Page 1

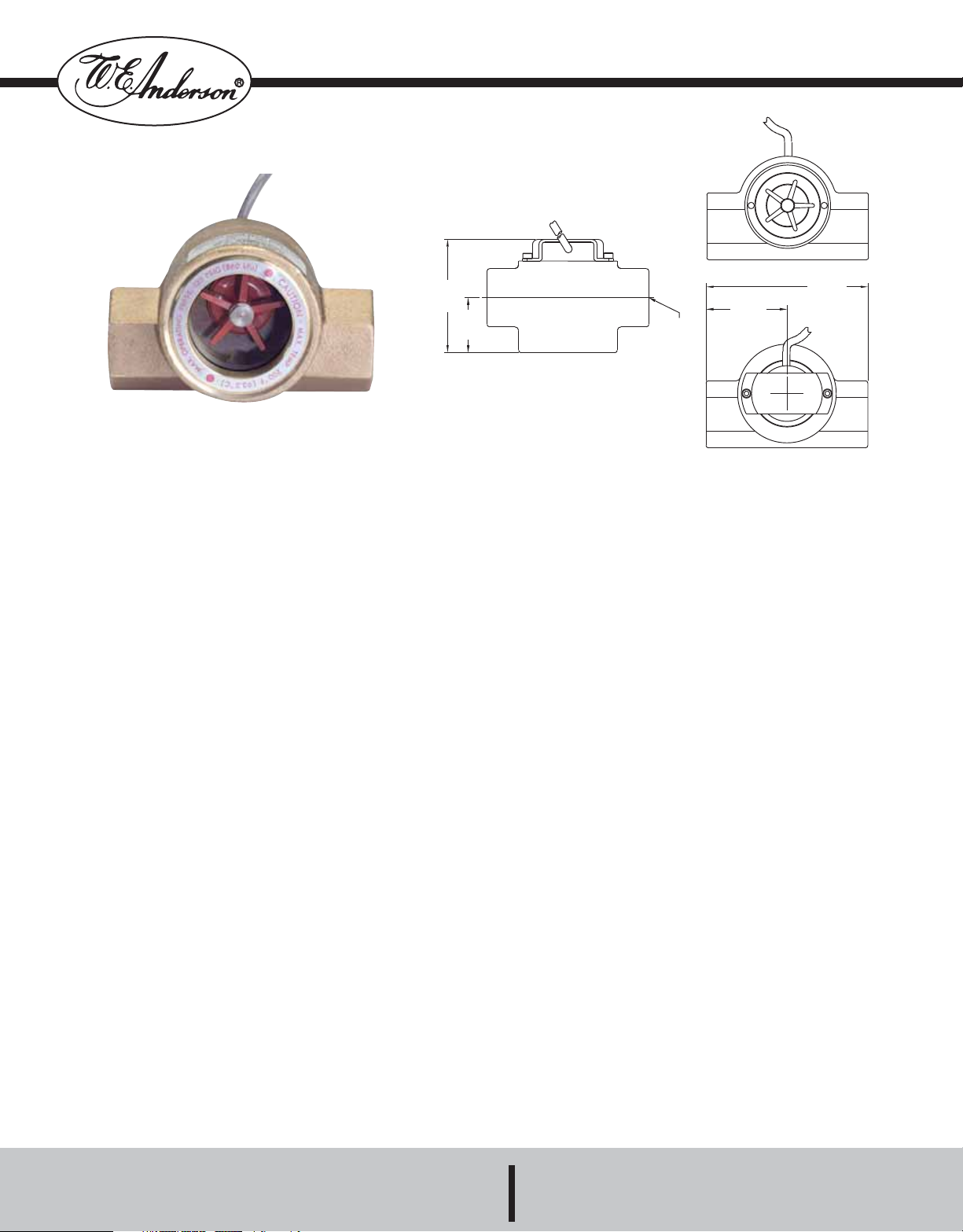

Series SFI-100T Sight Flow Indicator

2

[50.80]

4

[101.60]

3/4 NPT

2 PLCS

1-3/8

[34.93]

3

[76.20]

Specifications - Installation and Operating Instructions

Bulletin F-40

The SFT-100T is a low cost and durable flow transmitter that

combines our popular 100 Series Sight Flow indicator with our

A-711T output sensor. The SFI-100T sight flow indicator is constructed of a robust, solid brass body and a tempered glass window. A bright red impeller is featured for great visual indication

of flow through the window. The front window can be easily

unscrewed to clean out the sight flow indicator. Ideal for outdoor

appliations, the flow transmitter is weatherproof and unaffected

by UV light.

