Page 1

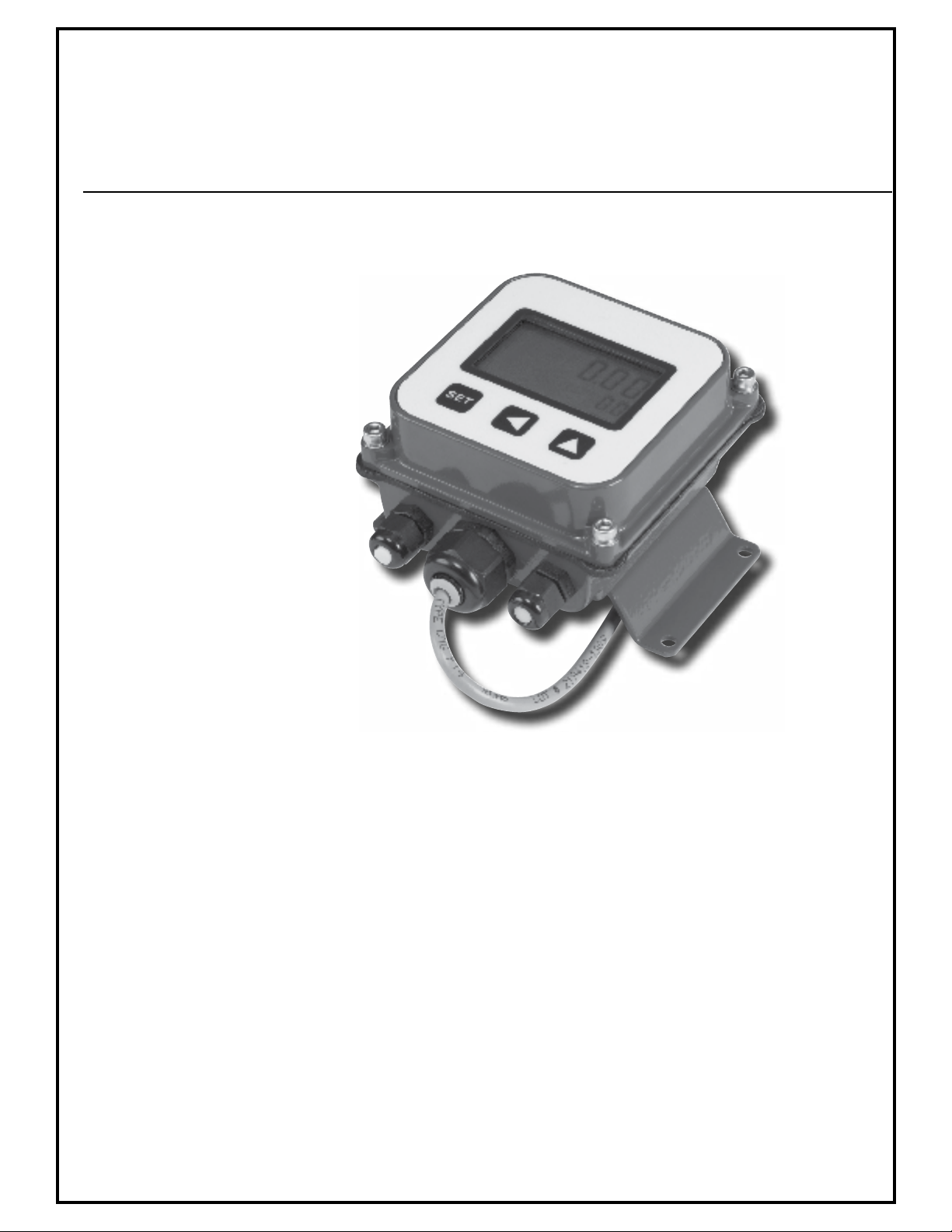

Series RTI

RATE/TOTAL DISPLAY

INSTRUCTIONS

F-RTI

Page 2

TABLE OF CONTENTS

GENERAL INFORMATION

General Information

General Information, Features, Specications ....................................................................................................Page 1

Installation

Wall Mount, Meter Mount, Panel Mount .............................................................................................................Page 2

