Page 1

Model RLD2 Refrigerant Leak Detector

O

N

/

O

F

F

S

E

N

S

.

R

E

S

E

T

Leak Detector

6-3/4

[171.29]

6

-19/64

[

159.9]

1

-33/64

[

38.4]

1

-21/64

[

33.7]

1

-31/64

[

37.6]

2-1/4

[

57.2]

Specifications - Installation and Operating Instructions

Bulletin TE-RLD2

he Model RLD2 is the most dependable negative corona refrigerant leak detector.

T

The responsive elements have a wide sensitivity range. This unit utilizes a five level

alarm system to detect excessive refrigerant in areas where there could be a

potential leak. The dual-color LED indicator lights provide visual indication of the

refrigerant gas concentration, various audio pitches facilitate detection, and its

ortable design is convenient for the user. The refrigerant leak detector can be

p

tilized in residential and commercial refrigeration systems, automotive, air

u

onditioning, and quality control testing environments.

c

TECHNICAL FEATURES

This device consumes low power by utilizing an 8–bit microprocessor controller.

Also equipped is dual-colored LED indicator light with progressive and real time

display. The sensitivity is adjustable with seven level alarming indicated by the

audio levels and LED display. The indicators are convenient for maintenance

because of the modular sensor, battery voltage indication and auto rest testing

when the detector is turned on.

OPERATION KEYS

• ON/OFF Key: Press it to turn on/off the detector.

• SENS Key: It is the sensitivity adjustment key, it can adjust the sensitivity level

according to the detection demands (max level:7). LED light will indicate the level

of sensitivity, meanwhile the frequency of audible alarm changes. The higher the

sensitivity level, the faster the alarm frequency.

• RESET Key: Reset the background halogen level to “zero”, any leak sources

higher than “zero” level is considered to be a leak and trigger the alarm.

Before Operating the Leak Detector:

In order to detect leaks in a refrigerant system, the system must have normal

operating pressure, or at least reach a minimum of 50 PSI. Low environmental

temperature (lower than 59°F or 15°C) may lower the system required pressure and

may make the leak less likely to be detected. No leak detected does not mean the

system does not have a refrigerant gas leak. Check the pressure before making the

conclusion. Leaking areas are usually covered with contaminants such as a

compressor oil or dirt, be careful not to let the sensor tip touch with these

contaminants. This product’s function is to detect halogen's relative change at the

sensor tip. Pinpointing the leak source needs to be done manually by adjusting the

sensitivity and resetting the detector by the user.

SPECIFICATIONS

ensor Type: Negative corona.

S

ensitivity: 3g/yr.

S

ensitivity Levels: 5.

S

Response Time: Less than 1 s (pump driven).

Temperature Limits: 32 to 125°F (0 to 52°C).

Power Requirements: (2) 1.5V AA alkaline batteries, included, user replaceable.

Battery Life: 30 hours.

arm Up Time: 5 s.

W

Pre-programmed gases: Detects gases that contain chlorine, fluorine, bromine,

ethylene oxide and SF-6, as well as: CFCs: R11, R12, R500, R503, etc.;

HCFCs:R22,R123,R124,R502, etc.; HFCs:R134A,R404A,R125, etc.; Mixtures

such as: AZ-50, HP62, MP39 etc.

Alarm Setting: Audio: Variable tick; Visual: Flashing LED.

Probe Length: 12˝ (30.48 cm).

Duty Cycle: Continuous.

Weight: 5.2 oz (147.4 g).

Agency Approvals: CE, RoHS.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyermail.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

PERATION

O

. Turn the detector on by pressing the ON/OFF key. All LED indicator lights will be on

1

or 3 seconds, and the detector will automatically reset. A rapid, steady beep will also

f

be heard.

2. After the auto-reset, only the first LED indicator light on the left will be on. This is the

power indicator light (see battery voltage indication section for more information).

. Begin searching for leaks. When refrigerant is detected, an audible buzzer will

3

ound with a different rate than the previous beeping sound. Also, the indicator lights

s

ill progressively turn on.

w

. The sensitivity cap can be adjusted at any time during operation by pressing the

4

SENS key. This adjustment will not interrupt detection. The default sensitivity level is

level 5.

