Dwyer SCD-8 User Manual

TYPE device and therefore should be installed in an enclosure free of airborne dust,

the device (e.g. key or specific tools are required for opening the enclosure) in case danger and damage on the

OFF

AL-H

OFF

AL-H

OFF

AL-H

AL-L

AL-H

OFF

ON

OFF

OFF

SCD8000/8100 Temperature Controller

Instruction Sheet

Thank you very much for choosing SCD8000/8100 series temperature controller. Please read this instruction sheet carefully

before using your SCD8000/8100 to ensure proper operation. Keep this instruction sheet handy for quick reference.

!

1

!

DANGER! CAUTION! ELECTRIC SHOCK!

SCD8000/8100 is an OPENhumidity, electric shock and vibration. The enclosure should prevent non-maintenance staff from operating

device may occur.

1. Prevent dust or metallic debris from falling into the device and cause malfunctions. DO NOT

board of SCD8000/8100 without being permitted. DO NOT use empty terminals.

2. Keep away from high-voltage and high-frequency environment during the installation in case of interference. Prevent using

the device in premises which contain:

(a) dust or corrosive gas; (b) high humidity and high radiation; (c) shock and vibration.

3. The power has to be switched off when wiring or changing the temperature sensor.

4. When installing the circuit board of the accessory, please make sure the power of the main unit is switched off and insert

the accessory into the correct slot on the main unit.

5. Make sure to use compensation wire which matches the thermocouple or platinum resistance when extending or

connecting the thermocouple or platinum resistance.

6. Keep the wire as short as possible when wiring a sensor to the controller. Separate the power cable and load wire in order

to prevent interference and induced noise.

7. Make sure the power cables and signal device are installed correctly before switching on the power; otherwise serious

damage may occur.

8. DO NOT

9. Please wait for 1 minute after the power is switched off to allow the capacitor to discharge and DO NOT

wiring within this period.

10. DO NOT

11. Please place SCD8000/8100 with other heating objects (e.g. power supply) within proper distance while installing

SCD8000/8100.

2

Power input DC 24V, isolated switching power supply

Voltage range 90% ~ 110% rated voltage

Power consumption Max. 10W + 3W × number of SCD2000 controllers connected in parallel (Max. 7)

Input sensor

Sampling cycle Thermocouple or platinum resistance: 1.0 second/all input

Control method PID, PID programmable, manual, ON/OFF

Output accessories

(optional)

Output functions

Alarm modes 12 alarm modes available

Communication RS-485 digital communication; supports baud rate 2,400bps ~ 115,200bps

Communication

protocol

Extension port

Vibration resistance 10 ~ 55Hz 10m/s

Shock resistance Max. 300m/s2 3 axes 6 directions, 3 times each

Ambient temperature 0°C ~ +50°C

Storage temperature -20°C ~ +65°C

Operation altitude < 2,000m

Ambient humidity 35% to 85% RH (non-condensing)

Pollution degree 2

3

touch the terminal or repair the device when the power is on; otherwise an electric shock may occur.

touch the internal terminal when SCD8000/8100 is either switched on or off in case you may damage the circuit.

Functions & Electrical Specifications

Thermocouple: K, J, T, E, N, R, S, B, L, U, TXK

Platinum resistance: Pt100, JPt100, Cu50

Relay output: SPST, Max. AC 250V load, 3A resistive load

Voltage pulse output: DC 24V, Max. 40mA current output

Current output: DC 4 ~ 20mA output (resistive load < 500Ω); for OUT1 and OUT2 only

Analog voltage output: 0 ~ 10V (resistive load > 1,000Ω); for OUT1 and OUT2 only

Control output, alarm output or proportional output (proportional output is only applicable in the

model with linear voltage and current output for OUT1, OUT2)

Supports Modbus ASCII/RTU

The extension port transmits 24V power supply and communication signals to extension module

SCD2000.

