Page 1

Bulletin F-41-STFLO

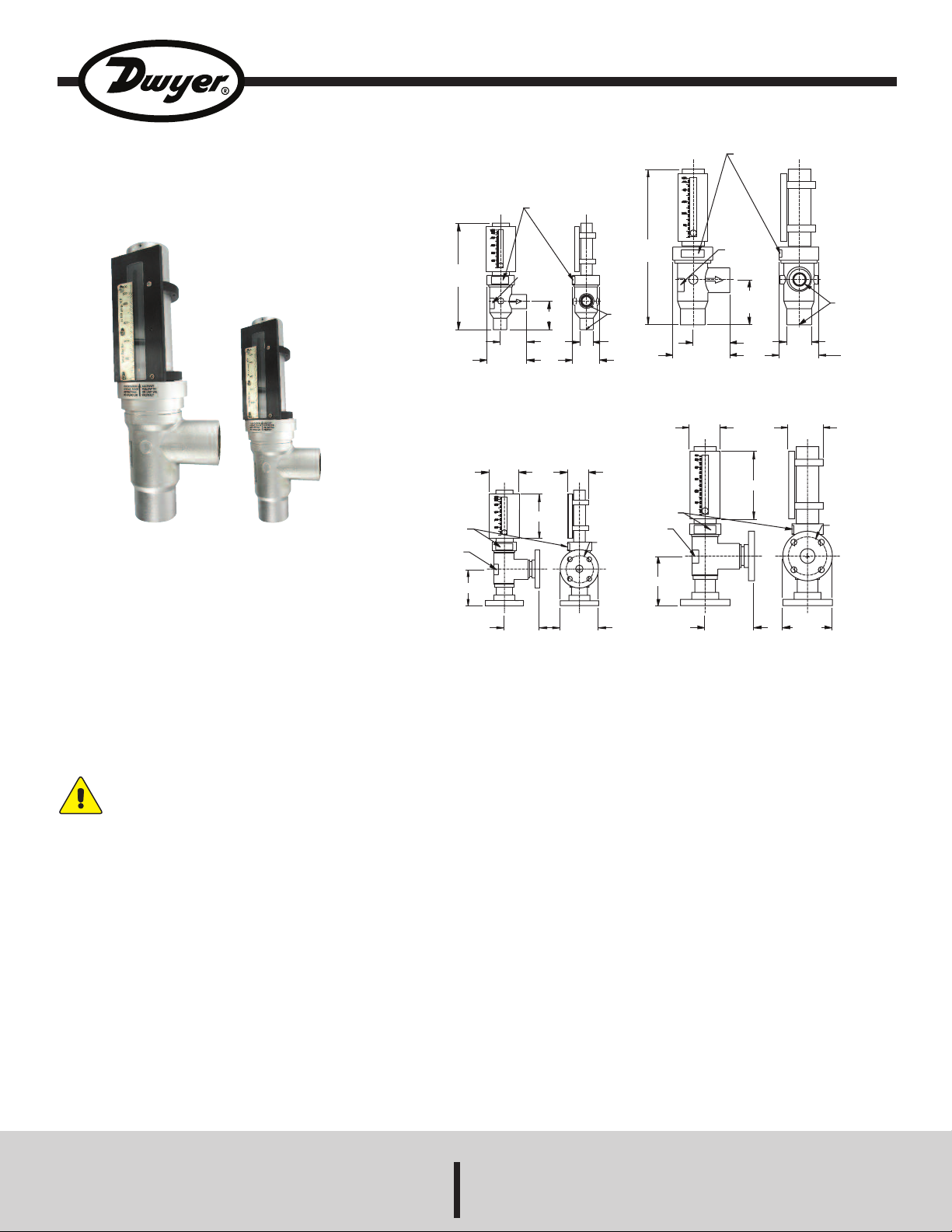

4-1/32

[102.25]

2-11/16

[68.07]

IN

10-21/32

[270.78]

LABEL, SEE

DETAIL 1

3/4 NPT CONNECTION

O

UT

2

-13/16

[

71.37]

LABEL

SEE

DETAIL 2

2-3/4

[69.95]

Ø1-11/32

[34.29]

3/4 NPT

1

5-21/32

[

397.28]

LABEL SEE

DETAIL 1

LABEL, SEE

DETAIL 2

IN

OUT

4

-1/2

[

114.38]

