Page 1

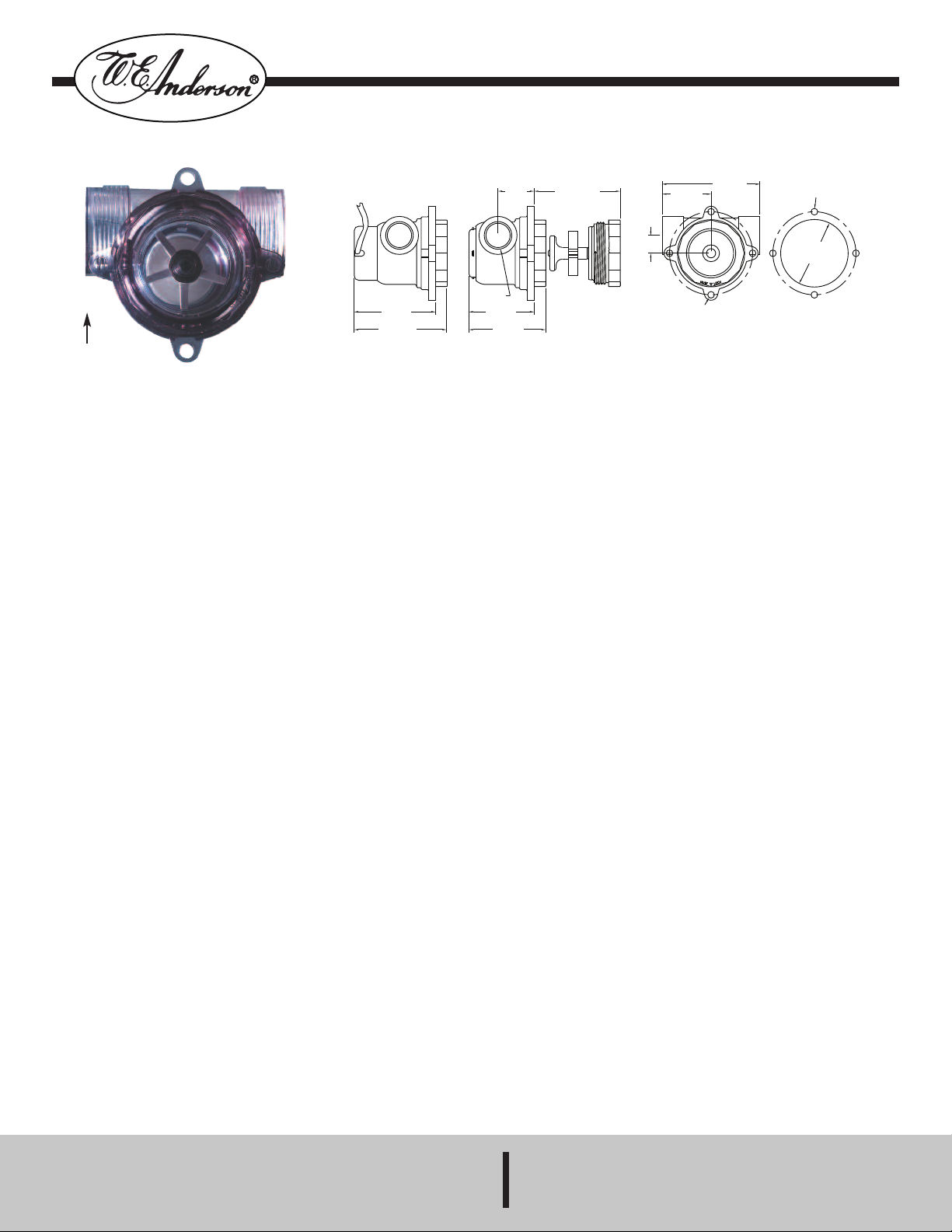

Series SFI-800 & SFI-801 Sight Flow Indicator

2-1/2

[63.50]

2-13/16

[71.44]

2-5/16

[58.74]

2

[50.80]

1

/4, 1/2 or

3/4˝ NPT

1-3/32

[27.78]

REMOVAL

CLEARANCE

2

-1/4

[

57.15]

17/32

[13.50]

2-15/16

[

74.61]

1-15/32

[37.30]

(

4) 1/4 DIA [6.35]

HOLE ON 2-1/2 DIA [63.5]

BOLT CIRCLE

2-1/32

[51.59]

P

ANEL

M

OUNT CUTOUT

(4) 13/64 DIA [5.16]

HOLE ON 2-1/2 DIA [63.5]

B

OLT CIRCLE

Specifications - Installation and Operating Instructions

Bulletin F-47

UP

SFI with A-711 Option

The Series SFI-800 Sight Flow Indicator provides protection for

expensive equipment and systems, accommodating fluid temperatures

as high as 212°F (100°C) and pressures up to 150 psi (10.34 bar). This

sight flow indicator is composed entirely of FDA/NSF-ratable materials.

It is exceptionally corrosion-resistant and can handle de-ionized water

and many acids, bases and salts. (Consult B. P. Amoco’s Extensive

“Chemical Guide” for further information on the Udel P1700 Polysulfone

resin).

