATC H

ONOFF

9

1. Power indicator: This green LED lights when AC power is ON.

2. Relay indicator: This red LED will light whenever the controller

energizes the relay, in response to the proper condition at the switch

input and after the time delay.

3. AC Power terminals: Connection of 120 VAC power to the

controller. The setting may be changed to 240 VAC if desired. This

requires changing internal jumpers; this is covered in the Installation

section of the manual. Polarity (neutral and hot) does not matter.

4. Relay terminals (NC, C, NO): Connect the device you wish to

control (pump, alarm etc.) to these terminals: supply to the COM

terminal, and the device to the NO or NC terminal as required. The

switched device should be a noninductive load of not more than 10

amps; for reactive loads the current must be derated or protection

circuits used. When the red LED is ON and the relay is in the energized

state, the NO terminal will be closed and the NC terminal will be open.

5. Time delay: Use potentiometer to set delay from 0.15 to 60

seconds. Delay occurs during switch make and switch break.

7

2 5

6

INPUT2B

4

DELAY

Step Four

Panel DIN Rail Mounting

The controller may be mounted by either a back panel using two screws

through mounting holes located at the corners of the controller or by

snapping the controller on 35 mm DIN Rail.

2.2"

.275"

3.475"

.225"

Note: Always install the controller in a location where it does not come

into contact with liquid.

Connecting switches to input terminals:

Please note a difference between Dwyer flow switches (N-channel and

P-channel). Use only the N-Channel switches with the TDC series of

controller. Wire the Red wire to the (+) terminal and the Black wire to

the (-) terminal. Wire the White wire to the (S). See the illustration below

to indicate wiring for your switch. Reversing Red and Black wire will

change switch from NC to NO. Note: connect the Shield wire on the Flow

switch to the GND terminal if required.

( + )

24 VDC

50 mA

Max.

INPUT

GND

INPUT1 INPUT2A INPUT2B

LATCH

ONOFF

( - ) ( S )

14 VDC

25 mA

Max.

35 mm

DIN Rail

6. Input indicators: Use these LEDs for indicating Flow or No-Flow

status of switch. For NC wiring, an Amber LED indicates No-Flow and

no LED indicates Flow. For NO wiring, an Amber LED indicates Flow

and no LED indicates No-Flow.

7. Invert switch: This switch reverses the logic of the relay control in

response to the switch: conditions that used to energize the relay will

now de-energize the relay and vice versa.

8. Latch switch (TDC): This switch determines how the relay will

be energized in response to the two sensor inputs. When LATCH is

OFF, the relay responds to switch Input 2A only; when LATCH is ON,

the relay will energize or de-energize only when

both switches (2A and

2B) are in the same condition (Flow or No-Flow). The relay will

remain latched until both switches change conditions.

9. Input terminals: Connect the switch wires to these terminals:

Note the polarity: (+) is a 24 VDC, 50 mA power supply (connected to

the red wire of a Dwyer flow switch), and (-) is the common ground

path from the switch (connected to the black wire). Also, the (S) is a 14

VDC, 25 mA supply (connected to the white wire). If polarity between

the red and black wires is reversed, the switch will change from NC to

NO.

Red

Black

FT10-XX02

GT10-XX02

NC Wiring

White

Red

Black

FT10-XX02

GT10-XX02

NO Wiring

White

LED Indication

Use LED's located above the input terminals to indicate whether the

switch is in a Flow or No-Flow state. With the flow switch wired NC, the

Amber LED indicates No-Flow and no LED indicates flow. Wiring the

switch NO (reversing the Red and Black wires), the Amber LED

indicates Flow and no LED indicates No-Flow.

NC Wiring

Amber

INPUT1

NC Wiring

Off

INPUT1

NO Wiring

Amber

INPUT1

NO Wiring

OFF

INPUT1

Page 4

INSTALLATION TROUBLESHOOTING

Step Five Step Six

VAC Power Input Wiring

Note: Polarity does not matter with the AC input terminal

POWER

Ground

Neutral

Hot

INVERT

--

+

RELAY 1

DELAY

POWER

AC

AC

120 VAC, 50 - 60 Hz

240 VAC, 50 - 60 Hz

GND

POWER

Ground

Neutral

Hot

INVERT

--

DELAY

+

RELAY 1

Relay Input Wiring

RELAY OUTPUT

NO NC

C

250 VAC, 12 A, 1/2 Hp

Alarm Contact @ No-Flow Pump Open @ No-Flow

POWER

INVERT

Note: The invert is switched between the Alarm and Pump Wirings.

Normally Open

Relay Wiring

The controllers use dry contact Single Pole Double

Throw (SPDT) relays rated at 250 Volts AC, 10

Amps, 1/2 Hp. The terminals are labeled Normally

Open (NO), Common and Normally Closed (NC).

Below shows four examples of basic wiring:

POWER

INVERT

--

+

RELAY 1

--

+

RELAY 1

DELAY

INVERT

--

+

DELAY

RELAY 2

Normally Closed

Relay Wiring

DELAY

INVERT

--

+

RELAY 2

DELAY

Controller Logic

For all controllers, please use the following guide to understand the

operation of the Dwyer TDC1/TDC2 controllers.

1. Make sure the Green power LED is On when power is supplied to the

controller.

2. For NC switch wiring, the input LED's on the controllers will be

Amber when the switch reads No-Flow and Off when the switch

reads Flow.

3. The input LED will always respond to its corresponding relay LED.

With invert Off, the relay LED will be On when the input LED is On

and Off when the input LED is Off. With invert On, the relay LED

will be Off when the input LED is On and On when the input LED

is Off.

4. The relay may be wired either NO or NC. The normal state of the

relay is when its LED is Off. With the LED On, the relay is in the

energized mode and all terminal connections are reversed.

5. TDC model only, Latch ON operation: When both input LED's are

ON, the relay will be energized (red LED On). After that, if one

switch input turns Off, the relay will remain energized. Only when

both switch LED's are Off will the controller de-energize the relay.

The relay will not energize again until both switch LED's are ON.

Reversing Invert switch will reverse logic. See the Logic Chart

below for further explanation.

Relay Latch Logic Chart

Invert Off

Latch Off

Invert ON

Latch Off

POWER

INVERT

--

+

RELAY 1

DELAY

INVERT

--

+

DELAY

RELAY 2

POWER

INVERT

--

+

RELAY 1

DELAY

INVERT

--

+

DELAY

RELAY 2

Note: The invert is switched changes between Normally Open and

Normally Closed.

Changing from 120 to 240 VAC

Remove the back panel of the controller and gently slide the printed

circuit board from the housing. Use caution when removing the PCB.

Located jumpers JWA, JWB and JWC on the PCB. To change to 240

VAC, remove jumpers from JWB and JWC and place a single jumper

across JWA. To change to 120 VAC, remove jumper JWA and place

jumpers across JWB and JWC.

120 VAC 240 VAC

JWA

JWC

JWB

JWA

JWC

JWB

— +

Input A

ON

OFF

Invert Off

— +

Input A

ON

OFF

ON

OFF

InputB

No Effect

No Effect

InputB

ON

ON

OFF

OFF

On Off

Relay

ON

OFF

Latch ON Latch ON

On Off

Relay

ON

No Change

No Change

OFF

— +

Input A

ON

OFF

Invert ON

— +

Input A

ON

OFF

ON

OFF

InputB

No Effect

No Effect

InputB

ON

ON

OFF

OFF

On Off

Relay

Off

On

On Off

Relay

Off

No Change

No Change

On

Loading...

Loading...