Page 1

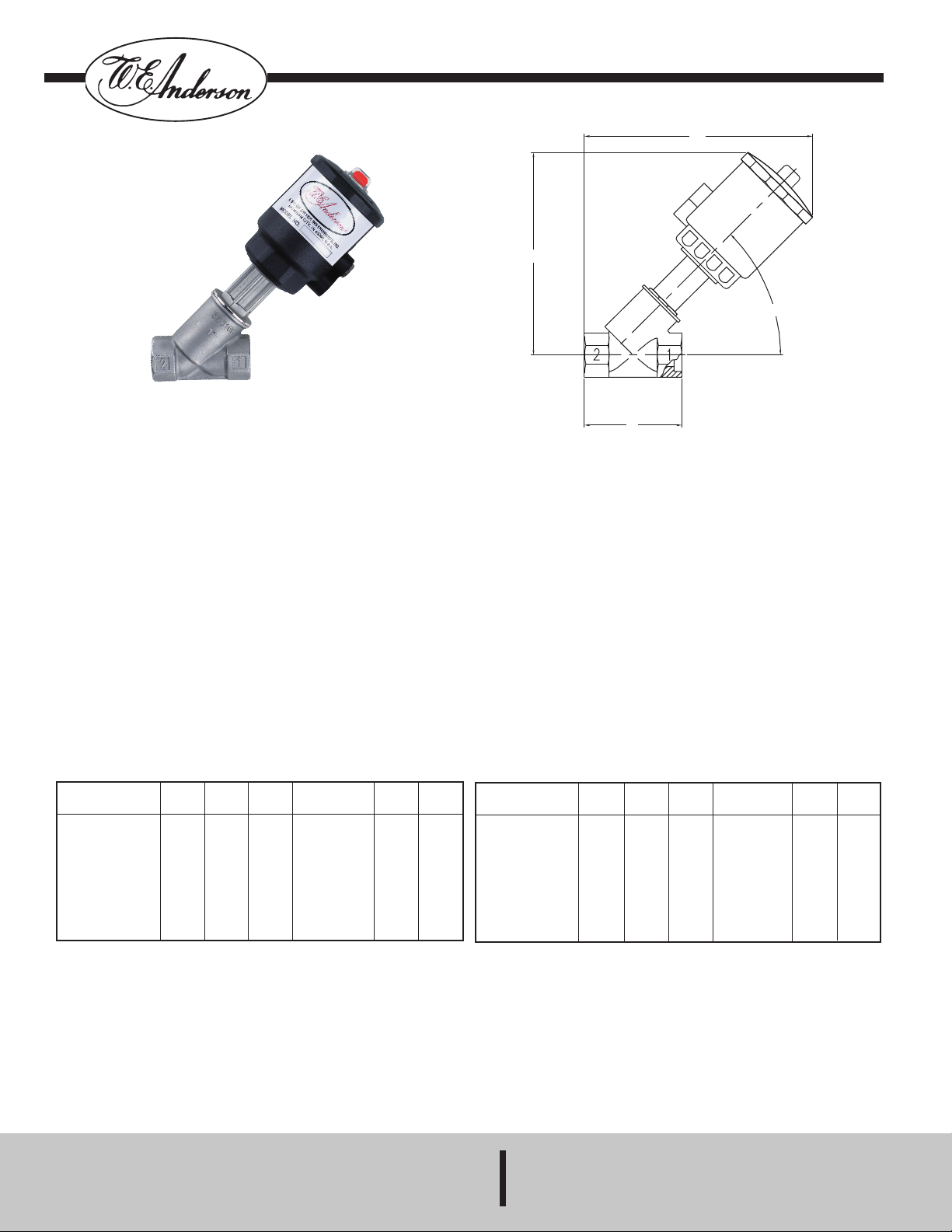

Series SAV Angle Seat Valves

A

1

C1

B1

4

5°

Specifications - Installation and Operating Instructions

ulletin F-89

B

The Series SAV Angle Seat Valve offers a compact, low cost

actuated valve package. The pneumatic, externally piloted, piston valve

can be operated with air or liquids, and provides bubble tight shutoff

and failsafe operation. Bronze and stainless steel body materials

provide broad media compatibility and corrosion resistance. The

Polyamide actuator housing resists corrosion for years of maintenancefree operation. The SAV can be used in most gas, liquid, steam, and

corrosive applications. For ease of installation, the SAV actuator

housing can be rotated 360 degrees.

Each SAV valve is manufactured with one of the following valve

functions:

NC (Normally Closed)

These valves are designed for flow over the seat (port 1 to 2). Caution:

Not recommended for waterhammer prevention.

NO (Normally Open)

These valves are designed for flow under the seat (port 2 to 1). Can be

used to prevent waterhammer on valve closure in liquid applications.

