Page 1

Series SN NAMUR Mount Solenoid Valve

™

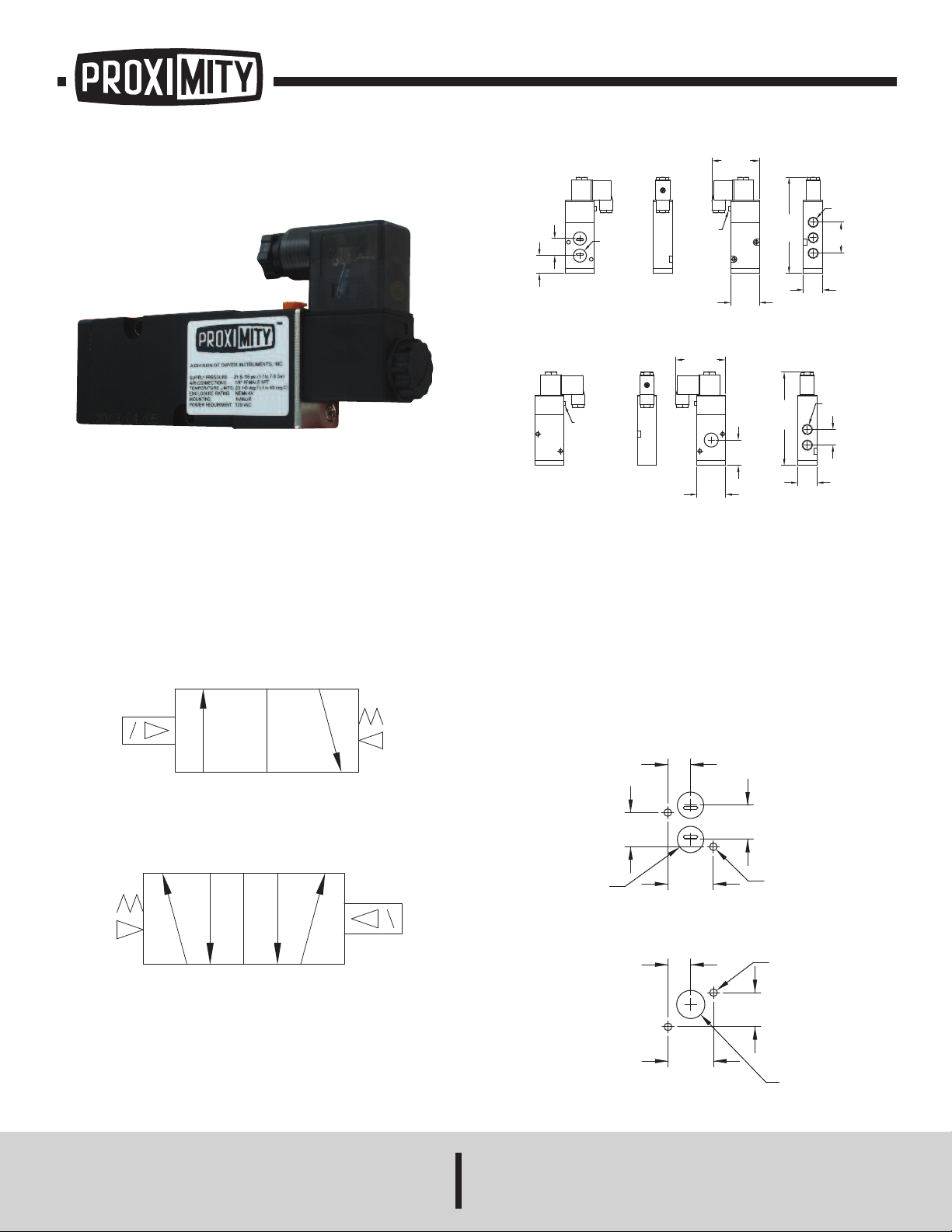

MANUAL

OVERRIDE

1-37/64

[40.08]

7/8

[22.23]

2X 1/4 NPTF

1-1/16

[26.99]

2-49/64

[70.25]

S

N-3X MODELS

5-11/64

[131.37]

1-25/64

[35.32]

1

-1/16

[

26.99]

1-47/64

[44.05]

3X 1/4 NPTF

S

N-5X MODELS

2-5/8

[66.68]

6

3/64

[

25.00]

61/64

[24.21]

N

AMUR

S

TANDARD

MANUAL

OVERRIDE

1

-37/64

[

40.08]

5-21/64

[135.33]