2

3 axes 10mins

Product Profile & Outline

Precaution

modify or uninstall the circuit

touch the internal

SCD8000/8100

1 I/O terminals

2 Status LED

3 Display and setup unit

4 DIN rail clip

5 Power input port

6 RS-485 communication port

7 Extension module fixing clip

8 Extension port

4

5

The standard SCD8000/8100 main unit is attached with 4 channels of inputs. You can purchase additional SCD-4T or SCD-4R

to expand the number of input channels. SCD8000/8100 supports maximum 8 channels of inputs which belong to group INA

and group INB. Each group possesses 4 input channels.

SCD8000/8100 series supports the following input sensors:

Input Sensor Type Register Value Range

Temperature measurement resistance (Cu50) 13 -50 ~ 150°C

Platinum resistance (Pt100) 12 -200 ~ 600°C

Platinum resistance (JPt100) 11 -20 ~ 400°C

Thermocouple TXK type 10 -200 ~ 800°C

Thermocouple U type 9 -200 ~ 500°C

Thermocouple L type 8 -200 ~ 850°C

Thermocouple B type 7 100 ~ 1,800°C

Thermocouple S type 6 0 ~ 1,700°C

Thermocouple R type 5 0 ~ 1,700°C

Thermocouple N type 4 -200 ~ 1,300°C

Thermocouple E type 3 0 ~ 600°C

Thermocouple T type 2 -200 ~ 400°C

Thermocouple J type 1 -100 ~ 1,200°C

Thermocouple K type 0 -200 ~ 1,300°C

Note: The default setting in SCD8000 is “thermocouple K type”. The default setting in SCD8100 is “Pt100".

Communication address: Input sensor types at H10A0 ~ H10A7; input upper limits at H1010 ~ H1017; input lower limits at

H1018 ~ H101F.

6

SCD8000/8100 supports maximum 16 channels of outputs, belonging to output groups OUT1, OUT2, SUB1 and SUB2, each

group with 4 channels. See the explanations below for how input channels correspond to output groups.

Without group INB (4 channels of input): Every channel corresponds to 2 groups of output and 2 groups of alarms. OUT1 and

SUB1 are for control output, and OUT1 can be used for proportional output. OUT2 and SUB2 are fixed for alarm output.

With group INB (8 channels of input): Every channel is paired with 2 groups of outputs. OUT1 and OUT2 are used for control

output or proportional output of CH1 ~ CH8. SUB1 and SUB2 are used for control output or alarm output.

See Table 1 for the relations between input and output.

Output Group

OUT1

OUT2 Alarm 1 output No corresponding output

SUB1 Control output Control output or alarm output No corresponding output

SUB2 Alarm 2 output No corresponding output Control output or alarm output

4 channels of input 8 channels of input

INA (CH1 ~ CH4) INA (CH1 ~ CH4) INB (CH5 ~ CH8)

Main control output or proportional

output

Note: SUB1 and SUB2 do not support SCD-46 and SCD-45. Please install the optional output modules you purchase into

the correct slot.

Communication Address of Output & How to Set up Parameters:

See Table 2 for the communication addresses of output and Table 3 for the definition of the value in the address.

CH1 CH2 CH3 CH4 CH5 CH6 CH7 CH8

OUT1, OUT2 H10A8 H10A9 H10AA H10AB H10AC H10AD H10AE H10AF

SUB1, SUB2 H10B0

INA INB

H10B1 H10B2

Panel Layout

Input

For SCD8100 / SCD-4R

For SCD8000 / SCD-4T

Output

Main control output or proportional

output

Table 1

H10B3 H10B4

Table 2

No corresponding output

Main control output or proportional

H10B5

output

H10B6

H10B7

Val ue = 0 Val ue = 1 Val ue = 2 Val ue = 3

OUT1, OUT2** Heating control Cooling control Proportional output Disable output

SUB1, SUB2** Heating control Cooling control Alarm output* Disable output

Table 3

*When there are only 4 channels of inputs, SUB1 cannot be used for alarm output but heating/cooling control only.