The A-711T output sensor has a VDC output with pulsing for

flow totalization and a proportional frequency change for flow

rate. For added versatility there are two output choices of 5 VDC

or a VDC equal to the input power supplied. The output is compatible with digital rate meters/totalizers and other electronic

systems.

INSTALLATION

1. Select a location that is free from excess vibration and within

the specified temperature limits.

2. When mounting horizontally, make sure the “belly” of the indicator is on the bottom. This will prevent entrapped bubbles from

collecting and degrading performance.

3. Use pipe thread sealant tape . Hand tighten system pipe fitting. If additional torque is needed to seal pipe joint, use strap

wrench on fitting.

SPECIFICATIONS

Service: Compatible fluids.

Wetted Materials:

Body: Brass.

Window: Tempered glass.

Rotor: Red UV stabilized PBT.

Rotor Pin: 316 Stainless Steel.

Thrust Washers: 300 series Stainless Steel.

Gasket: Buna-N.

Temperature Limits: -20 to 200°F (-28 to 93°C).

Pressure Limits: 125 psi (8.62 bar).

Viscosity Max: 200 SSU.

Weight: SFI only: 1.5 lb (0.7 kg); with A-711T: 1.8 lb

(0.8 kg).

ELECTRICAL SPECIFICATIONS (for A-711T Option

Only)

Temperature Limits: -20 to 212°F (-28 to 100°C).

Power Requirements: 8 to 28 VDC.

Output Signal: White lead: 5 VDC. Green lead: 8 to 28

VDC equal to supply voltage. Pulsed output with frequency rate proportional to flow rate.

Accuracy: ±5% of F.S.

Frequency Output Range: 0 to 100 Hz.

Electrical Connections: Black lead: Ground; White

lead: 5 VDC out pulse; Green lead: 8 to 28 VDC out

pulse; Red lead: 8 to 28 VDC supply.

4. Incoming flow may be connected to either port. However, for

best performance a straight section of pipe with a minimum of 10

times the tube diameter should be used on the inlet side.

W.E. ANDERSON DIV., DWYER INSTRUMENTS, INC.

P.O. BOX 358 • MICHIGAN CITY, INDIANA 46361 U.S.A.

Pat. 6,789,434

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

MAINTENANCE

With all mechanical type sensing units, a minimal amount of

cleaning is required. However if a 150-micron filter is used,

reduced cleaning can be expected.

