Page 1

Instruction Manual

PORTABLE TYPE

ULTRASONIC FLOWMETER

TYPE: CONVERTER PUX

DETECTOR PSX2

Dwyer Instruments, Inc.

Bulletin F-68

Page 2

BULLETIN F-68

PREFACE

You are now a proud owner of Dwyer Instruments ultrasonic flowmeter (Model PUX).

This manual explains cautions in use, wiring, operation, installation, troubleshooting, maintenance, and options

of the portable type ultrasonic flowmeter. Please read through the manual before using the instrument.

Keep this manual in a convenient location for future reference.

Manufacturer : Dwyer Instruments, Inc.

Type : Described on nameplate on main frame

Date of manufacture : Described on nameplate on main frame

Product nationality : Japan

Request

• Copy of contents of this manual in part or whole is not authorized

without permission.

• Contents of the manual are subject to change without prior notice.

© Dwyer Instruments, Inc.

Issued in June 2007

i

Page 3

CONTENTS

BULLETIN F-68

1. OVERVIEW.......................................................................................................................1 - 1

2. CHECK OF DELIVERED ITEMS ...................................................................................2 - 1

2.1 On purchase of converter .........................................................................................2 - 1

2.2 On purchase of detector ...........................................................................................2 - 2

3. NAME AND EXPLANATION OF EACH PART................................................................3 - 1

3.1 Name and explanation of main unit and sensor........................................................3 - 1

3.2 Explanation of keys ..................................................................................................3 - 2

4. POWER UP ..........................................................................................................................4 - 1

4.1 Operating power supply............................................................................................ 4 - 1

4.2 Turning on power supply..........................................................................................4 - 2

5. WIRING ............................................................................................................................... 5 - 1

5.1 Connection of dedicated cables ................................................................................5 - 1

5.2 Connection of analog input/output cable..................................................................5 - 1

5.3 Connection of RS-232C cable ..................................................................................5 - 2

6. INPUT OF PIPING SPECIFICATIONS ...........................................................................6 - 1

6.1 Display of pipe setup screen.....................................................................................6 - 1

6.2 Entry of site name (measurement is possible without entry).................................... 6 - 3

6.3 Outer diameter of piping (unit: mm) (range: 13 to 6000 mm) .................................6 - 4

6.4 Piping material..........................................................................................................6 - 5

6.5 Wall thickness (unit: mm).........................................................................................6 - 6

6.6 Lining material ......................................................................................................... 6 - 7

6.7 Lining thickness (unit: mm) (range: 0.01 to 100.00 mm) ........................................ 6 - 8

6.8 Kind of fluid .............................................................................................................6 - 9

6.9 Selection of sensor mounting method .................................................................... 6 - 10

6.10 Kind of sensor.........................................................................................................6 - 11

6.11 Transmission voltage (used when an indicator is 1 or less during

measurement)..........................................................................................................6 - 12

7. MOUNTING OF DETECTOR ............................................................................................7 - 1

7.1 Selection of mounting location.................................................................................7 - 1

7.2 Selection of mounting method..................................................................................7 - 3

7.3 Treatment of detector mounting face........................................................................7 - 4

7.4 How to mount small size (standard) sensor and small outer diameter

7.5 How to mount large size sensor................................................................................7 - 6

ii

sensor to pipe ............................................................................................................7 - 5

7.5.1 How to determine mounting position (large sensor) ................................................ 7 - 6

7.5.2 How to connect large size sensor.............................................................................. 7 - 7

7.5.3 How to mount large size sensor to pipe.................................................................... 7 - 8

Page 4

7.6 How to mount high temperature sensor to pipe........................................................7 - 9

BULLETIN F-68

7.7 How to mount medium diameter sensor to pipe.....................................................7 - 10

7.8 How to fold gauge paper (used for determining mounting position) .....................7 - 10

8. MEASUREMENT .............................................................................................................8 - 1

9. SETTING OPERATION (APPLICATION) ......................................................................9 - 1

9.1 How to use SITE SETUP function (SITE SETUP page) ......................................... 9 - 2

9.1.1 PARAMETER MEMORY: when registering data which are set and

calibrated on the page .............................................................................................. 9 - 2

9.1.2 ZERO ADJUST: when performing zero adjustment............................................... 9 - 3

9.1.3 RESPONSE SET: when changing output response.................................................9 - 3

9.1.4 OUTPUT CORRECTION: when calibrating measured value

(output calibration function) ..................................................................................... 9 - 4

9.1.5 CUT OFF: output cut off at low flow rate (low flow cutoff function) ..................... 9 - 5

9.1.6 TOTALIZE: when performing the integration process of measured data

(totalize)................................................................................................. 9 - 6

9.2 Setting of logging function (data logger page).........................................................9 - 7

(1) SETUP: when setting logging of measured data....................................................... 9 - 8

(2) GRAPH: when checking logged data on screen ...................................................... 9 - 11

(3) PRINT: when printing logged data in text ...............................................................9 - 13

(4) DELETE: when deleting logged data ......................................................................9 - 14

(5) START: when starting logging

[logging starts by conditions set in (1), “SETUP”] .................................................9 - 14

9.3 Setting of system (page title: SYSTEM SETUP)...................................................9 - 15

9.3.1 CLOCK SET: when setting the clock (set the present time) ................................. 9 - 15

9.3.2 COMMUNICATION: when setting serial communication

(data communication to personal computer) .......................................................... 9 - 15

9.3.3 SYSTEM OF UNITS: when setting the measurement and setting

unit system [selection of meter system and inch system]....................................... 9 - 16

9.3.4 MEASUREMENT METHOD: when changing measurement method .................. 9 - 17

9.3.5 MEMORY INITIALIZE: all setting parameters and logger data are initialized. ... 9 - 17

9.4 Setting of analog input/output (analog page) .........................................................9 - 18

9.4.1 Setting of analog input............................................................................................ 9 - 18

9.4.2 Setting of analog output.......................................................................................... 9 - 20

9.5 Use of printer function (printer page).....................................................................9 - 23

9.5.1 Selection of mode ................................................................................................... 9 - 23

9.5.2 Selection of items to print....................................................................................... 9 - 24

9.5.3 Setting of print time ................................................................................................ 9 - 27

9.5.4 To set printing intervals .......................................................................................... 9 - 31

9.5.5 To set graph scale in graph mode ...........................................................................9 - 31

9.5.6 Printing ...................................................................................................................9 - 32

9.5.7 Printing stop............................................................................................................ 9 - 32

iii

Page 5

9.6 System check function (system check page) ..........................................................9 - 33

BULLETIN F-68

9.6.1 ERROR CHECK .................................................................................................... 9 - 33

9.6.2 SIGNAL CHECK ................................................................................................... 9 - 35

9.6.3 OUTPUT CHECK .................................................................................................. 9 - 38

9.6.4 VERSION NO. ....................................................................................................... 9 - 38

10. MAINTENANCE AND CHECKUP................................................................................ 10 - 1

11. ERROR AND HANDLING .............................................................................................11 - 1

11.1 Error in LCD display .............................................................................................. 11 - 1

11.2 Error of key.............................................................................................................11 - 1

11.3 Error in measured value..........................................................................................11 - 2

11.4 Error in analog output.............................................................................................11 - 5

11.5 Display of error.......................................................................................................11 - 5

12. SPECIFICATIONS FOR SERIAL TRANSMISSION (RS-232C) ..................................12 - 1

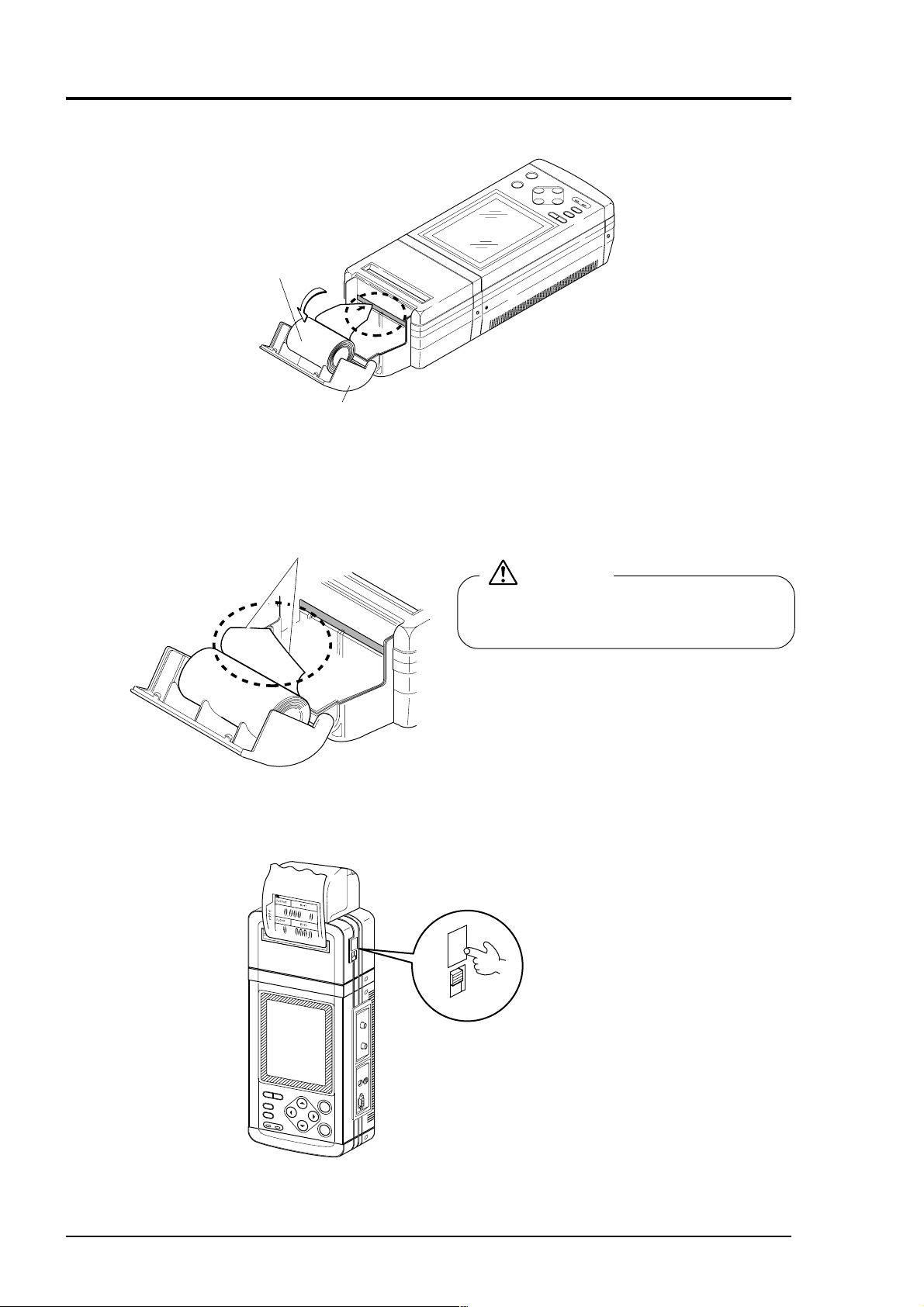

13. HOW TO USE PRINTER ................................................................................................13 - 1

13.1 How to connect printer ...........................................................................................13 - 1

13.2 How to load printer roll sheet .................................................................................13 - 2

14. REPLACEMENT OF BUILT-IN BATTERY...................................................................14 - 1

15. APPENDIX.......................................................................................................................15 - 1

15.1 Piping data .............................................................................................................. 15 - 1

15.2 Command tree ........................................................................................................15 - 7

15.3 Specifications..........................................................................................................15 - 8

15.4 Q & A ...................................................................................................................15 - 10

iv

Page 6

WARNING SYMBOLS AND THEIR MEANINGS

BULLETIN F-68

Be sure to observe the following precautions. They offer important information on safety.

• The degree of injuries or damages resulting from improper handling of this device is indicated

by different symbols.

Symbol

Improper handling of this device may cause dangerous

CAUTION

• The following symbols describe items to be observed.

Symbol

The symbol indicates “prohibition”.

Meaning

situations that result in personal injury or property

damage.

Symbol

Meaning

Meaning

Do not modify this device.

The symbol indicates “mandatory” action to be taken.

The symbol provokes “cautions”.

Be sure to pull out the plug.

Be careful. It may result in fire.

v

Page 7

SAFETY PRECAUTIONS

BULLETIN F-68

Be sure to read this “Safety Precautions” carefully beforehand for the correct and safe use of this

device.

WARNING

Do not touch the switch

Do not break or pull the power cord.

with a wet hand.

Do not touch the switch with a

wet hand. Otherwise it may

result in electric shock.

Prohibition Prohibition

Do not modify.

Do not modify this device.

Otherwise it may result in an

accident.

Modification

is prohibited.

Do not use electric parts soaked

Prohibition

Pull out the plug immediately

Do not repair.

in case of an emergency

Do not put heavy things on the

power cord. Do not modify or

pull the power cord.

Otherwise it may break and

result in electric shock and fire.

in water

Replace electric parts or wires

soaked in water due to floods or

some other reasons with new

ones. Otherwise it may result in

electric shock or fire.

Repair should be made only by

authorized servicepersons. Ask

your dealer for the repair.

Improper repair work may result

in electric shock, fire, or injury.

Pull out

the plug

In case abnormal odor, smoke or

fire is perceived, pull the power

plug immediately. Ask an

authorized serviceperson or your

dealer for repair.

Otherwise it may result in electric

shock or fire.

vi

Page 8

CAUTION

BULLETIN F-68

Keep warning labels clean.

Clean or replace the warning

labels so that they can always be

read correctly.

Otherwise it may result in an

accident.

Ask an authorized waste disposal

specialist for disposal.

Do not dispose the device

without proper authorization.

Otherwise it may cause

environmental pollution or result

in an accident.

Do not splash water.

Inspect the power plug periodically.

Inspect the power plug once

every 6 months. Wipe the dust

off the plug and insert it securely.

Otherwise it may result in electric

shock or fire.

Match power capacity

with the device ratings.

Be sure to connect the device to

the power with sufficient

allowable voltage and current.

Fire hazard

Otherwise it may result in fire.

Use an exclusive power adapter

and built-in battery

Do not wash or splash water on

the electrical parts inside the

device.

Prohibition

Otherwise it may result in electric

shock.

Be careful when carrying the device

When carrying the device,

exercise care to avoid physical

shock or vibration.

Otherwise it may cause failure.

Prohibition

favorable environment.

Do not use a power adapter or

built-in battery that is not

exclusive to the main unit.

Otherwise it may break and

cause failure.

Use the device in

Do not use the device in an

environment subjected to dust

or corrosive gases.

Otherwise it may cause failure.

vii

Page 9

1. OVERVIEW

BULLETIN F-68

This is a portable type ultrasonic flowmeter that allows easy measurement of flow rates in pipes

by installing a sensor on the outside of pipes.

A combination of the latest electronics and digital signal process technologies makes this instrument compact,

designed for improvement of performance and easy operation.

1 - 1

Page 10

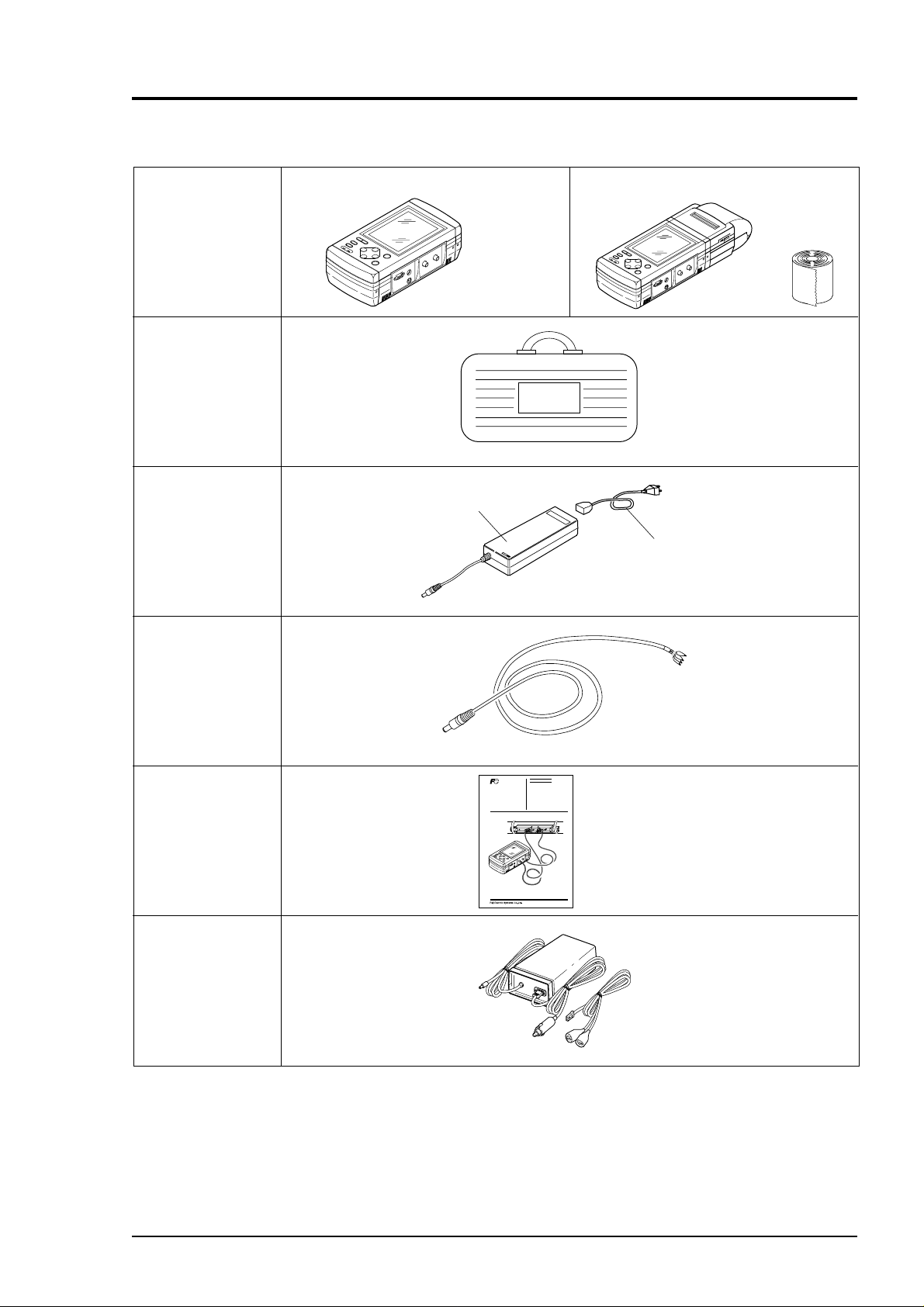

2. CHECK OF DELIVERED ITEMS

BULLETIN F-68

2.1 On purchase of converter (type: PUX)

Without printer With printer

Conversion unit

Carrying case

DWYER INSTRUMENTS, INC.

