Page 1

Series RHPLC Humidity/Temperature Transmitter

[1

[71.12]

1-3/32

35/64

[76.56]

®

Specications - Installation and Operating Instructions

Bulletin AQ-RHPLC

4-1/2

14.30]

The Series RHPLC Wall Mount Humidity/Temperature Transmitter is a compact

economical sensor for the building automation marketspace. The stylish housing is

well vented to provide air ow across the sensor to improve measurement accuracy.

Each unit utilizes a capacitive polymer sensing element to deliver a proportional

analog output. A combination humidity and temperature model can be congured

with current, voltage, RTD, or thermistor output. A wide selection of passive RTD or

thermistor temperature sensors are available in this series.

BENEFITS/FEATURES

• Reduced installation cost with combined humidity and temperature sensing

• Wide application environments from a large selection of temperature sensors and

2% to 3% accuracies

APPLICATIONS

• Air economizers

• Room comfort monitoring

MODEL CHART

Example RHPLC -3 N 2 A -FC RHPLC-3N2A-FC

Series RHPLC Humidity/temperature transmitter

Accuracy 2

Housing N North American style wall mount

Humidity Output 1

Temperature

Output

Options FC Factory calibration certicate (3%

3

2

3

2% accuracy

3% accuracy

Current 4-20 mA

Voltage 0-10 VDC

Voltage 0-5 VDC

0

None

1

Current 4-20 mA

2

Voltage 0-10 VDC

3

Voltage 0 to 5 VDC

A

10K Ω @ 25ºC thermistor type III

B

10K Ω @ 25ºC thermistor type II

C

3K Ω @ 25ºC thermistor

D

100 Ω RTD DIN 385

E

1K Ω RTD DIN 385

F

20K Ω @ 25ºC thermistor

accuracy units)

[27.69]

2X 11/64

[4.47]

2-51/64

SPECIFICATIONS

Sensor: Capacitive polymer.

Relative Humidity Range: 0-100% RH.

RH Accuracy: ±2% 10 to 90% RH @ 25°C for 2% accuracy units; ±3% 20 to 80%

RH @ 25°C for 3% accuracy units.

RH Hysteresis: ±0.8%.

RH Repeatability: ±0.1% typical.

Temperature Output Range: -40 to 140°F (-40 to 60°C).

Passive Thermistor Temperature Sensor Accuracy: ±0.36ºF @ 77°F (±0.2°C @

25°C).

Accuracy RTD Temp Sensor: DIN Class B; ±0.3°C @ 0°C (±0.54°F @ 77°F).

Accuracy Current/Voltage Temperature Output: ±0.9°F @ 72°F (±0.3°C @

25°C).

Temperature Limits: Operating: -40 to 140°F (-40 to 60°C); Storage: -40 to 176°F

(-40 to 80°C).

Power Requirements: 10-35 VDC for 4-20 mA or 0-5 VDC output; 15-35 VDC for

0-10 VDC output; 10-29 VAC for 0-5 VDC output; 15-29 VAC for 0-10 VDC output.

Response Time: 8 s (

Electrical Connections: Screw terminal block.

Drift: <0.25% RH/year.

Enclosure Material: Polycarbonate.

Weight: 4.4 oz (125 g).

Agency Approvals: CE.

t63).

31/64

[12.32]

[14.02]

3-1/64

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219-879-8000

Fax: 219-872-9057

www.dwyer-inst.com

e-mail: info@dwyermail.com

Page 2

INSTALLATION

Disconnect power supply before installation to prevent electrical

WARNING

Make sure all connections are in accordance with the job wiring diagram and in

accordance with national and local electrical codes. Use copper conductors only.

CAUTION

CAUTION

designed for AC voltage operation.