**When there are only 4 channels of inputs, OUT2 and SUB2 cannot be set up by the user but set up automatically as "alarm

output” by the controller.

Control Output:

SCD8000/8100 offers PID control, ON/OFF control, manual control and programmable PID control. Control output methods are

set at address H10B8 ~ H10BF (default = 0: PID), PID parameters at H1028 ~ H105F, ON/OFF parameters at H1058 ~ H106F,

and manual control parameters at H1070 ~ H107F.

Alarm Output:

SCD8000/8100 offers 12 alarm modes. The alarm modes are set up at address H10C0 ~ H10C7, upper limits at H1080 ~

H1087 and lower limits at H1088 ~ H108F.

SV Alarm Mode Alarm Output Operation

0 No alarm Off

Alarm output is enabled when the temperature reaches upper and lower

1

limits: The alarm will be enabled when PV exceeds SV + AL-H or falls below

SV – AL-L.

Alarm output will be enabled when the temperature reaches the upper limit:

2

The alarm will be enabled when the PV exceeds SV + AL-H.

Alarm output will be enabled when the temperature reaches the lower limit:

3

The alarm will be enabled when the PV falls below SV – AL-L.

Alarm output will be enabled when the PV is between SV + AL-H and SV –

4

AL-L.

Alarm output will be enabled when the temperature reaches the absolute

5

value of the upper and lower limits: The alarm will be enabled when the PV

exceeds AL-H or falls below AL-L.

Alarm output will be enabled when the temperature reaches the absolute

6

value of the upper limit: The alarm will be enabled when the PV exceeds

AL-H.

Alarm output will be enabled when the temperature reaches the absolute

7

value of the lower limit: The alarm will be enabled when the PV falls below

AL-L.

Upper/lower limit standby alarm: The alarm will be enabled when the PV

8

reaches SV and further exceeds SV + AL-H or falls below SV – AL-L.

Upper limit standby alarm: The alarm will be enabled when the PV reaches

9

SV and further exceeds SV + AL-H.

Lower limit standby alarm: The alarm will be enabled when the PV reaches

10

SV and further falls below SV – AL-L.

Upper limit hysteresis alarm: The alarm will be enabled when the PV exceeds

11

SV + AL-H. The alarm will be disabled when the PV falls below SV + AL-L.

Lower limit hysteresis alarm: The alarm will be enabled when the PV falls

12

below SV – AL-H. The alarm will be disabled when the PV exceeds SV –

AL-L.

7

LED Display

PWR: On B SCD8000/8100 is powered.

RUN: On B Any of the channel is executing.

COM: Flashing B Communication in progress

ERR: Indicating errors (red)

ERR LED is on indicates one of the following errors occur, and the output has to be disabled.

1. Memory EEPROM error.

2. Any of the input points is not connected.

3. Any of the input points exceeds the setup range.

4. Any of the input temperatures has not been stabilized.

8

Synchronous Communication Protocol & Auto ID Setup

This function allows the auto setup of communication protocol in extension module SCD2000 following the communication

protocol set in the SCD8000 main unit. The station IDs of SCD2000 decrease. See below for the steps.

1. Set the auto communication ID of SCD8000 as “1” (communication address: H10F8).

2. Switch off SCD8000. Connect SCD8000 with extension module SCD2000 and switch on SCD8000 again.

3. Default communication protocol: 9,600bps, 7 bits, Even, 1 stop bit, communication address = 01.

4. This function will consume 3 ~ 5 seconds more when you switch on SCD8000.

9

RS-485 Communication

1. SCD8000/8100 supports baud rates 2,400/4,800/9,600/19,200/38,400/57,600/115,200 bps and does not support

communication format 7, N, 1/8, E, 2/8, O, 2. Communication protocol = Modbus ASCII or RTU.

2. Function codes: H03 = read maximum 8 words in the register; H06 = write 1 word into the register.

3. Address and contents: Every parameter has 2 communication addresses. One is numbered by the function of the parameter,

and the other is by the order of channel (as shown in the table below).