D

E

E

N

F

O

F

F

O

Roll paper

AC power supply

adapter

Power cord

Analog input/output

cord

Instruction manual

(BULLETIN F-68)

()

AC power supply adapter

Dwyer Instruments, Inc.

Instruction Manual

PORTABLE TYPE

ULTRASONIC FLOWMETER

TYPE: CONVERTERPUX

DETECTOR

PSX2

Power cord

Bulletin F-68

(option)

DC power supply

adapter

D

C

O

U

T

P

U

T

D

C

I

N

P

U

T

2 - 1

Page 11

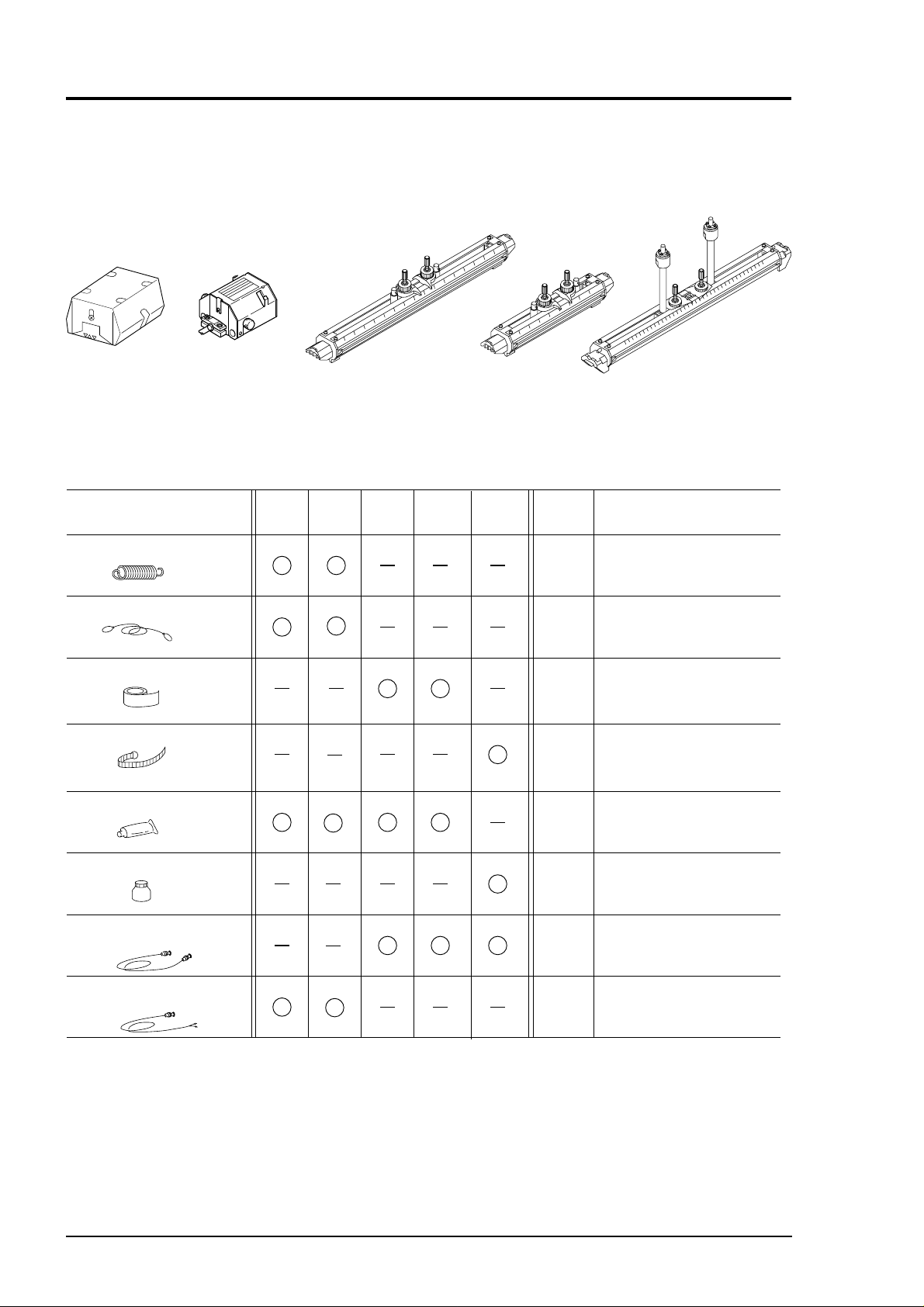

2.2 On purchase of detector (type: PSX2)

BULLETIN F-68

The following parts will be delivered.

So, make sure all the parts are delivered.

(1) Main unit

Large type (2pcs)

(Type: PSX2 D)

Middle type (2pcs)

(Type: PSX2 C)

(2) Accessories

• Fastening spring

• φ 2mm wire rope

• Plastic cloth belt

• Stainless steel beld

• Silicone grease

•

Grease for high temperature

• Cable for exclusive use

(BNC at both ends)

Large

type

Small type (standard)

(Type: PSX2 A & E)

Medium

type

Small

type

Small

diameter

Small diameter

(Type: PSX2 B)

High

tempe-

Quantity Remarks

rature

2 pcs

2 pcs

1 pc

4 pcs

(long)

2 pcs

(short)

1 pc

1 pc

2 pcs

High-temperature

(Type: PSX2 HT)

Maker: Shinetsu

Type:

Chemical Industry

G40M (100g)

Maker: Shinetsu

Chemical Industry

Type:

KS62M (100g)

• Cable for exclusive use

(BNC at one end)

2 - 2

2 pcs

Note) Supplied for

PSX2 D only

Page 12

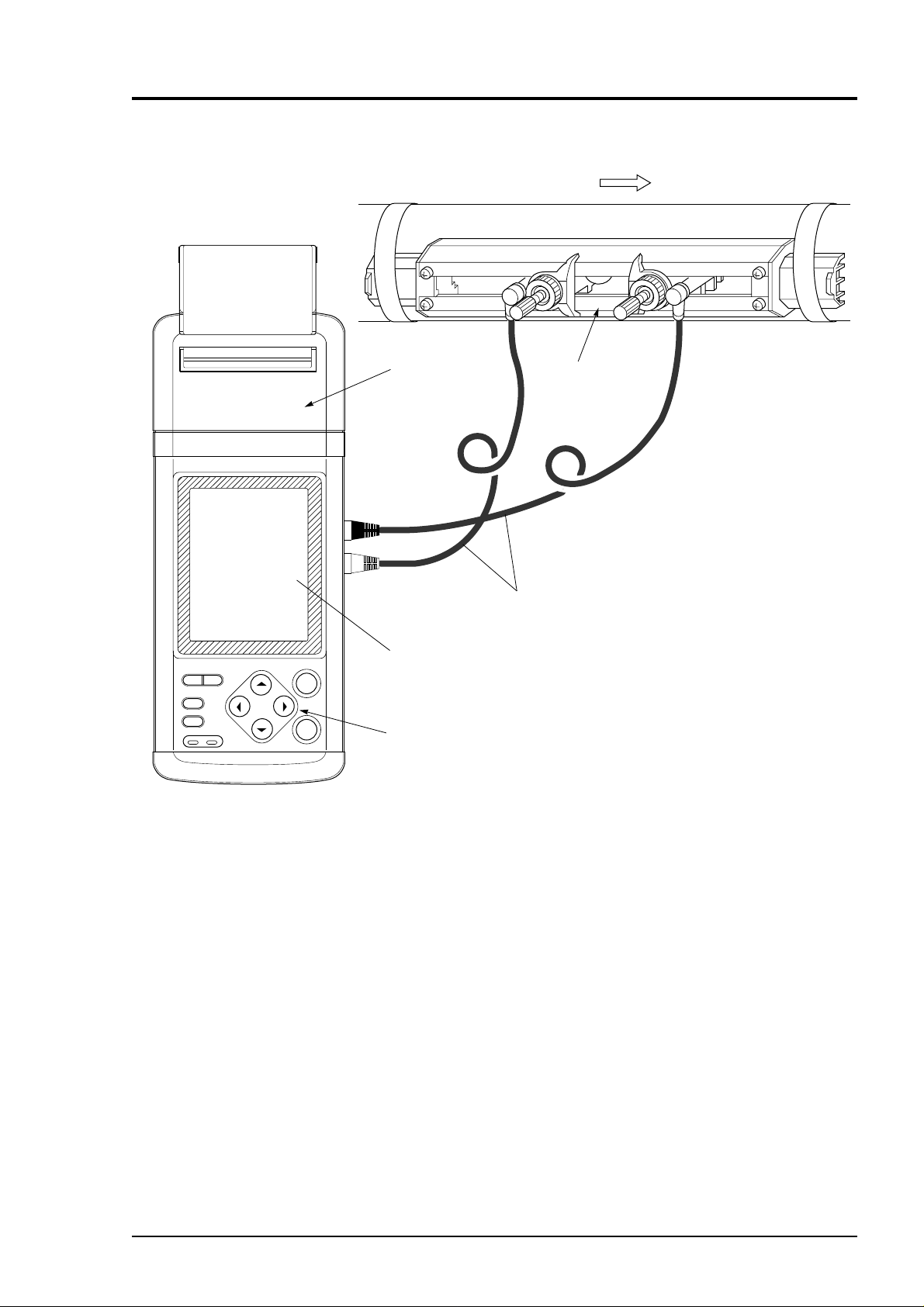

3. NAME AND EXPLANATION OF EACH PART

BULLETIN F-68

3.1 Name and explanation of main unit and sensor

Fluid

ON OFF

LIGHT

PRINT

FAST CHARGE

Printer

Detector

Cable for exclusive use

Display

window

ENT

DC IN

ESC

Keyboard

• Keyboard : Used for turning on/off power supply of the main unit, outputting a hard copy with

the printer, inputting fluid specifications and setting the function of the meter.

• Display window : Displays measured value. Also used for display in data input or setting by keys.

Because this is a large-size graphic LCD, indications are easier to read. Even at a

dark place, indications can be read by using the backlight.

• Printer (option) : Capable of printing all information possessed by the PUX including the hard copy of

display screen and printout of measured value.

Meter comprises a logger function (for storing measured values in memory).

After storing a few day's data in memory by the logger function, it can be printed.

• Detector : Attached to a pipe and receives/transmits ultrasonic wave.

• Cable for exclusive use: Used for transmitting to the instrument signals into which flow rates measured

by the detector have been converted.

3 - 1

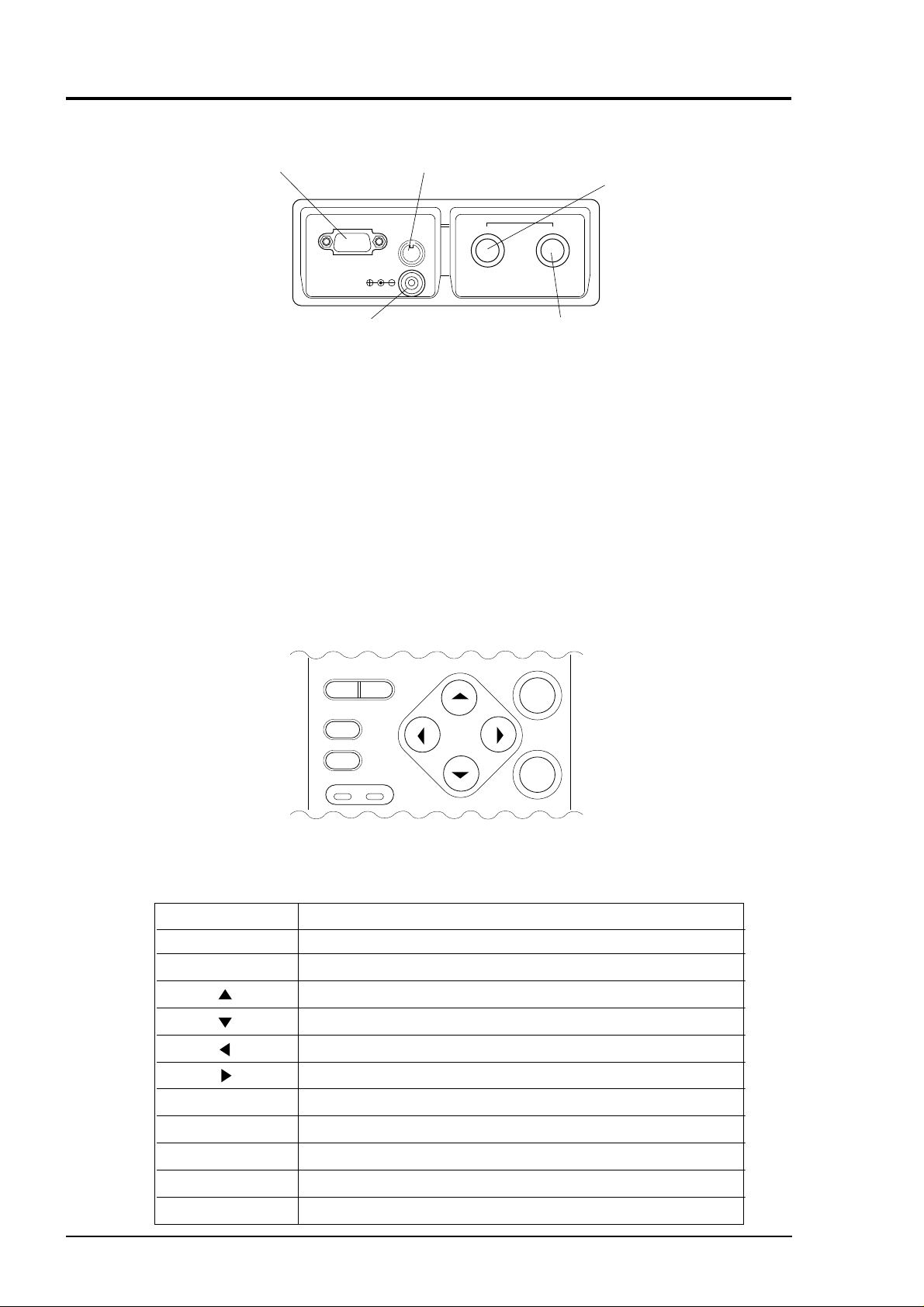

Page 13

SERIAL

BULLETIN F-68

(RS-232C connector for

personal computer)

SERIAL

ANALOG IN/OUT

(4 to 20mA DC analog I/O connector)

SENSOR

DC17.5V

ANALOG

IN/OUT

UPSTREAM

(Detector connector on

upstream side)

STREAMDOWNSTREAMUP

17.5 V DC (power connector)

• Connectors : 17.5V DC

Connector of main unit power supply. Inputs 17.5V DC.

Insert the plug of the power adapter tailored for this instrument.

: UP STREAM (upstream side), DOWN STREAM (downstream side)

These are connectors which receive sensor cords.

Connect matching the upstream and downstream sides.

: ANALOG IN/OUT

Connect analog input/output signals (4 to 20mA DC).

: SERIAL

Connector for serial transmission. Connect to an external system such as personal

computer.

3.2 Explanation of keys

Fig. 3-1 shows the layout of keys and Table 3-1 explains each key.

ON OFF

LIGHT

PRINT

FAST CHARGE

DOWNSTREAM (Detector connector on downstream side)

Connectors

ENT

ESC

DC IN

3 - 2

Fig. 3-1 Layout of keys

Table 3-1 Explanation of keys

Key indication lamp Description

ENT The keyed-in data, selected item, etc. will be set by pressing this key.

ESC Cancels any setting.

Moves the cursor upward, increments set value, etc.

Moves the cursor downward, decrements set value, etc.

Moves the cursor leftward, change scale, etc.

Moves the cursor rightward, change scale, etc.

ON/OFF Turns on/off power supply.

PRINT Prints the screen display (outputs a hard copy).

LIGHT Turns on/off the backlight of display screen.

FAST CHARGE

Turns ON in charge. Blinks in fully charged condition.

DC IN Turns ON with power cable connected.

