Page 1

SERIES PWD

PULSE DIVIDER

INSTRUCTIONS

F-PWD

Page 2

GENERAL INFORMATION & SPECIFICATIONS

Designed for use as a meter accessory, the PWD divider is used

primarily for pacing electronic metering pumps. Any number

from one to 9999 can be set on rotary switches. Each time the

divider has received the set number of pulses from the meter,

it puts out one pulse to stroke the pump. The PWD is also

useful in boiler and cooling tower feed and bleed operations,

and for lowering frequency output of high frequency meters.

Compatible with all Dwyer Instruments Inc. pulse output ow

meters, the PWD creates a programmable pulse meter with

an easily adjustable pulse rate.

The PWD comes in two different housings: an enclosure that

can be mounted near the pump, and a watertight housing for

mounting on the meter.

INSTALLATION & CONNECTIONS

MOUNTING

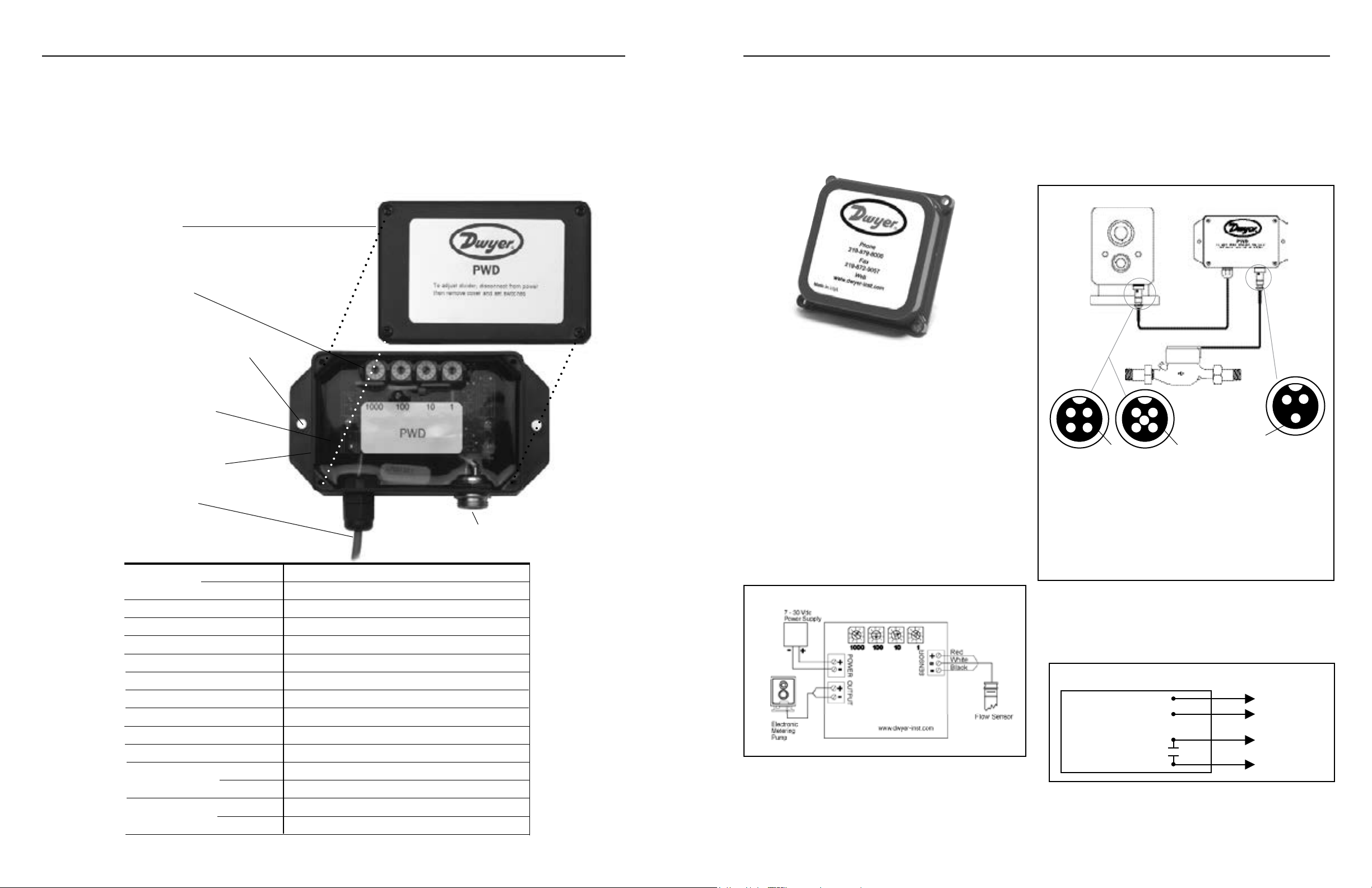

The PWD-M is factory-mounted on the ow sensor. The PWD-

W is mounted by attaching it to the metering pump with the

included double-backed, pressure-sensitive tape. Alternatively,

the control can be wall mounted with screws using the mounting brackets that extend out either side.