ON

OFF

ON

ON

OFF

ON

ON

OFF

ON

ON

OFF

ON

OFF

ON

ON

OFF

ON

AL-L SV AL-H

SV

AL-L

SV

SV

SV AL-H

AL-L

AL-L

AL-H

AL-H

AL-L SV

AL-L

AL-L

AL-L SV

AL-H

Disabled when higher

H10F3

H10F4

H10F5

H10F6

H10F7

INA INB

Content Explanation CH1 CH2 CH3 CH4 CH5 CH6 CH7 CH8

Present

temperature

value/input error

Unit; 0.1

See Table 5

H1000

(H1100)

H1001

(H1200)

H1002

(H1300)

H1003

(H1400)

H1004

(H1500)

H1005

(H1600)

H1006

(H1700)

code

Set temperature

value

Unit: 0.1

Max. temperature

value

Min. temperature

value

Error temperature

value

Proportional band

value (Pb)

than default value

Disabled when lower

than default value

-999 ~ +999

Unit: 0.1°C

0 ~ 9,999

Unit: 0.1

Ti value 0 ~ 9,999

Td value 0 ~ 9,999

Integration default

Proportional control

offset error value,

when Ti = 0

Proportional band

coefficient of output

1 and output 2

0.0 ~ 100.0%

Unit: 0.1%

0.0 ~ 100.0%

Unit: 0.1%

0.01 ~ 99.99

Unit: 0.01

Dead band of

control output 1 &

-99.9 ~ 999.9

output 2.

Hysteresis for

output 1

Hysteresis for

output 2

Read/write output

1 value

Read/write output

2 value

Upper limit for

alarm output

0 ~ 9,999

Unit: 0.1%

0 ~ 9,999

Unit: 0.1%

Unit: 0.1 %

Unit: 0.1 %

Alarm enabled

when temperature

exceeds upper limit

H1008

(H1101)

H1010

(H1102)

H1018

(H1103)

H1020

(H1104)

H1028

(H1105)

H1030

(H1106)

H1038

(H1107)

H1040

(H1108)

H1048

(H1109)

H1050

(H110A)

H1058

(H110B)

H1060

(H110C)

H1068

(H110D)

H1070

(H110E)

H1078

(H110F)

H1080

(H1110)

H1009

(H1201)

H1011

(H1202)

H1019

(H1203)

H1021

(H1204)

H1029

(H1205)

H1031

(H1206)

H1039

(H1207)

H1041

(H1208)

H1049

(H1209)

H1051

(H120A)

H1059

(H120B)

H1061

(H120C)

H1069

(H120D)

H1071

(H120E)

H1079

(H120F)

H1081

(1210)

H100A

(H1301)

H1012

(H1302)

H101A

(H1303)

H1022

(H1304)

H102A

(H1305)

H1032

(H1306)

H103A

(H1307)

H1042

(H1308)

H104A

(H1309)

H1052

(H130A)

H105A

(H130B)

H1062

(H130C)

H106A

(H130D)

H1072

(H130E)

H107A

(H130F)

H1082

(H1310)

H100B

(H1401)

H1013

(H1402)

H101B

(H1403)

H1023

(H1404)

H102B

(H1405)

H1033

(H1406)

H103B

(H1407)

H1043

(H1408)

H104B

(H1409)

H1053

(H140A)

H105B

(H140B)

H1063

(H140C)

H106B

(H140D)

H1073

(H140E)

H107B

(H140F)

H1083

(H1410)

H100C

(H1501)

H1014

(H1502)

H101C

(H1503)

H1024

(H1504)

H102C

(H1505)

H1034

(H1506)

H103C

(H1507)

H1044

(H1508)

H104C

(H1509)

H1054

(H150A)

H105C

(H150B)

H1064

(H150C)

H106C

(H150D)

H1074

(H150E)

H107C

(H150F)

H1084

(H1510)

H100D

(H1601)

H1015

(H1602)

H101D

(H1603)

H1025

(H1604)