Page 14

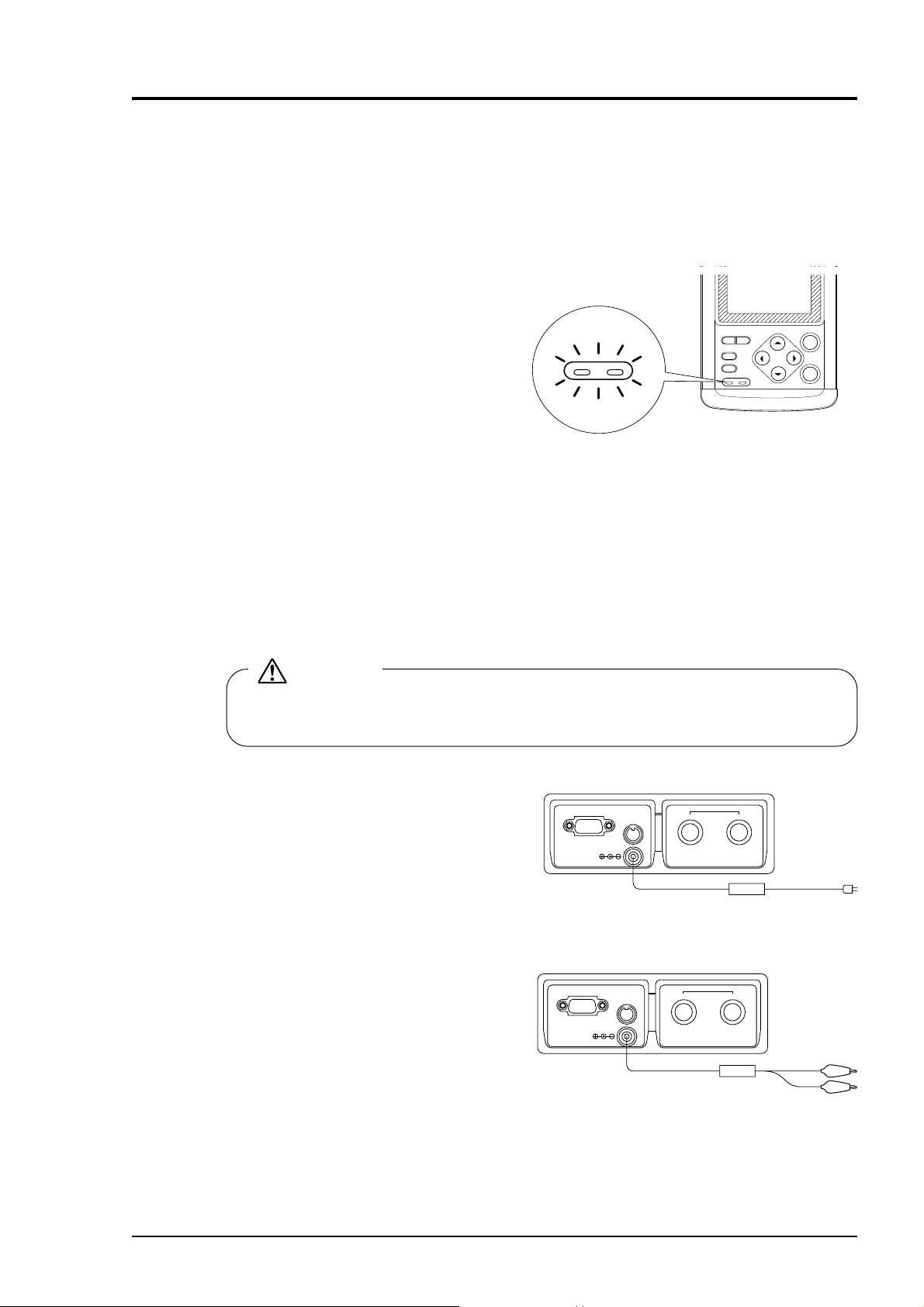

4. POWER UP

BULLETIN F-68

4.1 Operating power supply

There are two methods available for energizing this instrument; by the built-in battery or with

the power adapter.

(1) Energizing with built-in battery

q To charge the battery

Turn OFF the instrument power and

connect the AC power adapter. The

“FAST CHARGE” LED is lighted in

red, and “DC IN” LED is lighted in

green.

When the instrument is fully charged,

“FAST CHARGE” LED blinks in red.

* About 2 hours will be required for

charging.

* In the fully charged condition, the

instrument can measure for about 5

hours.

(On condition that the display backlight

is turned off and the printer is unused.)

w To energize by built-in battery

When turning on the power supply without connecting the power adapter, the instrument will

be energized by the built-in battery.

Before use, the battery should be fully charged.

FAST CHARGE

DC IN

ON OFF

LIGHT

PRINT

FAST CHARGE

ENT

DC IN

ESC

(2) Energizing by power adapter

CAUTION

Use the exclusive power adapter only. Don’t use other adapters, or it may result in an

accident.

• AC power adapter

q Connect the output plug of AC power

adapter to the 17.5V DC connector of

main unit.

w Insert the input plug of this adapter into

the power receptacle.

(This adapter has an input voltage range

of 90 to 264V AC (at 50/60Hz).)

• DC power adapter

q Connect the output plug of DC power

adapter to the 17.5V DC connector of

main unit.

w Connect the input wires (+ and -) of DC

power adapter to suitable DC power

supply.

SERIAL

SERIAL

DC17.5V

DC17.5V

ANALOG

IN/OUT

ANALOG

IN/OUT

SENSOR

SENSOR

STREAMDOWNSTREAMUP

STREAMDOWNSTREAMUP

(This adapter has an input voltage range

of 10 to 30V DC.)

4 - 1

Page 15

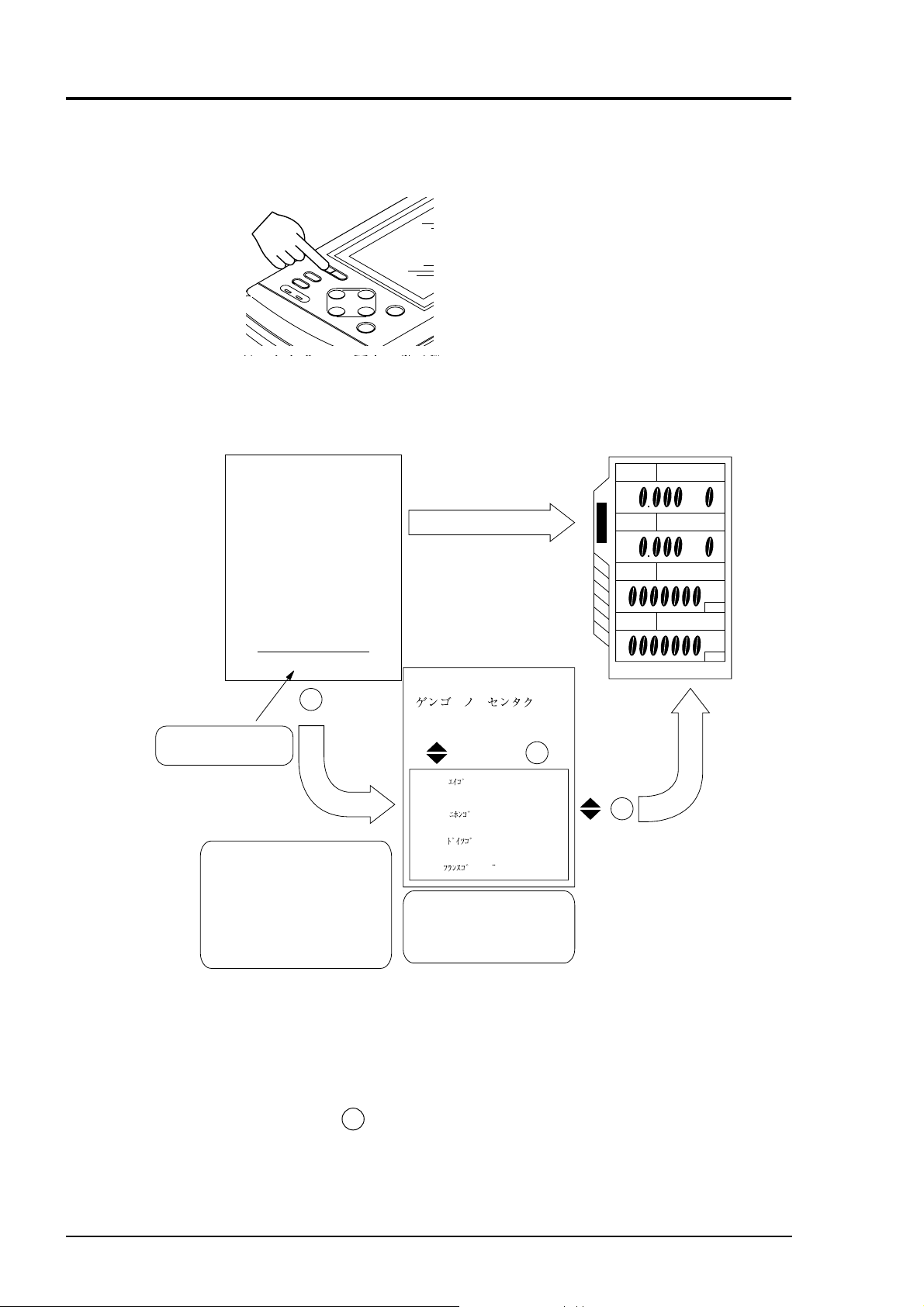

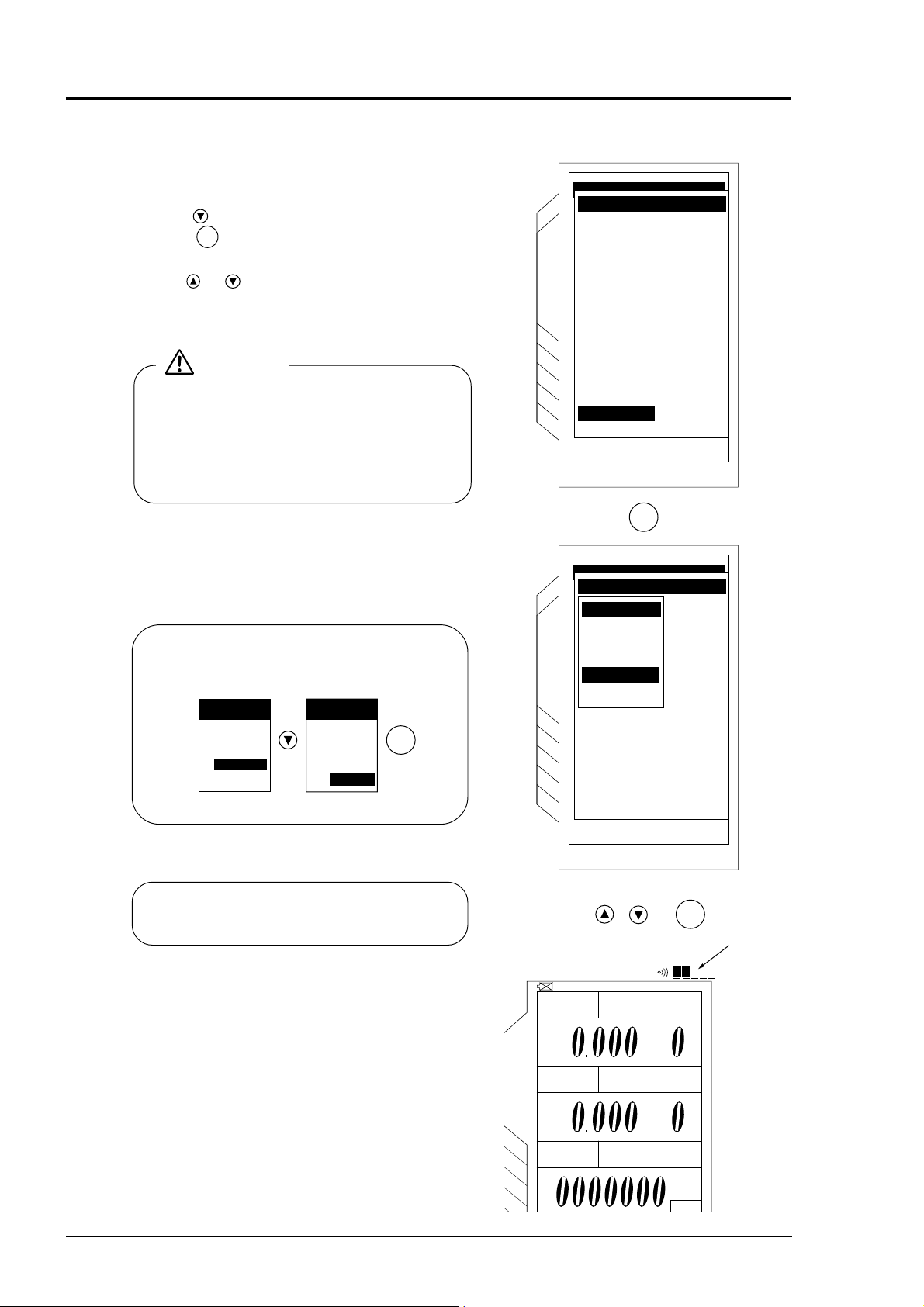

4.2 Turning on power supply

BULLETIN F-68

q Press the ON switch of the main unit to turn ON the power.

w Turn ON the power, and the following

screen appears.

DWYER INSTRUMENTS, INC.

English

ESC

Language to be set is

displayed.

To select the language

When the language display is

highlighted (for about 5 sec.), press

the ESC key, and the “LANGUAGE

SELECTION” screen appears.

In the screen that is displayed, select

your desired language and press the

ENT key. It returns to the

“MEASUREMENT” screen.

e If there is nothing you can do on the

screen for about 10 sec. the

“MEASURE” screen appears.

Select language

Wahle Sprache

Cholx de la langue

ENT

English/ /English/ANGLAIS

Japanese/ /Japanisch/JAPONAIS

German/ /Deutsch/ALLEMAND

French/ /Franzosisch/FRANCAIS

Note:

From the next step, the

language you selected can

be used.

95-06-27 11:49

FLOW RATE UNIT: m3/h

x10

VELOCITY UNIT: m/s

MEASURE

x10

+ TOTAL UNIT: ml

STOP

RESET

— TOTAL UNIT: ml

STOP

RESET

ENT

4 - 2

Note1) Select any of 4 languages: English, French, German, and Japanese (Katakana)

Note2) To return to the “LANGUAGE SELECTION” screen from the “MEASUREMENT” screen

in display, turn OFF the power once and then turn it ON again. In the initial screen that is

displayed, press the

ESC

key.