3-23/32

[94.23]

5

-11/16

[

144.65]

1

-1/2 NPT

Ø2-15/32

[62.99]

Ø4

[101.85]

1-1/2 NPT CONNECTION

3

[76.20]

LABEL, SEE

DETAIL 1

L

ABEL, SEE

DETAIL 2

5

[127.00]

4-31/32

[125.98]

5

[127.00]

6

-13/16

[

172.97]

3

-1/2

[

88.91]

Ø3-7/8

[Ø98.55]

Ø2-3/4

[Ø69.85]

2-1/8

[53.59]

3

[76.20]

4-1/2

[114.30]

LABLE, SEE

DETAIL 1

LABEL, SEE

DETAIL 2

3-11/16

[93.73]

3-9/16

[90.43]

3-7/8

[98.55]

3/4 FLANGE CONNECTION

1-1/2 FLANGE CONNECTION

Series STFLO Stainless Steel Flowmeters

Specifications - Installation and Operating Instructions

Series STFLO Stainless Steel Flowmeters are ideal for dirty or

opaque fluids, high temperature and high pressure service and harsh

environments, specifically steam applications.The direct reading scale

provides ±2% accuracy. Flowmeters can quickly be disassembled

without removing the body from the pipeline for easy cleaning.

SAFETY PRECAUTIONS

Personnel safety should be considered before pressurizing and

operating the system. There are numerous possibilities for

error in system operation and maintenance as well as

component installation. Because human eyes must necessarily

come into close proximity with the flowmeter to read it, Dwyer

SPECIFICATIONS

Service: Compatible with liquids and gases.

Wetted Material: T316 SS, Alnico magnet, PTFE.

Temperature Limits: See chart on page 7.

Pressure Limits: See chart on page 7.

Accuracy: ±2% FS.

Repeatability: ±0.5% of indicated flow rate.

Process Connections: 3/4˝ or 1-1/2˝ female NPT, optional flange

connections.

Scale Length: 3/4˝ models: 3.2˝ (8 cm); 1-1/2˝ models: 5.2˝ (13 cm).

Weight: 3/4˝ NPT models: 5.75 lb (2.6 kg); 1-1/2˝ NPT models: 14 lb (6.4

kg). 3/4˝ Flange: 9.75 lb (4.4 kg); 1-1/2˝ Flange: 22 lb (10 kg).

Instruments, Inc. recommends that safety shielding such as a

sheet of transparent, high impact material be used in front of

the meter. If hazardous, toxic, or flammable fluids are being

metered, recommended safeguard should include methods to

protect personnel from splash or rebound. A method of quick,

safe removal of dangerous fluids should also be included.

INSTALLATION

PREPARATION: Series STFLO Stainless Steel Flowmeters are ready to

install as-is, although the reading scales may need repositioning so the

scale is visible after installation. First, remove the protective caps from

the connection ports. Also, remove the plastic tubing above the inlet cap

in the meter core tube! This tubing blocks the float assembly in place

during shipment. Check that the float moves freely within the core tube,

and that no packing materials are in the meter.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

