Page 1

F-SPK

SPK

TM

Solar Panel

FEATURES

• Includes 5 watt solar panel, mounting hardware,

and 12V solar charge controller

• Reliable, maintenance-free operation

• Powers Dwyer Instruments Inc. ow meters

• Requires a 22-33 Amp-hour Sealed Lead Acid battery

APPLICATIONS

• Remote metering applications where electricity is

unavailable

• Back-up power supply for uninterrupted operation

GENERAL INFORMATION

The SPK solar panel makes it possible to use Dwyer Instru-

ments Inc. owmeters in remote applications where a reliable

source of electricity is not available or practical. The SPK is

intended for use with a standard 12V, 22-33 Amp-hour Sealed

Lead Acid battery (not included). It comes standard with a

charge controller and corrossion-resistant mounting hardware.

The SPK can also be used to provide up to a 40-day back-up

power supply for periods of darkness.

Page 2

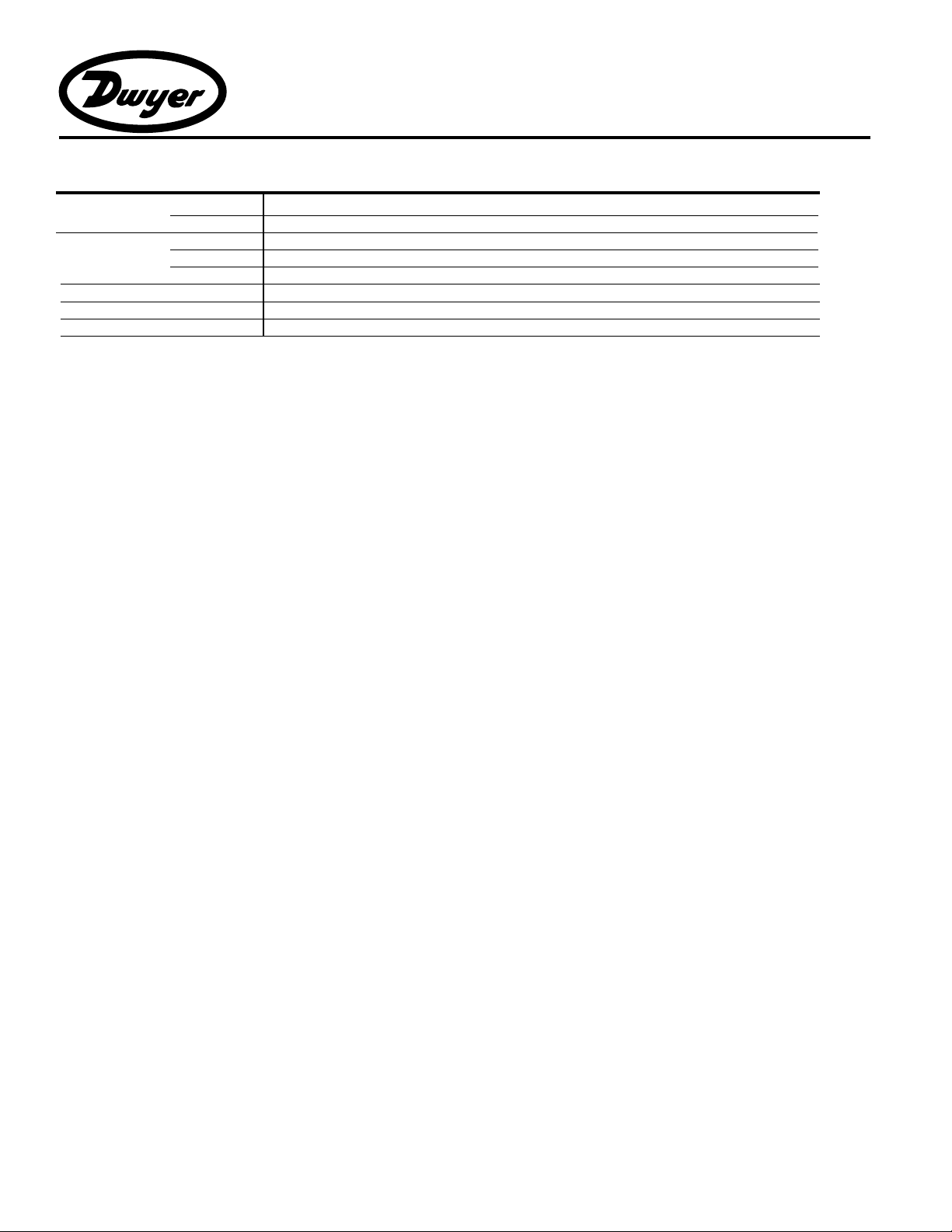

SPECIFICATIONS*

SPK

TM

Solar Panel

Electrical Current

Voltage

Dimensions Height

Width

Weight

Mounting

Operating Temperature Range

Change Controller

*Specications subject to change

290 mA (typical at design operating point)

17 V (typical at design operating point)

14.2”

8.5”

4 pounds (solar panel and mounting bracket)

Bracket, band clamps and mounting hardware for 1-1/2 or 2 inch vertical pipe

-40˚ F to +158˚ F (-40˚ C to +70˚ C)

High efciency series PWM regulator with temperature compensation and built-in lightning protection

BATTERY SELECTION

For powering Dwyer Instruments Inc. mechanical meters

along with display electronics, use a 12V Sealed Lead Acid

(SLA) deep-cycle battery with a minimum capacity of 22 Amphours. This should provide a conservative 40 day backup with

maximum battery service life. Marine/RV grade deep-cycle

batteries or automotive batteries may be used but must be

upsized in Amp-hour capacity by two times and four times

respectively to achieve the same battery service life in most

applications.