Page 16

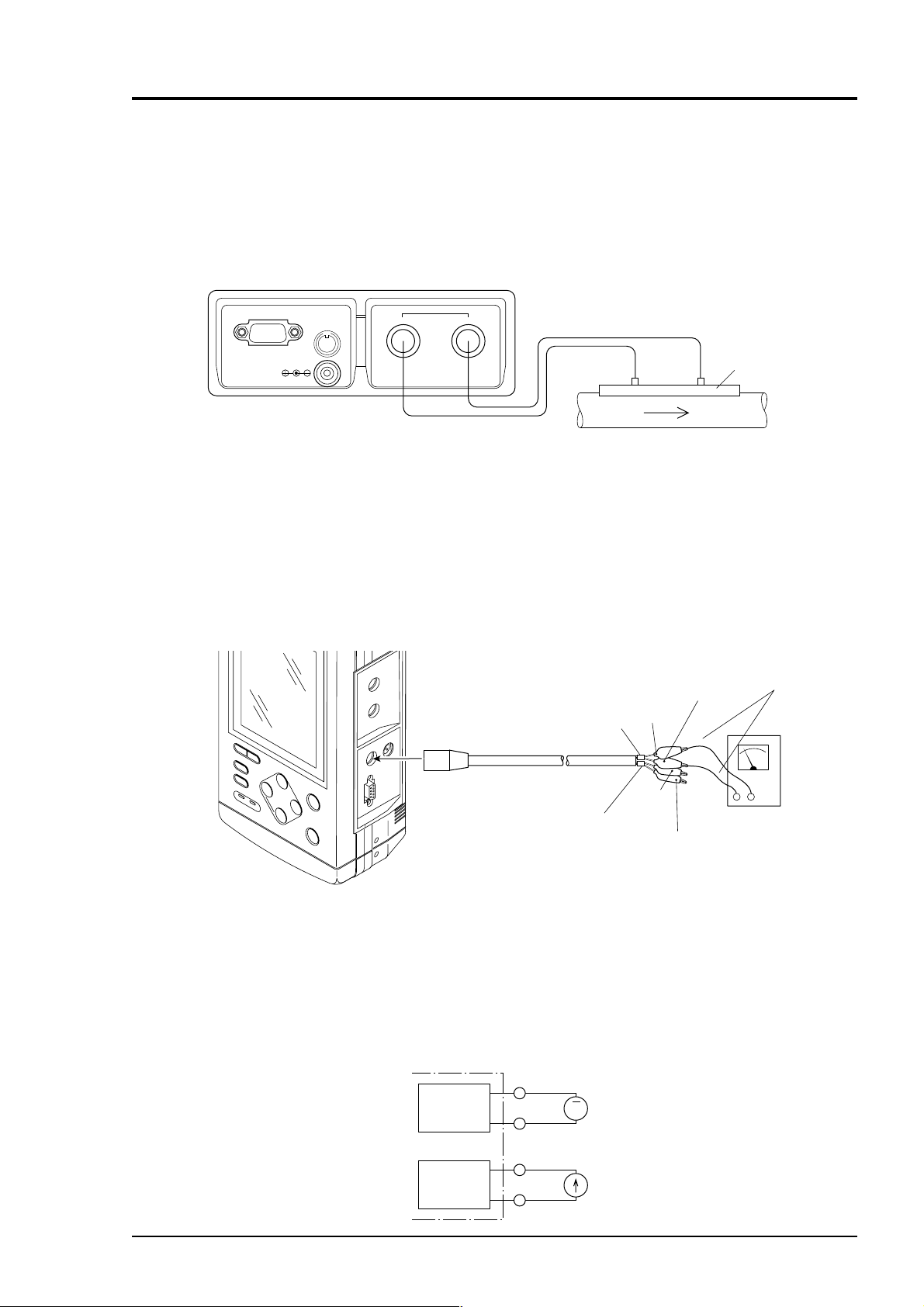

5. WIRING

BULLETIN F-68

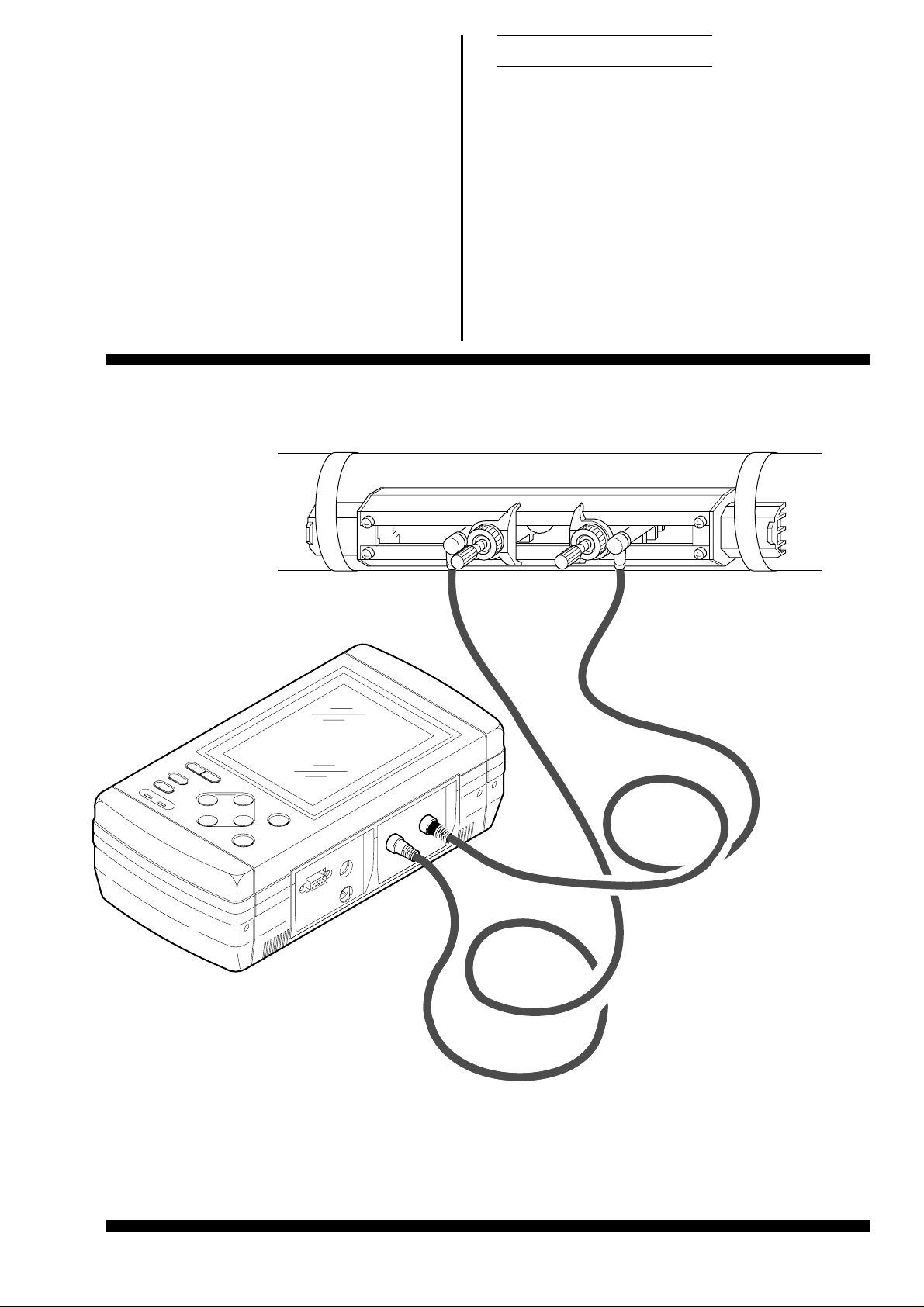

5.1 Connection of dedicated cables

This cable is used for connecting the detector to the main unit.

q Connect dedicated cables to the upstream and downstream sides of the detector.

w Connect one cable connected to the upstream side of the detector to the “UP STREAM” connector of

the main unit, and connect the other cable connected to the down stream side of the detector to the

“DOWN STREAM” connector.

SERIAL

DC17.5V

ANALOG

IN/OUT

SENSOR

STREAMDOWNSTREAMUP

Upstream Downstream

Flow direction

5.2 Connection of analog input/output cable (4 to 20 mA DC)

This cable is used for connection of receiving instruments (indicators, recorders, etc.) and the main unit.

Analog I/O cable is connected as shown below. The cable end is treated with a clip.

Red (+)

AO

(output)

Black (-)

Detector

4 to 20mA

Note) Plug the connector

into ANALOG

IN/OUT.

AI

(input)

Red (+)

Black (-)

-

+

Indicator,

recorder,

controller, etc.

q Connect clips of the analog I/O cable to the (+) and (-) sides of the receiving instruments, respectively.

w Connect the analog I/O cable to the “ANALOG IN/OUT” connector at the side panel of the main unit.

Note) Allowable load resistance of analog output should be adjusted to 1 kΩ or less.

Input resistance of analog input is 100Ω.

Converter

AO

AI

Red

Black

Red

Black

+

A

-

5 - 1

Page 17

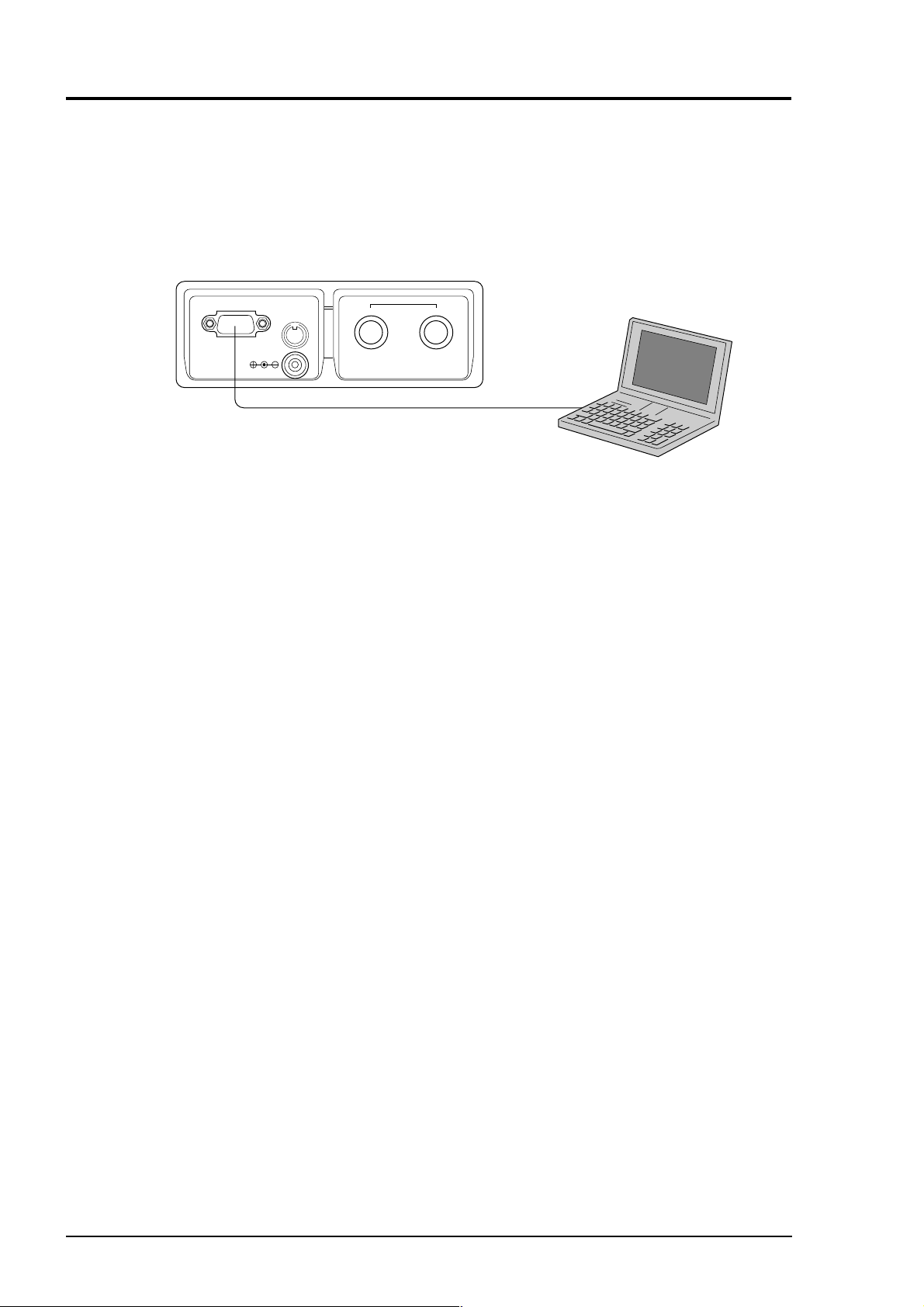

5.3 Connection of RS-232C cable

BULLETIN F-68

When using an optional personal computer, use RS-232C cable for serial transmission between

the RS-232C connector of the personal computer and the “SERIAL” connector of the main unit.

For PC software, refer to Chapter 12.

SERIAL

DC17.5V

ANALOG

IN/OUT

SENSOR

STREAMUP

RS-232C

STREAMDOWN

5 - 2

Page 18

6. INPUT OF PIPING SPECIFICATIONS

BULLETIN F-68

Before installing the detector, set the specifications of a pipe in the main unit to allow measurements.

Caution) Measurements cannot be accomplished without these settings.

95-06-27 11:49

6.1 Display of pipe setup screen

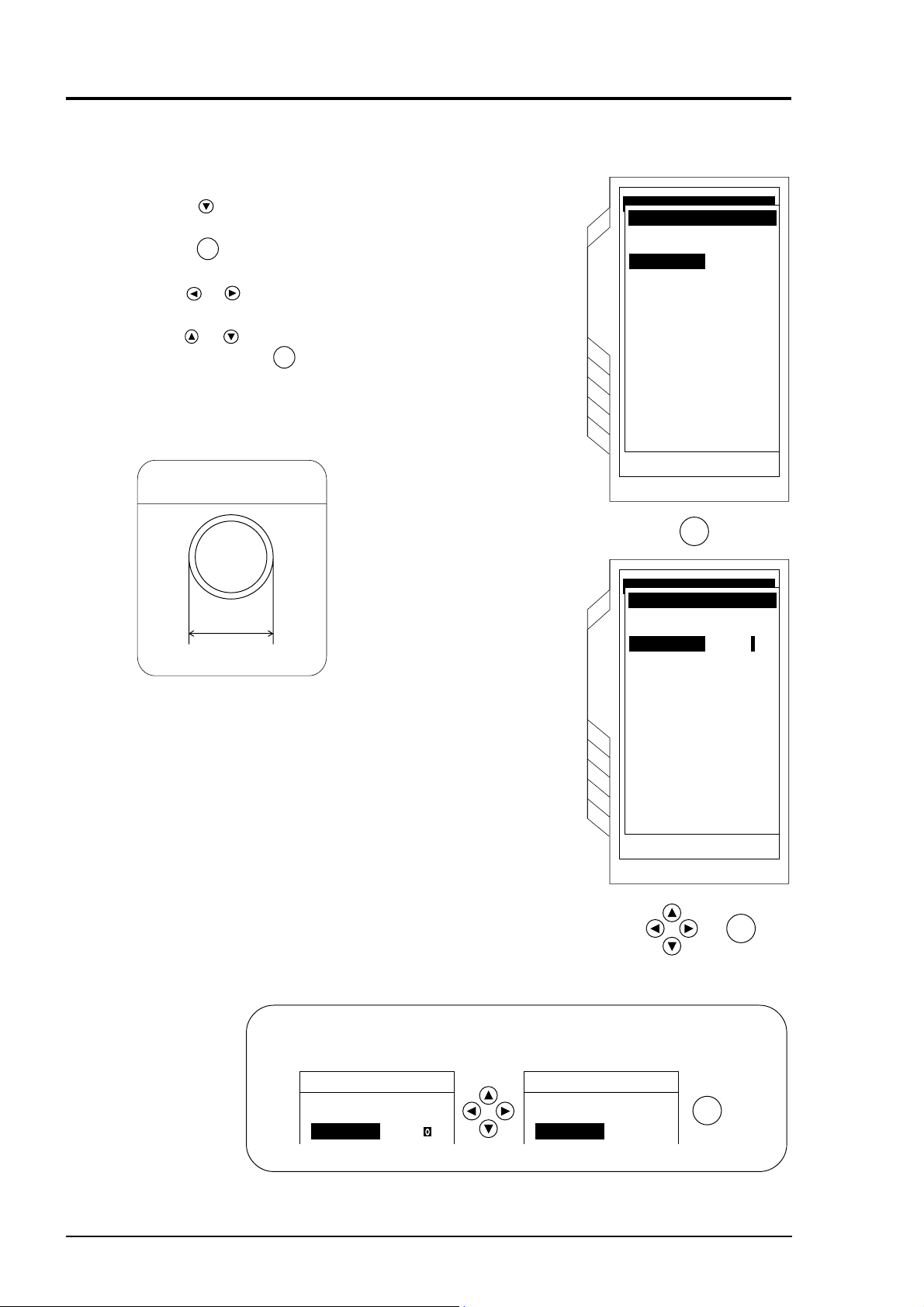

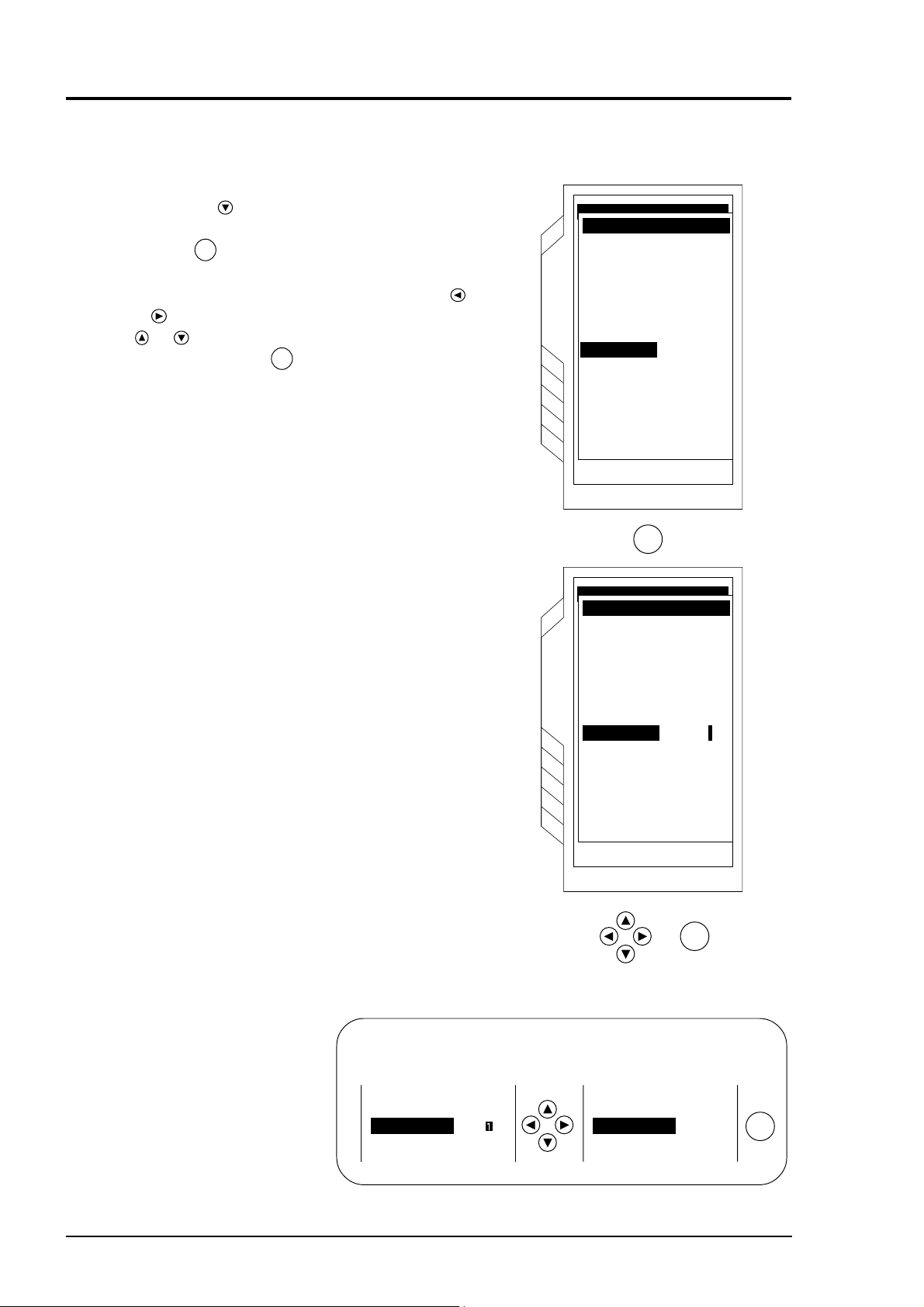

q Press the

to invert the “Tab”.

w Press the

menu screen is displayed.

To move the cursor on the screen, press the

key or

To invert “PIPE PARAMETER” on the menu

screen , press the

SETUP” screen.

key on the “MEASURE” screen

key, and the “SITE SETUP”

ENT

key.

key on the “SITE

Title of page

Invert the

PIPE

PARAMETER

FLOW RATE UNIT: m3/h

x10

VELOCITY UNIT: m/s

MEASURE

x10

+ TOTAL UNIT: ml

– TOTAL UNIT: ml

95-06-27 14:49

SITE SETUPSITE SETUP

PARAMETER MEMORY

PIPE PARAMETER

ZERO ADJUST

RESPONSE SET

SITE SETUP

CALIBRATION

CUT OFF

TOTALIZE

MANUAL ZERO

0 s e c

0 . 0 0 0 m / s

STOP

RESET

STOP

RESET

e Press the

ENT

key, and “PIPE

PARAMETER” screen is displayed.