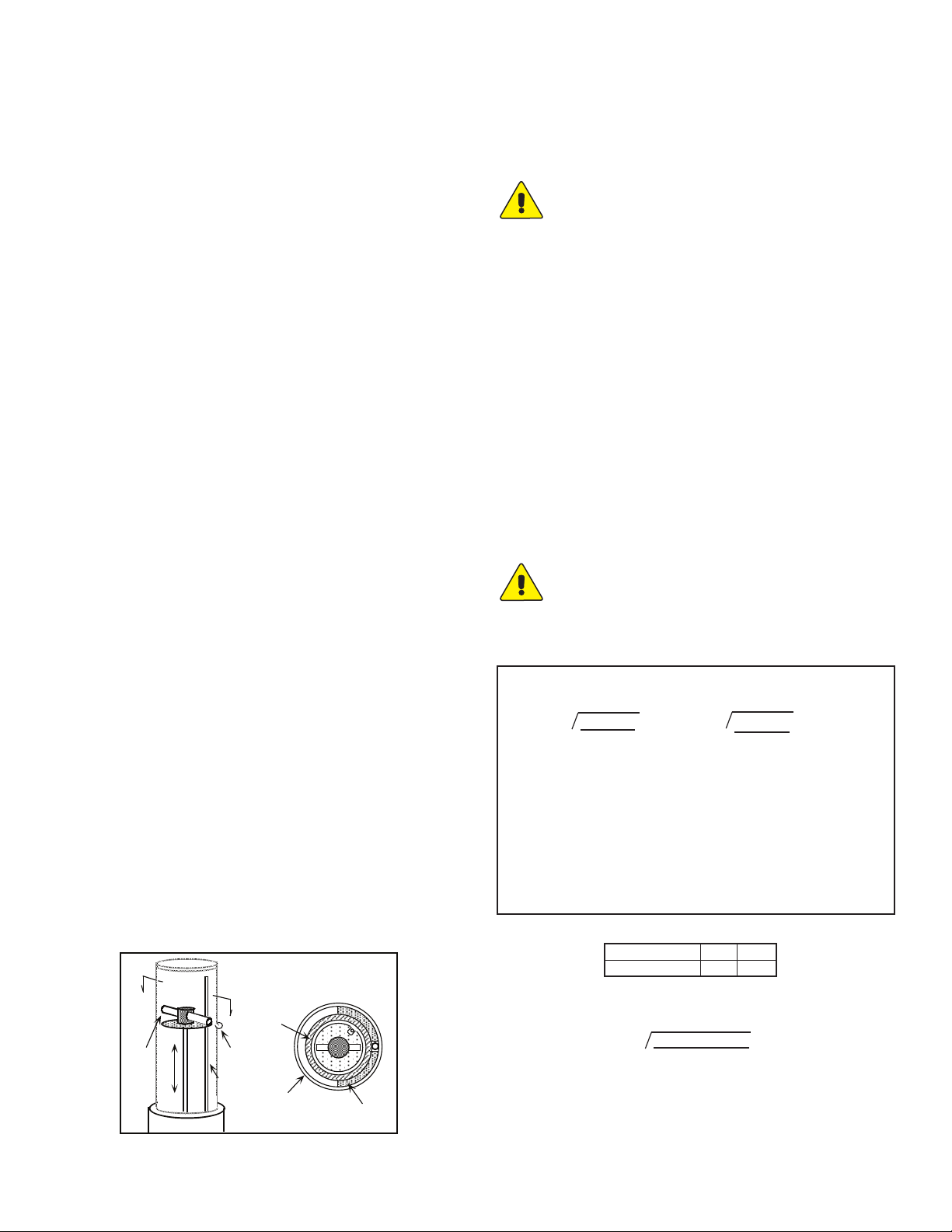

RECOMMENDED PIPING

SEC A-A, TOP VIEW

METAL

PRESSURE

TUBE

PHENOLIC

RACEWAY

A

A

MAGNET

BALL

INDICATOR

SNORKELGUIDE

READING

SCALES

Series STFLO Stainless Steel Flowmeters generally have no special

straight run or other piping requirements. Inlet piping should be the same

size as the meter connection. Some effect on meter accuracy may occur

at high flow velocities if inlet piping guidelines are violated. Please refer

to the table on the next page. When installing on different size pipe, use

standard pipe adapters and come into the meter inlet with a nipple 8

diameters long of the same size for greatest accuracy. Control valves

should be mounted on the outlet side of the meter. The use of a three

valve manifold around the meter is suggested, as it allows uninterrupted

process flow while the meter is being cleaned.

STARTUP

System flow should be started with the bypass valve open and meter

inlet and outlet valves closed. After the system is operating, open the

meter inlet valve gradually to equalize internal pressure. Then slowly

crack meter outlet valve and wait for float to stabilize. Finally, slowly

open the meter outlet and/or flow regulating valve all the way and close

the system by-pass valve.

AVOID SUDDEN SURGES THAT CAUSE THE METER

FLOAT TO SLAM INTO THE TOP OF THE READING

SCALES!

PLUMBING-IN

While the flowmeters should be vertical, exact plumbness is not

necessary. A general rule is that if the meter appears plumb, it is close

enough (even if off by 10º, the predictable reading error is usually less

than 1%). Pipe should be cut to proper lengths to avoid stress on the

meter. Avoid over-tightening, and do no use wrenches on the body or

reading scales. If using solvents in the vicinity of reading scales, the

scales should be removed until fumes clear.