Connections, RTI (Option -DRO), -DRO Relay Board Specications ...................................................................Page 3

Connection Diagrams

RTI, RTI-W-VPS .......................................................................................................................................................Page 4

RTI-X-DRO, RTI/EFS2 or IEFS Magmeter .............................................................................................................Page 5

RTI/EFS2 or IEFS Magmeter/Dual Power Supply ...............................................................................................Page 6

(Quick) Settings

Quick Settings Overview .......................................................................................................................................Page 7

Settings

K-Factor, Reading in Other Units ..........................................................................................................................Page 8

Set K, Set P/Flow Alarm, Set 20 mA, Set Decimal Point, Set Time Unit ...........................................................Page 8

Operation

Resettable Totalizer; 4 to 20 mA Output, Pulse Output ......................................................................................Page 9

Troubleshooting

Problems, Probable Causes, to Try ................................................................................................................ Back Page

The Series RTI ow displays are microcontroller-based indicator/transmitters that show ow rate and total and provide

output signals. The RTI is powered by external DC voltage and

has both pulse and 4 to 20 mA analog outputs. When the RTI

is being used in the 4 to 20 mA mode, it is a “two-wire” or

“loop-powered” device, meaning that the 4 to 20 mA output

signal doubles as its power supply.

The addition of a dual-relay output board allows for certain

applications requiring contact output isolation (e.g., certain

metering pumps and water treatment controls). Dual solid

state relays provide exactly the same pulse output as the

standard unit, and each can signal one external device. A

non-resettable total is also available. The RTI can be ordered

in a plastic enclosure with a 115 VAC power supply for use

with mechanical meters, or with a built-in 115 VAC/12 to 24

VDC dual power supply for magmeters.

FEATURES

Electronics Module

Display

Setup Keys**

The RTI can be factory-mounted on the meter (-M) or remotely

wall mounted with the brackets provided (-W). The RTI is also

available as a panel mount (-P) with an open back for easy

installation in the user’s own electrical enclosure. Most RTI’s

can be converted from wall-to-meter or meter-to-wall mount

congurations after installation if needed.

Housings for the -W and -M models are rugged cast aluminum,

potted and gasketed for maximum environmental protection.

A membrane keypad allows settings to be changed without

removing the cover. (Password protection, a standard feature,

can be used to prevent settings from being changed.)

**Includes password protection for tamper prevention

when needed

TABLES AND DIAGRAMS

Features, Specications .......................................................................................................................................Page 1

Meter Mount, Panel Mount ..................................................................................................................................Page 2

Dual Relay Board Specications ..........................................................................................................................Page 3

Connections: RTI, RTI-W-VPS ................................................................................................................................Page 4

Connections: RTI-X-DRO, RTI/EFS2 or IEFS Magmeter .......................................................................................Page 5

Connections: RTI/EFS2 or IEFS Magmeter/Dual Power Supply ........................................................................Page 6

Quick Settings Overview .......................................................................................................................................Page 7

K-Factor ..................................................................................................................................................................Page 8

Resettable Totalizer ..............................................................................................................................................Page 9

Troubleshooting Problems, Probable Causes, to Try .....................................................................................Back Page

