Page 1

MAINTENANCE/REPAIR

SF2 Series

Sight Flow Meters

Regular maintenance of the total system is recommended to assure sustained optimum performance. These devices are

not field repairable and should be returned to the factory if recalibration or other service is required. After first obt aining a

Returned Goods Authorization (RGA) number , send the unit freight prepaid to the following. Please include a clear description of the problem plus any application information available.

Dwyer Instruments, Inc.

Attn: Repair Department

102 Highway 212

Michigan City , IN 46360

Important Points!

Product must be maintained and installed in strict accordance

with the National Electrical Code and Dwyer product catalog

and instruction bulletin. Failure to observe this warning could

result in serious injuries or damages.

For hazardous area applications involving such things as (but

not limited to) ignitable mixtures, combustible dust and

flammable materials, use an appropriate explosion-proof

enclosure or intrinsically safe interface device.

The pressure and temperature limitations shown on the

individual catalog pages and drawings for the specified flow

switches must not be exceeded. These pressures and

temperatures take into consideration possible system surge

pressures/temperatures and their frequencies.

Selection of materials for compatibility with the media is critical

to the life and operation of Dwyer flow switches. Take care in

the proper selection of materials of construction, particularly

wetted materials.

Life expectancy of switch contacts varies with applications.

Contact Dwyer if life cycle testing is required.

Ambient temperature changes do affect switch set points,

since the specific gravity of a liquid can vary with temperature.

Flow switches have been designed to resist shock and vibration;

however, shock and vibration should be minimized.

Filter liquid media containing particulate and/or debris to

ensure the proper operation of our products.

Electrical entries and mounting points in an enclosed tank

may require liquid/vapor sealing.

Flow switches must not be field-repaired.

Physical damage sustained by the product may render it

unserviceable.

Instruction Bulletin No. 201917

(For Additional Information, See Dwyer Catalog)