PIPE

PARAMETER

screen is

displayed.

--- SENSOR SPACING ---

125.7mm

96-06-24 10:57

SITE SETUP

SITE SETUP

PIPE PARAMETER

PIPE PARAMETER

SITE NAME

SITE NAME

OUTER DIAMETER

PIPE MATERIAL

WALL THICKNESS

LINING MATERIAL

SITE SETUP

LINING THICKNESS

KIND OF FLUID

SENSOR MOUNTING

SENSOR TYPE

13.00 m m

CARBON STEEL

0.01 m m

NO LINING

0.01mm

WATER

V

PSX2 B

X

1TRANS, VOLTAGE

6 - 1

Page 19

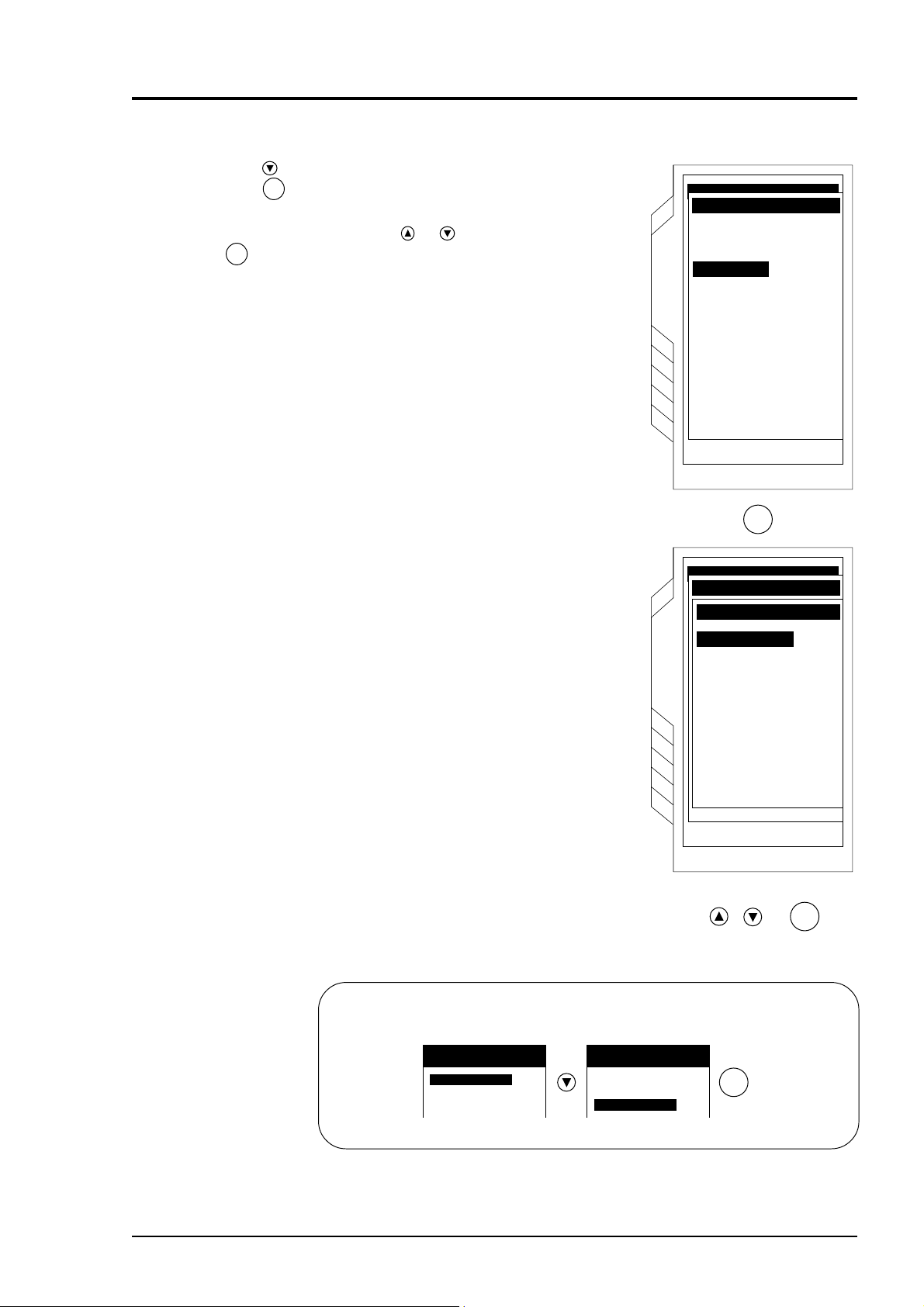

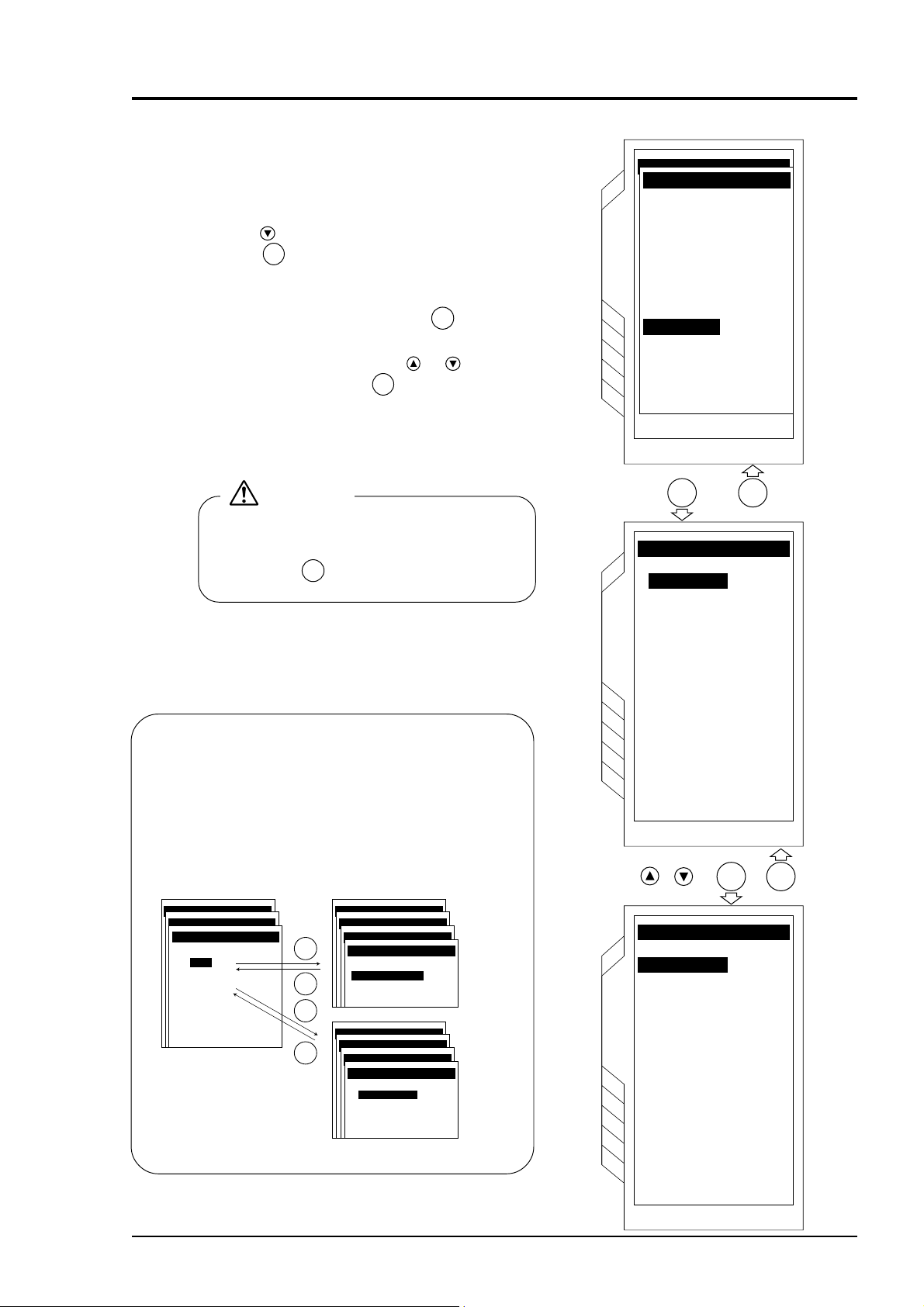

r Outline of PIPE PARAMETER

BULLETIN F-68

96-06-24 10:57

SITE SETUPSITE SETUP

PIPE PARAMETERPIPE PARAMETER

SITE NAMESITE NAME

OUTER DIAMETER

PIPE MATERIAL

WALL THICKNESS

LINING MATERIAL

SITE SETUP

LINING THICKNESS

KIND OF FLUID

SENSOR MOUNTING

SENSOR TYPE

13.00 m m

CARBON STEEL

0.01 m m

NO LINING

0.01mm

WATER

V

PSX2 B

X

1TRANS, VOLTAGE

Enter site name (name of pipe to be used for measurement) → Page 6 - 3

Set external dimensions of pipe → Page 6 - 4

Set pipe material → Page 6 - 5

Set pipe thickness → Page 6 - 6

Set lining material → Page 6 - 7

Set lining thickness → Page 6 - 8

Set kind of fluid → Page 6 - 9

Set selection of sensor mounting method → Page 6 - 10

Set type of sensor → Page 6 - 11

Set transmission voltage → Page 6 - 12

t Display of mounting dimensions

When the settings are completed on the “PIPE PARAMETER” screen, press the

“SITE SETUP” menu screen.

At the last line the “SENSOR SPACING” value is displayed.

96-06-24 10:57

95-06-27 14:49

ESC

key to display the

SITE SETUP

PIPE PARAMETER

SITE NAME

SITE SETUP

PIPE PARAMETER

OUTER DIAMETER

PIPE MATERIAL

WALL THICKNESS

LINING MATERIAL

SITE SETUP

LINING THICKNESS

KIND OF FLUID

SENSOR MOUNTING

SENSOR TYPE

TRANS, VOLTAGE

13.00 m m

CARBON STEEL

0.01 m m

NO LINING

0.01mm

WATER

V

PSX2 B

X

1TRANS, VOLTAGE

ESC

SITE SETUP

PARAMETER MEMORY

SITE SETUP

PIPE PARAMETER

ZERO ADJUST

RESPONSE SET

SITE SETUP

CALIBRATION

CUT OFF

TOTALIZE

--- SENSOR SPACING - --

125.7mm

MANUAL ZERO

0 s e c

0 . 0 0 0 m / s

Mounting

dimension

Install the sensor according to chapter 7. MOUNTING OF DETECTOR and the mounting

dimension is as displayed on the last line.

6 - 2

Page 20

6.2 Entry of site name (measurement is possible without

BULLETIN F-68

entry)

Enter the name of the site (where measurement is performed). This name is registered with site memory

(r of page 6 - 2).

Select a character and press the

Then, select “CLOSE” and press the

you entered wrong characters, press the

ENT

key. Characters will be displayed one by one at top of the screen.

ENT

key to complete entry (up to 20 characters can be entered). If

ESC

key and characters can be cleared one by one.

SITE SETUPSITE SETUP

PIPE PARAMETERPIPE PARAMETER

SITE NAMESITE NAME

Close

Select "CLOSE"

and press the key

to compl

ENT

ete entry.

PIPE NO.1 is selected from SITE NAME.

SITE SETUPSITE SETUP

PIPE PARAMETERPIPE PARAMETER

SITE NAME

SITE NAME

OUTER DIAMETER

PIPE MATERIAL

WALL THICKNESS

LINING MATERIAL

SITE SETUP

LINING THICKNESS

KIND OF FLUID

SENSOR MOUNTING

SENSOR TYPE

PIPE NO. 1

13.00 m m

CARBON STEEL

0.01 m m

NO LINING

0.01mm

WATER

V

PSX2 B

1 TIMETRANS, VOLTAGE

6 - 3

Page 21

6.3 Outer diameter of piping (unit: mm)

BULLETIN F-68

(range: 13 to 6100 mm)

Press the key on the “PIPE PARAMETER” screen to

invert the “OUTER DIAMETER”.

Press the

Use the

ENT

key, and you can enter the outer dimension.

or key to cause the digit to move in the right

and left direction

Use the

After entry, press the

or key to enter the numeric.

ENT

key.

Note) Enter outer dimensions, but not nominal diameter

(example: 20A → 20).

Outer diameter of piping

Outer

diamerer

SITE SETUPSITE SETUP

PIPE PARAMETERPIPE PARAMETER

SITE NAME

OUTER DIAMETER

OUTER DIAMETER 13.00 m m

PIPE MATERIAL

WALL THICKNESS

LINING MATERIAL

SITE SETUP

LINING THICKNESS

KIND OF FLUID

SENSOR MOUNTING

SENSOR TYPE

SITE SETUPSITE SETUP

PIPE PARAMETERPIPE PARAMETER

SITE NAME

OUTER DIAMETEROUTER DIAMETER 0013.00 m m

PIPE MATERIAL

WALL THICKNESS

LINING MATERIAL

SITE SETUP

LINING THICKNESS

KIND OF FLUID

SENSOR MOUNTING

SENSOR TYPE

CARBON STEEL

NO LINING

ENT

CARBON STEEL

NO LINING

PIPE NO.1

0.01 m m

0.01 m m

WATER

V

PSX2 B

4 TIMESTRANS. VOLTAGE

0.01 m m

0.01 m m

WATER

V

PSX2 B

4 TIMESTRANS. VOLTAGE

6 - 4

ENT

Example) When the outer diameter of piping is 318.5 mm:

PIPE PARAMETER

SITE NAME

OUTER DIAMETEROUTER DIAMETER OUTER DIAMETEROUTER DIAMETER

0013.0 mm

PIPE PARAMETER

SITE NAME

0318.50mm

ENT

Page 22

6.4 Piping material

BULLETIN F-68

Press the key to invert the “PIPE MATERIAL”.

Press the

Select the material by using the

the

Note) If you select “OTHER”, enter the sound velocity

ENT

key, and the “PIPE MATERIAL” screen will appear.

ENT

key.

(range: 1000 to 3700m/s). See page 15 - 6, Table @1.

or key. After entry, press

SITE SETUPSITE SETUP

PIPE PARAMETERPIPE PARAMETER

SITE NAME

OUTER DIAMETER

PIPE MATERIALPIPE MATERIAL

WALL THICKNESS

LINING MATERIAL

SITE SETUP

LINING THICKNESS

KIND OF FLUID

SENSOR MOUNTING

ENT

SITE SETUPSITE SETUP

PIPE PARAMETERPIPE PARAMETER

SITE NAME

PIPE MATERIALPIPE MATERIAL

OUTER DIAMETER

CARBON STEEL

CARBON STEEL

PIPE MATERIALPIPE MATERIAL

STAINLESS STEEL

WALL THICKNESS

LINING MATERIAL

SITE SETUP

LINING THICKNESS

KIND OF FLUID

SENSOR MOUNTING

SENSOR TYPE

TRANS, VOLTAGE

CAST IRON

COPPER

ALUMINUM

DUCTILE IRON

ASBESTOS

PIPE NO.1

318.50 m m

CARBON STEEL

0.01 m m

NO LINING

0.01 m m

WATER

V

PSX2 BSENSOR TYPE

4 TIMESTRANS. VOLTAGE

PVC

FRP

Example) When the piping material is cast iron:

PIPE MATERIALPIPE MATERIAL PIPE MATERIALPIPE MATERIAL

CARBON STEELCARBON STEEL

STAINLESS STEEL

CAST IRON

CARBON STEEL

STAINLESS STEEL

CAST IRONCAST IRON

ENT

ENT

6 - 5

Page 23

6.5 Wall thickness (unit: mm) (range: 0.01 to 100.00mm)

BULLETIN F-68

Press the key to invert the “WALL THICKNESS”.

Press the

pages 15 -1 to 15 - 6, Piping Data ).

Use the

left.

Using the

press the

ENT

key, and wall thickness can be entered (See

or key to move the digit to the right and

or key, enter the numeral. After entry,

ENT

key.

Lining and wall thickness of piping

SITE SETUPSITE SETUP

PIPE PARAMETERPIPE PARAMETER

SITE NAME

OUTER DIAMETER 318.50 m m

PIPE MATERIAL

WALL THICKNESS

LINING MATERIAL

SITE SETUP

LINING THICKNESS

KIND OF FLUID

SENSOR MOUNTING

SENSOR TYPE

CARBON STEEL

NO LINING

PIPE NO.1

0.01 m m

0.01mm

WATER

V

PSX2 B

4 TIMESTRANS. VOLTAGE

Lining thickness

Wall thickness

ENT

SITE SETUPSITE SETUP

PIPE PARAMETERPIPE PARAMETER

SITE NAME

OUTER DIAMETEROUTER DIAMETER 318.50 mm

PIPE MATERIAL

WALL THICKNESS

LINING MATERIAL

SITE SETUP

LINING THICKNESS

KIND OF FLUID

SENSOR MOUNTING

SENSOR TYPE

CARBON STEEL

NO LINING

0.01 mm

0.01 mm

WATER

V

PSX2B

4 TIMESTRANS. VOLTAGE

6 - 6

ENT

Example) When the wall thickness is 1.25mm

PIPE MATERIAL CAST IRON

WALL THICKNESS

LINING MATERIAL NO LINING

000.0 mm

PIPE MATERIAL CAST IRON

WALL THICKNESS

LINING MATERIAL NO LINING

001.25mm

ENT

Page 24

6.6 Lining material

BULLETIN F-68

Press the key to invert “LINING MATERIAL”.

Press the

ENT

key, and “LINING MATERIAL”

screen will appear.

Using the

selection, press the

or key, select the material. After

ENT

key.

Note) If you select “OTHER”, enter the sound velocity

(range 1000 to 3700m/s). See page 15-6,

Table @1.