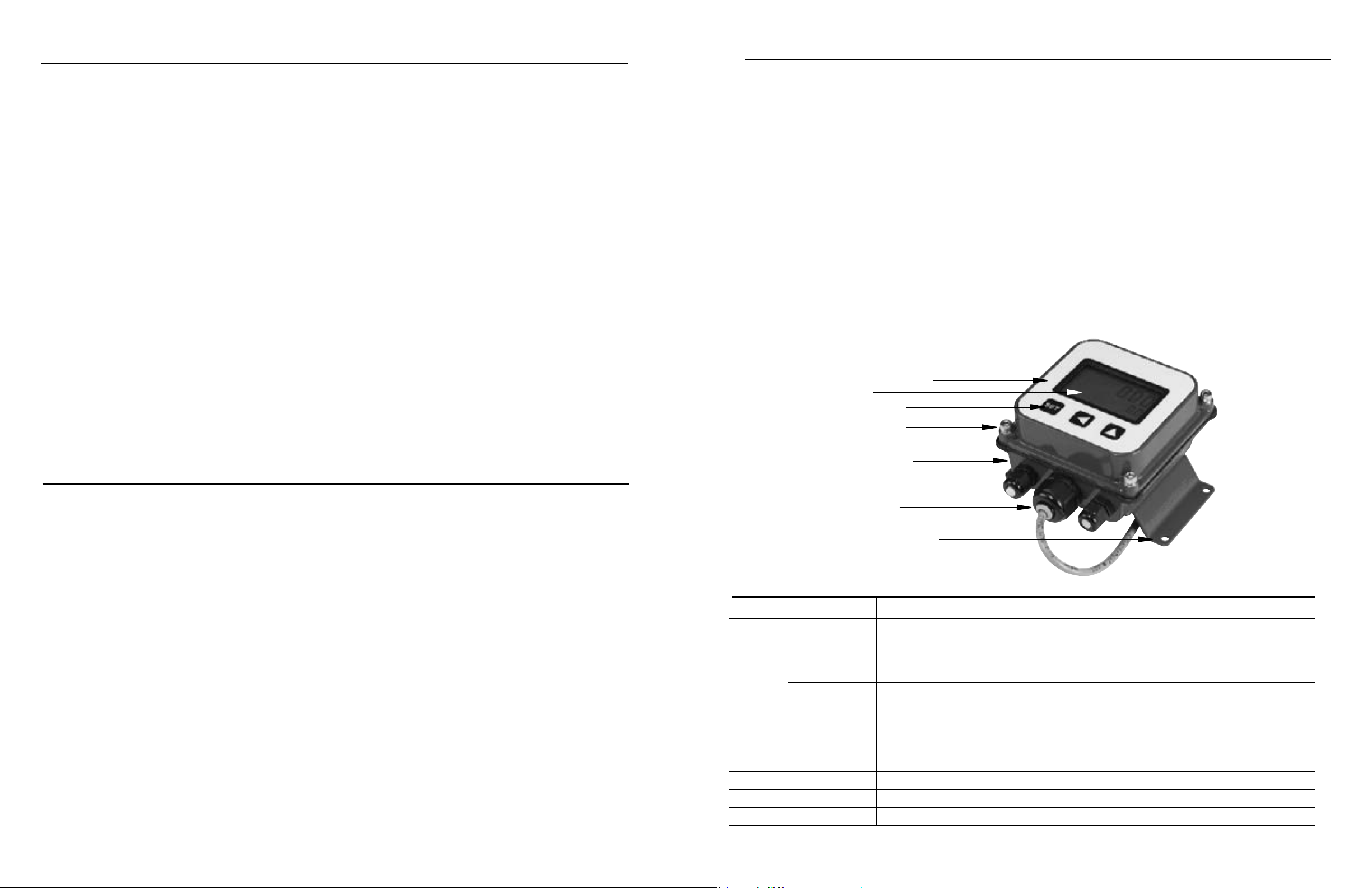

Cover Screws

Lower Housing

Strain Relief

Wall-Mount Brackets

SPECIFICATIONS*

Power

Display Rate

Total

Outputs Current Sinking Pulse

Analog

Pulse Output Range

Input

Input Range

K-Factor Range

Flow Alarm Output Range

Operating Temperature

Environmental

**Includes password protection for

tamper prevention when needed

RTI

12 to 30 VDC, 4mA (4 to 20 mA when loop-powered)

6-digit autorange, 1/2" character height

8-digit, 5/16" character height

Scaled Pulse output (0.1 sec duration 6.1 Hz max), or (High Alarm output or Low Alarm output)

Sensor pass-through Pulse output (unscaled)

4 to 20 mA loop; 24 to 30 Vdc

0.1 - 9999999.9 units/pulse

5V pulse or contact closure

1.0 - 1,500 pulses/second

.001 - 99999.999

.01 - 999999.99

-30 to 65˚ C (-22 to 148˚ F)

NEMA 4X, IP66

*Specications subject to change

Page 1

Page 3

INSTALLATION

INSTALLATION

Wall Mount. To mount a Series RTI display to the wall, hold the

unit in the desired position, mark the holes in the mounting

feet, drill and mount with screws. With the RTI-W-VPS option

(Built-in 115 VAC power supply), rst remove the front cover

to gain access to the mounting screw holes.