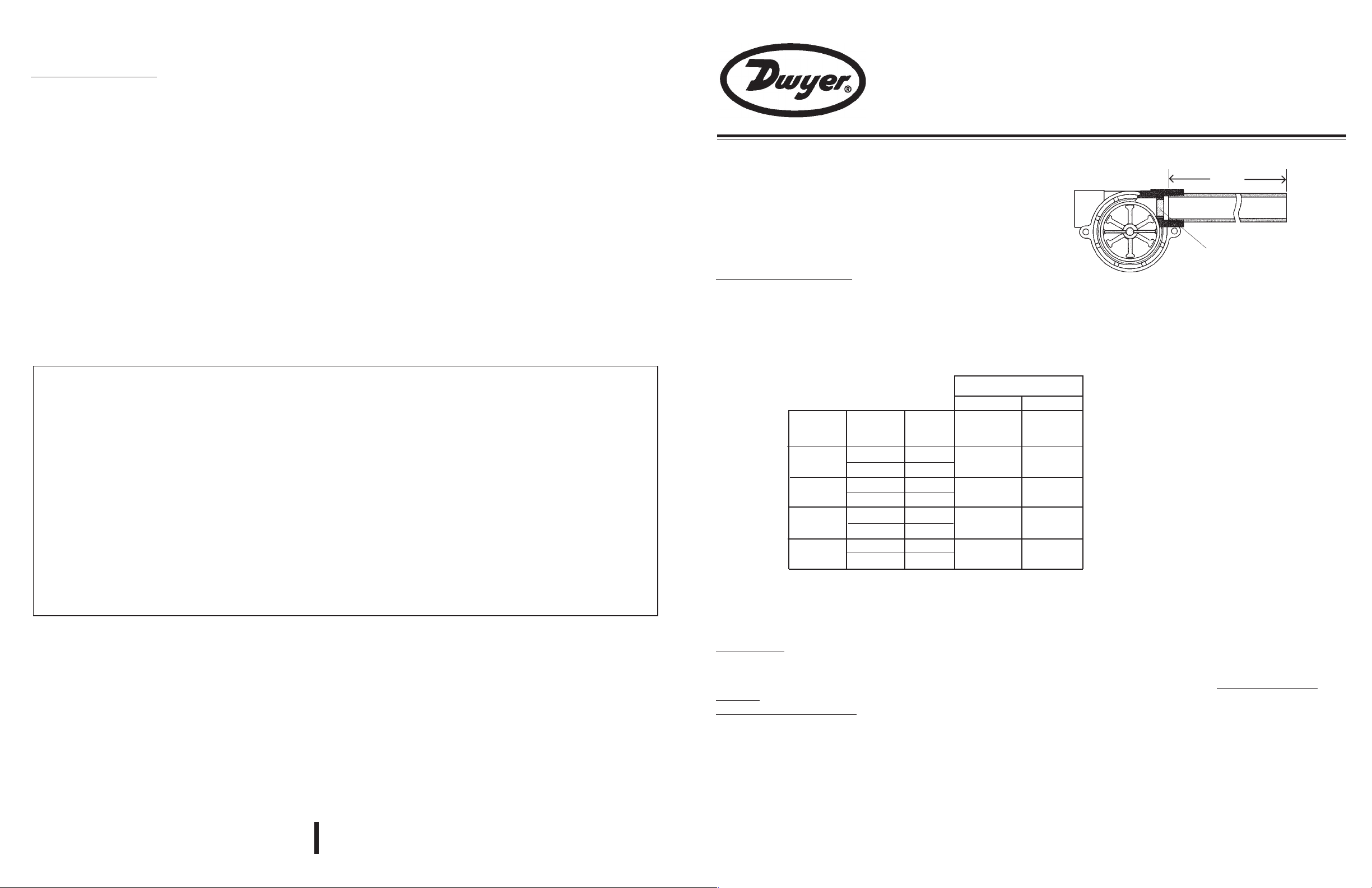

SF2 Sight Flow Meter units monitor dynamic fluid flow . The rotor reacts

to turbulence, pulsation, entrained air, and other flow anomalies induced

in the flow stream by other process hardware. For optimum performance, install SF2 Sight Flow Meter units where nominal flow conditions exist, with ports located at the top. Incoming flow may be placed

to either port. A minimum of 8" of straight pipe on the inlet side is

recommended.

Low Flow Applications

A low flow adapter is supplied with all SF2 Sight Flow Meter units. It is used to produce accurate response at low flow

rates. Press fit the adapter as shown above, in the port selected for incoming flow. See Flow Range Chart below.

Flow Range - GPM

Port Size

NPT

.25"

.50"

.75"

1.0"

Input

Power

24 VDC

1 10 V AC

24 VDC

1 10 V AC

24 VDC

1 10 V AC

24 VDC

1 10 V AC

Model

Number

SF2-104

SF2-101

SF2-114

SF2-111

SF2-124

SF2-121

SF2-134

SF2-131

Standard

Range

0.5 - 5.0

4.0 - 20.0

3.0 - 30.0

5.0 - 60.0

Low Flow*

Range

0.1 to 1.0

1.5 to 12.0

N/A

N/A

* With use of low flow

adapter supplied

8" Min.

Low Flow

Adapter

←

Incoming

Flow

DWYER INSTRUMENTS,INC.

P.O.BOX 373 MICHIGAN CITY, INDIANA 46361, U.S.A.

Installation: SF2 Sight Flow Meters connect to piping via NPT mating thread forms. The following guidelines are provided to

assist with installation for a leak-free seal, without damage to the unit: 1) Apply pipe thread sealant to male pipe threads. 2)

Thread SF2 Sight Flow Meter unit onto male pipe thread until hand-tight. 3) Tighten pipe 1 to 1-1/2 additional turns. 4) If improper

seal results, continue turning pipe into unit in 1/4 turn increments. Do not exceed one additional turn. Recommended Pipe

Sealants: (a) Permatex® "No More Leaks" (b) Teflon® Thread Tape.

Filtration and Cleaning: 150 micron filtration is recommended. However, should foreign particles enter the SF2 Sight

Flow Meters, accumulation is easily cleared by removing the lens from the body. The lens is removed by turning its center rib 45°

counter-clockwise and then pulling it out. To reinstall the lens, simply reverse the process. Pressure must be relieved from the

system prior to sensor clean-out.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Lit-By Fax: 888/891-4963

Page 2

Specifications

Wetted Materials

Body

Rotor Pin

Rotor

Lens

O-Ring

Operating Pressure, Max.

Operating Temperature, Max.

Brass Body

Electronics

Viscosity , Max.

Input Power

Relay Contact Ratings (SPDT)

Repeatability

Set Point Accuracy (Factory Set)

Set Point Differential

Electrical Termination

Brass

Ceramic

PPS Composite/Teflon/PPS Composite

Polysulfone

Buna N/Viton

200 PSIG @ 70°F 80 PSIG @ 212°F

212°F (100°C)

150°F (65.5°C)

200 SSU

12 VDC, 24 VDC or 110 VAC

1 Amp, 24 VDC Resistive 0.5 Amp, 110 VAC

2% Maximum Deviation

±5%

15% Maximum

22 AWG PVC-Jacketed, 24" Cable. Color codes: Red = +VAC/VDC;

Black = Ground; White = N.O. Contact; Brown = N.C. Contact; Green = Common.