SURGE & WATER HAMMER PREVENTION

Operating Limits are for non-shock conditions only. Flowmeters are more

accurate and less likely to be damaged when the fluid flow is smooth.

Water hammer is a hazardous phenomenon and should be eliminated

from any fluid system. Water hammer is a series of pressure shocks

create by a sudden change in the flow velocity of liquid in a pipe. This

sudden change, often caused by a fast acting valve or starting, stopping,

or change in speed of a pump, generates an immediate rise in pressure

that sometimes makes a noise similar to striking the pipe with a hammer.

The pressure wave is transmitted from the source throughout the

system, subjecting every component to the sudden shock. Pressure

returns to normal only when a larger vessel or pipe section is reached,

the energy dissipated thru friction and pipe expansion, or some

component ruptures. Rupture of piping, valves, flowmeters, or other

components have obvious safety ramifications that must be addressed.

SURGE CHAMBERS & ACCUMULATORS

Flowmeters are more accurate and less likely to be damaged when the

fluid flow is smooth. If the meter must be installed on a line where

reciprocating pumps causing pulsation are used, surge chambers,

accumulators, or desurgers are strongly suggested to dampen the shock

wave. This is a good, general practice for all flowmeters.

READING SCALES ROTATION

Series STFLO Stainless Steel Flowmeters use magnetically-linked ball

indicators and the scale may be positioned over approximately a 300 ˚

range. However, the magnet position must also be changed accordingly,

requiring removal of the reading scales (see “Disassembly”). On

standard STFLO Stainless Steel Flowmeters as depicted in Figure 1, the

magnet slides out of the carrier at the top of the float assembly. The

screw holding the carrier to the float may be loosened to allow rotation

of the carrier toward the desired scale location. Re-tighten the screw

(thread sealant is recommended), replace magnet, and reassemble the

meter (see “Assembly”). Verify that the ball indicator has been “captured”

by the magnet. If not, rotate the reading scales until the ball is “grabbed”

by the float magnet.

Although not essential, the meter reading scales should be filled to a

level above the float on liquid systems. The snorkel tube (present in most

standard models) allows escape of entrapped gases except for a small

pocket in the upper end which helps cushion hydraulic shock. To assure

proper filling and to flush any foreign particles from the meter, operate

the system at full flow briefly at startup.

READING FLOW

Read flow directly from the scale as the number nearest to the center of

the ball indicator.

COMPENSATING FOR SYSTEM CHANGES

To find the correct flow reading for a system whose fluid conditions vary

from those for which the meter is scaled, use the conversion equations

provided. The most practical method of applying the formulae is to

calculate a conversion factor for the new system condition and

multiplying the scale reading by that factor. In the problems to the right,

“Q’s” has been assigned a value of “1” to determine the conversion

factor. (Dwyer Instruments, Inc. can provide special scales at additional

cost for other fluids and/or units.)

CAUTION: DO NOT OPERATE THE FLOWMETER ON A

SYSTEM EXCEEDING THE OPERATING LIMITS OF THE

UNIT. WHEN CHANGING OPERATING CONDITIONS, MAKE

SURE THAT THE NEW SYSTEM CONDITIONS ARE WITHIN

THE FLOWMETER OPERATING LIMITS, AND ALL WETTED

MATERIALS ARE COMPATIBLE WITH THE FLUID.

CORRECTING READINGS FOR NEW LIQUID CONDITIONS

Qa= Q

s

√

Ps(Pf-Pa)

Pa(Pf-Ps)

or Qa= Q

s

√

ds(df-da)

da(df-ds)

Where:

Qa=Actual flow, GPM (or same units as scale)

Qs=Meter reading from scale, (scale units)

ps=Specific gravity of calibration liquid related to water in std.

atmosphere at 70˚F being 1.00

pa=Specific gravity of metered liquid, same base

ds=Density of calibration liquid, lbs/ft3

da=Density of metered liquid, lbs/ft3

pf=Specific gravity of meter float

df=Density of the meter float as per Table below

FLOAT SPECIFIC GRAVITIES/DENSITIES

Material

Stainless Steel

pf

8.05

df

501.1

EXAMPLE: Using a standard stainless steel meter scaled for water (ps

= 1.00), what is the conversion factor for an oil with a specific gravity of

0.85?