Bronze NPT Dimensions

Port Connection

1/2˝

3/4˝

1˝

1-1/4˝

1-1/2˝

1-1/2˝

2˝

2˝

A1 (in)

2.56

2.95

3.54

4.33

4.72

4.72

5.91

5.91

B

1

6

.4

2

6.81

8.11

10.04

10.63

12.05

1

1.02

12.44

(in

)

C1 (in)

5.51

5.79

6.93

8.66

9.25

10.67

9.45

10.87

Actuator

Diameter (in)

2.76

2.76

3.32

3.32

4.58

4.58

4.58

5.54

NO CV

6.61

12.18

23.20

33.06

33.30

53.94

NC CV

6.61

12.18

23.2

33.64

53.36

53.94

68.44

77.72

SPECIFICATIONS

VALVE BODY

Service: Gases and liquids compatible with wetted materials.

Wetted Materials:

Valve Body: Bronze or AISI 316L SS;

Plug and stem: AISI 316L SS;

Stem O-ring: Viton®;

Seat and seal: PTFE.

Line Sizes: 1/2 to 2˝.

Pressure Limits: See tables on next page.

Temperature Limits: 14 to 358°F (-10 to 180°C).

Flow Leakage: Meets ANSI Class VI.

ACTUATOR

Type: Piston/pneumatic spring.

Pilot Connections: NAMUR solenoid mounting pad.

Pilot Media: Air, water, inert gas.

Pressure Limits: See tables on next page.

Temperature Limit: 185°F (85°C).

Stainless Steel NPT Dimensions

Port Connection

1/2˝

3/4˝

1˝

1-1/4˝

1-1/2˝

1-1/2˝

2˝

2˝

A1 (in)

3.35

3.74

4.13

4.72

5.12

5.12

5.91

5.91

B

1

7

.4

8

7.68

8.62

10.47

10.67

12.09

11.22

12.64

(in

)

C1 (in)

6.14

6.30

7.17

8.90

9.06

10.47

9.45

10.87

Actuator

Diameter (in)

2.76

2.76

3.32

3.32

4.58

4.58

4.58

5.54

NO CV

6.61

12.18

23.2

33.06

33.30

53.94

NC CV

6.61

12.18

23.2

33.64

53.36

53.94

68.44

77.72

W.E. ANDERSON DIV., DWYER INSTRUMENTS, INC.

P.O. BOX 358 • MICHIGAN CITY, INDIANA 46360 U. S.A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyermail.com