For powering Dwyer Instruments Inc. low power (<50mA)

magnetic ow meters use only deep-cycle SLA batteries (not

marine/RV orautomotive grade batteries) with a minimum ca-

pacity of 33 Amp-hours. In climates where meters are operating in full pipe mode much of the time with extended periods

of cloudy days, operating continuously through the year, or in

latitudes above 50 degrees, the required battery Amp-hour

capacity should be reviewed before selection. To learn more,

consult the Appendix in our solar power application note

found at www.dwyer-inst.com.

In summary, the minimum recommended battery capacity, as

described above, will be adequate in most climates and applications. However, under marginal conditions, a larger capacity battery may provide superior reliability, better battery

service life and lower life-cycle costs.

LOCATION

The solar panel should oriented as much as possible toward

the midday sun. Locate where there is no signicant shading

of the solar panel. The Solar Charge Controller and Sealed

Lead Acid (SLA) battery should be located in close physical

and thermal proximity. Both must be shaded from direct

sunlight to minimize temperature differences between them

which will greatly diminish the battery service life. Also insulate

the bottom of the battery if heat could be absorbed from the

surface (concrete, metal etc.) on which the battery is resting.

Also take measures to prevent accumulation of moisture (rain,

snow, ice, ooding) between the battery terminals which could

discharge the battery.

If the battery and Solar Charge Controller are housed in an

enclosure, the outside must be white or shiny metallic to minimize solar heat build up inside that is seriously detrimental

to the service life of the battery. Even light colors (such as the

standard ANSI 61 Gray) can elevate the interior of the enclosure

by 40F (22C.) If other colors are used, the enclosure must be

shaded from direct sunlight or painted glossy white. In addition,

because even sealed batteries could vent if the Solar Charge

Controller fails, for safety reasons the enclosure should be

vented, particularly if it contains other electrical equipment.

Page 3

INSTALLATION

SPK

TM

Solar Panel

The solar panel is designed to mount to a either a 1-1/2 to 2

inch diameter vertical pipe. First attach the 45 degree angle

bracket to the panel with the two M6 bolts, at washers and

nuts provided as shown. Before tightening the bolts. Be sure to

position the bracket to the side of the black cable cover rather

than over it to avoid stressing the panel. (At latitudes above 50

degrees performance may be improved by bending the bracket

so that the angle of the panel to the horizontal is increased

to approximately the local latitude plus 15 degrees. To avoid

damage to the panel, do this before bolting the bracket to the

panel). Next use the two sets of ¼-20 bolts, nuts, at and

lock washers to attach the angle bracket to the pipe mount

C-channel. Then attach the entire assembly to the pipe using

the two band clamps as shown. Turn the panel to face true (not

magnetic) south in the northern hemisphere or north in the

southern hemisphere before tightening the clamps securely.

Connect the solar charge controller, ow meter and battery

as shown in the wiring diagram. Clean battery terminals and

secure connections to the battery using grease or other means

of preventing corrosion. For safety, an in-line fuse holder should

be installed at the positive battery connection with a 1 Amp

time lag (slow-blow) fuse. In unprotected locations a weatherproof fuse holder (such as Bussmann HFB-R) and outdoor-rated

wirenuts should be used.

1-1/2 to 2 inch pipe

1/4-20 hardware

solar panel

M6 hardware

C-channel

band clamps

Page 4

WIRING DIAGRAM

TM

SPK

Solar Panel

MAINTENANCE

Periodic cleaning of the solar panel glass is recommended to

remove dust accumulation. Snow and ice may need removal if it remains more than 2 weeks. Installing the panel at a

steeper than 45 degree angle may make this unnecessary in

most areas. Battery service life for good quality SLA batteries

should be 4-6 years. Actual maintenance replacement interval will depend on local conditions and criticality of data.

WARRANTY/RETURN

Refer to "Terms and Conditions of Sale" in our catalog or on our website. Contact customer service to receive

a Returns Goods Authorization number before shipping

your product back for repair. Be sure to include a brief

description of the problem plus any relevant applciation

notes.

TM

Dwyer Instruments, Inc. • 102 Indiana Highway 212 • Michigan City, IN 46360 • USA

(P) 219.879.8868 • (F) 219.872.9057 • 1.800.872.9141 • www.dwyer-inst.com

PL-OM-65200394-082012

8/20/12

Loading...

Loading...