H102D

(H1605)

H1035

(H1606)

H103D

(H1607)

H1045

(H1608)

H104D

(H1609)

H1055

(H160A)

H105D

(H160B)

H1065

(H160C)

H106D

(H160D)

H1075

(H160E)

H107D

(H160F)

H1085

(H1610)

H100E

(H1701)

H1016

(H1702)

H101E

(H1703)

H1026

(H1704)

H102E

(H1705)

H1036

(H1706)

H103E

(H1707)

H1046

(H1708)

H104E

(H1709)

H1056

(H170A)

H105E

(H170B)

H1066

(H170C)

H106E

(H170D)

H1076

(H170E)

H107E

(H170F)

H1086

(H1710)

Alarm enabled

Lower limit for

alarm output

when temperature

falls below lower

H1088

(H 1111)

H1089

(H1211)

H108A

(H1311)

H108B

(H1411)

H108C

(H1511)

H108D

(H1611)

H108E

(H1711)

limit

Tuning for upper

limit of analog

output

Tuning for lower

limit of analog

output

Input sensor type See “Input” section

Current (4 ~ 20mA)

or voltage output

tuning

Current (4 ~ 20mA)

or voltage output

tuning

H1090

(H1112)

H1098

(H1113)

H10A0

(H1114)

H1091

(H1212)

H1099

(H1213)

H10A1

(H1214)

H1092

(H1312)

H109A

(H1313)

H10A2

(H1314)

H1093

(H1412)

H109B

(H1413)

H10A3

(H1414)

H1094

(H1512)

H109C

(H1513)

H10A4

(H1514)

H1095

(H1612)

H109D

(H1613)

H10A5

(H1614)

H1096

(H1712)

H109E

(H1713)

H10A6

(H1714)

0: heating

Output function

for output 1

1: cooling

2: proportional

H10A8

(H1115)

H10A9

(H1215)

H10AA

(H1315)

H10AB

(H1415)

H10AC

(H1515)

H10AD

(H1615)

H10AE

(H1715)

output

Output function

for output 2

0: heating (default)

1: cooling

2: alarm

H10B0

(H1116)

H10B1

(H1216)

H10B2

(H1316)

H10B3

(H1416)

H10B4

(H1516)

H10B5

(H1616)

H10B6

(H1716)

0: PID

Control method

1: ON-OFF

2: manual

3: PID

H10B8

(H1117)

H10B9

(H1217)

H10BA

(H1317)

H10BB

(H1417)

H10BC

(H1517)

H10BD

(H1617)

H10BE

(H1717)

programmable

Alarm 1 output

mode

Alarm 2 output

mode

Heating/cooling

cycle for output 1

Heating/cooling

cycle for output 2

See “Alarm Output”

section

See “Alarm Output”

section

1 ~ 99 seconds

0 = 0.5 second

1 ~ 99 seconds

0 = 0.5 second

H10C0

(H1118)

H10C4

(H1518)

H10C8

(H1119)

H10D0

(H 111A)

H10C1

(H1218)

H10C5

(H1618)

H10C9

(H1219)

H10D1

(H121A)

H10C2

(H1318)

H10C6

(H1718)

H10CA

(H1319)

H10D2

(H131A)

H10C3

(H1418)

H10C7

(H1818)

H10CB

(H1419)

H10D3

(H141A)

H10C4

(H1518)

H10C5

(H1618)

H10C6

(H1718)

H10CC

(H1519)

H10D4

(H151A)

H10CD

(H1619)

H10D5

(H161A)

H10CE

(H1719)

H10D6

(H171A)

0: stop

Run/Stop the

control

1: executing

2: program stops

H10D8

(H 111B)

H10D9

(H121B)

H10DA

(H131B)

H10DB

(H141B)

H10DC

(H151B)

H10DD

(H161B)

H10DE

(H171B)

3: program pauses

Status of PID

auto-tuning

Positive/negative

proportional

0: stop

1: executing

0: positive

1: negative (slope)