NOTICE

MOUNTING

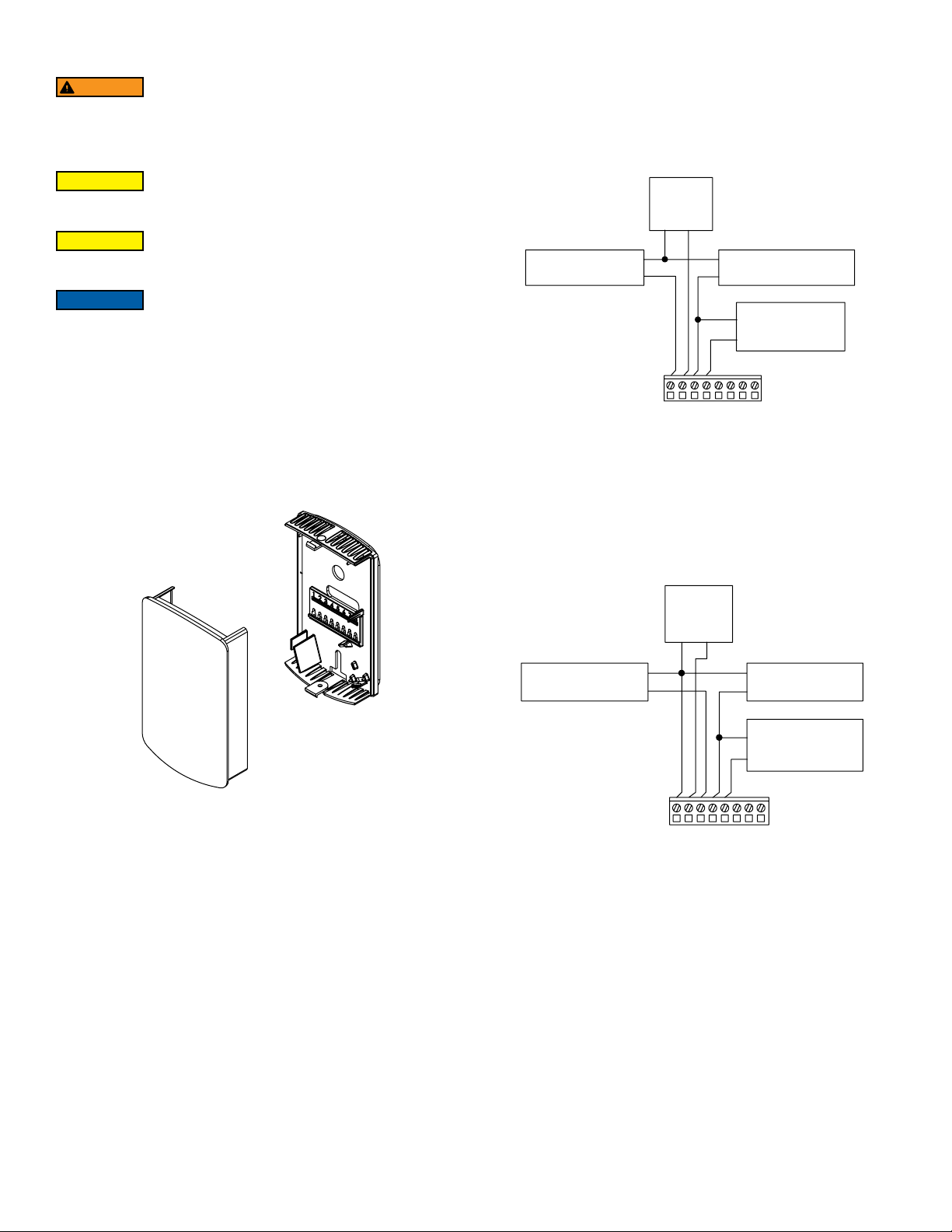

1. Push tab on top and bottom of cover and lift cover from back plate (See Figure 1).

2. Select the mounting location, away from diffusers, lights, or any external

inuences.