The Series SFI-801 Sight Flow Indicator is similar to the SFI-800

except it is made of UV stablized materials. It can be used in outdoor

applications where indication of water flow or control is needed. The

materials are not FDA approved.

Three output options are available for the SFI-800 and 801:

The A-711 is a unique, patent pending sensor that outputs two pulse

voltage signals proportional to flow rate. Pulse outputs are a 5 VDC

pulse and a pulse of the input supply voltage used, which can be 8 to 28

VDC. This sensor can be used to monitor flow rate and flow totalization.

The A-712 is a sensor that outputs a linear 1 to 10 VDC signal proportional to flow rate. This sensor can be used to monitor flow rate.

The A-713 is a flow switch with open collector outputs. One output is

active above setpoint and the other output is active below setpoint. The

setpoint can be changed by pressing a button at the desired flow rate.

FI Model Only

S

SPECIFICATIONS

Service: Compatible fluids.

Wetted Materials:

Body: SFI-800: Polysulfone, SFI-801: UV Stabilized Polycarbonate;

Window: SFI-800: Polysulfone, SFI-801: UV Stabilized Polycarbonate;

Rotor: SFI-800: White Polysulfone, SFI-801: Red UV Stabilized PBT;

Rotor Pin: 316 SS;

Thrust Washers: 300 Series SS;

O-ring: SFI-800: Fluoroelastomer (NSF Grade), SFI-801:Buna-N.

Temperature Limits: SFI-800: -20 to 212°F (-28 to 100°C); SFI-801: -20

to 130°F (-28 to 55°C).

Pressure Limits: SFI-800: 150 psi (10.34 bar); SFI-801: 125 psi (8.62

bar).

Viscosity Max: 200 SSU.

Weight: SFI-800: 3.35 oz (95 g); SFI-800-A711: 5.0 oz (142 g).

ELECTRICAL SPECIFICATIONS (for A-711 Option Only)

Temperature Limits: -20 to 212°F (-28 to 100°C).

Power Requirements: 8 to 28 VDC.

Output Signal: White lead: 5 VDC. Green lead: 8 to 28 VDC equal to

supply voltage. Pulsed output with frequency rate proportional to flow

rate.

Accuracy: ±5% of F.S.

Frequency Output Range: 0 to 100 Hz.

Electrical Connections: Black lead - Ground; White lead: 5 VDC out

pulse; Green lead: 8 to 28 VDC out pulse; Red lead: 8 to 28 VDC supply.

ELECTRICAL SPECIFICATIONS (for A-712 Option Only)

Temperature Limits: -20 to 212°F (-28 to 100°C).

Power Requirements: 15 to 28 VDC.

Output Signal: White lead: 1 to 10 VDC.

Accuracy: ±5% of F.S.

Electrical Termination: Black lead: Ground; Red lead: 15 to 28 VDC

input; White lead: 1 to 10 VDC output.

W.E. ANDERSON DIV., DWYER INSTRUMENTS, INC.

P.O. BOX 358 • MICHIGAN CITY, INDIANA 46361 U.S. A.

ELECTRICAL SPECIFICATIONS ( for A-713 Option Only)

Temperature Limits: -20 to 212°F (-28 to 100°C).

Power Requirements: 8 to 28 VDC.

Output Signal: White lead: Normally open switch; Green lead: Normally

closed switch. Both open collector, 100 mA max, 28 VDC max.

Electrical Connections: Black lead: Ground; White lead: Normally open;

Green Lead: Normally closed; Red lead: 8 to 28 VDC.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

page 2

INSTALLATION

1. Select an indoor location (SFI-800 only) that is free from excess vibration, within the specified temperature limits, and away from direct sunlight. (SFI-800 is adversely affected by ultraviolet light.)

Note: The SFI-801 is rated for indoor or outdoor use and is not

affected by ultraviolet light.

2. When mounting horizontally, make sure the “belly” of the indicator is

on the bottom. This will prevent entrapped bubbles from collecting and

degrading performance.

3. All Series 800 and 801 units may be panel mounted using the (4) four

holes integrated into the body.

4. Use plumbers tape thread sealant. Do not use pipe dope compounds,

which can craze and crack the polysulfone housing. Hand tighten system pipe fitting. If additional torque is needed to seal pipe joint, use strap

wrench on fitting.

5. If using solvent-based glues like PVC cement, in the piping system,

do so with the meter’s body removed until glue has cured, then purge

the system before reinstalling. Do not solder brass fittings with the body

installed, because the heat generated to solder the brass fittings will

damage the flowmeter.

6. Incoming flow may be connected to either port. However, for best performance a straight section of pipe with a minimum of 10 times the tube

diameter should be used on the inlet side.

MAINTENANCE

With all mechanical type sensing units, a minimal amount of cleaning is

required. However if a 150-micron filter is used, reduced cleaning can be

expected.