A meter-mounted RTI Series can be converted to a wall mount

using an MMK mounting kit offered in our Series FPCA.

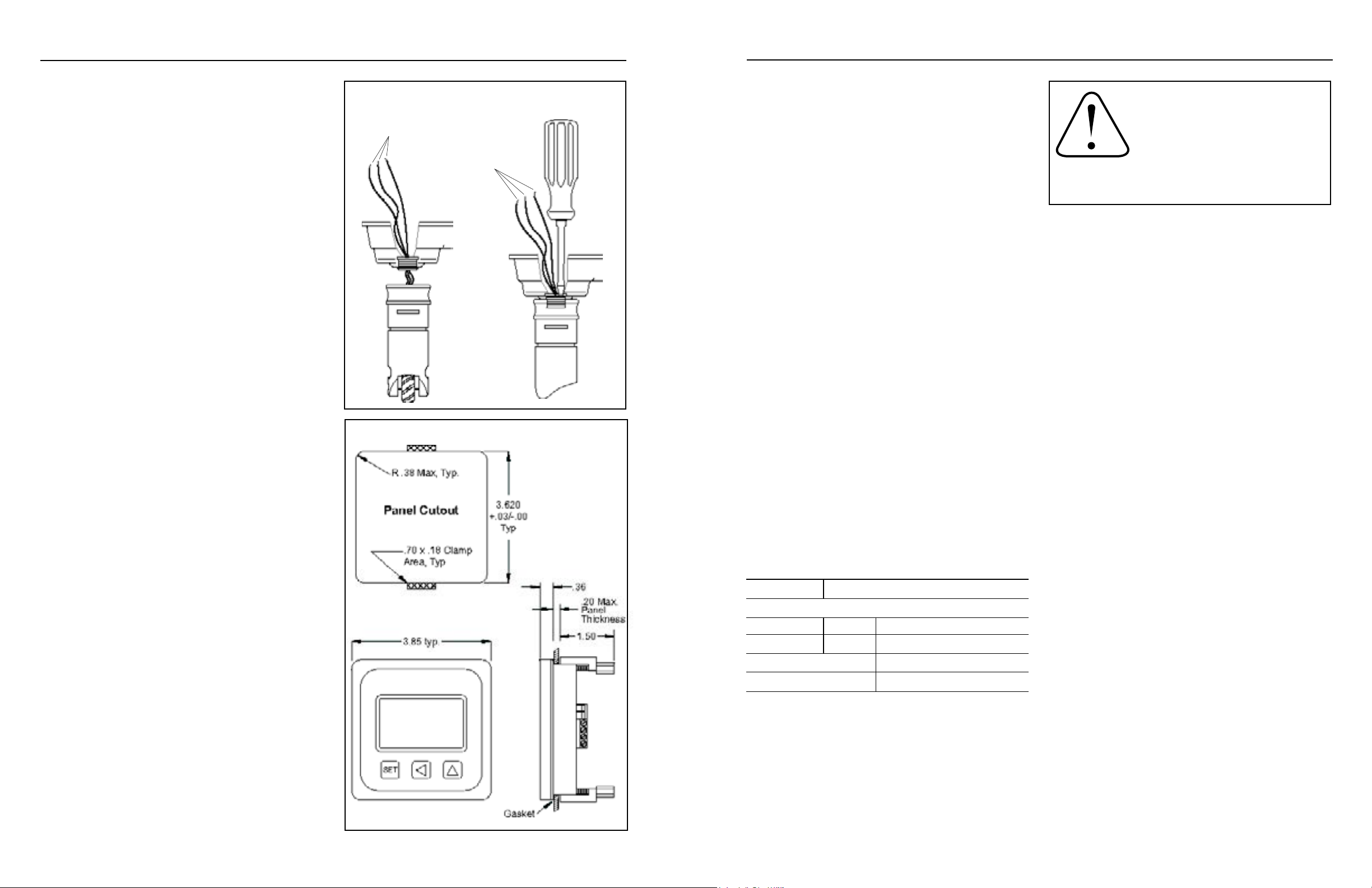

Meter Mount. If the Series RTI display was ordered as an -M

model, the housing is made to be directly mounted to the ow

sensor and therefor needs no further installation.

