Dwyer SBLTX User Manual

Series SBLTX Submersible Level Transducer

Specifications - Installation and Operating Instructions

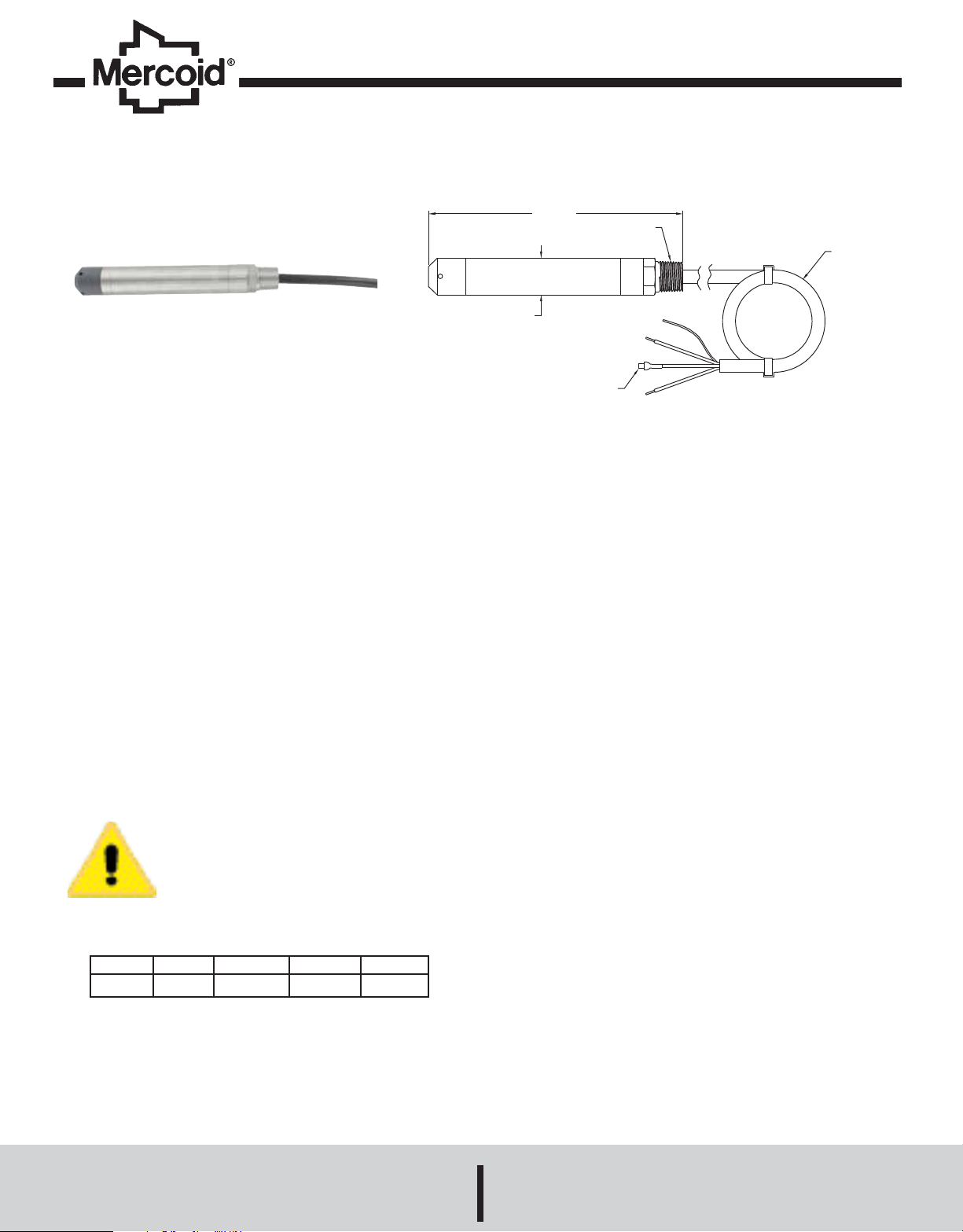

6-15/16

Ø1

[Ø25.40]

[176.21]

BREATHER TUBE

1/2 NPT

Bulletin L-37

SUBMERSIBLE

CABLE

The SBLTX Submersible Level Transducer is manufactured for years of trouble free service. The transducer consists of a piezoresistive sensing element, encased in a 316

SS housing. Bullet nose design protects diaphragm from

damage. Comes equipped with a 270-pound tensile strength,

shielded, vented cable. Ventilation tube in the cable automatically compensates for changes in atmospheric pressure

above the tank.