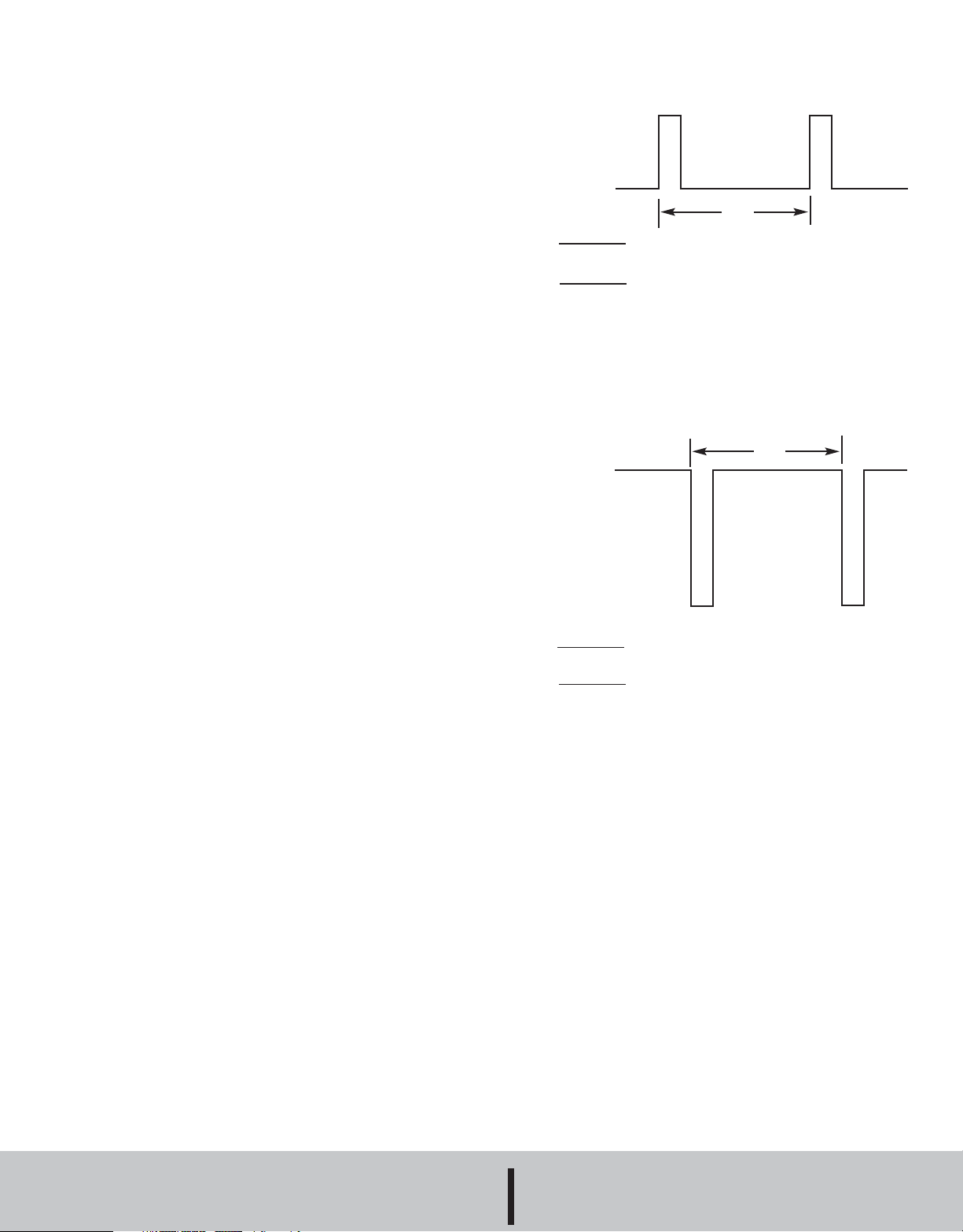

OUTPUT SIGNALS (for units with A-711T Option)

White Wire Connection:

However, because Dwyer Instuments, Inc. utilizes a patented

sensing design, no magnets are molded inside the impeller, to

attract ferrous material. This greatly reduces the necessary

maintenance when used in mechanical systems with ferrous

residuals. If residuals are found inside the unit, clean with mild

detergent. Inspect for impeller wear. If impeller vibration is

noticeable, or if the unit produces an oscillation (whirring or

buzzing) sound, replace the impeller.

A-711T SENSOR OPTION INSTALLATION

This procedure is for customers who purchased an SFI-100T

Sight Flow Indicator and want to replace the A-711T Sensor.

1. Orient the sight flow indicator with the “belly” down. The sensor “pocket” should be in the 9 o’clock position (as one is facing

the unit).

2. Position the A-711T sensor with the wire cable leads at 6

o’clock and the exposed sensor portion at 9 o’clock.

3. Firmly and evenly press the sensor onto the back of the sight

flow indicator. The assembly will only go on one way.

4. Place bracket over the A-711T and line up the screw holes in

the bracket with the holes in the back of the SFI-100T body.

Screw in the provided mounting screws with the provided lock

washer going in between the bracket and the screw head.

5 Volts

0 Volts

ƒ

GPM = Freq (Hz) for SFI-100T-1/2˝-A711T

2.0

GPM = Freq (Hz) for SFI-100T-3/4˝-A711T

1.5

Green Wire Connection:

ƒ

8 - 28 Volts

5. Follow electrical installation for lead termination.

ELECTRICAL INSTALLATION (for A-711T Option Only)

1. Connect the RED wire from the sensor to the positive 8 to 28

VDC power supply output.

2. Connect the BLACK wire from the sensor to the negative or

ground connection of the power supply output.

3. Connect the WHITE wire to get a 5 VDC digital pulse where

the frequency of the pulse is proportional to the flow rate.

4. Connect the GREEN wire to get an 8 to 28 VDC pulse where

the frequency of the pulse is proportional to the flow rate. The

voltage level will be equal to the supply voltage (on the RED

wire) minus approximately 0.7 volts.

CAUTION: DO NOT Connect the white and green leads together. Any unused output connections should remain disconnected.

0 Volts

GPM = Freq (Hz) for SFI-100T-1/2˝-A711T

2.0

GPM = Freq (Hz) for SFI-100T-3/4˝-A711T

1.5

©Copyright 2010 Dwyer Instruments, Inc. Printed in U.S.A. 2/10 FR# 83-443327-00 Rev. 1

W.E. ANDERSON DIV., DWYER INSTRUMENTS, INC.

P.O. BOX 358 • MICHIGAN CITY, INDIANA 46361 U.S.A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...