H10E0

(H 111C)

H10E8

(H 111D)

H10E1

(H121C)

H10E9

(H121D)

H10E2

(H131C)

H10EA

(H131D)

H10E3

(H141C)

H10EB

(H141D)

H10E4

(H151C)

H10EC

(H151D)

H10E5

(H161C)

H10ED

(H161D)

H10E6

(H171C)

H10EE

(H171D)

H1007

(H1800)

H100F

(H1801)

H1017

(H1802)

H101F

(H1803)

H1027

(H1804)

H102F

(H1805)

H1037

(H1806)

H103F

(H1807)

H1010

(H1808)

H104F

(H1809)

H1057

(H180A)

H105F

(H180B)

H1067

(H180C)

H106F

(H180D)

H1077

(H180E)

H107F

(H180F)

H1087

(H1810)

H108F

(H1811)

H1097

(H1812)

H109F

(H1813)

H10A7

(H1814)

H10AF

(H1815)

H10B7

(H1816)

H10BF

(H1817)

H10C7

(H1818)

H10CF

(H1819)

H10D7

(H181A)

H10DF

(H181B)

H10E7

(H181C)

H10EF

(H181D)

INA INB

Content Explanation CH1 CH2 CH3 CH4 CH5 CH6 CH7 CH8

output

Other statuses Other statuses

Communication

specifications

See Table 4

H10F0

Temperature

unit

H10F8

Auto ID

setup

H10F1

Open special

function

(H1234)

H10F9

Reserved

H10F2

Return to

default

(H1357)

H10FA

Baud rate

Reserved

H10FB

ASCII = 0

RTU = 1

Reserved

H10FC

8 bits=0

7 bits=1

Reserved

H10FD

2 stop=0

1 stop=1

Reserved

H10FE

Parity

Reserved

H10FF

Address

1 ~ 247

Communication Parameter Setting:

Content 0 1 2 3 4 5 6

Baud rate 2,400bps 4,800bps 9,600bps 19,200bps 38,400bps 57,600bps 115,200bps

Parity bit None (N) Even (E) Odd (O)

Tabl e 4

Error Codes:

The error codes can be read from address H1000 ~ H1007. When the input operation is in normal status, H1000 ~ H1007 are

for input values. When input error occurs (except for stable status and input exceeding the range), SCD8000/8100 will read

error codes in H8001 ~ H8002.

H1000 Error description

H8001 EEPROM cannot be written in.

H8002 Input sensor is not connected.

H8003 Group INB is not connected.

Table 5

Analog output current tuning scale: 1μA/scale

Analog output voltage tuning scale: 1mV/scale

Returning to Default Value: Write H1234 into address H10F1 and H1357 into address H10F2. Restart SCD8000/8100.

Programmable Communication Parameter Setting:

INA INB

Content Explanation CH1 CH2 CH3 CH4 CH5 CH6 CH7 CH8

Read remaining time of the step Unit: sec H111E H121E H131E H141E H151E H161E H171E H181E

Read remaining time of the step Unit: min H111F H121F H131F H141F H151F H161F H171F H181F

Read the NO. of the current

pattern

0 ~ 7 H1120

H1220 H1320 H1420 H1520 H1620 H1720 H1820

Read the NO. of the current step 0 ~ 7 H1121 H1221 H1321 H1421 H1521 H1621 H1721 H1821

NO. of start pattern 0 ~ 7 H1122 H1222 H1322 H1422 H1522 H1622 H1722 H1822

NO. of start step 0 ~ 7 H1123 H1223 H1323 H1423 H1523 H1623 H1723 H1823

Programmable Parameter Setting:

Content Explanation

Max. number of

steps in the pattern

Number of cycles of

pattern 0 ~ 7

execution

NO. of current link

pattern

0 ~ 7 = N: The pattern

executes from step 0 to

N.