An RTI Series module can be converted from a wall-to a metermount using the WMK adapter kit fouund in Series FPCA that

includes a lower housing and associated hardware. This can

be accomplished as follows:

1) Remove the strain relief through which the ow sensor

cable runs.

2) Cut the cable to about 6” in length. Carefully strip the

cable jacket to expose the three colored wires (red,

white, and black) inside.

3) Route the wires through the threaded connector

pre-installed in the bottom of the housing.

4) Start the threaded connector into the female thread on

the top of the ow sensor. Be sure to match the

oblong shape on the bottom of the housing to the

depression on the top of the ow sensor.

5) Using an ordinary screwdriver inserted in one side of

the slot (see drawing), tighten the screw as much as

possible.

6) Strip the wire ends, make the connections to the

RTI Series display as shown in Connections

Diagrams, and then use the cover screws to attach the

display to the top of the housing.

Panel Mount. Using the “Panel Cut out” drawing as a guide,

cut a square hole in the panel. Remove the clamps from the

back of the RTI-P and insert the display unit through the cutout,

taking care that the panel sealing gasket is in place between

the front of the panel and the ange of the display. Hold the

display in place while starting the screw of one of the two

clamps. Finger tighten the screw, then install the other clamp.

When both are in place, rmly tighten the clamps with a small

wrench or nut driver.

Sensor Wires

Meter Mount

Sensor Wires

Panel Mount

Connections. To connect the Series RTI ow display to a ow

sensor or an external device such as a chemical metering

pump, follow the Standard Connections diagrams on pages

4 thru 6.

If the RTI's 4 to 20 mA current signal is not required, connect

the power terminals to any 12 to 30 VDC voltage source.

Dual Relay Output (Option -DRO). If you purchase the RTI with

option -DRO, the required component will come preinstalled,

and no extra procedures are required.

If you are retrotting an existing installation of an RTI with the

dual relay board, please follow the instructions below:

1) Peel the backing off of the double-stick tape and afx

it to the bottom of the relay board.

2) Carefully attach the board to the RTI as shown in

the connection diagram on page 5. Be sure that the

red wire faces the “Sensor Input” side of the RTI, and

that the white wire faces the “Pulse Output” side.

3) Connect the white wire to the “Pulse Scaled” positive

terminal, and the red wire to the “Power 4 to 20 mA”

positive terminal.

4) Connect devices to the relays as desired.

-DRO Relay Board Specications

Output Voltage 0 to 130 VAC/DC

Output Current (each output)

Temperature 50˚ C 85˚ C

Current Limit 100 mA 50 mA

Max Pulses/Second 5

Contact Time Per Output 100 ms

Caution: If output is being used to

control an external device, such as a

metering pump, do not connect the device until programming is completed.

If malfunction or incorrect program-

ming of the output could cause personal injury or property damage, separate safeguards

must be installed to prevent such injury or damage.

Page 2 Page 3

Page 4

CONNECTION DIAGRAMS

CONNECTION DIAGRAMS

Connections for RTI/3-Wire Mechanical Meter

3-Wire

Mechanical

Meter

Connections for RTI-X-DRO (Dual Relay Output Option)

NOTE: Outputs may be paralleled

to switch up to 200 mA AC/DC

Connections for RTI-W-VPS (115 VAC Option)

RTI

Connections for Series RTI to Series EFS2 or IEFS Electromagnetic Flow Sensors

24 Vdc Power

Sensor

Power

Input

Forward Output

Reverse Output

-RFO

EFS2/IEFS

Power

4-20mA

Pulse

Scaled

Pulse

Pass-Thru

RTI

To

Proportional

Feed

Metering

Pump

Page 4

Page 5

Page 5

CONNECTION DIAGRAMS

RTI Display with 4 to 20 mA Output

When running the RTI with a magmeter (which requires power), the RTI must be connected to two power supplies, one for the magmeter

and one for the 4-20 mA loop. You may either use a dual power supply, or two single power supplies (one of which may be the 4-20 mA

loop itself). See diagrams below.