SITE SETUPSITE SETUP

PIPE PARAMETERPIPE PARAMETER

SITE NAME

OUTER DIAMETER

PIPE MATERIAL

WALL THICKNESS

LINING MATERIAL

LINING MATERIAL

SITE SETUP

LINING THICKNESS

KIND OF FLUID

SENSOR MOUNTING

ENT

SITE SETUPSITE SETUP

PIPE PARAMETERPIPE PARAMETER

SITE NAME

LINING MATERIALLINING MATERIAL

OUTER DIAMETER

PIPE MATERIALPIPE MATERIAL

WALL THICKNESS

LINING MATERIAL

SITE SETUP

LINING THICKNESS

KIND OF FLUID

SENSOR MOUNTING

SENSOR TYPE

TRANS. VOLTAGE

NO LINING

NO LINING

TAR EPOXY

MORTAR

PYREX GLASS

PIPE NO.1

318.50 m m

CAST IRON

1.25 m m

NO LINING

0.01 m m

WATER

V

PSX2 BSENSOR TYPE

4 TIMESTRANS. VOLTAGE

RUBBER

TEFLON

OTHER 2000 m/s

ENT

Example) When the lining material is mortar

LINING MATERIALLINING MATERIAL LINING MATERIALLINING MATERIAL

NO LININGNO LINING

TAR EPOXY

MORTAR

ROBBER

LINING MATERIAL

NO LINING

TAR EPOXY

MORTAR

MORTAR

ROBBER

ENT

6 - 7

Page 25

6.7 Lining thickness (unit: mm) (range: 0.01 to 100.00 mm)

BULLETIN F-68

When the lining material is set to items other than

“None” in 6.6 Lining material.

Press the

THICKNESS”.

Press the

can be performed.

The cursor can shift the numeric digit by using the

or key. The numeric can be entered by using the

or key.

After entry, press the

key to invert the “LINING

ENT

key, the lining thickness numeric entry

ENT

key.

SITE SETUPSITE SETUP

PIPE PARAMETERPIPE PARAMETER

SITE NAME

OUTER DIAMETER 318.50 m m

PIPE MATERIAL

WALL THICKNESS

LINING MATERIAL

SITE SETUP

LINING THICKNESS

KIND OF FLUID

SENSOR MOUNTING

SENSOR TYPE

CARBON STEEL

NO LINING

ENT

PIPE NO.1

0.01 m m

0.01mm

WATER

V

PSX2 B

4 TIMESTRANS. VOLTAGE

SITE SETUPSITE SETUP

PIPE PARAMETERPIPE PARAMETER

SITE NAME

OUTER DIAMETER 318.50 m m

PIPE MATERIAL

WALL THICKNESS

LINING MATERIAL

SITE SETUP

LINING THICKNESS

KIND OF FLUID

SENSOR MOUNTING

SENSOR TYPE

CARBON STEEL

0.01 m m

NO LINING

000.01mm

WATER

V

PSX2 B

4 TIMESTRANS. VOLTAGE

ENT

Example) When the lining thickness is 1.25 mm

6 - 8

LINING MATERIAL MORTAR

LINING THICKNESSLINING THICKNESS

KIND OF FLUID

000.0 mm

WATER

LINING MATERIAL MORTAR

LINING THICKNESSLINING THICKNESS

KIND OF FLUID

001.25mm

WATER

ENT

Page 26

6.8 Kind of fluid

BULLETIN F-68

Select kind of fluid and enter the dynamic viscosity

coefficient.

For fluid having no item, enter sound velocity.

(Range: 500 to 2500 m/s)

Press the key to invert the “KIND OF FLUID”.

Press the

will appear.

Note 1) To return the screen to the “PIPE

Select kind of fluid by using the

After selection, press the

appear, to enter the dynamic viscosity coefficient.

The initial value is set to water coefficient.

ENT

key. The “KIND OF FLUID” screen

PARAMETER”, press the

ESC

key.

or key.

ENT

key, the screen will

SITE SETUPSITE SETUP

PIPE PARAMETERPIPE PARAMETER

SITE NAME

OUTER DIAMETER

PIPE MATERIAL

WALL THICKNESS

LINING MATERIAL

SITE SETUP

LINING THICKNESS

KIND OF FLUIDKIND OF FLUID

SENSOR MOUNTING

PIPE NO.1

318.50 m m

CAST IRON

1.25 m m

MORTAR

1.25mm

WATER

V

PSX2 BSENSOR TYPE

4 TIMESTRANS. VOLTAGE

CAUTION

There is no need to change “1.004 E-6m

when measuring water. Return the screen by

pressing the

ESC

key.

Note 2) When “OTHER” is selected, enter sound ve-

locity. See page 15-6, Tables 20 and 22.

Remarks

Dynamic viscosity coefficient is set to water (20°C).

When measuring accurately or measuring fluid other than

water, enter as needed.

(See page 15-6.)

(Range: 0.001 × 10

SITE SETUPSITE SETUP

PIPE PARAMETERPIPE PARAMETER

KIND OF FLUIDKIND OF FLUID

WATER

WATER

SEA WATER

OTHER

-6

to 999.999 × 10-6m2/s)

SITE SETUPSITE SETUP

PIPE PARAMETERPIPE PARAMETER

ENT

ESC

ENT

ESC

KIND OF FLUIDKIND OF FLUID

WATERWATER

KINEMATIC VISCOSITYKINEMATIC VISCOSITY

1.003 E -6 m 2 / s

SITE SETUPSITE SETUP

PIPE PARAMETERPIPE PARAMETER

KIND OF FLUIDKIND OF FLUID

OTHEROTHER

SOUND VELOCITYSOUND VELOCITY

2500 m / s

KINEMATIC VISCOSITY

1.003 E -6 m 2 / s

2

/s”

"WATER"

"OTHER"

ENT ESC

KIND OF FLUIDKIND OF FLUID

WATERWATER

SEA WATER

OTHER

SITE SETUP

ENT ESC

WATERWATER

KINEMATIC VISCOSITYKINEMATIC VISCOSITY

1.004E-6 m2/s

SITE SETUP

6 - 9

Page 27

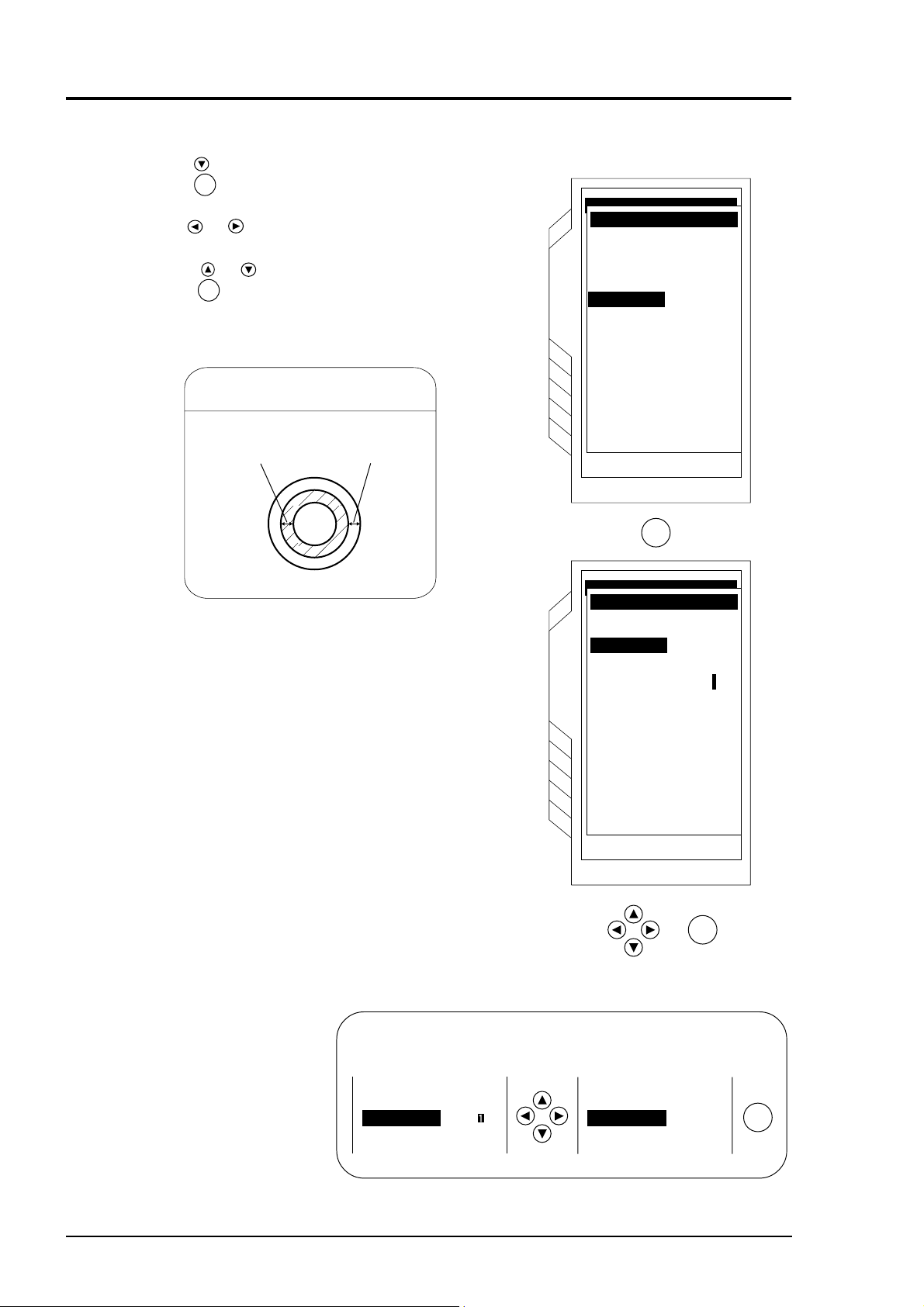

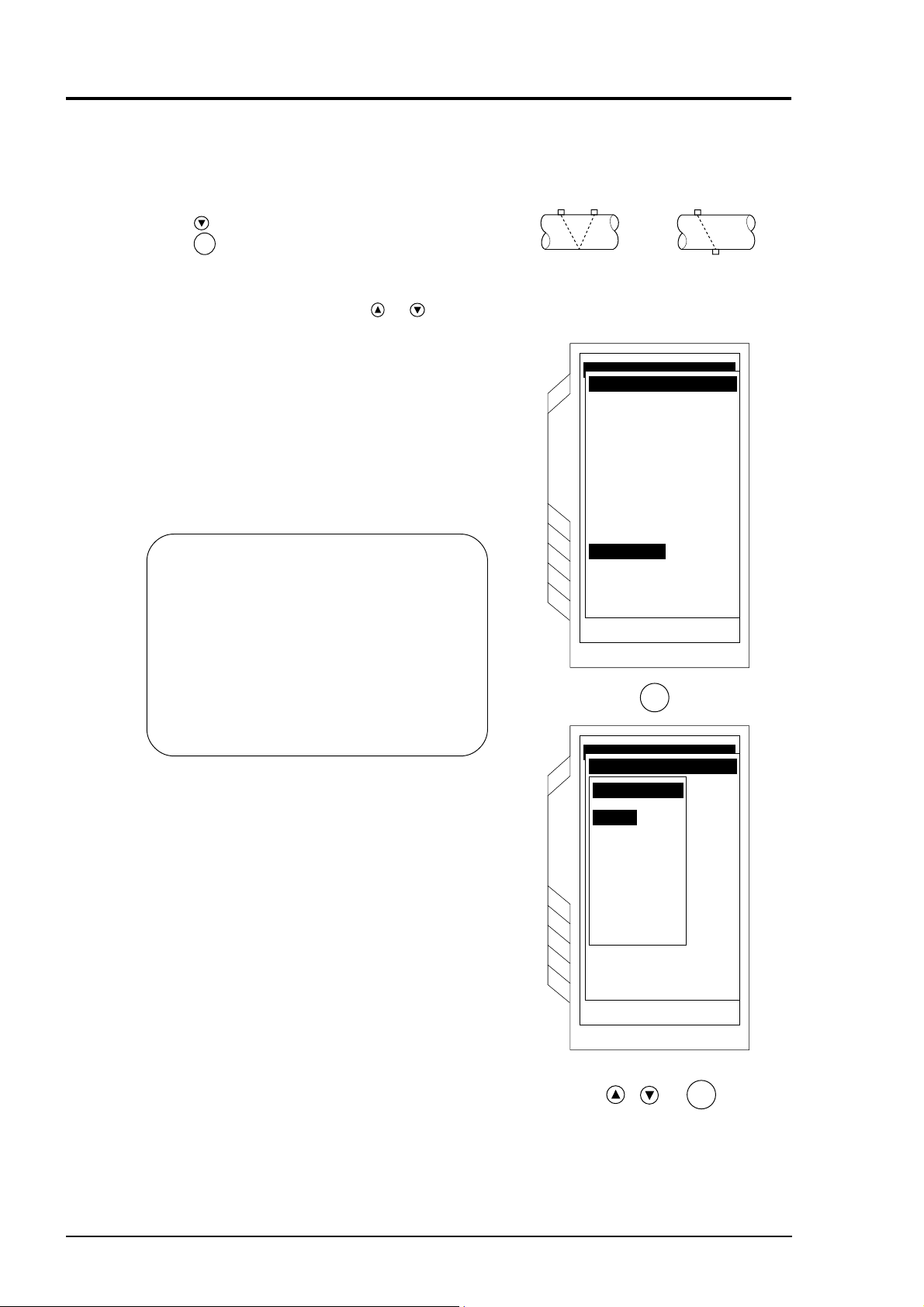

6.9 Selection of sensor mounting method

BULLETIN F-68

Mounting methods available for the sensor are V method

and Z method as illustrated.

To select the mounting method;

Press the

Press the

key to invert the “SENSOR MOUNTING”.

ENT

key. The “SENSOR MOUNTING” screen

will appear.

V method

Z method

Select either V or Z method using the

or key.

Remarks

Select the V method generally. Use the Z method in

the following cases:

• Ample space is not provided.

• High turbidity

• Weak receiving waveform

• Thick scale is deposited on the pipe internal

surface.

SITE SETUPSITE SETUP

PIPE PARAMETERPIPE PARAMETER

SITE NAME

OUTER DIAMETER

PIPE MATERIAL

WALL THICKNESS

LINING MATERIAL

SITE SETUP

LINING THICKNESS

KIND OF FLUID

SENSOR MOUNTING

SENSOR MOUNTING

ENT

SITE SETUPSITE SETUP

PIPE PARAMETERPIPE PARAMETER

SITE NAME

SENSOR MOUNTINGSENSOR MOUNTING

OUTER DIAMETER

V

PIPE MATERIALPIPE MATERIAL

Z

WALL THICKNESS

LINING MATERIAL

SITE SETUP

LINING THICKNESS

KIND OF FLUID

SENSOR MOUNTING

SENSOR TYPE

TRANS. VOLTAGE

PIPE NO.1

318.50 m m

CAST IRON

1.25 m m

MORTAR

1.25mm

WATER

V

PSX2 BSENSOR TYPE

4 TIMESTRANS. VOLTAGE

6 - 10

ENT

Page 28

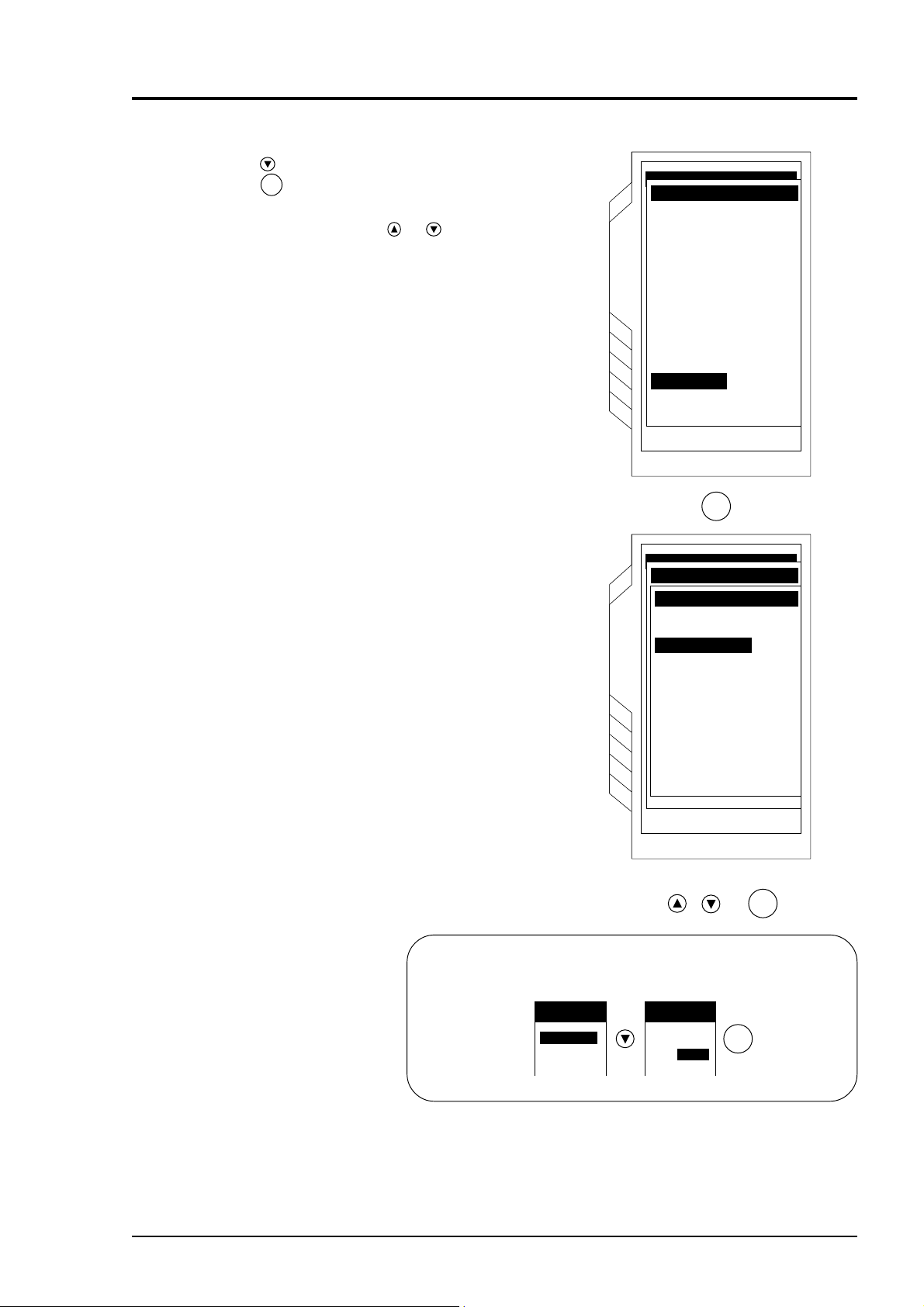

6.10 Kind of sensor

BULLETIN F-68

Press the key to invert “SENSOR TYPE”.

