Page 1

BULLETIN F-41-SF

Series SF Sight Flow Transmitter

Specifications - Installation and Operating Instructions

700462-00

GENERAL

Series SF Sight Flow Transmitter integrates tangential turbine

technology with hermetically sealed circuitry to provide accurate flow measurement and control in the harshest environments. The 2-wire loop-powered design transmits a 4 to 20

mA signal proportional to flow rate. Models can accurately

measure flow in both directions and can be mounted in any

orientation. Series SF Transmitters are ideal for measuring

flow rates in cooling and lubrication circuits, HVAC systems,

aggressive chemical metering, and batching systems.

MECHANICAL INSTALLATION

The Series SF Sight Flow Transmitter has a 1/2 NPT(F)

plumbing connections. It is recommended to use a paste

type pipe sealant on the threads. Teflon tape sealant can

also be used as long as it is applied so the tape does not

enter the flow stream (pieces of tape can wrap around the

turbine and impeded rotation).

The recommended mounting orientation would be any

plane that will place the axis of the turbine vertical or horizontal with respect to ground. The unit will operate satisfactory with the axis at other angles, but side loading of the

bearing surfaces will lead to premature wear of the rotating

parts.

For the best flow measurement results, place the inlet (references to “inlet” and “outlet” refer to unidirectional systems) of the flow sensor at least 10 straight pipe diameters

downstream from any fitting, valve, elbow, reducer, etc. that

causes nonstable flow conditions. Ideally, 5 straight pipe

diameters should be placed at the outlet of the sensor. If

the sensor must be placed closer to a source of nonstable

flow than the recommended distances, some instability of

the output signal may result. The average signal will be

accurate.

Place the sensor in such a position that the round access

cover can be removed for cleaning and turbine servicing. A

union placed near the sensor is recommended to allow

easy removal.

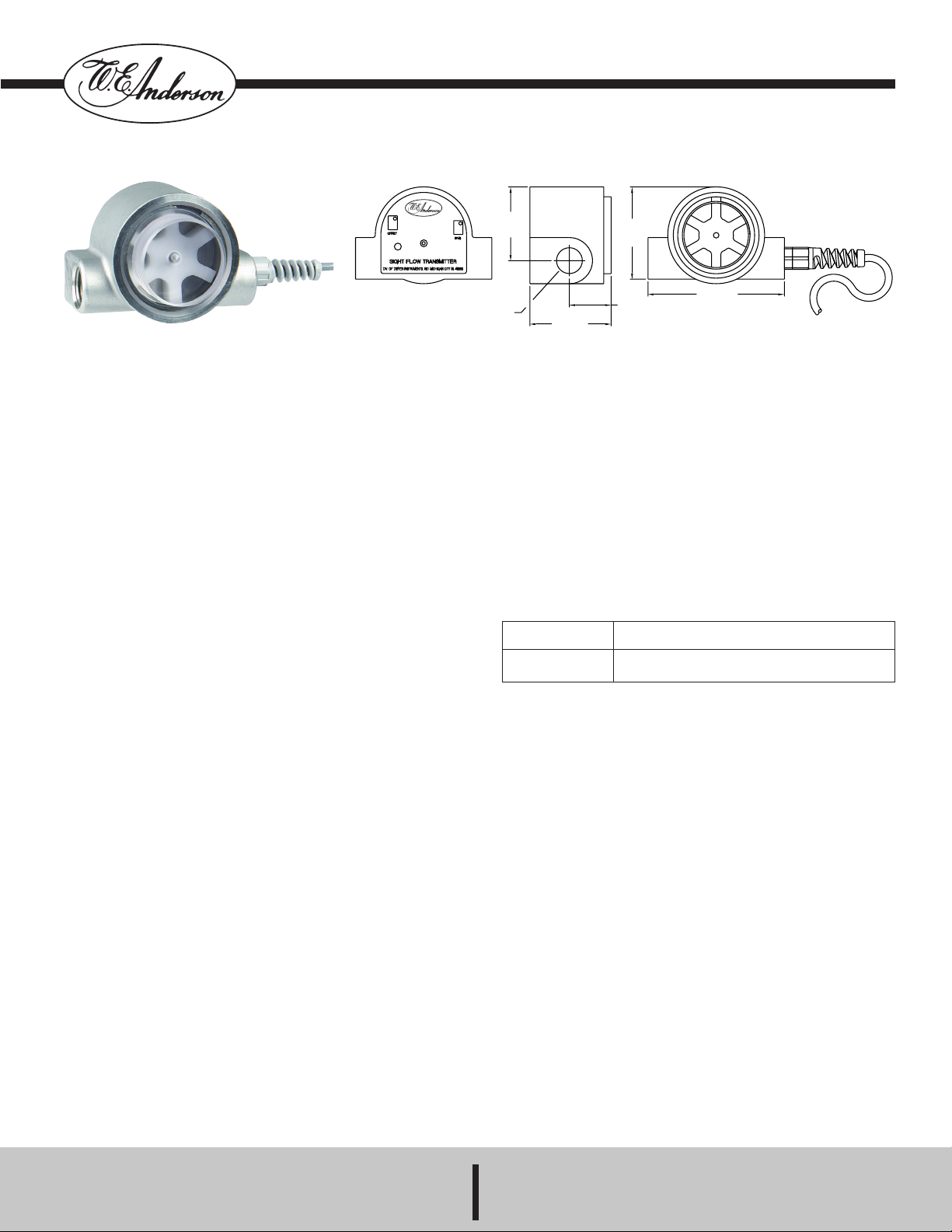

[50.80]

1/2⬙ NPT (F)

2

2-7/16

[61.91]

PHYSICAL DATA

Flow Range: 0.5 to 15 GPM (2

to 60 LPM).