(QUICK) SETTINGS

QUICK SETTINGS OVERVIEW

Caution: Important! Do not connect power to the power supply until all connections have

been made and conrmed correct, and the cover has been put back into place.

Series RTI/4 to 20 mA Output with Two Separate Power Supplies

Sensor

Input

Power

24 Vdc

Power

Forward Output

Reverse Output

24 Vdc

Power

(Option-15 only)

EFS2/IEFS

Power

4-20mA

4-20 mA Device

(e.g. pump, PLC)

Series RTI/4 to 20 mA Output with PWC2 Dual Power Supply (Part of Series FPCA)

Caution: It is essential for safety and proper operation to use a ground connection for the

115 VAC power. Do not use this power supply without proper grounding.

See following page for step-by-step instructions on changing these settings

Pass through all settings and return to original display to save settings.

Pulse

Scaled

Pulse

Pass-Thru

RTI

PCW2 Dual Power Supply

RTI

*NOTE: Use the up arrow key to reach your desired digit. Then press the left arrow key to move

to the next digit. Repeat the process until the entire number is entered.

Series EFS2/IEFS

Magmeter

Page 6

Page 7

Page 6

SETTINGS

OPERATION

K-FACTOR

At a minimum, every Series RTI ow display must be programmed with the “K-factor”. (This is the number of pulses

that the meter produces per gallon of ow.) If you wish the

RTI to read in units other than gallons, see below.

The K-factor on any Dwyer Instruments Inc. ow sensor

tting or in-line meter can be found on the model-serial la-

bel. The line reading K = xxxx gives the desired number. For

depth-adjustable sensors, look in the instruction manual

under your pipe size.

Fixed Depth Meter

Find Your K-Factor Here

READING IN OTHER UNITS

Changing Volume Units. The default K-factor units are

pulses per gallon. To read your total in metric or other

units instead, the standard K-factor must be converted to

the desired volume units. For example, to read in pulses

per liter, the K-factor must be multiplied by the applicable

number shown below.

NOTE: Both rate & total will read in whatever units you choose.

To Convert K to: Multiply by:

Liters .26418

Cubic Meters 264.18

Fluid Ounces .0078

Cubic Feet 7.48

Set K. Begin by pressing the SET key once. The prompt SET K

should appear on the display. The digit to the far right will be

blinking. Use the up arrow key to reach your desired value. Then

press the left arrow key to move to the next digit. Repeat the process until the entire number is entered. (Note that the decimal is

xed at three places. If you only have two decimal places for your

K-factor, enter a zero for the third digit.) Press SET to advance.

(Note: If unable to set K-factor, the unit is "locked" to prevent

tampering. Please contact Dwyer Instruments Inc. for assistance.)

Set P/Flow Alarm. At this screen you may select between pulse

output (P) or ow alarm (A) functions. If the pulse output and

ow alarm features are not being used, this step can be skipped.

The P (pulse output) setting does not affect anything if it is not

being used.

Set P is the default that appears on a new Series RTI. On an RTI

that has been previously set up with ow alarm function, an A will

appear on this screen. To move between P and A screens, rmly

press all three keys for 5-10 seconds, then use the up arrow to

scroll through the three options: P, AL HI (high ow alarm) and

AL LO (low ow alarm).

Set P. From this screen, follow the same process as for Set K

to enter the desired pulse rate. This is the number of gallons

(or whatever units are programmed) between pulses. (Note:

Using the pulse output function disables the high and low ow

alarm functions.) (6.1 Hz max output)

Set Flow Alarm. From the A screen, use the up arrow key to

choose either AL HI or AL LO and then press the SET key to set

the alarm rate. Use the up arrow and left arrow as above to

reach the desired digits. (Note: Using the ow alarm function

disables the pulse output function.)

Set 20 mA. Press the SET key to advance to SET 20 to set the ow

rate in volume units per time unit, at which 20 mA is desired. Use

the up arrow key to reach your desired value. Then press the left

arrow key to move to the next digit. Repeat the process until the

entire number is entered. The processor will automatically scale

the 4 to 20 mA loop accordingly, with 4 mA at zero ow.