0 ~ 199: The pattern

has been executed for 1

~ 200 times

0 ~ 8: 8 refers to end of

program; 0 ~ 7 refer to

the NO. of next pattern

Pattern 0 Pattern 1 Pattern 2 Pattern 3 Pattern 4 Pattern 5 Pattern 6 Pattern

7

H2068

H2070

H2078

H2069 H206A H206B H206C H206D H206E H206F

H2071 H2072 H2073 H2074 H2075 H2076 H2077

H2079 H207A H207B H207C H207D H207E H207F

Address Default Content Explanation

2000H ~ 203FH 0

2080H ~ 20BFH 0

Target temperatures for pattern 0 ~ 7

Pattern 0: 2000H ~ 2007H

Execution time for pattern 0 ~ 7

Pattern 0: 2080H ~ 2087H

Unit: 0.1°C

Time: 0 ~ 900 (Unit: 1 min)

4. Communication format: H03 = read bit data; H06 = write bit data

ASCII Mode:

Read Command Read Response Message Write Command Write Response Message

Start word ’:’

Start word ’:’ Start word ’:’ Start word ’:’

Machine address 1 ‘0’ Machine address 1 ‘0’ Machine address 1 ‘0’ Machine address 1 ‘0’

Machine address 0 ‘1’ Machine address 0 ‘1’ Machine address 0 ‘1’ Machine address 0 ‘1’

Command 1 ‘0’

Command 0 ‘3’

Read start address of

data/bit

Read length of data/bit

(word/bit)

‘1’

‘0’

‘0’

‘0’

‘0’

‘0’

Command 1 ‘0’

Command 0 ‘3’

Length of response

data (byte)

Data content in H1000

‘0’

‘4’

‘0’

‘1’

‘F’

Write data content

‘4’

Command 1 ‘0’

Command 0 ‘6’

Data address

‘1’

‘0’

‘0’

‘1’

‘0’

Write data content

‘3’

Command 1 ‘0’

Command 0 ‘6’

Data address

‘1’

‘0’

‘0’

‘1’

‘0’

‘3’

Read Command Read Response Message Write Command Write Response Message

‘0’

‘2’

LRC1 check ‘E’

Data content in H1001

LRC0 check ‘A’

End word 1 CR

End word 0 LF

LRC1 check ‘0’

LRC0 check ‘3’

End word 1 CR

End word 0 LF

‘0’

‘0’

‘0’

‘0’

‘E’

‘8’

LRC1 check ‘F’

LRC0 check ‘D’

End word 1 CR

End word 0 LF

LRC1 check ‘F’

LRC0 check ‘D’

End word 1 CR

End word 0 LF

LRC Check:

Sum up the contents from “machine address” to “data content”, e.g. H01 + H03 + H10 + H00 + H00 + H02 = H16. Obtain

2’scomplement H EA.

RTU Mode:

Read Command Read Response Message Write Command Write Response Message

Machine address H01 Machine address H01 Machine address H01 Machine address H01

Command H03

Read start address of

data

Read length of data

(bit/word)

H10

H00

H00

H02

CRC low byte HC0

CRC high byte HCB

CRC low byte HBB

CRC high byte H15

Command H03 Command H06 Command H06

Length of response

data (byte)

Data content 1

Data content 2

H04 Write data address

H01 H03 H03

HF4

Write data content

H03 CRC low byte HDD

H20 CRC high byte HE2

H10 H10

Write data address

H01

Write data content

H20

CRC low byte HDD

CRC high byte HE2

CRC (Cyclical Redundancy Check) is obtained by the following steps:

unsigned int reg_crc = 0xffff;

i = 0;

while (length--)

{ reg_crc ^= RTUData[i];

i ++;

for (j = 0; j < 8; j++)

{ if (reg_crc & 0x01) reg_crc = (reg_crc >> 1) ^ 0xA001;

else reg_crc = reg_crc >> 1;

}

}

return(reg_crc);

Software for Setting up Communication on PC: Download the free software on Dwyer’s website.