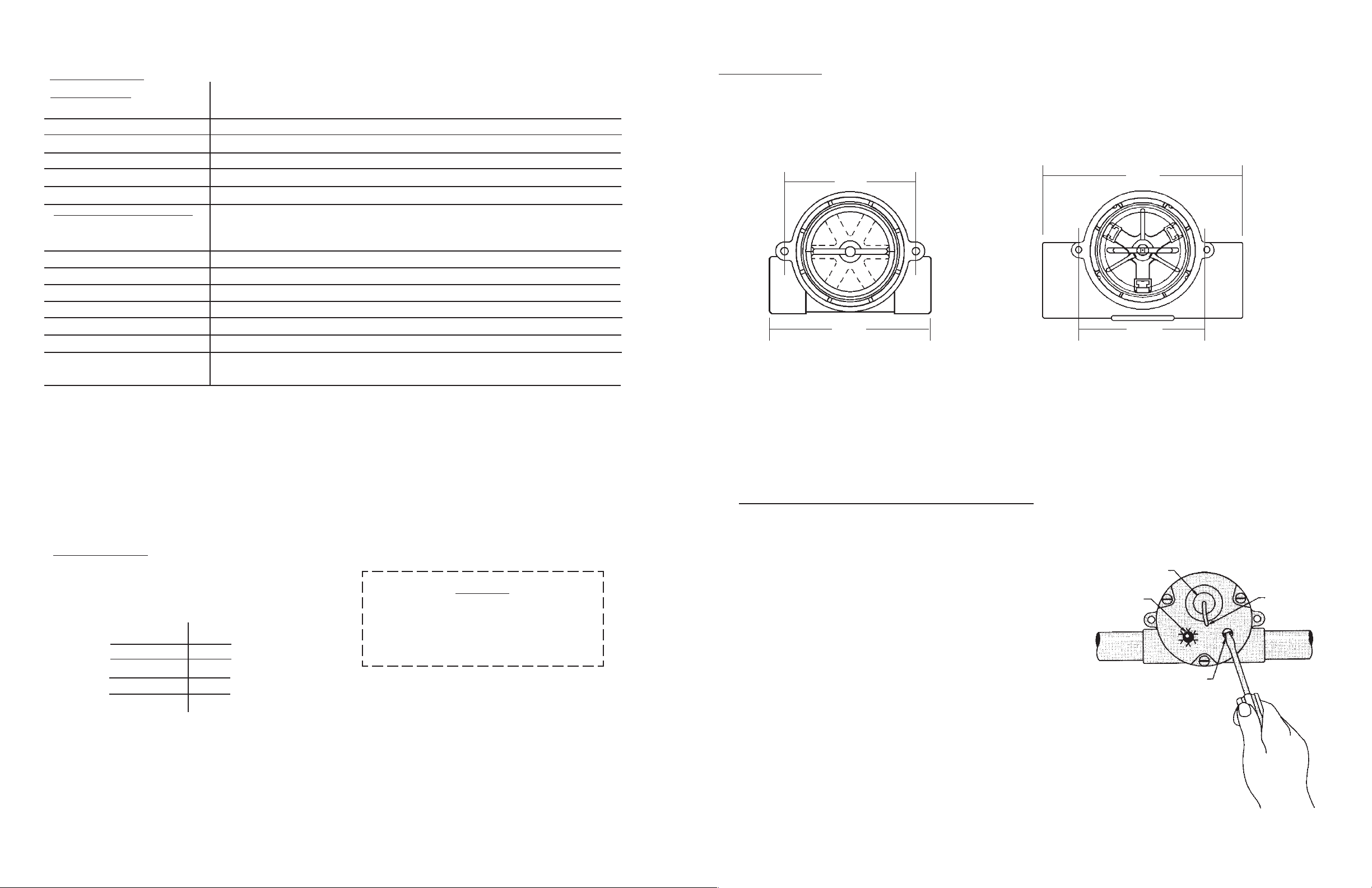

Panel Mounting

Any SF-2 sensor may be panel mounted using holes integrated into the bodies:

Two (2) mounting holes are provided on the body centerline, as shown below.

#8-32UNC-2B screws are required for mounting.

2.50"

3.06"

1/4" &1/2"

3.94"

2.5"

3/4" & 1"

Electrical Data

Input power and output are connected via a

multi-conductor, PVC-jacketed 24" cable.

Color codes are shown below:

+VAC/VDC

Ground

N.O. Contact

N.C. Contact

Common

Red

Black

White

Brown

Green

WARNING

When determining chemical compatibility of

materials of construction, the flow media and

application-associated environmental conditions should be carefully considered.

Switch Set Point Calibration with LED Signal

With the unit installed in the line and power supplied, complete the following steps to calibrate

switch actuation point with proper flow rate. A small flat-blade screwdriver is all that is required.

Adjust liquid flow in the line to the rate

1.

at which actuation is desired.

2.

Insert screwdriver into opening on

backside of housing and fit blade into

the potentiometer adjustment screw

inside.

3.

If LED is not illuminated, slowly turn

screwdriver counter-clockwise and

stop as soon as LED illuminates.

4.

If LED is illuminated, turn screwdriver

clockwise until LED light goes out.

Then, slowly turn screwdriver

counter-clockwise and stop as soon

as LED illuminates.

LED Indicator Is Illuminated

When Relay Switch Is

Closed. Aids Field

Calibration.

1/2" Strain Relief Hole

Cable

Output

Set Point

Adjustment

Loading...

Loading...