Qa= 1.00

FIGURE 1

Thus, actual flow of the oil would be the observed scale reading times

1.00 (8.05 - 0.85)

x

√

0.85 (8.05 - 1.00)

=1.11

Page 3

MAXIMUM FLOWS (WITHOUT EFFECTING ACCURACY)

SPIRAL RETAINING

RING

INNER FLANGE

RING

READING

SCALE

SIGHT TUBE

ASSEMBLY

STATIC O-RING

SEAL

MAGNET(S)

CORE TUBE / FLOAT

ASSEMBLY

FOR UNDERSIZED PIPES CONNECTED DIRECTLY TO

FLOWMETER INLETS

DATA

PIPE

NPS

1/4

3/8

1/2

3/4

1

1-1/4

1-1/2

2

2-1/2

3

ata per Cameron Hydraulic Data. Based on 5 FPS max. liquid velocity having

D

*

no effect on flowmeters accuracy if the inlet pipe is smaller than the meter

connections.

†

CFM=0.445 x (psig + 14.7) x (ID)

S

o effect on flowmeters accuracy if the inlet pipe is smaller than the meter

n

connections.

(ID)

0.132

0.243

0.387

0.679

1.100

1.904

2.592

4.272

6.096

9.413

2

MAX. *

GPM LIQ.

1.72

2.98

4.74

8.31

13.47

23.32

31.74

52.29

74.56

115.2

ATMOS.

0.864

1.59

2.53

4.44

7.20

12.5

17.0

28.0

39.9

61.6

MAX. SCFM AIR @ †

50 PSIG

3.80

7.00

11.1

19.5

31.7

58.8

74.6

123

176

271

2

Based on 20 FPS max. air velocity having

.

100 PSIG

6.74

12.4

19.8

34.7

56.1

97.2

132

218

311

480

CORRECTING READINGS FOR NEW GAS CONDITIONS

s

√

Psx Tgx P

Pg x Tsx P

s

g

Qg= Q

Where:

Qg=SCFM, corrected to new conditions

Qs=SCFM read on meter scale

Pg=Operating pressure, psia (psig + 14.7)

Qs=Pressure stated on scale, psia (psig + 14.7)

Tg=Operating temperature, absolute (˚F +460)

Ts=Temperature stated on scale, absolute (˚F + 460)

Pg=Specific gravity of metered gas

Ps=Specific gravity stated on scale

200 PSIG

12.6

23.2

37.2

64.9

105

182

248

408

582

804

VISCOSITY CONSIDERATIONS

Each liquid flowmeter has so-called “Viscosity Immunity Ceiling” (V.I.C.).

Usually, if the viscosity of the metered liquid is less than the V.I.C., the

meter will be influenced significantly, and must be calibrated for that

viscosity. Effects of viscosity on a given flowmeter are not always

predictable. Two apparently similar liquids with comparable densities

and viscosities may impact meter calibrations quite differently. The table

below provides general guidelines for the typical maximum viscosity for

meter models without affecting accuracy.

AVERAGE V.I.C., CENTISTOKES, FOR

STANDARD “THRU VIEW”FLOWMETERS

100% GPM,

3/4˝ METERS

0.54-0.80

1.20-2.60

3.80-7.00

10.0-23.0

100% GPM,

CTS

1-1/2˝ METERS

3

11.0-15.0

7

21.0-35.0

15

50.0

25

70.0-120

CTS

50

100

250

500

MAINTENANCE

Upon final installation of the Series STFLO Stainless Steel Flowmeters,

no routine maintenance is required. A periodic check of the system

calibration is recommended. The Series STFLO Stainless Steel

Flowmeters are not field serviceable and should be returned if repair is

needed (field repair should not be attempted and may void warranty). Be

sure to include a brief description of the problem plus any relevant

application notes. Contact customer service to receive a return goods

authorization number before shipping.

METER DISASSEMBLY

EXAMPLE: If using a standard meter scaled for SCFM Dry Air @ 100

psig, 70˚F on argon (SP. GR.=1.378) at 50 psig, 100˚F, what would the

conversion factor be?

Qa= 1.00

64.7 x1.00 x530

√

114.7 x1.378 x560

= 0.622

Thus, actual flow of the argon would be the observed scale reading

times 0.622.