Page 2

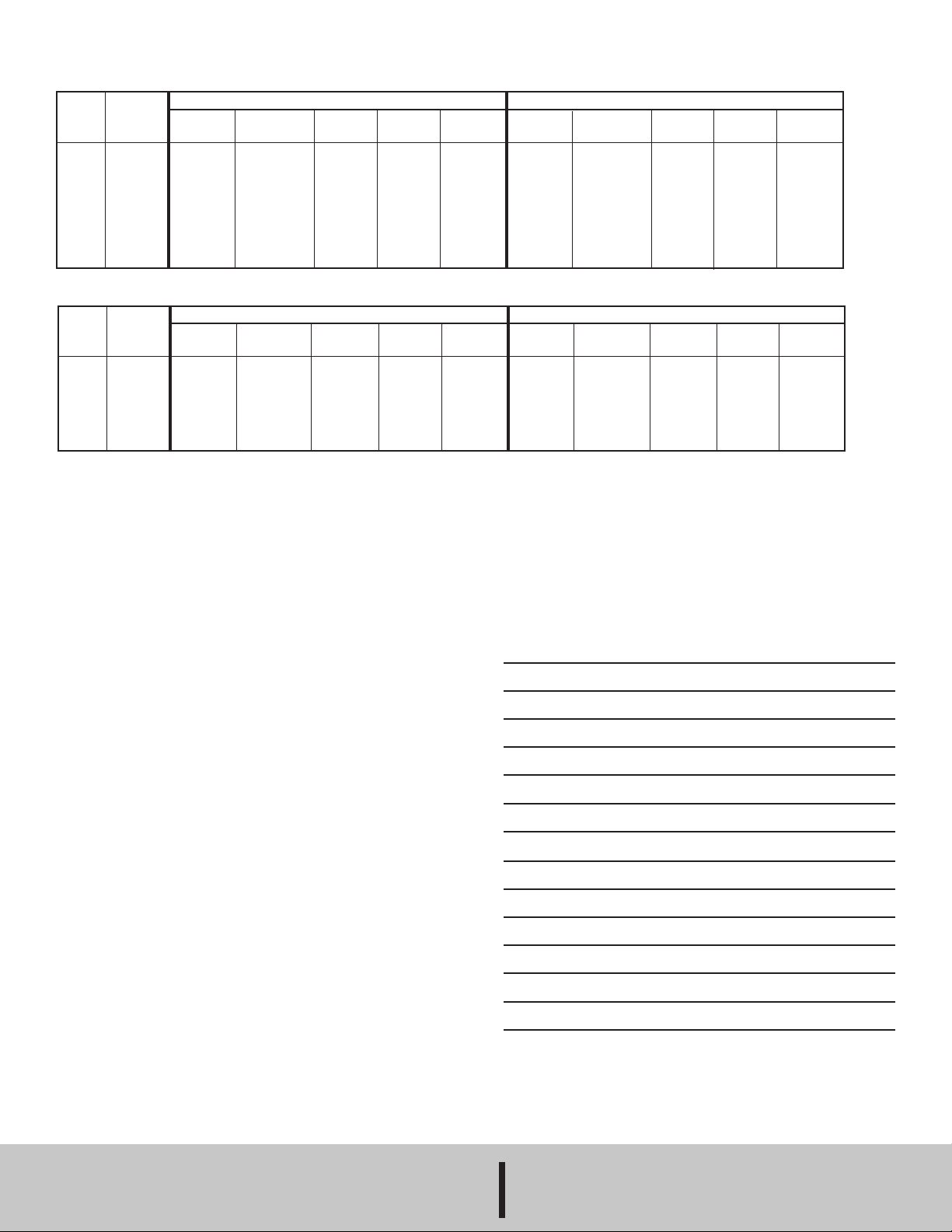

LINE AND PILOT PRESSURE CHARTS (psi)

Normally Closed

Stainless Steel

Actuator

Valve

Diameter

Size

1/2

3/4

1-1/4

1-1/2

1-1/2

Normally Open

Valve

Size

1/2

3/4

1-1/4

1-1/2

INSTALLATION

1. Prior to Installation, be sure system is not under pressure and all

scale and debris is free from piping system.

2. The valve can be installed in any position, with the direction of flow

as indicated on the inlet/outlet ports by the connection numbers 1 and

2.

3. The actuator can be rotated 360 degrees in the direction indicated

on the product label to facilitate easy pilot mounting connection.

4. Apply thread tape or sealant to pipe threads only.

5. Use hex flats on valve to secure the valve and pipe. Never tighten

the valve by using the actuator to turn.

6. Pipework should be supported to prevent any stress on valve body.

1

2

2

1

2

2.76˝

2.76˝

3.32˝

3.32˝

4.58˝

4.58˝

4.58˝

5.54˝

Actuator

Diameter

2.76˝

2.76˝

3.32˝

3.32˝

4.58˝

5.54˝

Max. Line

Pressure

230

230

230

230

230

143

232

232

Max. Line

Pressure

230

230

230

230

230

230

Max. Steam

Pressure

150

150

150

150

150

150

150

150

Max. Steam

Pressure

150

150

150

150

150

150

Flow

Direction

Overseat

Overseat

Overseat

Overseat

Overseat

Overseat

Overseat

Overseat

Stainless Steel

Flow

Direction

Underseat

Underseat

Underseat

Underseat

Underseat

Underseat

Min. Pilot

Pressure

60

60

60

60

60

60

60

60

Min. Pilot

Pressure

60

60

60

60

60

60

Max. Pilot

Pressure

143

143

143

114

114

114

114

114

Max. Pilot

Pressure

143

143

143

114

114

114

Bronze

60

60

60

60

60

60

60

60

60

60

60

60

60

60

Max. Pilot

Pressure

143

143

143

114

114

114

114

114

Max. Pilot

Pressure

143

143

143

114

114

114

Max. Line

Pressure

230

230

290

230

230

230

160

220

Max. Line

Pressure

230

290

290

230

230

220

WARRANTY

The Series SAV is warranted from defects in materials or workmanship

for (1) year from the date of purchase. If required, contact our customer

service department for a Return Goods Authorization and send to:

Attn: Repair Department

Dwyer Instruments, Inc.

102 Indiana Highway 212

Michigan City, IN 46361

Max. Steam

Pressure

150

150

150

150

150

150

150

150

Max. Steam

Pressure

150

150

150

150

150

150

Flow

Direction

Overseat

Overseat

Overseat

Overseat

Overseat

Overseat

Overseat

Overseat

Bronze

Flow

Direction

Underseat

Underseat

Underseat

Underseat

Underseat

Underseat

Min. Pilot

Pressure

Min. Pilot

Pressure

NOTES:

OPERATION

1. Flow direction is from ports 2 to 1 for normally closed valves, For

liquids, flow should be under the seat to prevent waterhammer.

2. Pilot pressure is from 22-150 psi, dependent on process pressure.

Review pilot/media pressure relationship charts before initial system

operation.

3. Optional Series PV Solenoid Pilot Valves can be installed for

operation with 120 VAC power supply (other voltages available).

MAINTENANCE

The Series SAV requires no maintenance. Care should be taken to

make sure that the ratings of the valve are not exceeded with respect

to maximum pressures and temperatures, and that the media is

compatible with all materials.

SPARE PARTS

The Series SAV valve is completely safe to disassemble in the field. A

seal kit is available for all valves and actuator sizes compromising:

piston lip seal, actuator steam O-ring, plug soft seal (PTFE), body seal

and O-ring. Specify valve size and type when requesting a seal kit.

©Copyright 2014 Dwyer Instruments, Inc. Printed in U.S.A. 3/14 FR# RV-443112-00 Rev. 4

W.E. ANDERSON DIV., DWYER INSTRUMENTS, INC.

P.O. BOX 358 • MICHIGAN CITY, INDIANA 46360 U. S.A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyermail.com

Loading...

Loading...