SN-3X MODELS

P

R

T

T

A

10

SN-5X MODELS

RPS

T T

A

T

B

5/8

[16.00]

15/16

[24.00]

2X 49/64

[Ø19.45]

61/64

[24.21]

1-17/64

[32.00]

2X 13/64

[Ø5.31]

5/2 WAY NAMUR

5/8

[16.00]

2X 13/64

[Ø5.31]

15/16

[24.00]

1-17/64

[32.15]

Ø25/32

[Ø19.81]

3/2 WAY NAMUR

Specifications - Installation and Operating Instructions

Bulletin V-SN

The Series SN Solenoid Valves are designed to easily mount directly to

pneumatic valve actuators reducing the need for tubing, fittings or brackets,

thereby reducing assembly cost. The SN solenoid comes with BUNA O-rings and

offers a manual override as a standard feature. The 3/2 solenoids are designed for

spring return actuators and 5/2 solenoids are designed to be used with double

acting actuators. The SN series is available in a variety of voltage for any

application.

Operation

SN-3 (3/2 way)

SN-5 (5/2 way)

SPECIFICATIONS

Power Requirements: 24 VAC, 110 VAC, 220 VAC, 12 VDC, or 24 VDC.

Supply Pressure: 22 to 116 psi (1.5 to 7.9 bar).

Air Connections: 1/4˝ female NPT.

Temperature Limits: 23 to 140°F (-5 to 60°C).

Electrical Connection: DIN 43650 form A.

Enclosure Rating: IP65.

Mounting: NAMUR.

Standard Features: Manual override.

Weight: 1.0 lb (.45 kg).

Agency Approvals: CE.

Mounting Patterns

The solenoid valve comes with standard NAMUR mounting.

PROXIMITY CONTROLS

A DIVISION OF DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Figure 1

Figure 2

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

NSTALLATION

NUT

LOCKING SCREW

SCREW GASKET

HOUSING

LOCKING SCREW

WITH INSULATION

SCREW TERMINAL 2(-)

FRONTAL GASKET

SCREW TERMINAL 1(+)

CONTACTS

WIRE PROTECTION

SCREW TERMINAL 3

GROUND

I

ote: Make sure that port o-rings are correctly placed inside o-ring groove.

N

. Affix solenoid valve to actuator and tighten screws.

1

2. Disconnect solenoid wire hood.

Note: Terminal designation (1) Positive (2) Neutral (3) Ground.

3. Energize solenoid valve several times and test for leaks and proper operation.

ote: Solenoid nut should be hand tight.

N

ANUAL OVERRIDE

M

he Proximity solenoid valve comes equipped with a manual override. A small push

T

button located between the valve body and the coil allows for the overriding of the

solenoid if necessary. The normal position for the button head is in a raised

position. Rotation of the button in the counter clockwise direction will manually

verride the solenoid and lock the solenoid in the disengaged position until the

o

crew head is returned to its original position.

s

Solenoid Classification

The Proximity solenoid valve is designed to IP65 standard.

NEMA 4, 4X: Watertight and dust tight - indoor and outdoor. Protects against

indblown dust, rain, splashing water and hose directed water. Also corrosion

w

esistant.

r

WIRING

Wire in accordance with the National Electrical Code and local regulations.

o aid in the wiring, the solenoid on the SN may be rotated 360°. For unwired

T

odels it is recommended to use 18 AWG copper wire rated at 90°C or greater.

m

Wiring the SN with DIN connector. See Figure 3.

1. Remove center screw and pull wiring assembly from the body.

2. Remove gasket and place small screw driver in slot to pry out the terminal block

rom the cover.

f

. Thread wire through the gland nut, gland gasket, washer and connector cover.

3

. Connect wires to proper terminals on the terminal block.

4

. Snap terminal block back into the cover. The connector cover may be rotated in

5

90° increments to position the cable entry as needed for the application. Reinstall

the center screw and screw back into the solenoid body.

AINTENANCE/REPAIR

M

pon final installation of the Series SN, no routine maintenance is required. The

U

eries SN is not field serviceable and should be returned if repair is needed. Field

S

repair should not be attempted and may void warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on our website. Contact

ustomer service to receive a Return Goods Authorization number before shipping

c

he product back for repair. Be sure to include a brief description of the problem

t

lus any additional application notes.

p

Figure 3

©Copyright 2014 Dwyer Instruments, Inc. Printed in U.S.A. 2/14 FR# RV-444160-00 Rev. 5

PROXIMITY CONTROLS

A DIVISION OF DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...