3. Mount transmitter on a vertical surface to a standard electrical box using the two

#6

4. M2C type screws provided.

5. Pull wires through sub base hole and make necessary connections.

6. Reattach cover to base plate

shock and equipment damage

Use electrostatic discharge precautions (e.g., use of wrist straps)

during installation and wiring to prevent equipment damage.

Do not exceed ratings of this device, permanent damage not

covered by warranty may result. The 4-20 mA models are not

Avoid locations where severe shock or vibration, excessive

moisture, or corrosive fumes are present.

Wiring

Use a minimum of 22 AWG to maximum 18 AWG wire for wiring to terminals. Refer to

Figures 2 and 3 for wiring information.

Current Output Models: Wire as shown in Figure 2. Current outputs must be powered

with 10-35 VDC. If the RH output is not required, wire the negative terminal of the

power supply to terminal 1 of the transmitter. If the unit has a passive temperature

sensor, wire to terminals 3 and 4.

POWER

SUPPLY

-

+

RH RECEIVER

4-20 mA

Voltage Output Models: Voltage outputs may be powered with 10-35 VDC (0-5 V

models), 15-35 VDC (0-10 V models) or 10-29 VAC (0-5 V modes), 15-29 VAC (0-10

V models). Note polarity when using DC power. Wire the RH voltage output as shown

in Figure 3. If the unit has a voltage temperature output, wire the temperature receiver

between terminal 4 and the negative terminal of the power supply. If the temperature

or RH voltage output is not used it may be left disconnected. If the unit has a passive

temperature sensor, wire to terminals 4 and 5.

-

+

1 2 3

Figure 2: Current output wiring

TEMP RECEIVER

4-20 mA

+

4 5 6 7 8

PASSIVE TEMP.

SENSOR

(IF PRESENT)

Figure 1: Removal of cover from back plate

RH RECEIVER

POWER

SUPPLY

-+

-

+

1 2 3 4 5 6 7 8

Figure 3: Voltage output wiring

-

+

TEMP

RECEIVER

PASSIVE TEMP.

SENSOR

(IF PRESENT)

Page 3

TROUBLESHOOTING

1. Verify that the unit is mounted in the correct position.

2. 4-20 mA Models:

Verify appropriate supply voltage. The transmitter requires a minimum of 10 and a

maximum of 35 VDC at its connections for proper operation. Choose a power supply

with a voltage and current rating which meets this requirement under all operating

conditions. If the power supply is unregulated, make sure voltage remains within these

limits under all power line conditions. Ripple on the supply should not exceed 100mV.

Loop Resistance – The maximum allowable loop resistance depends on the power

supply voltage. Maximum loop voltage drop must not reduce the transmitter voltage

below the 10 VDC minimum. Maximum loop resistance can be calculated with the

following equation. Vps is the power supply voltage.

-10.0

ps

Rmax =

V

20 mA

Some receivers, particularly loop powered indicators, may maintain a xed loop

voltage to power the device. This voltage drop must also be subtracted from the power

supply voltage when calculating the voltage margin for the transmitter. The following

equation takes this into account. Vrec is the receiver xed voltage.

-10.0-V

V

ps

Rmax =

rec

20 mA

Voltage Output Models:

Verify appropriate supply voltage. The voltage output models require a 10-35 VDC (0-5

V models), 15-35 VDC (0-10 V models) or 10-29 VAC (0-5 V modes), 15-29 VAC (0-10

V models) for proper operation maximum. Maximum output load is 5 mA.

MAINTENANCE/REPAIR

Upon nal installation of the Series RHPLC, no routine maintenance is required. The

Series CDWP is not eld serviceable and is not possible to repair the unit. Field repair

should not be attempted and may void warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sale” in our catalog and on our website. Contact

customer service to receive a Return Goods Authorization number before shipping the

product back for repair. Be sure to include a brief description of the problem plus any

additional application notes.