Accuracy: 30 Watts: 0.14A @

220VAC, 0.28A @ 110VAC,

0.07A @ 120VDC, 0.28A @

24VDC.

Temperature Range: 20 to

225°F (-7 to 107°C).

Maximum Pressure: 500 psig

(34 bar) Model SF10, 200 psig

(14 bar) Model SF11.

Repeatability: 0.5% Full Scale.

2-5/8

[66.68]

1-1/8

[28.58]

3-11/16

[93.66]

Supply Voltage: 12 to 35 VDC.

Output: 4 to 20 mA.

Loop Resistance: 1150Ω max.

Response Time: 2 seconds to

90% (step change in flow rate).

Wetted Parts: 316 SS shaft and

case, iglide

seal and acetal copolymer, (polycarbonate cover on Model

SF11).

Connections: 2″ NPT(F).

Wire Leads: 22 AWG ⫻ 9′

(2.7m).

®

bearings, Buna-N

MODELS

Model

Number

SF10 316 Stainless Steel

SF11 Clear Polycarbonate

Cover Material

ELECTRICAL INSTALLATION

The Series SF Sight Flow Transmitter is a two-wire looppowered device desined to transmit a 4-20mA signal

proportional to flow rate. The noise-immune current transmission from the sensor can be routed with low cost two

conductor twisted-pair cable. The current operates on 1235VDC and requires a source capable of supplying at least

20mA of current. The circuit has built-in polarity protection

and over-current limiting to protect both the sensor and

what the sensor is connected to.

To connect the sensor:

1. Connect the red wire from the sensor to the positive 1235VDC power supply output.

2. Connect the black wire from the sensor to the positive

side of the loop load (resistor, chart recorder, data aquisition board, meter, etc.). This connection may be labeled “420mAInput” on some devices.

3. If applicable, connect the negative side of the loop load

to the negative side of the power supply.

®

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361 U.S.A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/982-9057 e-mail: info@dwyer-inst.com

Lit-by-Fax: 888/891-4963

Page 2

4. Apply power to the system.

5.If everything ois operating correctly, the green LED on the

sensor will dimly illuminate and 4mA will be flowing in the

loop. If fluid is flowing through the sensor, the current will

be higher than 4mA.

Troubleshooting

If the LED does not illuminate:

• Check wiring terminations for good connections.

• Check wiring polarity.

• Verify correct supply voltage.

• Insure the load impedance is within allowable

limits.

• Apply the DC supply voltage directly across the

sensor wires. If the LED does illuminate, the load is

either: too great of impedance or an open circuit. If

the LED does not illuminate, the sensor’s lead

wires or circuit are defective.

SERVICE and MAINTENANCE

The Series SF Flow Transmitter is designed to provide

years of low maintenance service in industrial environments. As with all mechanical rotating devices, the bearing

surfaces will wear with use. The life of the parts will depend

on factors such as cleanliness of fluid, media, mounting

orientation, temperature, fluid velocity and frquency of

operation. The sensor was designed with simple fieldreplacement of the rotating parts.

To inspect or replace the rotating components:

1. Relieve pressure in the piping system.

3. Remove the access cover with pliers, taking care not to

damage the o-ring seal.

4. Pull out turbine assembly and shaft.

5. Inspect the shaft for things that may have wrapped

around it.

6. Inspect the turbine bearing surface for wear and elongation. replace as necessary.

7. Clean any rust off of the magnets that may have accumulated.

8. Reassemble the unit by placing the turbine into the body

cavity with the two magnet pockets facing inward. Place

the shaft into the turbine hole and guide it into the retaining

hole in the body cavity. Lubricate the o-ring with glycerine

or other lubricant and press it into the pocket of the body.

Replace the retaining ring securely before applying pressure to the system.

Circuit Recalibration:

1. Place a milliamp meter into the current loop.

2. Turn off the flow going through the sensor. Adjust the

OFFSET control for a reading of 4mA on the milliamp meter.

3. Adjust the flow rate through the sensor to full flow rate.

Adjust the SPAN control for a reading of 20mA on the milliamp meter. The zero and span adjustment are not interactive and should require additional adjustments.

2. Remove the retainer ring that secures the turbine access

cover.

©Copyright 1998 Dwyer Instruments, Inc.

Printed in U.S.A. 3/98

FR R1-443038-00

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361 U.S.A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/982-9057 e-mail: info@dwyer-inst.com

Lit-by-Fax: 888/891-4963

Loading...

Loading...