Page 1

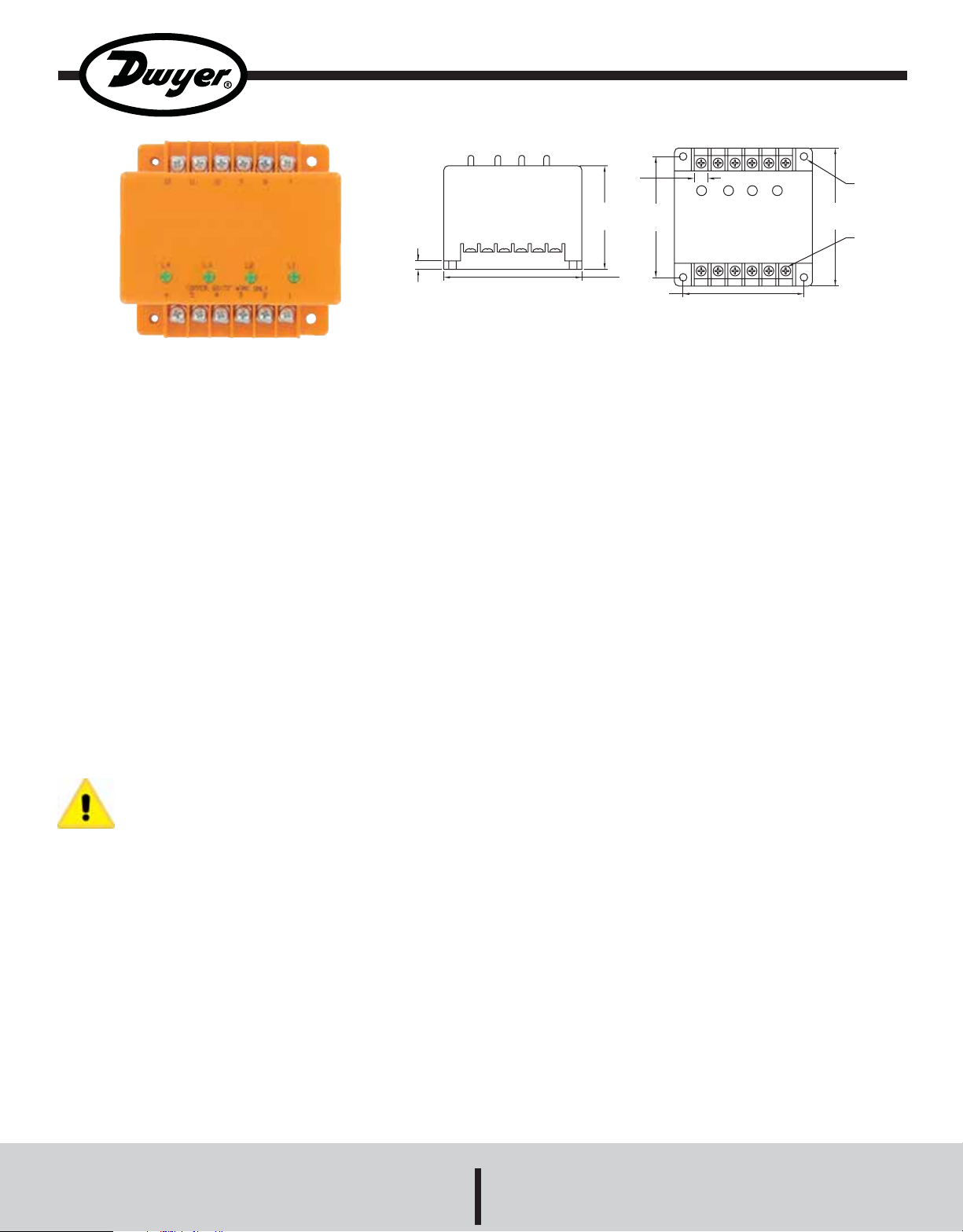

Series QPC Quadraplex Pump Controller

Specifications - Installation and Operating Instructions

Bulletin L-41

1/4

(6.35)

The Series QPC is used where four pumps are required to

alternate to provide equal run time on each. Alternating loads

allows for equal wear on all pumps lengthening their operation life.

The Series QPC has five inputs allowing the four outputs to

operate properly even if one of the inputs fails to open or close.

Four LED indicators show the load that is energized by the SPST

output contacts. The QPC is available in two sequence

configurations: sequence-on-simultaneous-off (SOSO) and firston-first-off (FOFO). In the SOSO sequence, an additional load is

energized each time a higher level switch is activated, and all loads

are de-energized simultaneously when the lowest level switch

deactivates. In the FOFO sequence, the loads are energized in the

same manner as the SOSO sequence, but loads are de-energized

individually as each level switch deactivates. In either sequence,

the lead load position is advanced to equalize run time on each

pump. An inrush delay on both models reduces line sags by

preventing multiple loads from energizing simultaneously. See the

next page for more details on SOSO and FOFO sequencing.