Intrinsic Safety Approval Classification

The SBLTX is UL listed for use in Hazardous (Classified) Locations. The protection method is by Intrinsic Safety, “ia”. It was investigated by UL under UL Standard 913 Sixth Edition and CSA

Standard No. 157-92.

For use in Hazardous (Classified) Locations:

Class I Div. 1 Groups A,B,C,D

Class II Div. 1 Groups E,F,G

Class III Div. 1

Temperature Code: T4 @ 80°C ambient

Install in accordance with control drawing 01-700797-00.

WARNING: To prevent ignition of flammable

or combustible atmospheres, disconnect

power before servicing.

Use with approved safety barriers using entity

evaluation.

Entity Parameters

Vmax

28VDC

Imax

93mA

Ci

0.051_F

Li

240_H

Pi

0.651W

SPECIFICATIONS

Service: Compatible liquids.

Wetted Materials: 316 SS, 316L SS, Buna-N; Cable:

Polyurethane or ETFE; Bullet Nose: PVC.

Accuracy: ±0.25% of full scale.

Temperature Limit: 0 to 176°F (-18 to 80°C).

Compensated Temperature Range: 0 to 176°F (-18 to 80°C).

Thermal Effect: Less than ±0.02% full scale/ °F.

Pressure Limit: 2X full scale.

Power Requirement: 10 to 28 VDC.

Output Signal: 4 to 20 mA DC, 2-wire.

Response Time: 50 ms.

Max. Loop Resistance: 900 ohms.

Electrical Connections: Wire pigtail.

Mounting Orientation: Suspended in tank below level being

measured.

Weight: 2.2 lb (1.0 kg).

Agency Approvals: CE, UL Intrinsically Safe to UL Standard

913. (See Intrinsic Safety Approval Classification.)

The following standards were used for CE approval:

IEC 61000-4-2: 2001

IEC 61000-4-3: 2006

IEC 61000-4-4: 2004

IEC 61000-4-5: 2005

IEC 61000-4-6: 2006

IEC 61000-4-8: 2001

CENELEC EN 55011: 2003

CENELEC EN 61326: 2003

89/336/EEC EMC Directive

MERCOID DIVISION

DWYER INSTRUMENTS, INC.

P.O. BOX 258 • MICHIGAN CITY, IN 46361 U.S.A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

