Dwyer SCV User Manual

P.O. Box 373, 102 Indiana Hwy. 212

R

E-mail: info@dwyer-inst.com - Website: www.dwyer-inst.com

Tel. 219/879-8000 - Fax 219/872-9057

Dwyer Instruments Inc.

Michigan City, IN 46361 USA

Check Valve - Spring Series

Characteristics

Working pressure at 20°C (73°F) water temperature:

- D16 - D63 (3/8”-2”): PN 16 bar (240 p.s.i.)

- D75 - D110 (2½”-4”): PN 10 (150 p.s.i.)

2

ENGLISH

Assembly Instructions

Solvent socket or threaded unions

Loosen the union nuts (4) and separate these and the end connectors (5) from the valve body. Pass

the pipe through the nuts and then place the bushes over the ends of the pipe. The solvent unions

should be glued onto the pipe using a PVC adhesive and pressure should not be applied to the

system until a drying period of at least 1 hour per 14.5 psi of working pressure has elapsed. In the

case of threaded unions, PTFE tape should be applied to the male threads. The pipes can now be

attached to the valve by hand tightening down the nuts.

Installation may be vertically and horizontally

Foot valve

Use the screen instead of the end connector of the fluid entrance to transform the check valve into a

foot valve.

Foot valves are a particular type of check valves which are installed on the base of an aspiration pipe

of a pump to prevent the impulsion pipe from emptying.

The valve must be installed between the pump and the tank in order to let the fluid access the pump

and stopping it when returning to the tank. The entry of the valve is protected by a screen filter to

prevent the entry of unwanted elements which could exist in the tank or deposit.