5. If an alarm occurs before the sensing tip touches the leakage source, press the

ESET key to reset the current to zero until there is no alarm, then continue detecting.

R

. When done using, press the ON/OFF key to turn off the detector.

6

etecting Method

D

1. Visually examine the refrigeration system. The oily and dirty spots, node valves,

coils, connectors, or pipelines are the areas most likely to leak gases.

2. Start leak detecting at the joint at a distance of about 1 to 3 cm, moving at a speed

f about 1 cm/s.

o

. When an alarm is triggered, it may indicate a leak is close by. Detect around that

3

rea again and see if the alarm is repeatable. If a leak is confirmed, pinpoint the leak

a

source by mo ving slowly from the non-leaking to the leaking area from different

directions. Another method to pinpoint the leak is to move the detector away from the

leaking area, reset the unit, and repeat the above process. Once confirmed, mark

around the leak and continue detecting the whole line of the system.

. Additional work may be needed to eliminate possible ambiquity, such as other

4

ontaminants in the area of the leak. Clean the leaking area with a dry cloth and blow

c

ith clean, dry air, and repeat step 3 to confirm the leak.

w

Recommendations Based on Environment

Depending on the environment around the leak, different methods may need to be

used to detect properly.

1. In areas where the atmosphere is contaminated with the refrigerant, press the

RESET key to make the detector ignore the leak in the background. Make sure not to

move the sensor tip away from the contaminated background while resetting the

detector.

2. In windy areas, the leaked halogen refrigerant may be quickly diluted or removed

from the leak source. The user may use a wind shield to isolate the leak area or

temporarily turn off the fan.

3. To avoid false alarm, prevent the sensor tip from touching any moisture or other

solvent.

