Page 1

Bulletin PC-1-SCS

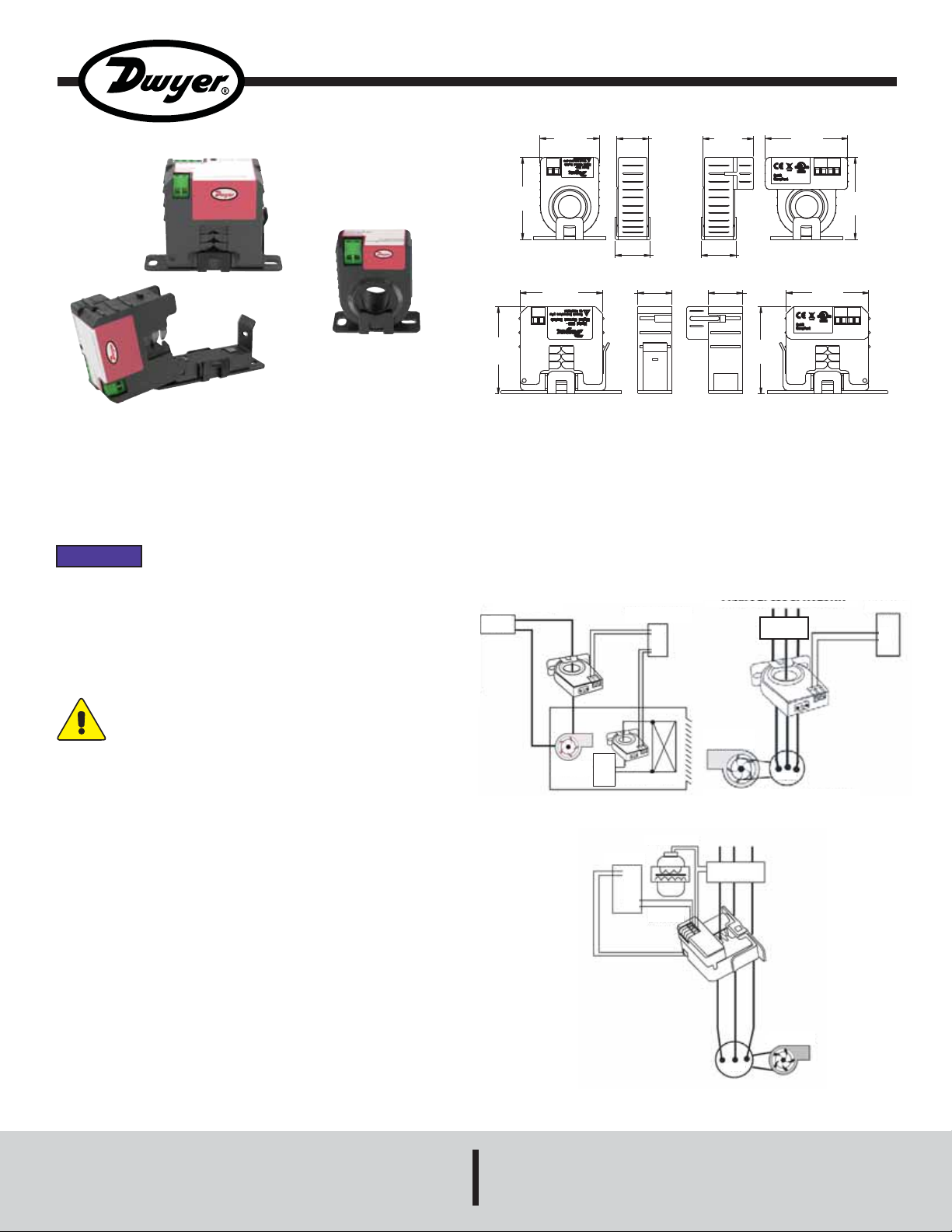

POWER

SOURCE

BUILDING AUTOMATION

CONTROLLER

FAN OR

PUMP

POWER

SOURCE

HEATING ELEMENT

DI

DI

CONTACTOR

CONTROLLER

DI

MOTOR

FAN OR PUMP

CONTROL POWER

CONTACTOR

CONTROLLER

DI

DO

RELAY COIL

24 V AC/DC

POWER

FAN OR PUMP

Series SCS Current Switches

Specifications - Installation and Operating Instructions

The Series SCS Low Cost Current Switches are ideal for monitoring

whether fans, pumps, or motors are operating. The current flowing through

the core of the device powers the circuit without an external power supply.

All models have a built in solid state output and are easy to install. Optional

LED’s and 10 Amp relay modules are available. The Series SCS is available

in both Split and Solid Core configurations.

NOTICE

The Series SCS Current Switches are intended to provide an input to

equipment under normal operating conditions. Where failure or malfunction

of the current switch could lead to personal injury or property damage to

the controlled equipment or other property, additional precautions must be

designed into the control system. Incorporate and maintain other devices

such as supervisory or alarm systems or safety or limit controls intended to

warn of, or protect against, failure or malfunction of the SCS.