Set Decimal Point. Press the SET key again for the D prompt.

Pressing the up arrow key switches among no decimal place, one

decimal place, and two decimal places.

Set Time Unit. When the SET key is pressed again, a

blinking time unit appears. Press the up arrow key

to select SEC (seconds), MIN (minutes), HR (hours) or

DAY (days) (for example, gal/min, or gal/hr).

Resettable/Non-Resettable Totalizer. Unless the unit has been

ordered with the non-reset option, a RESET prompt is visible in

the lower right corner above the up arrow key, when the display

is in use. Press the up arrow key at any time to reset the totalizer

to zero. (Note: If you need to reset a unit that has been ordered

with a non-resettable totalizer, contact Dwyer Instruments Inc.)

1234.1

123456.7

RESET

This key resets total to zero

when in normal run mode.

CAUTION: Do not touch up Arrow button un-

less you intend to RESET Total to Zero.

TOTAL IS NOT RECOVERABLE.

Operation of 4 to 20 mA Output. If the 4 to 20 mA output is in use

and is correctly connected, the signal should vary between 4 mA

and 20 mA in proportion to the ow, with the top ow rate set by

the user (see Settings, page 8). At no time should the signal drop

below 4 mA. A reading between 0 and 4 mA indicates a fault of

some type, typically in the loop power supply or the connections

(see Troubleshooting, back page). In the rare instance that the

4 to 20 signal uctuates excessively (“paints”), it may need to

be damped by additional averaging. Contact Dwyer Instruments

Inc. for information on how to increase ltering.

Operation of the Pulse Output. If the pulse output is being

used (either standard electronic or relay-type), it should pulse

for 0.1 second every time the set number of gallons has been

totalized. If a pulse-responsive metering pump is properly con-

nected to this output, it should stroke periodically. If this does

not occur, see Troubleshooting, back page.

WARRANTY/RETURN

Refer to "Terms and Conditions of Sale" in our catalog or on

our website. Contact customer service to receive a Returns

Goods Authorization number before shipping your product

back for repair. Be sure to include a brief description of the

problem plus any relevant applciation notes.

Changing Time Units: To read your rate in liters per sec-

ond (for example), convert the K-factor volume units as

shown above and change the time units to Seconds, us-

ing the Set Time Unit instructions at right.

Page 8

To save settings and return to normal operation after entering

settings, press SET again. When the unit is connected to an

operating ow sensor, the rate (larger digits) and total (smaller

digits) indicator numbers should appear in the display.

Page 9

Page 7

TROUBLESHOOTING

Problem

Probable Cause Try...

Display blank No power to the unit Check for minimum 12 VDC at power

terminals

Short in sensor circuit Disconnect sensor, see if display returns

(zero ow rate)

Display missing segments Damaged display module Contact Dwyer Instruments, Inc. for replacement

Display reading meaningless Unit’s microcontroller crashed Disconnect and reconnect power, if problem

characters repeats, contact distributor for

return/replacement

Display reads normally, Wrong K-factor or time base entered Enter correct K-factor from meter, tting, or

ow rate incorrect manual

Display reads normally, Wrong pulse output setting Use “Set P” to correct pulse output setting

incorrect pulse output

Polarity reversed on pulse output terminals Reverse leads

Display reads normally, but Wrong 20 mA setting Use “Set 20” to correct target top ow rate

no (or incorrect) 4 to 20 mA output

Inadequate loop power supply voltage Check voltage (For 4 to 20 mA applications,

24 VDC recommended)

Polarity incorrect in 4 to 20 mA loop circuit Compare to Connections diagram

Display reads zero when Flow sensor failed Consult ow sensor manual for how to test

there is ow

Break in ow sensor circuit Check for continuity with multimeter

Display reads ow rate when Long ow sensor wire, running parallel to Reroute wire or change to shielded wire

there is none power wires

Flow sensor malfunction See ow sensor manual to check

Dwyer Instruments, Inc. • 102 Indiana Highway 212 • Michigan City, IN 46360 • USA

(P) 219.879.8868 • (F) 219.872.9057 • 1.800.872.9141 • www.dwyer-inst.com

PL-OM-65200385-091912

9/19/12

Loading...

Loading...