Important: Read the following carefully and completely before

installing or connecting QPC units.

Note: DO NOT exceed specified electrical rating. Doing so may

result in damage to control unit and load device.

3

(76.20)

(101.6)

3/8

(9.53)

4

3-1/4

(82.55)

3-1/4

(82.55)

4

(101.6)

Ø7/32

(5.56)

#8-32

SPECIFICATIONS

Power Requirement: 120 VAC, 50/60 Hz.

Power Consumption: 2.5 VA (approximate).

Sensitivity: 100 k ohm.

Isolation Voltage: 2500 V (input to output).

Temperature Limits:

Operating: -4 to 131°F (-20 to 55°C);

Storage: -40 to 185°F (-40 to 85°C).

Switch Type: SPST.

Switch Voltage: 5.1 V open circuit.

Switching Current: 10 µA, short circuit.

Electrical Rating: 5 A @ 120 VAC resistive; 278 VA inductive.

Response Times:

Power Up: <1 s;

Operate: <25 ms;

Inrush: 5 s;

Release: <150 ms.

Indicators: (4) LED’s show active output relay.

Enclosure: Polycarbonate dust cover.

Mounting: Surface.

Weight: 16 oz (454 g).

Agency Approvals: Intrinsically safe to UL standard 913. For

use in hazardous (classified) locations: Class I, Group A, B, C, D;

Class II, Group E, F, G; Class III.

WARNING: To prevent ignition in hazardous locations,

disconnect before servicing.

INSTALLATION

1.Lock out all electrical current to relevant control panel during

installation.

2.Fasten the surface mount QPC unit in the control panel.

3.Make the appropriate connections as shown in the wiring

diagram (Figure A) to the corresponding numbered contacts on

the QPC unit. For use in hazardous location, refer to control

drawing 194 in Figure B.

4. Resume power to control panel and monitor system for proper

functionality.