Pressure / temperature diagramm

psi

bar

18

270

PN 16

16

240

14

210

12

180

PN 10

10

150

Pressure

8

120

6

90

4

60

2

30

0

0

0 10 20 30 40 50 60 70 80 90

32 50 68 86 104 122 140 158 176 194

Temperature

20 years / water flow

PVC

CPVC

°C

°F

Relative flow chart

D20 - ½” 68 5

D25 - ¾” 133 9

D32 - 1” 208 15

D40 - 1¼” 383 27

D50 - 1½” 667 47

D63 - 2” 850 60

D75 - 2½” 1533 107

Kv= l/min at 1 bar

Cv= GPM at 1 psi

Cv Kv

FLOW

DIRECTION

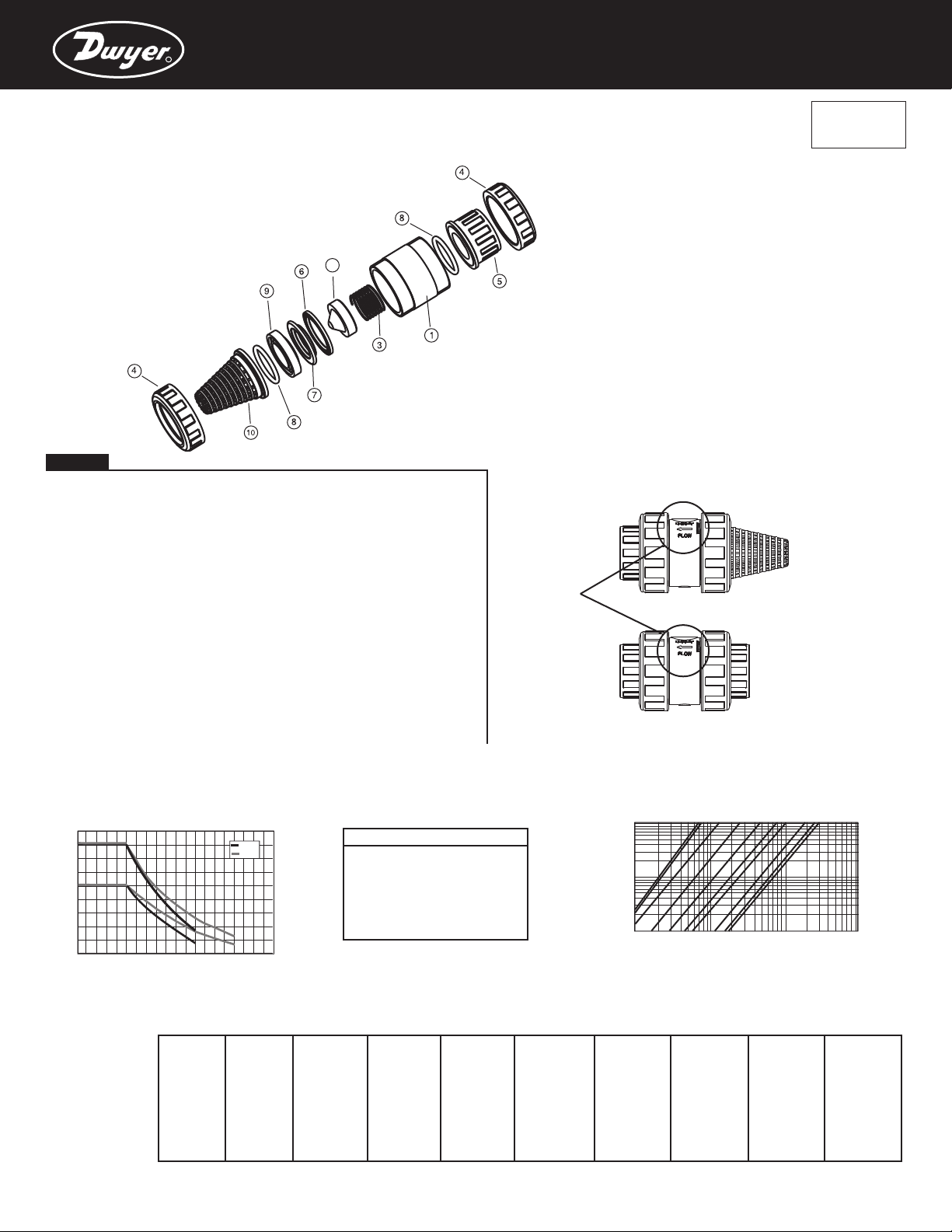

Components

Description

1. Body PVC / CPVC

2. Cone PVC / CPVC

3. Spring Inox. Steel AISI 302

4. Union nut PVC / CPVC

5. End connector PVC / CPVC

6. Cone o-ring PVC / CPVC

7. Body o-ring EPDM / Viton®

8. End connector o-ring EPDM / Viton®

9. Seal-carrier PVC / CPVC

10. Screen PP

Material

Pressure loss diagram

Check valve

”

/8

”

¾”

D

Flow

¼

1

1

0

4

D

1.000

”

-

D

264

2”

1½

- ”

3 -

6

50

D75 - 2

D

-

32

3

½”

-

-

6

5 -

1

20

D

D

D2

150

15

psi

mca

10

1

Pressure loss

0

0

100

26,4

Scv-1

”½

”

”

3D 0

- 4

-

0

9

D11

(l/min)

10.000

(GPM)

2.642

EDITION: 12 - 2006

Pressure loss diagram

Foot valve

D16 - 3/8” D20 - ½” D25 - ¾” D32 - 1” D40 - 1¼” D50 - 1

A B A B A B A B A B A B A B A B A B A B

0.42 0.34 0.44 0.34 0.54 0.17 0.35 0.13 3.15 0.13 25.85 0.38 39.80 0.70 50.00 0.40 83.50 0.45 77.2 0.46

0.85 0.52 0.92 0.58 1.06 0.22 1.13 0.18 5.20 0.12 20.70 0.27 34.50 0.48 44.20 0.29 74.80 0.39 67.5 0.36

1.35 0.58 1.60 0.19 1.65 0.15 1.62 0.15 7.35 0.16 17.50 0.19 27.501 0.28 36.50 0.23 64.90 0.31 60.1 0.30

2.08 0.28 2.05 0.18 2.18 0.18 2.02 0.14 9.38 0.21 12.30 0.11 21.15 0.17 30.90 0.20 50.38 0.21 49.6 0.22

2.44 0.34 2.48 0.22 3.21 0.29 2.59 0.14 12.17 0.31 8.86 0.09 12.65 0.09 25.50 0.15 43.08 0.18 41.1 0.18

2.80 0.60 3.10 0.30 3.91 0.38 3.07 0.15 15.05 0.43 3.22 0.09 6.25 0.08 20.35 0.12 35.22 0.14 31.5 0.14

- - 3.53 0.35 4.32 0.44 3.51 0.16 - - - - - - 12.30 0.11 28.75 0.11 24.6 0.13

- - - - - - 4.20 0.20 - - - - - - 6.27 0.11 18.02 0.08 15.8 0.01

- - - - - - - - - - - - - - - - 8.28 0.11 7.9 0.08

A= Flow (m³/h)

B= Pressure loss (bar)

• WE RESERVE THE RIGHT TO CHANGE ALL OR PART OF THE FEATURES OF THE ARTICLES OR CONTENTS OF THIS DOCUMENT, WITHOUT PRIOR NOTICE.

½” D63 - 2” D75 - 2½” D90 - 3” D110 - 4”

Loading...

Loading...