10

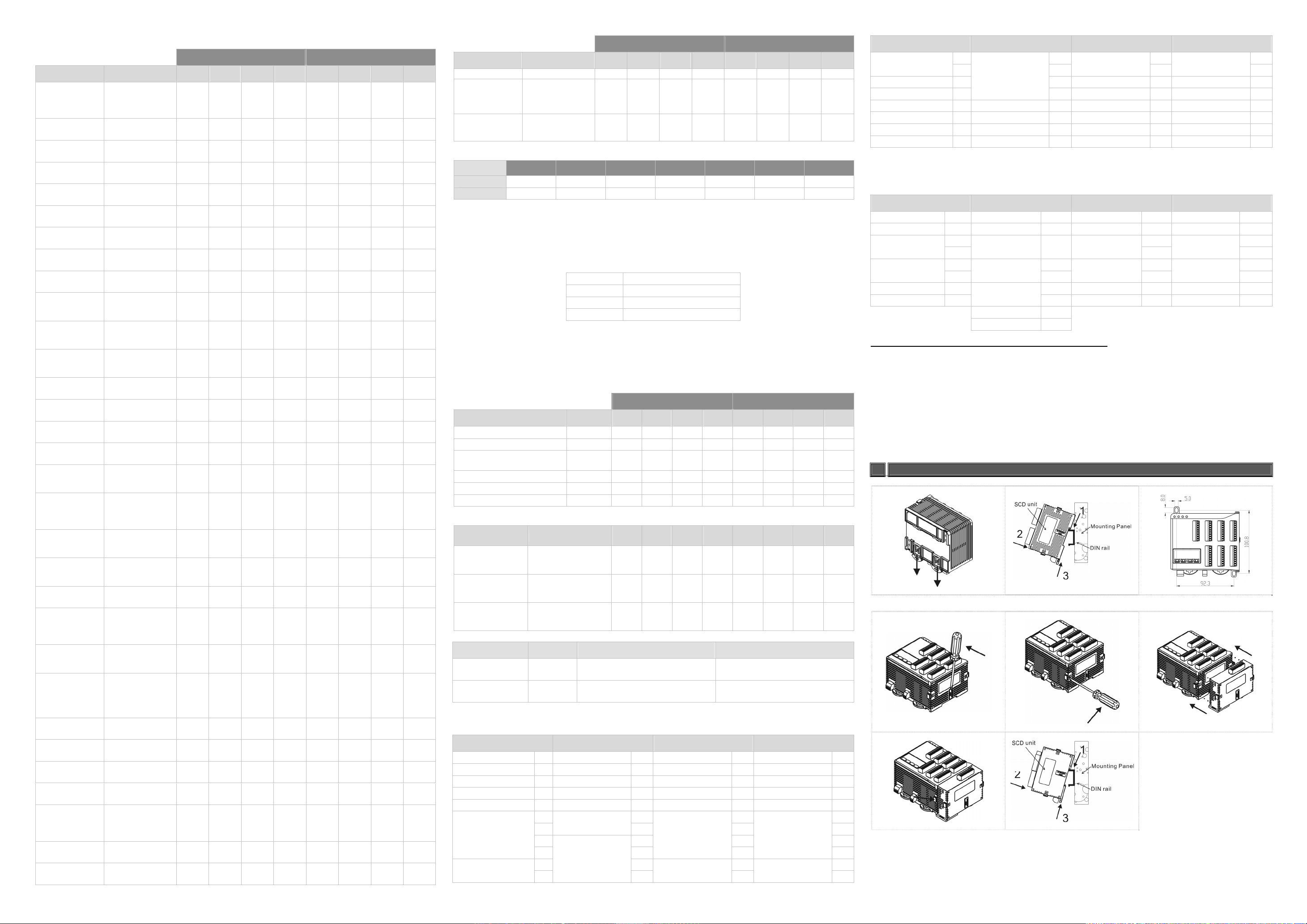

How to Mount & DIN Rail Size

Connect maximum 7 SCD2000 controllers to SCD8000 by using DIN rail.

‘E’

‘8’

H01

H20

Loading...

Loading...