STEAM

Series STFLO flowmeters are recommended for use with vapors,

especially steam. The conversion factor may be determined with the

following formula:

Where:

Mfh=Actual flow, lbs/hr.

Qm=Meter scale reading, Std. (SCFM Dry Air @ 100 psig, 70˚F)

M

= Qm _______

fh

5.879

√S

v

Sv=Specific volume of media (from steam table)

EXAMPLE: When using a standard gas meter scaled from SCFM Dry Air

@ 100 psig, 70˚F, what is the conversion factor for lbs/hr. steam at 50

psig, 300˚F?

Mfh=

5.879

√6.727

Thus, actual flow of steam in lbs/hr. would be the observed scale reading

times 2.267.

FIGURE 2: PARTIALLY EXPLODED DRAWING OF SERIES STFLO

STAINLESS STEEL FLOWMETERS

It is not necessary to remove the flowmeters from the pipeline for

cleaning or replacing parts. The body remains plumbed into the pipe,

allowing easy service and even installation of the different sensing

elements to accommodate new flow rates or fluids. Figure 2 shows some

of the major components. Step by step disassembly and reassembly

instructions and photos are included in the following.

Page 4

CAUTION: BE SURE PRESSURE IS FULLY VENTED AND FLUIDS

COMPLETELY DRAINED BEFORE DISASSEMBLING THE

FLOWMETER. DISCONNECT POWER TO ELECTRONIC

ACCESSORIES. WEAR SAFTEY GLASSES AND PROTECTIVE

CLOTHING IF THERE IS A CHANCE OF EXPOSURE TO

HAZARDOUS FLUIDS!

1. Remove the reading scale by removing the two set screws in the black

rings attaching the reading scale to the sight tube. Lift the reading scale up

and off of the meter. Set the screws aside where they will not be lost.

2. Using a screwdriver, carefully pry the notched end of the spiral retaining

ring out of the body groove. Move the screwdriver blade under the ring- the

action is very much like putting a key on a key ring. Continue until the entire

spiral ring has been removed from the groove (please see the photo

below).

FLOWMETER ASSEMBLY

In general, replace all parts in reverse order of the disassembly.

1. Place the slotted meter tube into the body, aligning the “key” at the

bottom of the tube with the keyslot in the bottom of the body.

2. Place the spider over the meter tube with the “notched leg over the

snorkel tube or guide rod. Slide the spider down to the meter tube’s

shoulder.

3. Place the meter float in the meter tube, aligning the notch in the indicator

disk with the snorkel.

3. Using hands only, pull the sight tube straight up out of the body with a

slight twisting motion, lifting it clear of the body and snorkel. The inner

flange ring will lift off with the sight tube.

4. Remove the float assembly by lifting it up and away from the snorkel.

The core tube assembly may then be lifted out. If stuck, CAREFULLY pry

at the top of the slot with a brass rod, taking care not to damage the body

or core tube. The spider ring and O-ring will come out with the core tube. If

the core tube is stuck, try removing the metal spider ring first (please see

the photo below).

INSPECTION & CLEANING

Inspect parts for nicks, scratches, chips, wear, and contaminant build-up.

The edges of the core tube slot, ID of the core tube and OD of the piston

(largest section at the float assembly bottom) are precision machined.

Damage to these areas can destroy the meter’s accuracy. Also inspect the

O-ring, the bottom section of the sight tube, and the inside of the upper

body section. Damage to these areas may result in leaking. Clean, rinse,

and dry all parts carefully, including the O-ring, preferably with a mild

detergent and water and a soft cloth or soft tube brush. If solvents are

used, make sure they are compatible with meter parts.

CAUTION: DO NOT SCRAPE OR USE ABRASIVE

MATERIALS FOR CLEANING!

4. Seat the O-ring on the sight tube, lubricating it with a small amount of

service-compatible silicone grease or petroleum jelly to facilitate

replacement.

Page 5

5. Using hands only, press the sight tube firmly down into the meter body

with a twisting motion. Be careful not to rock the sight tube side to side and

bend the snorkel tube/guide inward where it might interfere with float

movement. Rotate sight tube as necessary for scale visibility and/or

alignment of the raceway screw.

6. Slide the inner flange ring over the sight tube. When properly seated, the

top of the flange ring should be flush with the bottom edge of the snap ring

groove.