Press the

Select any sensor from the type code of sensor to be used.

Select the sensor by using the

ENT

key to display kind of sensor.

or key.

SITE SETUPSITE SETUP

PIPE PARAMETERPIPE PARAMETER

SITE NAME

OUTER DIAMETER

PIPE MATERIAL

WALL THICKNESS

LINING MATERIAL

SITE SETUP

LINING THICKNESS

KIND OF FLUID

SENSOR MOUNTING

SENSOR TYPE

ENT

SITE SETUPSITE SETUP

PIPE PARAMETERPIPE PARAMETER

SITE NAME

SENSOR TYPE

OUTER DIAMETER

PIPE MATERIALPIPE MATERIAL

WALL THICKNESS

LINING MATERIAL

SITE SETUP

LINING THICKNESS

KIND OF FLUID

SENSOR MOUNTIN

SENSOR TYPE

TRANS, VOLTAGE

PSX2 E

PSX2 HT

PSX2 C/SX1 B

SX1 C

PSX2 D

PSX2 A

B

PSX2

PSX2 CG

PIPE NO.1

318.50 m m

CAST IRON

1.25m m

MORTAR

1.25mm

WATER

V

PSX2 BSENSOR TYPE

4 TIMESTRANS. VOLTAGE

ENT

Example) When model of sensor is PSX2 A

SENSOR TYPE SENSOR TYPESENSOR TYPE

PSX2 E PSX2E

PSX2A

PSX2B

PSX2A

PSX2B

ENT

6 - 11

Page 29

6.11 Transmission voltage (used when an indicator is 1 or

BULLETIN F-68

less during measurement)

SITE SETUPSITE SETUP

Press the key to invert the “TRANS. VOLTAGE”.

Press the

ENT

key. The screen is ready to allow the

selection of the transmission voltage level.

Use the

or key to select the level.

Select “4 TIMES” or “8 TIMES” generally.

CAUTION

If the indicator cannot be set to 2 or more

with the level at “8 TIMES”, ultrasonic wave

may be attenuated due to contamination or

scales deposited on the piping external and

internal surfaces. Change measurement

location.

Example)When transmission voltage

is set to eight-fold

TRANS. VOLTAGE TRANS. VOLTAGE

1

TIME

2

TIMES

4

TIMES

8

TIMES

1

TIME

2

TIMES

4

TIMES

8

TIMES

ENT

PIPE PARAMETERPIPE PARAMETER

SITE NAME

OUTER DIAMETER

PIPE MATERIAL

WALL THICKNESS

LINING MATERIAL

SITE SETUP

LINING THICKNESS

KIND OF FLUID

SENSOR MOUNTING

TRANS. VOLTAGE

ENT

SITE SETUPSITE SETUP

PIPE PARAMETERPIPE PARAMETER

SITE NAME

TRANS. VOLTAGETRANS. VOLTAGE

OUTER DIAMETER

PIPE MATERIALPIPE MATERIAL

WALL THICKNESS

LINING MATERIAL

SITE SETUP

LINING THICKNESS

KIND OF FLUID

SENSOR MOUNTING

SENSOR TYPE

TRANS, VOLTAGE

1 TIME

2 TIMES

4 TIMES4 TIMES

8 TIMES

PIPE NO.1

318.50 m m

CAST IRON

1.25 m m

MORTAR

1.25mm

WATER

V

PSX2 ASENSOR TYPE

4 TIMESTRANS. VOLTAGE

6 - 12

The indicator will be updated on the

“MEASURE” screen only.

If less than 2 indicators (intensity of receiving

waveform) are displayed on the “MEASURE” screen,

raise the transmission voltage.

ENT

Indicator

95-06-27 11:49

FLOW RATE UNIT: m3/h

x10

VELOCITY UNIT: m/s

MEASURE

x10

+ TOTAL UNIT: ml

STOP

RESET

Page 30

7. MOUNTING OF DETECTOR

BULLETIN F-68

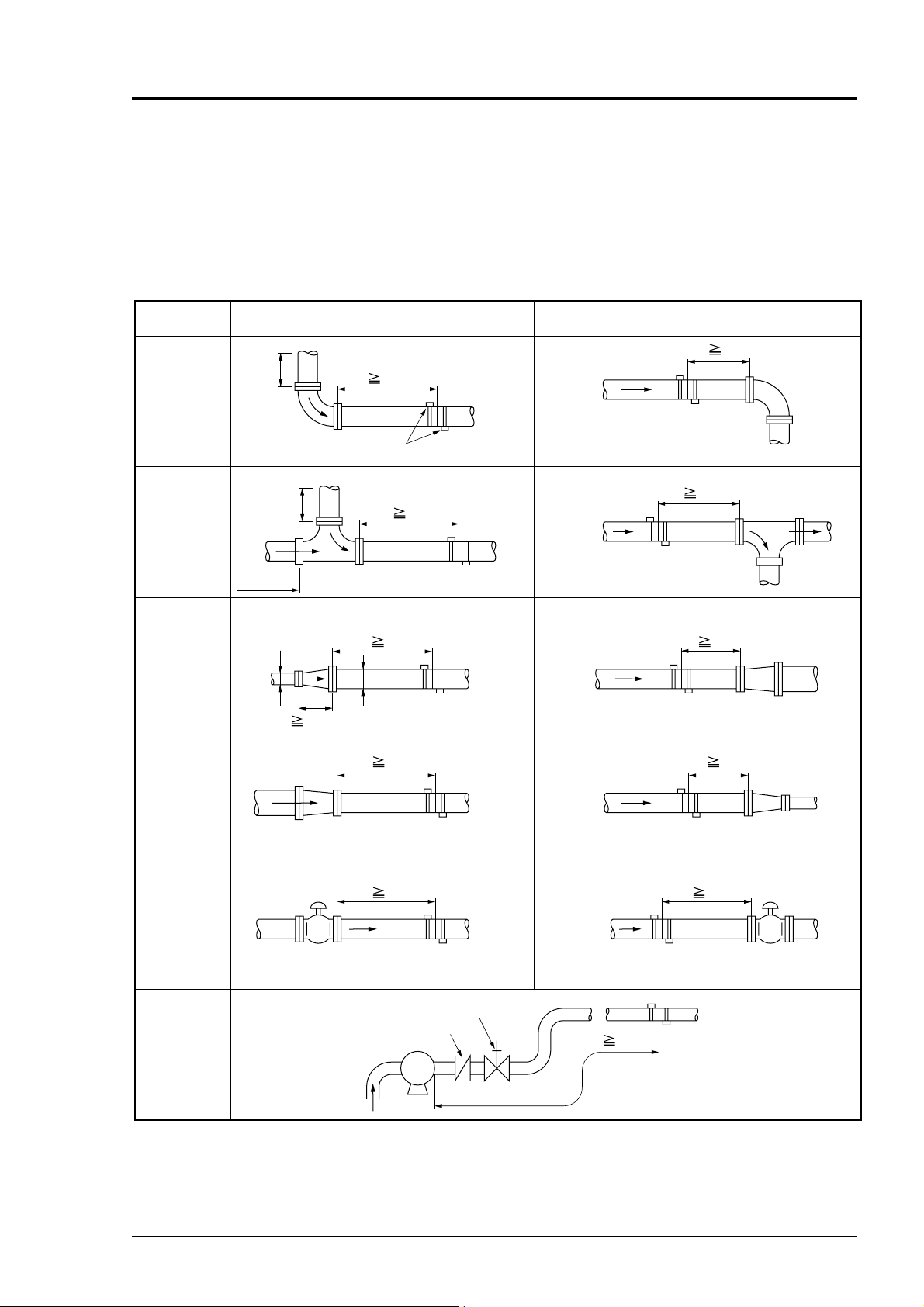

7.1 Selection of mounting location

Detector mounting location, i.e., the conditions of the pipe subjected to flow rate measurement exert a

great influence on measurement accuracy. So select a location meeting the conditions listed below.

(1) There is a straight pipe portion of 10D or more on the upstream side and that of 5D or more on the

downstream side.

(2) No factors to disturb the flow (such as pump and valve) within about 30D on the upstream side.

Classification For upstream side For downstream side

L5D

90° bend

Tee

Diffuser

Reducer

More than 10D

More than

More than

10D

0.5D

More than

10D

1.5D

L 10D

Detector

L 50D

L 30D

D

L 10D

L 10D

L5D

L5D

L 30D

Valves

Flow control valve exists on upstream side.

Stop valve

Check valve

Pump

Flow control valve exists on downstream side.

L 50D

P

Extracted from Japan Electric and Machinery Industry Society (JEMIS-032)

L 10D

7 - 1

Page 31

(3) Pipe is always filled with fluid. Neither air bubbles nor foreign materials are contained in the fluid.

BULLETIN F-68

(4) There is an ample maintenance space around the pipe to which the detector is to be mounted (see

figure below).

Note 1) Secure an adequate space for allowing a person to stand and work on both sides of a pipe.

Note 2) D indicates the inside diameter of a pipe.

200

or more

Note

2000 or more

200

or more

D + 1200 or more 600 or more

D

600 or more

D : Pipe diameter

Space required for mounting detector

(5) For a horizontal pipe, mount the detector within ±45° of the horizontal plane.

For a vertical pipe, the detector can be mounted at any position on the outer circumference.

Air bubbles

Pipe

45°

Horizontal plane

45°

Deposits of

sludge

(6) Avoid mounting the detector near a deformation, flange or welded part on the pipe.

7 - 2

Welded part Welded part

Flange or welded

Page 32

7.2 Selection of detector

BULLETIN F-68

(1) Selection of mounting methods

There are 2 methods for mounting the detector; V method and Z method. For the mounting space, see

the following sketch.

<Large sensor>

L=About D

Detector

D

D

V method

<Small diameter sensor, small sensor or high-temperature sensor>

Length of frame of each sensor

L

V method Z method

Frame

Mounting method

D

Length of frame of each sensor

L=About D/2

Detector

Z method

L

L: Mounting dimension

mounting dimension for

sensor displayed on the

SITE SETUP screen

Employ the Z method in the following cases.

• Mounting space need be saved (mounting space of the Z method is about one half of the V

method's).

• Turbid fluid such as sewage is to be measured.

• Pipe has mortar lining.

• A thick film of scale may have been formed on the inner surface of pipe because it is old.

(2) Detector selection standards

The Z method for large size sensor is recommended for outer diameter 300mm or more.

PSX2 D should be used as much as possible for pipes such as old pipes, cast iron pipes, and mortar

lining pipes, through which it is difficult for ultrasonic signals to pass.

Detector

Type Diameter Temperature

PSX2 B

PSX2 A/E

PSX2 HT

PSX2 D

13 100mm (V method)

50 350mm (V method)

300 400mm (Z method)

50 350mm (V method)

300 400mm (Z method)

200 3000mm (V method)

200

6000mm

(Z method)

-40 +100°C

-40 +100°C

-40

-40 +80°C

+200°C

7 - 3

Page 33

7.3 Use of surface-treated accessories

BULLETIN F-68

Eliminate pitting, corrosion, unevenness, etc. with paint thinner and sandpaper from the pipe portion

where the detector is to be mounted.

Note) In case jute is wound on a pipe, it should be peeled off before the above treatment.

When cast iron pipe is used, grind the sensor mounting surface by using a sander for smoothness.

Detector Width

Small outer

diameter

Small size

(standard) sensor

PSX2A

Large size sensor

PSX2D

High temperature

PSX2 HT

PSX2B

320 mm or more

540 mm or more

Mounting dimension

(L) + 200 mm or more

530 mm or more

Jute is wound

Pipe

Width

7 - 4

Page 34

7.4 How to mount small size (standard) sensor and small

BULLETIN F-68

outer diameter sensor to pipe

q Loosen the lock nut and slide the sensor so as to

meet the mounting dimension and then tighten

the nut.

w Apply a coat of silicone grease to the

transmitting surface of the sensor. Spread the

compound over the entire area.

Keep the sensor retracted by turning the element

holder counterclockwise.

After cleaning the surface of the pipe, the sensor

should be mounted.

Lock nut

Element holdder

BNC connector

Scale

Frame

Transmitter unit

Saddle

Cursor

Mounting

dimension (L)

CAUTION

Apply a small quantity (like toothpaste) of

silicon grease to the transmitter unit.

e Fix the both ends (saddles) of the sensor to the

pipe by cloth belts.

Mounting will be facilitated by winding the cloth

belts on the pipe in advance.

Cloth belts are usable at 80°C or lower. If

beyond 80°C, stainless steel belts should be

used.

(

)

r Make sure the sensor is mounted in parallel with

the pipe axis and the mounting dimension is

right. Then, turn the element holder clockwise

until the sensor comes in close contact with the

pipe.

Stop turning the element holder when it stiffens

because the transmitting surface comes in

contact with the pipe surface. Be careful not to

turn the holder excessively.

Element holder

Cloth belt

Cable

Element holder

7 - 5

Page 35

7.5 How to mount large size sensor

BULLETIN F-68

7.5.1 How to determine mounting position (large sensor)

Determine the mounting position by carrying out the following work.

For this work, gauge paper is necessary (For the gauge paper, refer to page 7-10).

q Match the edge of gauge paper with the line at

about 100mm from one end of the pipe portion

treated for detector mounting, and wind the

gauge paper so that the line marked on the paper

is parallel with the pipe axis (fix with tape not to

allow deviation). At this time, the edge of gauge

paper should be aligned.

w Extending the line marked on the gauge paper,

mark straight line A on the pipe.

e Mark a line along on edge of the gauge paper.

The intersection of this line and straight line A is

replaced with A

.

0

r In mounting by the V method, peel the gauge

paper and measure the mounting dimension from

A0 to determine A2 position. At this position,

mark a line orthogonal to the straight line A.

Line drawn

on gauge paper

Draw line A.

Draw a line

along the edge.

A

2

100mm

Align this edge.

A

0

A

0

A0 and A2 become the mounting positions.

Example) L = 200mm

t In mounting by the Z method, measure the

circumference from A

with a measuring tape.

0

At 1/2 of the circumference, determine points B

and B1, and mark a line (straight line B)

connecting those points.

y Mark the points B

Measure the mounting dimension from B

and peel off the gauge paper.

0

0

to

determine B2 position. At this position, make a

line orthogonal to the straight line B.

A0 and B2 become the mounting positions.

Example) L = 100mm

200mm

A

B

A

0

1

B

1

B

2

B

0

A

0

Straight line B

100mm

B

0

0, B1

A

0

B

B

0

0, A1

2

7 - 6

Page 36

7.5.2 How to connect large size sensor for PSX2 D type only

BULLETIN F-68

q Slide the detector cover slightly. Remove the

cover with a driver.

w Determine the mounting posture of sensor on the

pipe.

Align the transmission direction marks.

Cover

Transmission direction mark

Transmission direction mark

e Put a mark on the inlet of coaxial cable.

When the pipe is horizontally installed with the

detector, allow the coaxial cable to be suspended

to prevent entry of water from the cable inlet.

When the pipe installed vertically, it does not

matter how the coaxial cable should be installed.

Note) Upstream and downstream sensors

should be able to be distinguished.

r Connect the coaxial cable to terminal (G, +) and

fix it with the cable clamp.

Cable retainer

Rubber bush

t Replace the cover.

7 - 7

Page 37

7.5.3 How to mount large size sensor to pipe

BULLETIN F-68

qq

q Height adjustment of guide plate

qq

• Place the sensor on the pipe surface in parallel

with the pipe axis.

• Loosen the guide plate fixing screw and slide

the guide plate until its edge and transmitting

surface touch the surface of pipe.

Transmission

surface

Fixing screw

Guide plate

Pipe

• Then tighten the fixing screw.

ww

w How to determine the length of wire rope

ww

• Place the sensor on the marked lines and fit the

wire rope and fastening spring.

• Loosen the wire clip and pull the wire rope

until the overall length of fastening spring

approximates 180mm. Then tighten the wire

clip.

(The fastening spring has a free length of

110mm.)

• While fixing the wire rope, remove the sensor.

ee

e Mounting of sensor

ee

• Wipe off contaminants from the transmitting

surface of sensor and the sensor mounting

surface of pipe.

• Apply the silicone grease on the transmitting

surface of sensor wile spreading it evenly.

• Film thickness of the silicone grease should be

about 3mm.

• Spread the wire rope near the marked lines in

the left-right direction, bring the sensor in

close contact and fit the wire rope.

Fastening

spring

600

Tramsmitting

180

Sensor

surface

Transmission

direction mark

Loosen this wire clip

and pull the wire rope.

Marked lines

Pipe

• Align the matching mark of sensor with the

marked line. In addition, make the

transmitting direction marks of sensors face

each other.

• Make sure the matching mark of sensor is

aligned with the marked line and connect the

coaxial cable to the converter.

Note) Do not pull the coaxial cable.