PWD-W/LMI PUMP

The 24" pigtail that extends from the PWD-W connects to an

LMI metering pump and is connected as shown.

The input connector on the control mates with any three-pin

Dwyer® connector. (Dwyer® Meters or ow sensors to be used

with a PWD-W should be ordered with Dwyer® connectors.)

PD10W/LMI Pump

FEATURES

SPECIFICATIONS*

Page 2

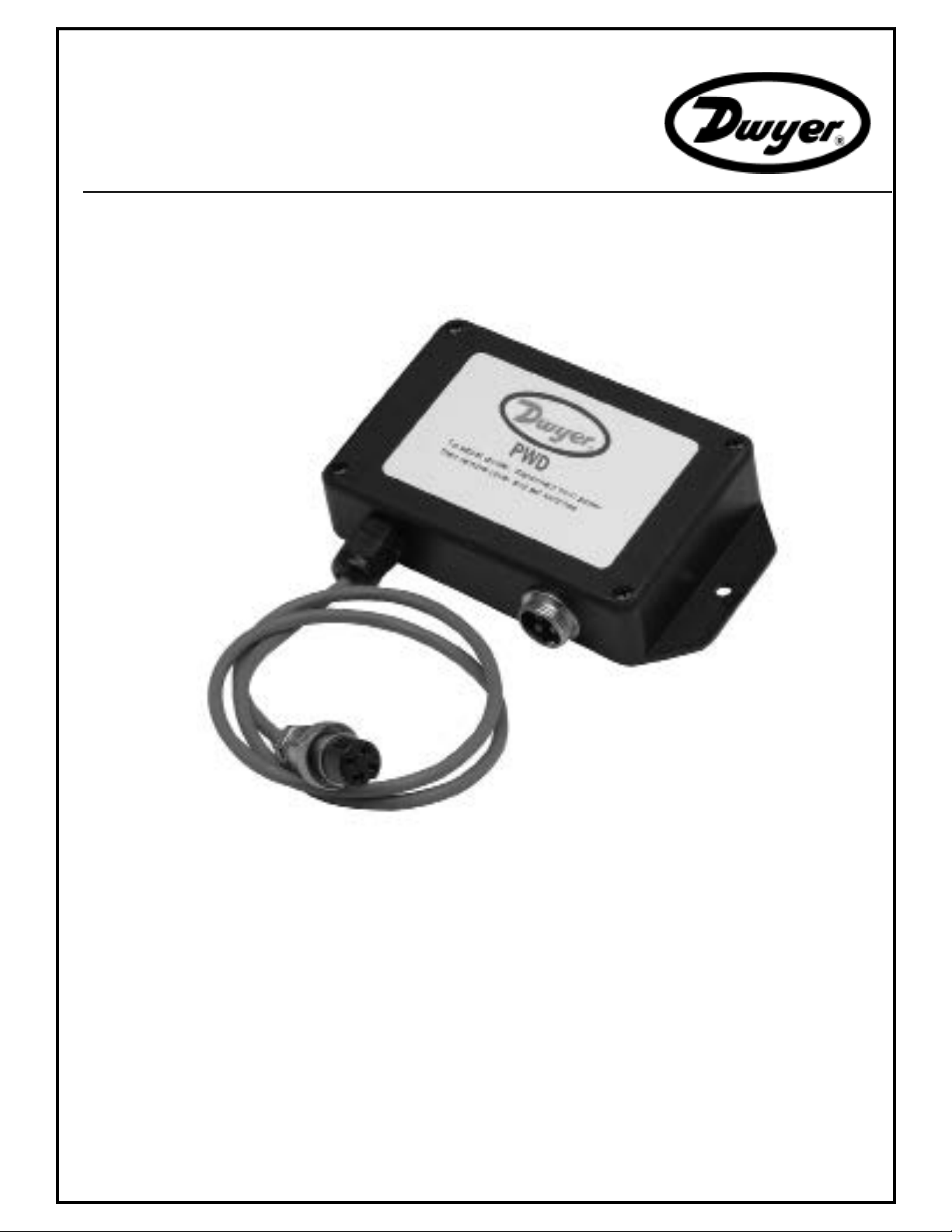

Protective cover

Rotary Switches (4)

Mounting Holes:

(Double-backed pressure-sensitive

tape also supplied standard)

Potted for environmental

protection

Wall (Pump) housing shown

(Meter mount also available)