1-1/16

[26.9]

[68.6]

MODELS

2-9/16

[65.0]

MODELS

SCS-111100-R

2-9/16

[65.0]

2-35/64

[64.5]

1-27/32

[47.0]

2-35/64

[64.5]

SCS-111100 AND SCS-120025

2-45/64

[68.6]

SCS-220015, SCS-220150, AND SCS-211125

MODELS

2-9/16

[65.0]

MODELS

1-1/16

[26.9]

63/64

[24.9]

1-5/64

[27.4]

1-9/16

[39.6]

1-5/64

[27.4]

2-45/64

SCS-220150-R AND SCS-211125-R

SPECIFICATIONS

Output: Isolated, normally open.

External Relay: SPST N.O., 10A at 260 VAC (5A at 30 VDC).

Power Requirements: None, self-powered.

Temperature Limits: 5 to 140°F (-15 to 60°C).

Isolation Voltage: 600 VAC RMS.

Frequency: 50/60 Hz.

Enclosure rating: UL, V-O flammability rated, ABS plastic housing (solid

core) or Type 66 Nylon (split core).

Agency Approval: UL, CE.

Caution: Risk of Shock

Disconnect power supply before making electrical connections.

Contact with components carrying hazardous voltage can cause

electrical shock and may result in severe personal injury or

death.

INSTALLATION

MOUNTING

1.

Detach the plastic mounting bracket from the current switch housing.

2.

Using the two included screws, attach the mounting bracket to the

rear of the electrical panel or enclosure.

3.

Re-attach the current switch housing to the plastic mounting bracket.

WIRING (See figures 1 through 4 for examples of wiring)

1.

Disconnect the power to the conductor cable from the power source.

2a.

For solid core devices, slide the power conductor cable through the

sensing hole of the current switch.

2b.

For split core devices, open the core using the release tab. Snap the

core closed around the power conductor cable. Make sure that the

core release tab is locked in its original position.

3.

Wire the Series SCS output terminals to the control box Digital Input

(DI) terminal (30 V max. terminal voltage). For snap-on relay models,

see figures 3 and 4 for wiring information.

4.

Reconnect the power conductor cable.

FIGURE 1

FIGURE 2

FIGURE 3

Phone: 219/879-8000 www.dwyer-inst.com

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

STATUS

STATUS

OPEN SETPOINT CLOSED

STATUS

STATUS

OPEN SETPOINT CLOSED

STATUS

STATUS

OPEN SETPOINT CLOSED

2. Slowly turn the setpoint screw counterclockwise until the Status Closed

STATUS

STATUS

OPEN SETPOINT CLOSED

CURRENT > 135 A

CONTACTOR

DO

DI

24 V AC/DC

RELAY COIL

FAN OR PUMP

CONTROL

POWER

120 VAC

LED turns on and the Status Open LED turns off.

FIGURE 7

FIGURE 8

3. Turn the setpoint screw an additional 1/4 turn counterclockwise to

create a deadband to prevent hunting.

The Series SCS is now calibrated to signal current flows below normal full

load amperes.

Output Status:

• Normal: Output Closed

• Alarm: Output Open

Over Current Status Condition (Locked Roter, Seized Impeller):