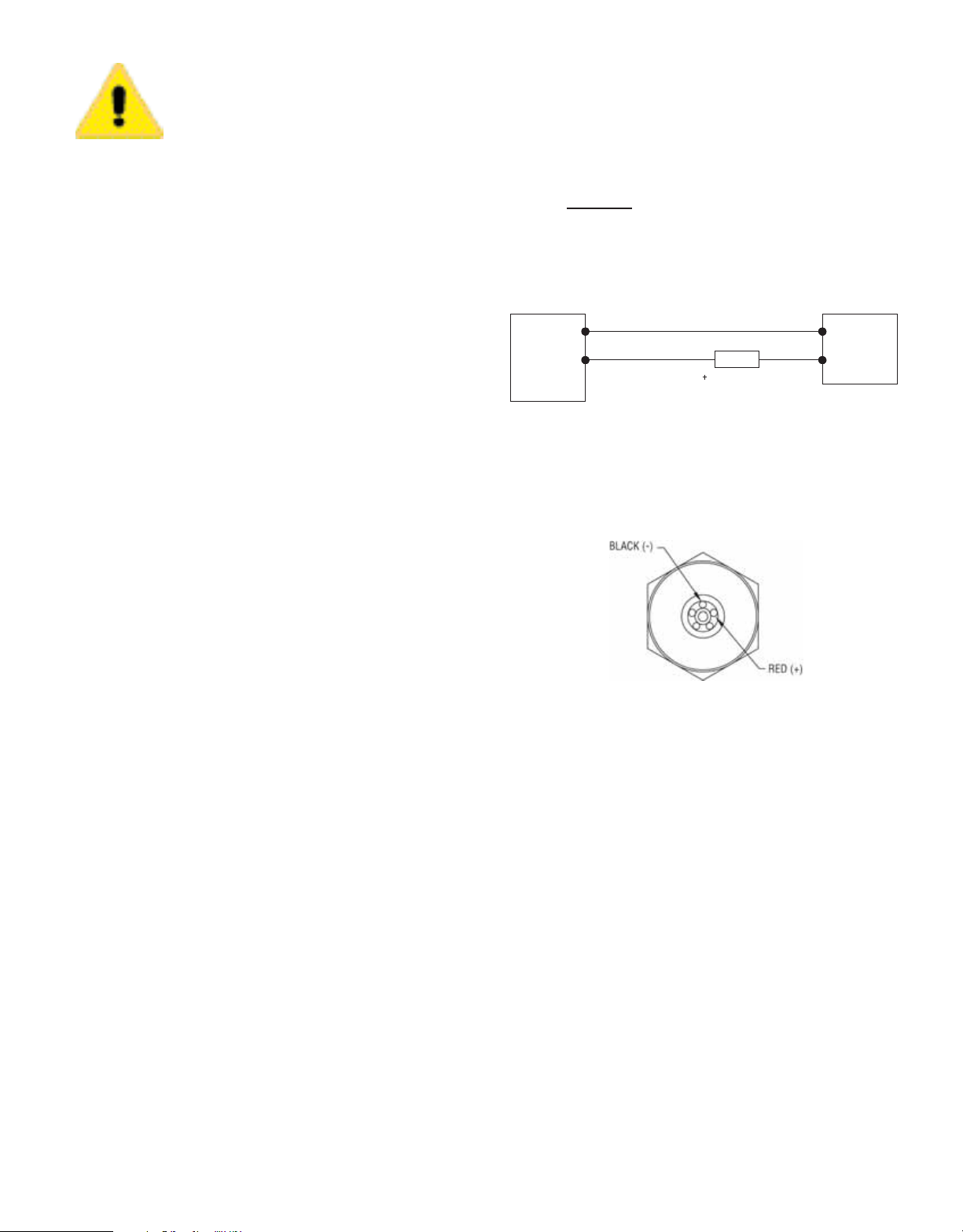

CAUTION: Do not exceed specified supply

POWER

SUPPLY

10-28 VDC

-

RECEIVER

BLACK

RED

PRESSURE

TRANSDUCER

mA

voltage ratings. Permanent damage not covered by warranty will result. This device is not

designed for 120 or 240 volt AC operation.

Use only on 10 to 28 VDC.

INSTALLATION

1. Location: Select a location where the temperature of the trans-

ducer will be between 0 and 176°F (-18 to 80°C). Distance from

the receiver is limited only by total loop resistance.

2. Position: The transducer is not position sensitive. However all

standard models are originally calibrated with the unit in a position

with the pressure connection downward. Although they can be

used at other an gles, for best accuracy it is recommended that

units be installed in the position calibrated at the factory.

3. Mounting: The transducer can be mounted via several methods. It can be suspended from the electrical cable, it can be

placed resting on the bottom of the tank in either horizontal or vertical orientation, or it can be attached to a pipe or hang wire by the

1/2˝ NPT male connection on the top of the housing.

4. Electrical Connections

Wire Length - The maximum length of wire connecting the trans-

ducer and receiver is a function of wire size and receiver resistance. Wiring should not contribute more than 10% of the receiver

resistance to total loop resistance. For extremely long runs (over

1000 feet), choose receivers with higher resistance to minimize

the size and cost of connecting leads. Where wiring length is

under 100 feet, wire as small as 22 AWG can be used.

5. Wiring

An external power supply delivering 10-28 VDC with minimum

current capability of 40 mA DC (per transducer) is required to

power the control loop. See Fig. A for connection of the power

supply, transducer and receiver. The range of appropriate receiver

load resistance (RL) for the DC power supply voltage available is

expressed by the formula:

RL Max = Vps – 10V

20 mA DC

Shielded cable is recommended for control loop wiring.

Fig. A

Black wire is negative (-) and red wire is positive (+).

Fig. B

MAINTENANCE

After final installation of the pressure transducer and its companion receiver, no routine maintenance is required. A periodic check

of system calibration is suggested. The Series SBLTX transducer

are not field repairable and should be returned if repair is needed

(field repair should not be attempted and may void warranty). Be

sure to include a brief description of the problem plus any relevant

application notes. Contact customer service to receive a return

goods authorization number before shipping.

Loading...

Loading...