If new flow internals are used, the scale may have to be remounted on the

sight tube. Depending on the model type, this can be done either by

loosening the mounting screw, or reattaching the scale with double sided

adhesive (new flow internals are shipped with a new scale).

REPLACEMENT PARTS

Under proper care, there should be no need to stock replacement parts. If

the service or environment is quite harsh, or frequent meter disassembly

dictated, a spare O-ring may be desirable.

Otherwise, parts only need to be replaced if damaged. Any visible damage

to the entire surface of the O-ring or sight tube (particularly from the bottom

edge) indicates need for replacement. To insure accuracy, the inside

surface of the meter core tube, slot edges, and OD of the float piston

should be free of nicks, chips, with no visible erosion of any surfaces. If

abrasive particles are suspended in the meter fluid, it may be desirable to

keep replacement core tube/float assemblies on hand (Dwyer Instruments,

Inc. may also be able to recommend a more abrasive-resistant

construction).

To order parts, include the model and serial number of the units involved,

and description of the part ordered. If converting the meter to a new

application, in addition to the model and serial numbers, SEND DWYER

INSTRUMENTS, INC. COMPLETE APPLICATION DATA INCLUDING

FLUID, MAXIMUM FLOW RATE, MAXIMUM AND OPERATING

PRESSURES AND TEMPERATURES, AND APPLICATION

PARTICULARS OR FLUID CHARACTERISTICS. This information is

essential for Dwyer Instruments, Inc. to provide proper items, and verify

that the new application is within the operating limits of the flowmeter.

7. Separate the coils of the spiral retaining ring, and insert one end into the

body groove. Wind the ring into the groove, making sure the ring is properly

seated. Then replace the ball indicator (the tip of a screwdriver can be used

to help locate the magnet), and replace the raceway and raceway cover.

Slide the reading scale over the sight tube, aligning the top of the black

metal of the reading scale with the screw hole on the sight tube. The

reading scale should read zero. Use the set screws to secure the reading

scale in place. Verify that the indicator ball moves with the magnet.

TEMPERATURE VS. PRESSURE, OPERATING LIMITS, SERIES STFLO STAINLESS STEEL FLOWMETERS*

METER SIZE

& MATERIAL

3/4” NPT

1-1/2” NPT

0˚F (-18°C)

1000 (68.9)

800 (55)

70˚F (21°C)

1000 (68.9)

800 (55)

MAXIMUM NON-SHOCK WORKING PRESSURE, PSIG @ ˚F

300˚F (148°C)

1000 (68.9)

800 (55)

350˚F (176°C)

990 (68.2)

790 (54.4)

400˚F (204°C)

970 (66.8)

780 (53.7)

450˚F (232°C)

950 (65.5)

770 (53)

500˚F (260°C)

930 (64.1)

760 (52.4)

600˚F (315°C)

900 (62)

750 (51.7)

*OPERATING LIMITS GIVEN ARE BASED ON WATER OR AIR. FOR MORE SEVERE SERVICE, CORROSIVE, AND OTHER MEDIA AND/OR ENVIRONMENTAL

FACTORS, AN ADDITIONAL CORRECTION FACTOR DOWN-RATING THESE LIMITS MAY BE REQUIRED. LIMITS ARE BASED ON TESTING AND PRACTICAL

EXPERIENCE. POSSIBLE EXTREME APPLICATIONS CONDITIONS CANNOT BE FORESEEN. THUS, DATA OFFERED ONLY AS A GUIDE. IT IN NO WAY

CONSTITUTES A SPECIFIC RECOMMENDATION OR WARRANTY EXPRESSED OR IMPLIED.

Page 6

TROUBLESHOOTING

SYMPTOM

FLOAT HANG-UP:

FLOAT BOUNCE:

LOSS OF BALL

INDICATOR:

APPARENT FALSE

READINGS, LIQUID

METERS:

APPARENT METER

READING MIGRATION

(reading changes but flow

appears constant):

LEAKAGE:

NOTE: Flowmeters are hydrostatically pressure tested before they are shipped. Dwyer Instruments, Inc. encourages you to contact your Dwyer Instruments, Inc.

representative or the factory with any questions regarding proper installation and operation of our flowmeters.