The Series SFI-800 Dwyer®Sight Flow Indicator utilizes a patent pending sensing design, no magnets are molded inside the impeller, to attract

ferrous material. This greatly reduces the necessary maintenance when

used in mechanical systems with ferrous residuals. If residuals are found

inside the unit, clean with mild detergent. Inspect for impeller wear. If

impeller vibration is noticeable, or if the unit produces an oscillation

(whirring or buzzing) sound, replace the impeller.

A-711, A-712, or A-713 SENSOR OPTION INSTALLATION

This procedure is for customers who purchased an SFI-800, 801 Sight

Flow Indicator and want to add the A-711, A-712, or A-713 Sensor

Option.

1. Orient the sight flow indicator with the “belly” down. The sensor

“pocket” should be in the 6 o’clock position (as one is facing the unit).

2. Position the A-711, A-712, or A-713 sensor with the wire cable leads

at 3 o’clock and the exposed sensor portion at 6 o’clock.

3. Allow the sensor package to rest on the four (4) tabs on the back of

the sight flow indicator.

4. Firmly and evenly press the sensor onto the back of the sight flow

indicator.

5. The assembly will only go on one way. The sensor is not intended for

removal.

6. Follow electrical installation for lead termination.

ELECTRICAL INSTALLATION (for A-711 Option Only)

1. Connect the RED wire from the sensor to the positive 8 to 28 VDC

power supply output.

2. Connect the BLACK wire from the sensor to the negative or ground

connection of the power supply output.

3. Connect the WHITE wire to get a 5 VDC digital pulse where the frequency of the pulse is proportional to the flow rate.

4. Connect the GREEN wire to get an 8 to 28 VDC pulse where the frequency of the pulse is proportional to the flow rate. The voltage level will

be equal to the supply voltage (on the RED wire) minus approximately

0.7 volts.

CAUTION: DO NOT Connect the white and green leads together. Any

unused output connections should remain disconnected.

The Series SFI-800 & SFI-801 Sight Flow Indicators are not field serviceable and should be returned if repair is needed (field repair should

not be attempted and may void warranty). Be sure to include a brief

description of the problem plus any relevant application notes. Contact

customer service to receive a return goods authorization number before

shipping.

CAUTION: Be sure that the window locking mechanism is in the

locked position. This would be at the 6 o’clock position, when

mounted on the horizontal plane with the belly down.

Page 3

R

ED

H

IGH

FLOW

L

OAD

L

OW

FLOW

L

OAD

8-28 VDC

P

OWER

SUPPLY

BLACK

G

REEN

WHITE

A-713

page 3

OUTPUT SIGNALS (for units with A-711 Option)

White Wire Connection:

5 Volts

0 Volts

ƒ

GPM = Freq (Hz) for SFI-800-1/2˝-A711

4.5

GPM = Freq (Hz) for SFI-800-3/4˝-A711

1.7

GPM = Freq (Hz)

4.5

GPM = Freq (Hz) for SFI-801-3/4˝-A711

1.7

Green Wire Connection:

8 - 28 Volts

for SFI-801-1/2˝-A711

ƒ

ELECTRICAL INSTALLATION (for A-713 Option Only)

1. Connect the RED wire from the sensor to the positive 8 to 28 VDC

power supply output.

2. Connect the BLACK wire from the sensor to the negative or ground

connection of the power supply output.

3. Connect the WHITE wire to the load that is energized when flow rate

is above setpoint (high flow). Connect other end of load to the positive

end of the power source. This wire may be left unconnected.

4. Connect the GREEN wire to the a load that is energized when flow

rate is below setpoint (low flow). Connect other end of load to the positive end of the power source. This wire may be left unconnected.

5. Adjust flow rate to desired setpoint and press the push to set button.

The setpoint light will flash to indicate setpoint has been changed. The

setpoint light will then turn on above setpoint and off below setpoint.

Example of Wiring Diagram

0 Volts

GPM = Freq (Hz) for SFI-800-1/2˝-A711

4.5

GPM = Freq (Hz) for SFI-800-3/4˝-A711

1.7

GPM = Freq (Hz)

for SFI-801-1/2˝-A711

4.5

GPM = Freq (Hz) for SFI-801-3/4˝-A711

1.7

ELECTRICAL INSTALLATION (for A-712 Option Only)

1. Connect the RED wire from the sensor to the positive 15 to 28 VDC

power supply output.

2. Connect the BLACK wire from the sensor to the negative or ground

connection of the power supply output.

3. Connect the WHITE wire to receive the 1 to 10 VDC linear output

(see equations below).

GPM = Output Voltage for SFI-800-1/2˝-A712

0.50

GPM = Output Voltage for SFI-800-3/4˝-A712

0.25

GPM = Output Voltage

0.49

GPM = Output Voltage

0.27

for SFI-801-1/2˝-A712

for SFI-801-3/4˝-A712

Page 4

Copyright 2011 Dwyer Instruments, Inc. Printed in U.S.A. 9/11 FR# 83-443156-00 Rev. 5

W.E. ANDERSON DIV., DWYER INSTRUMENTS, INC.

P.O. BOX 358 • MICHIGAN CITY, INDIANA 46361 U.S. A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...