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

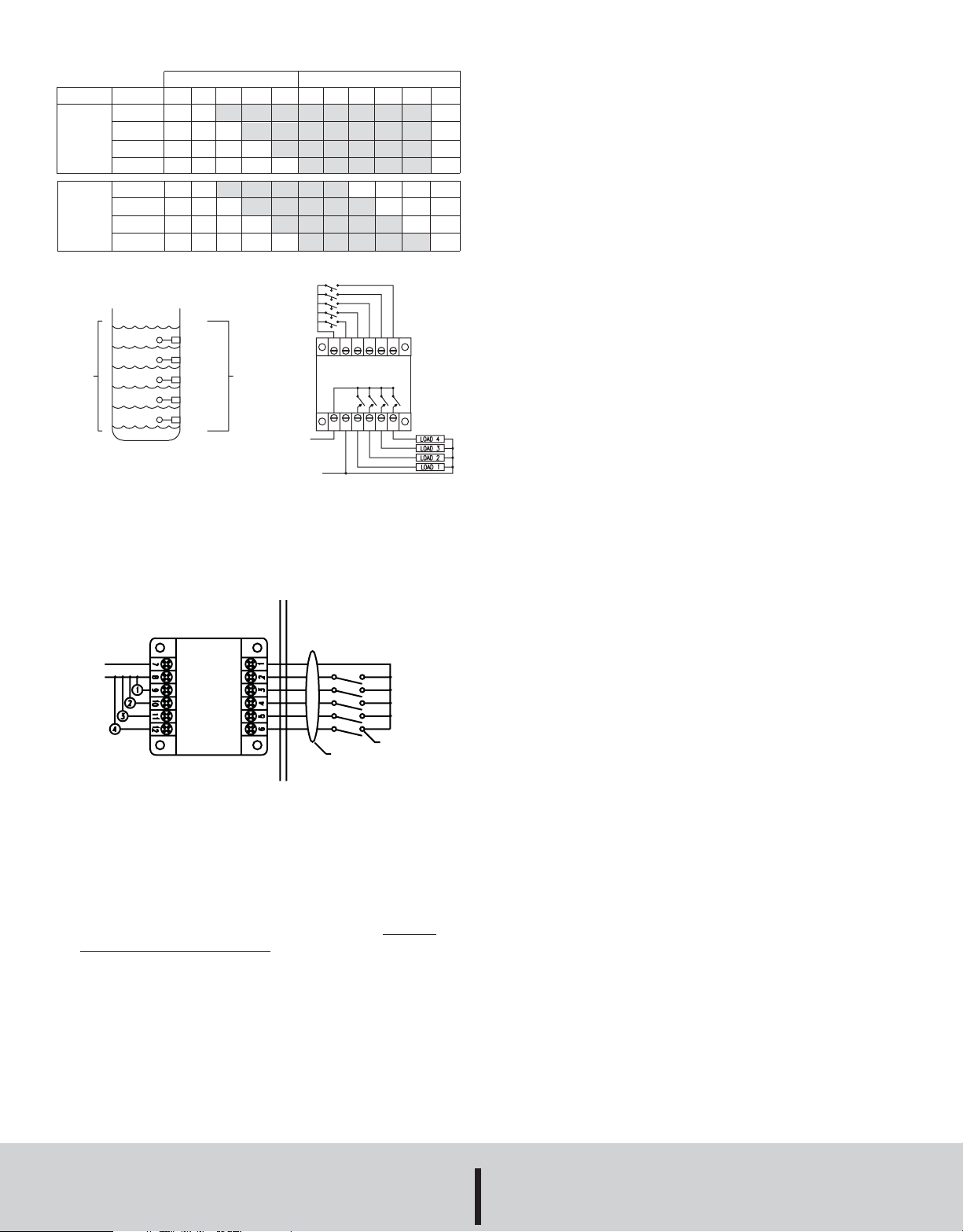

EXCITATION TABLE

Increasing Level Decreasing Level

ABCDEFEDCB A

Load 1 Off Off On On On On On On On On Off

SOSO Load 2 OffOffOffOnOnOnOnOnOnOn Off

Outputs Load 3 Off Off Off Off On On On On On On Off

Load 4 Off Off Off Off Off On On On On On Off

Load 1 Off Off On On On On On Off Off Off Off

FOFO Load 2 OffOffOffOnOnOnOnOnOffOff Off

Outputs Load 3 Off Off Off Off On On On On On Off Off

Load 4 Off Off Off Off Off On On On On On Off

3RD LAG

2ND LAG

1ST LAG

LEAD

OFF

123456

7 8 9 10 11 12

HOT

NEUTRAL

WATER

LEVEL

F

E

D

C

B

A

3RD LAG

2ND LAG

1ST LAG

LEAD

OFF

INPUT

LEVEL

SWITCH

Figure A

SEQUENCING DESCRIPTION

SOSO - As the 3rd lag, 2nd lag, lag and lead switches open, the

loads remain energized. When the off switch opens, all four loads

de-energize simultaneously. If any switch fails to open, the loads

still de-energize when the off switch opens. The lead advances

one position each time the loads de-energize.

FOFO - When the 3rd lag switch opens, all four loads remain

energized. The 2nd lag switch opens next, and the lead load deenergizes. When the lag switch opens, the lag load de-energizes.

Next, the lead switch opens and the 2nd lag load de-energizes.

Finally, the off switch opens and the 3rd lag load de-energizes. At

the end of each cycle, the lead advances one position for each

load energized during the cycle. For example: if loads one and two

cycle on and off, the lead will advance two positions. Load three

will be the lead load for the next cycle.

MAINTENANCE

Upon final installation of the Series QPC Quadraplex Pump

Controller, no routine maintenance is required. A periodic check of

the system calibration is recommended. The Series QPC is not

field serviceable and should be returned if repair is needed (field

repair should not be attempted and may void warranty). Be sure

to include a brief description of the problem plus any relevant

application notes. Contact customer service to receive a return

goods authorization number before shipping.

CONTROL DRAWING 194

HAZARDOUS LOCATION

CLASS I, GROUPS A, B, C, D; CLASS II,

GROUPS E, F, G, ; CLASS III

OFF

LEAD

LAG

2nd LAG

3rd LAG

INTRINSICALLY SAFE WIRING

SEE NOTES 1 AND 2

SWITCH CONTACT SEE NOTE 3

CONTROL

VOLTAGE

LOADS

NON-HAZARDOUS LOCATION

HOT

NEUTRAL

Figure B

NOTES:

1. Maximum distance between unit and switch is 1000 feet.

2. All intrinsically safe wiring shall be separated from nonintrinsically safe wiring. Refer to article 504 of the National

Electrical Code ANSI/ NFPA 70 for installation of intrinsically

safe wiring.

3. Switch contact shall be any non-energy strong or generating

mechanical switch type device containing no capacitance or

inductance.

©Copyright 2007 Dwyer Instruments, Inc. Printed in U.S.A.12/07 FR# R3-443592-01 Rev. 1

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...