To leads or metering

pump connector

Enclosure Wall (Pump) Mount

Meter Mount

Temperature

Divider Range

Setting Mechanism

Power

Maximum Sensor Load

Maximum Input Frequency

Maximum Output Frequency

Output

Output Pulse Width

Input Connection Wall Mount

Meter Mount

Output Connection Wall Mount

Meter Mount

*Specications subject to change

Epoxy-encapsulated ABS housing with cover

Cast aluminum sealed housing

0 to 130˚F (-18 to 55˚C)

1 to 9999

Rotary switches

7 to 30 Vdc @ 4 mA

20 mA

350 Hz (pulses/second)

8 Hz (pulses/second)

Solid state relay; 0 to 250 V, 170 mA max AC/DC

0.1 second

Dwyer connector

Terminal

Pump connector on 24" lead

Comes with 18' lead

Input connector for meter

PWD-M meter mounted version

POWER SOURCE

Power for the PWD can be supplied by the metering pump if

the pump has a sensor power supply. Some pumps require

an external power supply, available from Dwyer Instruments

Inc. LMI pump and Dwyer® connectors are available.

CAUTION:

Power supplies 18 Vdc and higher must be regulated to

prevent damage to the PWD caused by voltages exceeding

its 30 V allowable maximum supply voltage due to AC line

variations and light loading.

CONNECTIONS

The PWD-M can be connected as shown.

PWD-M

PWD-M

Dwyer® is a registered trademark of Dwyer Instruments Inc.

LMI Pump

LMI Connector

(supplied with

PWD-W)

1

4

2

3

Sockets

Meter

2

1

5

3

4

Sockets

Sockets

PWD

Dwyer®

Sensor

Connector

(order with

ow meter)

3

1

2

-PC4 Option -PC5 Option

1. Auxiliary Power Source

2. Pulse Input

3. Ground

4. No Connection

1. Remote On

2. Ground

3. Pulse Input

4. Aux. Power Source

5. Not Used

1. Ground

2. Input Signal

3. Sensor Power

+7-30 Vdc*

*CAUTION: If power is supplied to the ow sensor from the

PWD, ensure that the voltage supplied to the sensor does not

exceed the sensor's allowable maximum input voltage.

PWD-W/NONLMI PUMP

If a metering pump is used that requires a connection other

than the LMI connector supplied, cut the LMI connector off.

Connect the PWD-W to the pump using the diagram below in

conjunction with the wiring diagram in the pump manual.

PWD-W/Non-LMI Pump

Red

Black

Green

White

7-30 Vdc

Ground

Signal +

Common

PWD

POWER

OUTPUT

+

–

+

–

The input connector on the control mates with any three-pin

Dwyer® connector. (Dwyer® Meters or ow sensors to be used

with a PWD-W should be ordered with Dwyer® connector.)

Page 3

Page 3

SETTING

WARRANTY/RETURN

The four numbered rotary switches marked "1000", "100",

"10", and "1" control the ratio of meter pulses to pump

strokes. Before setting the switches, disconnect power

to the unit by removing the connector from the pump or

unplugging the power adapter.

To set any four-digit number, rotate the dials to the appropri-

ate numbers. For example, to set 1521, set the four switches

to "1", "5", "2", and "1". Any unused switches should be set to

zero. For example, to set 8, position the dials to "0", "0", "0",

"8". See samples below.

Setting Examples

TROUBLESHOOTING

Problem

Metering pump not stroking Meter dials not turning Check visually, then check for

adequate ow

Probable Cause

Try...

Refer to "Terms and Conditions of Sale" in our catalog or on

our website. Contact customer service to receive a Returns

Goods Authorization number before shipping your product

back for repair. Be sure to include a brief description of the

problem plus any relevant applciation notes.

Meter pickup not working Remove from meter, check with a

magnet

Pump connector not plugged in all the way Check or tighten threaded locking

ring (LMI)

Pump doesn’t supply power to the PWD Check pump manual, add power

supply

PWD set to large number or all zeroes Check rotary switches, esp. for

leading zeroes

Pump strokes continually Pump not set for external pacing Check pump manual and selector

switch

Pump doesn’t stroke often enough PWD set for wrong number Review setting on this page, check

or too often rotary switches

Multiple contacts from meter Set PWD to 1 contact/pump stroke

(0001) and see if the pump strokes

once for each magnet revolution

Meter ordered with wrong pulse rate Check meter model/serial tag

Page 4

Page 5

Dwyer Instruments, Inc. • 102 Indiana Highway 212 • Michigan City, IN 46360 • USA

(P) 219.879.8868 • (F) 219.872.9057 • 1.800.872.9141 • www.dwyer-inst.com

PL-OM-65200393-082012

8/20/12

Loading...

Loading...