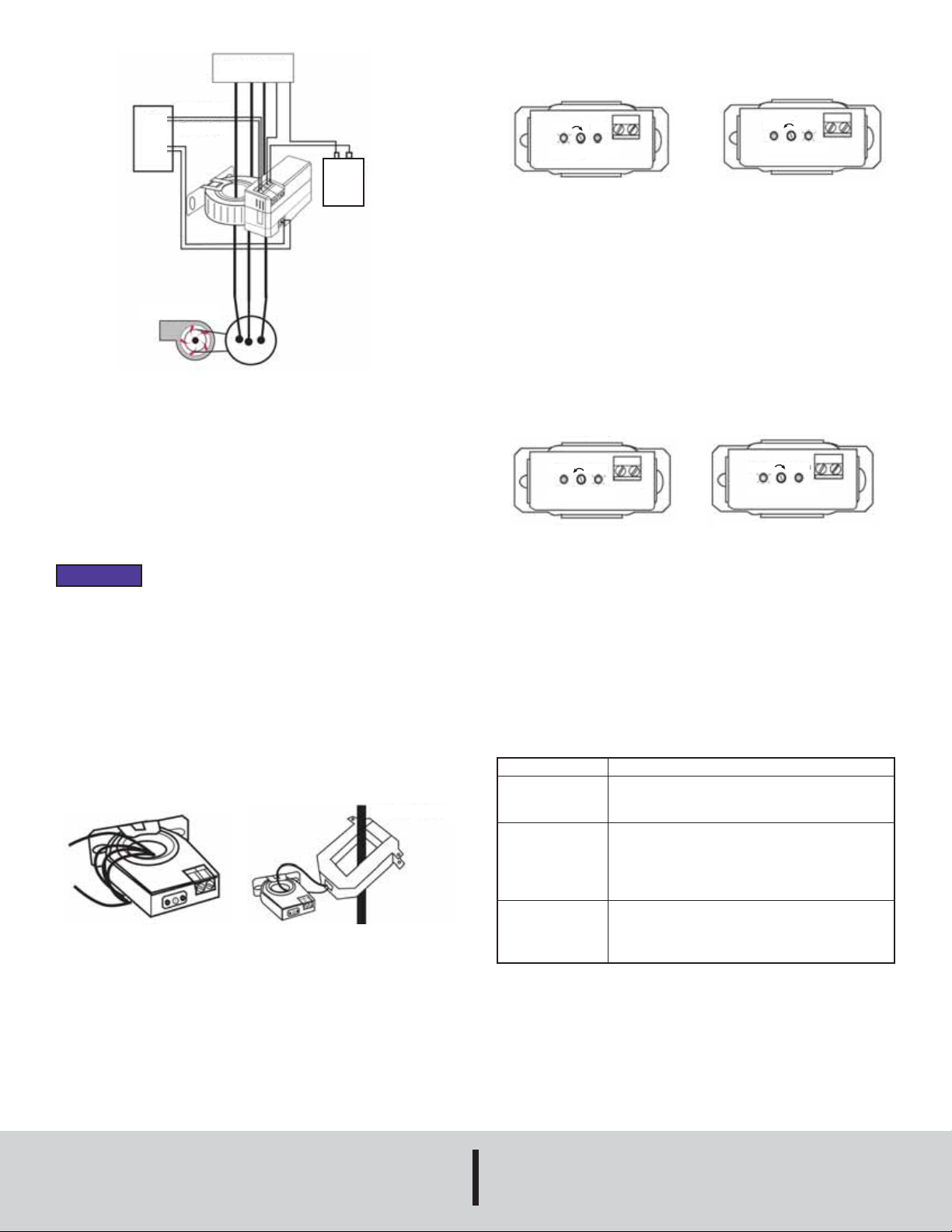

FIGURE 4

INCREASING/DECREASING MEASURED CURRENT

If the measured current is too low to be detected or is higher than the

maximum current rating of the SCS, use the following methods to increase

1. Turn the set point screw counterclockwise until the Status Open LED

turns off and the Status Closed LED turns on.

Note: This is the default factory setting.

or decrease current.

If measured current is too low to be detected:

Wrap the conductor (wire) through the sensing hole and around the SCS

body to produce multiple turns to increase the measured current. Use the

below equation to determine how many wraps are necessary:

Measured current = actual current times the number of turns. (See figure 5).

NOTICE

Failure to derate the current capacity could result in damage to the Series

SCS when using multiple turns to increase the measured current. Use the

FIGURE 9

2. Slowly turn the set point screw clockwise until the Status Closed LED

turns off and the Status Open LED turns on.

3. Turn the setpoint screw an additional 1/4 turn clockwise to create a

deadband to prevent hunting.

FIGURE 10

following formula to determine the new maximum current:

The Series SCS is now calibrated to signal current flows above normal full

New maximum current = SCS current rating / number of turns

load amperes.

For example, Model SCS-211125 with 4 turns = 135 A / 4 = 33.8 A, new

maximum current.

Output status:

• Normal: Output Open

If measured current is above ratings of the switch:

• Alarm: Output Closed

Use a 5 A Current Transformer (CT) to reduce the current passing through

the SCS as shown in figure 6. Run the current transformer secondary wire

through the sensing hole. Terminate the 2 secondary wires of the 5 A

current transformer to each other, and then install the 5 A current

transformer on the monitored conductor.

TROUBLESHOOTING

Symptom

Series SCS solid

state output does

not function

Action

Verify that the maximum amperage range has not

been exceeded. Voltages or currents above the

rated levels may damage the Series SCS.

The set point screw has a slip clutch to prevent

Set point screw

keeps turning

damage at either end. To return the LED to its

original setting, turn the set point screw 20 full

turns counterclockwise and start the calibration

procedure again.

FIGURE 5: SERIES SCS SHOWN

SET POINT CALIBRATION (For Adjustable Models Only)

Position the Series SCS such that the status output panel faces you.

Confirm the monitored load (for example, a motor or heater) is running, and

then use the following methods to calibrate the Series SCS.

Under Current Status Condition (Belt Loss, Coupling Shear, Fan,

and Pump Status):

1.

WITH FOUR TURNS

FIGURE 6: SERIES SCS

WITH CT TRANSFORMER

Turn the setpoint screw clockwise until the Status Closed Light-Emitting

Diode (LED) turns off and the Status Open LED turns on.

©Copyright 2008 Dwyer Instruments, Inc. Printed in U.S.A. 12/08 FR# R6-443696-00

Motor is turned on

and switch does

not close

MAINTENANCE

Upon final installation of the Series SCS Current Switches, no routine

maintenance is required. A periodic check of system calibration is

recommended. The Series SCS is not field serviceable and should be

returned if repair is needed (field repair should not be attempted and may

void warranty). Be sure to include a brief description of the problem plus

any relevant application notes. Contact customer service to receive a

return goods authorization number before shipping.

Insufficient current to the load leads (for example a

motor or heater) to reach the set point threshold.

To turn switch on, wrap the cable multiple times

through the sensing hole (see Figure 5).

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Loading...

Loading...