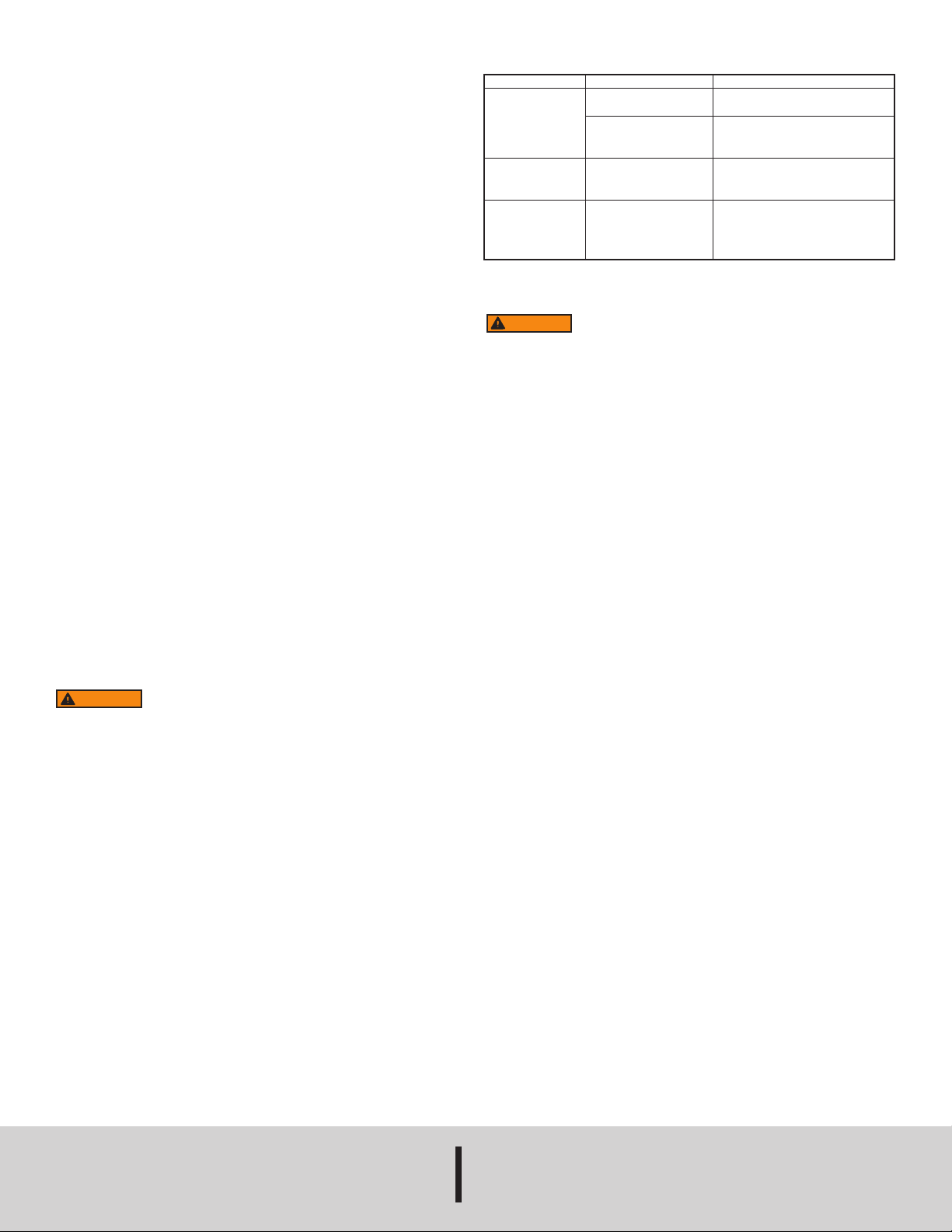

ROUBLESHOOTING

T

Problem

he detector could

T

ot turn on.

n

The detector could

not respond to a

onfirmed leak.

c

he detector gives

T

alse alarm when

f

here is no halogen

t

present.

AINTENANCE

M

roper maintenance is important and may extend the service life and improve the

P

performance of your detector.

WARNING

eep the sensor tip clean: Use cotton cloth or dry air to clean the shield on the

K

ensor tip if it gets contaminated. If the sensor tip itself is contaminated, soak the tip in

s

absolute alcohol for a few minutes, and then use compressed air to blow it dry or dry

it with cloth. Note: Never use strong solvents such as gasoline, mineral oil, or

turpentine, as these solvents may coat the sensor with a thin film and reduce the

sensitivity of the detector making the detector slow to respond to a leak. Put the

etector and the tip in a dry and clean place; remove the batteries if the detector is not

d

sed for a long time.

u

REPAIR/WARRANTY

Model RLD2 is not field serviceable and should be returned if repair is needed. Field

repair should not be attempted and may void warranty. Refer to “Terms and

Conditions of Sale” in our catalog and on our website. Contact customer service to

receive a Return Goods Authorization number before shipping the product back for

repair. Be sure to include a brief description of the problem plus any additional

application notes.

Reason

he energy of batteries is

T

oo low to turn on.

t

he pole piece of the

T

attery connector has

b

been oxidized.

Sensor tip has aged.

tmospheric composition

A

as changed.

h

Turn the power off before replacing the sensor tip. Voltage

cross the tip may pose an electrical hazard.

a

Solution

lease replace new batteries.

P

crape the oxidization layer.

S

Change a new sensor as soon as

possible.

ress RESET key to set the

P

ackground to “Zero” level. Try to

b

void the change of temperature or

a

humidity.

BATTERY INSTALLATION/REPLACEMENT

WARNING

closed space without flammable gas.

Battery Voltage Indication

Users can check the battery level in the standby mode from the battery level indicator

light. The color of the power indicator light will change according to the battery level.

The indication of the colors are:

Green Meets requirement for normal work.

Orange Low battery working voltage.

Red Below the permitted working voltage. Please replace the batteries

Battery Replacement

1. Push open the battery door located at the bottom of the detector, then remove the

door.

2. Install two AA batteries into the detector, paying attention to the polarity marking on

the side of the case, and then place the battery door back.

©Copyright 2014 Dwyer Instruments, Inc. Printed in U.S.A. 5/14 FR# R6-444134-00 Rev. 1

To reduce the risk of igniting flammable gases in a closed

atmosphere, batteries must only be replaced in an open area or

as soon as possible.

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyermail.com

Loading...

Loading...