Caused by particles, sludge, etc. (including failure to remove

the plastic tubing used to block meter float during shipment)

inside the core tube and/or sight tube holding float. A bent

snorkel tube/guide rod (usually caused by careless

disassembly or violent surges) may also be causing float to

stick. Violent surges may also unseat the internals in

extreme cases.

Caused by pumping/compressor surges or other pulsation

sources, loose valve disks or similar mechanical

components, extreme violation of inlet piping

recommendations, or for gas applications, harmonics

commonly found in systems with low pressure, low density

gas.

Caused either by rotating the sight tube without realigning

the float magnet, or sudden flow surges or shocks.

Liquid density not according to calibration data (different

temperature or new liquid or liquid mixture), excessive

dissolved or suspended solids or gases, partial clogging of

core tube slot or foreign matter interfering with float

movement, or viscosity levels above the meter’s immunity

index (V.I.C.)

NOTE: If the meter is suspected of giving false readings, and

none of the causes mentioned is found, please advise

Dwyer Instruments, Inc. as to the method used in

determining the suspected flow “error”. Each Flowmeter is

individually calibrated by traceable methods, and carefully

inspected. There may be some error in checking the meter

against another standard.

Frequently caused by use of soft disc type valves, which

may need to be replaced with a valve more suited to flow

control. Can also be indicative of changing fluid conditions

(density, viscosity, etc.). Problems with other elements of the

flow system, including leaks, clogged filters,

pump/compressor wear, etc. may first appear as a change in

meter reading-one of the functions of a flowmeter.

If at the junction of the body and sight tube, it is indicative of

either (a) damaged O-ring (most common); (b) damaged

sight tube; or (c) damage to the gland section of the body. It

may also be caused by improper reassembly of the

flowmeter in the field.

If there is leakage at the pipe connections to the meter, it is

probably caused from over-tightening pipes on a prior

installation (or the initial installation).

USUAL CAUSE

Remedies include tapping the meter gently to temporarily

dislodge the float, but if problem reoccurs, meter should be

disassembled & cleaned, and/or snorkel/guide rod

straightened. If hang-up caused by sludge or pipe scale,

clean lines & install a filter or other form of cleaner in

supply line. If surges have caused the internals to unseat,

install a desurger, accumulator, etc.

Modification of piping, such as addition of a desurger,

receiver, accumulator, vibration eliminators, loops, hoses,

etc. between the source and meter should remedy the

problem. Severe vibration may ultimately damage the

meter, and should be avoided. If “bounce” seems to be

from some other source, or shocks such as “water

hammer” (a potentially dangerous condition), discontinue

using the meter and contact Dwyer Instruments, Inc.

Check the ball alignment to magnet by removing the

raceway cover and using the tip of a small screwdriver to

locate the float magnet. Rotate the sight tube as required,

and replace raceway (or disassemble meter to change

magnet position if required). If the alignment is okay,

eliminate system shock or surges with desurgers or

accummulators.

By determining the actual density (due to changes in

mixture, temperature, etc.), the correction formulae may be

applied. If dissolved gases are in the liquid, some

elimination means should be provided on the supply side

(also recheck all piping, as improper seals at connection

points are common sources of air in the liquid). If the

metered liquid is near the boiling point producing partial

“flash gas” at the meter, relocate the meter to point of lower

temperature and/or higher pressure, or cool lines and/or

increase system pressure. Note: It is potentially dangerous

to meter near the “flash point” of any fluid, and this practice

should be avoided. Consult Dwyer Instruments, Inc. for

recommendations. The previous recommendations

regarding cleaning the meter and/or filtration will also solve

problems due to dirt. If metering liquids with high

viscosities, consult Dwyer Instruments, Inc. (may require

special calibration). If none of these causes seem to be

present, contact Dwyer Instruments, Inc. for assistance.

Verifying the proper fluid conditions are known and

applying correction formulae as needed will remedy

problems associated with changing fluids. Cleaning,

servicing, and replacement and/or repair of other system

components may be required.

Replace any damaged parts immediately, using the proper

assembly procedures indicated in this instruction and the

assembly detail drawings.

Remove the body and inspect for damage-if none is

visible, check pipe threads, reapply proper thread

lubricant/sealant, and reinstall. If leak persists, replace

meter body.

SUGGESTED REMEDY

©Copyright 2012 Dwyer Instruments, Inc. Printed in U.S.A. 12/12 FR# R1-443701-00 Rev.1

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...