RESISTANCE VS TEMPERATURE TABLE

Temperature Resistance Curves (in Ohms)

°C °F A B C D E F

-55

-67.0

-50

-45

-40

-35

-30

-25

-20

-15

-10

-5

0

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

105

110

115

120

125

130

135

140

145

150

-58.0

-49.0

-40.0

-31.0

-22.0

-13.0

-4.0

5.0

14.0

23.0

32.0

41.0

50.0

59.0

68.0

77.0

86.0

95.0

104.0

113.0

122.0

131.0

140.0

149.0

158.0

167.0

176.0

185.0

194.0

203.0

212.0

221.0

230.0

239.0

248.0

257.0

266.0

275.0

284.0

293.0

302.0

607800.00

441200.00

323600.00

239700.00

179200.00

135200.00

102900.00

78910.00

61020.00

47540.00

37310.00

29490.00

23460.00

18780.00

15130.00

12260.00

10000.00

8194.00

6752.00

5592.00

4655.00

3893.00

3271.00

2760.00

2339.00

1990.00

1700.00

1458.00

1255.00

1084.00

939.30

816.80

712.60

623.60

547.30

481.80

425.30

376.40

334.00

297.20

265.10

237.00

963849.00

670166.00

471985.00

336479.00

242681.00

176974.00

130421.00

97081.00

72957.00

55329.00

42327.00

32650.00

25392.00

19901.00

15712.00

12493.00

10000.00

8057.00

6531.00

5326.00

4368.00

3602.00

2986.00

2488.00

2083.00

1752.00

1480.00

1255.00

1070.00

915.50

786.60

678.60

587.60

510.60

445.30

389.60

341.90

301.00

265.80

235.30

208.90

186.10

289154.70

201049.80

141595.50

100943.70

72804.30

53092.20

39126.30

29124.30

21887.10

16598.70

12698.10

9795.00

7617.60

5970.30

4713.60

3747.90

3000.00

2417.10

1959.30

1597.80

1310.40

1080.60

895.80

746.40

624.90

525.60

444.00

376.50

321.00

274.65

235.98

203.58

176.28

153.18

133.59

116.88

102.57

90.30

79.74

70.59

62.67

55.83

78.32

80.31

82.29

84.27

86.25

88.22

90.19

92.16

94.12

96.09

98.04

100.00

101.95

103.90

105.85

107.79

109.74

111.67

113.61

115.54

117.47

119.40

121.32

123.24

125.16

127.08

128.99

130.90

132.80

134.71

136.61

138.51

140.40

142.29

144.18

146.07

147.95

149.83

151.71

153.58

155.46

157.33

783.2

803.1

822.9

842.7

862.5

882.2

901.9

921.6

941.2

960.9

980.4

1000.0

1019.5

1039.0

1058.5

1077.9

1097.4

1116.7

1136.1

1155.4

1174.7

1194.0

1213.2

1232.4

1251.6

1270.8

1289.9

1309.0

1328.0

1347.1

1366.1

1385.1

1404.0

1422.9

1441.8

1460.7

1479.5

1498.3

1517.1

1535.8

1554.6

1573.3

2394000.00

1646200.00

1145800.00

806800.00

574400.00

413400.00

300400.00

220600.00

163500.00

122280.00

92240.00

70160.00

53780.00

41560.00

32340.00

25360.00

20000.00

15892.00

12704.00

10216.00

8264.00

6722.00

5498.00

4520.00

3734.00

3100.00

2586.00

2166.00

1822.60

1540.00

1306.40

1112.60

951.00

815.80

702.20

606.40

525.60

N/A

N/A

N/A

N/A

N/A

Page 4

NOTES

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

Printed in U.S.A. 9/21 FR# 443637-50 Rev. 1©Copyright 2021 Dwyer Instruments, Inc.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219-879-8000

Fax: 219-872-9057

www.dwyer-inst.com

e-mail: info@dwyermail.com

Loading...

Loading...