Otherwise, the sensor will be

activated to disturb measurement.

Fastening spring

Marked line

Sensor

Pipe

Transmission mark

Marked line

Matching mark

Transmission

mark

dimension (L)

Marked lline

Mounting

Matching

mark

7 - 8

Page 38

7.6 How to mount high temperature sensor to pipe

BULLETIN F-68

q Loosen the lock nut and slide the sensor so as to

meet the mounting dimension and then tighten

the nut.

w Apply a coat of grease for high temperature to

the transmitting surface of the sensor. Spread the

compound over the entire area.

Keep the sensor retracted by turning the element

holder counterclockwise.

After cleaning the surface of the pipe, the sensor

should be mounted.

BNC connecot

Frame

High temperature

grease

Lock nut

Scale

Element holder

Cursor

Mounting

dimension

(L)

Spatula

Transmission

unit

Saddle

e Fix the both ends (saddles) of the sensor to the

pipe by stainless belts.

r Make sure the sensor is mounted in parallel with

the pipe axis and the mounting dimension is

right. Then, turn the element holder clockwise

until the sensor comes in close contact with the

pipe.

Stop turning the element holder when it stiffens

because the transmitting surface comes in

contact with the pipe surface. Be careful not to

turn the holder excessively.

Stainless belt

Stainless belt

Element

holder

Cable

7 - 9

Page 39

7.7 How to mount medium diameter sensor to pipe

BULLETIN F-68

q Spread silicone grease over the whole

transmitting side of the sensor. Care should be

taken to prevent entry of air bubbles.

Clean the surface of the pipe, then mount the

sensor.

w Press the sensor against the pipe. Align the

center of the sensor with the intersection of the

marking line, and the mounting dimension

reference surface with the marking line.

Silicone grease

e Make sure that the center mark on the sensor is

aligned with the marking line. Then, connect the

coaxial cable to the transmitter.

Note) Do not pull the coaxial cable. If it is

pulled, the sensor is shifted which

results in incorrect measurements due to

poor contact with the pipe.

7.8 How to fold gauge paper

(used for determining mounting position)

q Prepare a sheet of paper (vinyl sheet) of 4 D or

more in length and 200 mm or longer in width (D

is preferable) as shown below.

w Draw a line intersecting at right angles with the

longest sides about 100 mm from one paper end.

To be aligned

Marking line

4D

Parallel

Center mark

200 mm or

D or larger

About 100 mm

7 - 10

Page 40

8. MEASUREMENT

BULLETIN F-68

When wiring, piping settings and mounting of the sensor are completed, start the measurement.

The contents displayed on the MEASURE screen are as follows.

Instantaneous flow meter

⋅ On the MEASURE screen, instantaneous flow, instantaneous flow velocity, analog output, and analog input

are displayed.

Of the 4 stages displayed on the MEASURE screen, 2 contents can be arbitrarily allocated to the 1st and 2nd

stage. Allocation is accomplished by selection of “UNIT”.

If the flow rate is displayed when water flow stops, refer to page 9-3, “ZERO ADJUST” and page 9-5,

“CUT OFF”.

If the flow display fluctuates, refer to page 9-3 “RESPONSE SET”.

Integrated flow rate

⋅ When the integrated flow rate is displayed, “+TOTAL” and “-TOTAL” are fixed on the third stage and 4th

stage, respectively.

⋅ Integrated flow rate value is available in the range from 0000000 to 999999. If the value exceeds 9999999,

it resets to 0000000.

Instantaneous flow rate,

flow velocity, etc.

How to view display

x10

Mantissa Exponent

X10 0 =1 time

1

=10 times

X10

2

=100 times

X10

Example)

When the cursor points to

the "MEASURE"

Tab as displayed, use

care since the measurement value will not

change.

Move the cursor within

the screen by pressing

the key.

1.200

corresponds to

1.2X10=12.

x10

Battery alarm

95-06-27 11:49

FLOW RATE

UNIT: m3/h

x10

VELOCITY UNIT: m/s

MEASUREMEASURE

1

x10

+ TOTAL UNIT: mL

- TOTAL

NORMAL

Status display

Integrated flow rate in forward direction

Integrated flow rate in reverse direction

UNIT: mL

IndicatorClock

Unit of indication

value

UNIT

L/s

L/min

L/h

ML/d

m3/s

m3/min

m3/h

Mm3/d

BBL/s

BBL/min

BBL/h

STOP

RESET

STOP

RESET

Resetting of integrated flow rate

MBBL/d

m/s

AI %

AO %

Unit of totalize

Status display of

totalize

Instantaneous

flow rate

Instantaneous

flow velocity

Analog input

Analog output

8 - 1

Page 41

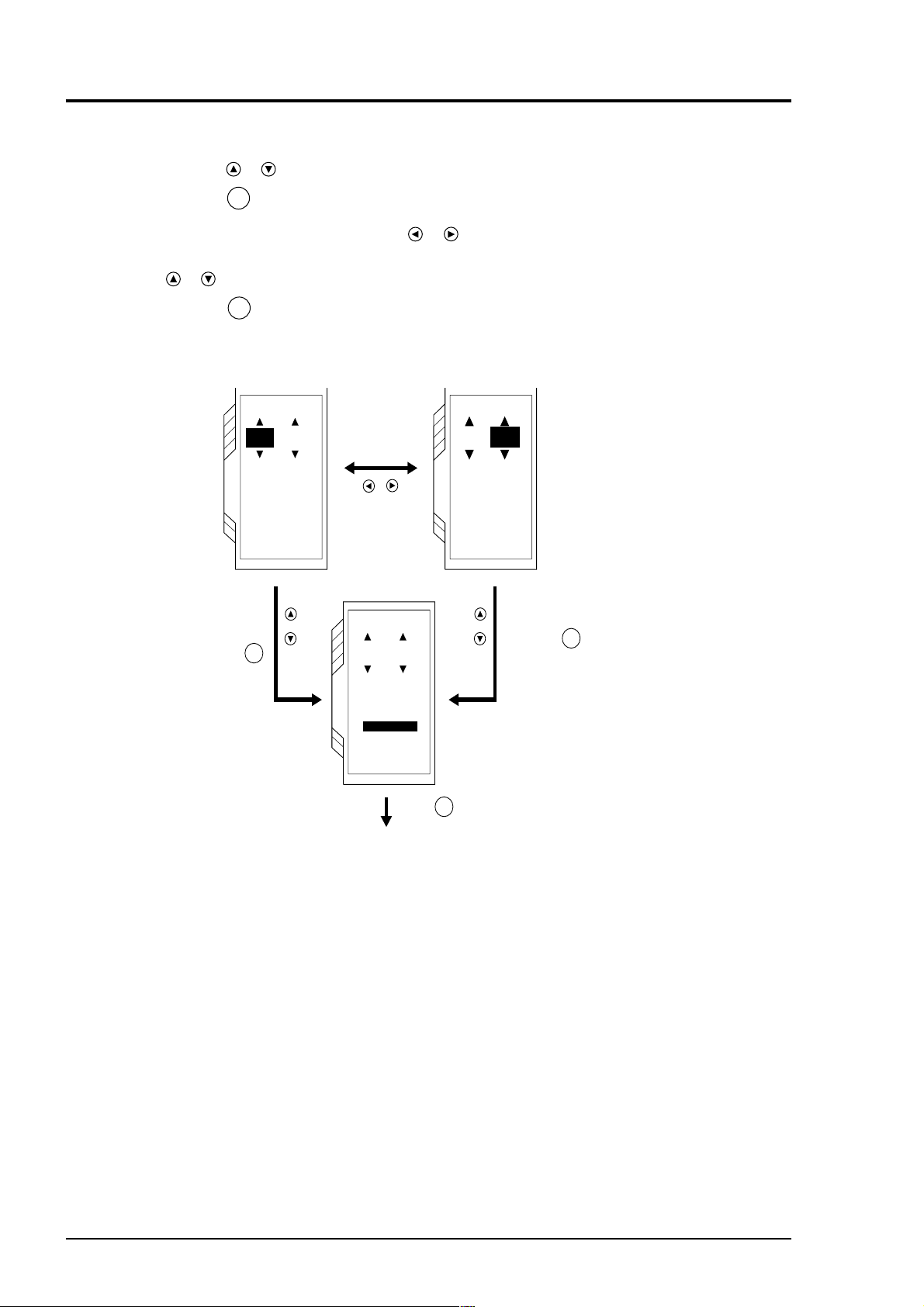

qq

BULLETIN F-68

q “Indicator”

qq

Shows the intensity of ultrasonic receiving signal.

Check if 2 or more indicators are displayed.

If one or less indicator is displayed, raise the transmission voltage level as shown on page 6-12.

When the sensor is not connected, the indicator may be lighted by sensing noises. But, this is not

an error.

ww

w “Status display”

ww

Check if “NORMAL” is displayed. If the sensor is not connected, other messages may be displayed.

This is not an error.

In case other message is displayed after installing and connecting the sensor, take corrective actions

according to page 9-33, “System check function”.

If “NORMAL” is not displayed when 1 or less indicator is display, refer to page 11-2, “Error in

measured value”.

ee

e “Battery alarm”

ee

When activating this instrument on the built-in battery, check if the BATTERY ALARM ( ) is not

displayed. If “BATTERY ALARM” is displayed, the power is turned OFF in about 20 minutes.

When charging the battery, refer to page 4-1 “To charge the battery”.

rr

r Unit of integration

rr

When changing the unit of integration, refer to page 9-6, “TOTALIZE: when performing the

integration process of measured data (totalize)”.

tt

t Unit of indication value

tt

To change the units of flow rate and flow

velocity on the MEASURE screen;

q Move the cursor to “UNIT” by pressing the

key.

or

ENT

w Press the

key, and the screen

appears, enabling the unit of flow rate to be

selected. Select any unit by pressing the

key and press the

or

yy

y Status display of integration

yy

ENT

Meaning of display

STOP: Not totalized

RUN: Totalizing in progress

To start the action of integration, refer to page

key.

FLOW RATE UNIT: m3/h

x10

VELOCITY UNIT: m/s

MEASURE

x10

+ TOTAL UNIT: ml

– TOTAL UNIT: ml

NORMAL

STOP

RESET

STOP

RESETRESET

Point the cursor to

UNIT of flow rate

and press the

key, and Menu

screen is displayed.

9-6, “TOTALIZE”.

uu

u “Clock set”

uu

This instrument has a timer function. For the

timer to set the time, refer to page 9-15,

FLOW RATE UNIT: m3/h

“CLOCK SET”.

The timer function should be used based on this

watch.

ii

i Reset

ii

The integration value can be set to 0 or “any

other numeric value”. To reset the integration

value, point the cursor to “RESET” by pressing

or

the

key, and then press the

When you want to reset to any value or 1000 for

example, refer to page 9-7, “To set reset data”.

ENT

key.

VELOCITY UNIT: m/s

MEASURE

+ TOTAL UNIT: ml

– TOTAL UNIT: ml

NORMAL

x10

x10

STOP

RESETRESET

STOP

RESET

Point the cursor to

RESET and press

ENT

the key,

and totalize is

reset.

ENT

UNITUNIT

L/s

L/min

L/h

ML/d

m3/s

m3/min

m3/h

Mm3/d

BBL/s

BBL/min

BBL/h

MBBL/d

m/s

AI %

AO %

8 - 2

Page 42

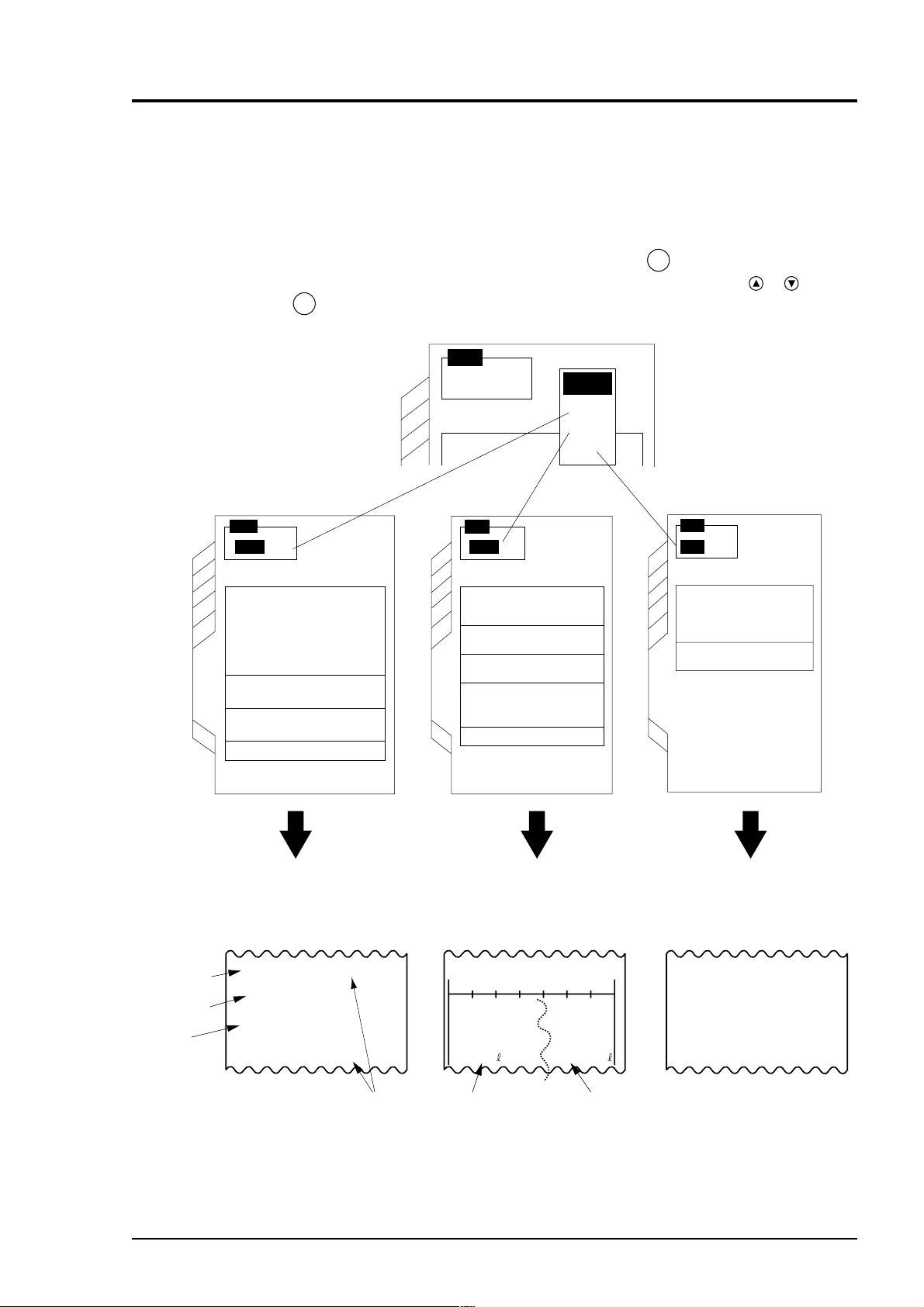

9. SETTING OPERATION (APPLICATION)

BULLETIN F-68

This section describes an outline and page configuration of each function page

SITE SETUPSITE SETUP

Condition settings for

measurement

SITE SETUP

PARAMETER MEMORY

PIPE PARAMETER

ZERO ADJUST

RESPONSE SET

SITE SETUPSITE SETUP

CALIBRATION

CUT OFF

TOTALIZE

--- SENSOR SPACING ---

126.7mm

MANUAL ZERO

0 s e c

0 . 0 0 0 m/s

ANALOG

Settings of analog input

and output

ANALOG IN /OUT

INPUT

DISPLAY

INPUT RANGE

ADJUST

OUTPUT

DISPLAY

ANALOGANALOG

RANGE UNIT

OUTPUT RANGE

OUTPUT MODE

BURN-OUT

ADJUST

0.000E0

m/s

1.000E0

0.8-4-20mA

HOLD

LOGGERLOGGER

Saving of measured value to

memory, and display and

output of data

FIow Site.

**

**

**

**

**

**

**

**

REMAIN

255 BLOCK

LOG NAME

EMPTY

**

EMPTY

**

EMPTY

**

EMPTY

**

EMPTY

**

EMPTY

**

EMPTY

**

EMPTY

**

DATA

MODE

SETUP

No

1

2

3

LOGGERLOGGER

4

5

6

7

8

9

10

PRINTERPRINTER

Various outputs on printer

MODE

TEXT

UNIT

TIMER MODE

PRINTER

SAMPLING PERIOD

PRINT OUT

FLOW RATE

VELOCITY

+ TOTAL

— TOTAL

ANALOG IN OFF

OFF

OFF

OFF

TIMER

00:00:01

SYSTEM SETUP

Change of basic system

settings of main unit

SYSTEM SETUP

CLOCK SET

COMMUNICATION

SYSTEM SETUP

SYSTEM OF UNITS

MEASUREMENT METHOD

MEMORY INITIALIZE

95-06-25 15 : 17 : 00

BAUD RATE

PARITY

STOP BIT

300

NONE

1 BIT

METRIC

1

SYSTEM CHECKSYSTEM CHECK

Check function of

device status

SYSTEM CHECK

ERROR CHECK

SIGNAL CHECK

OUTPUT CHECK 0.00%

VERSION NUMBER

SYSTEM CHECKSYSTEM CHECK

9 - 1

Page 43

9.1 How to use SITE SETUP function (SITE SETUP page)

BULLETIN F-68

9.1.1 PARAMETER MEMORY: when registering data which are set and calibrated on the page

“P ARAMETER MEMOR Y” allo ws you to register data which are set and calibrated on the “SITE SETUP”

page to the memory of the main unit.

When measurements are performed in the same pipe, registered data can be loaded to help you in achieving measurements. (Up to 20 registrations of data can be made to the memory.)

MODE

[Operation]

q Select “PARAMETER MEMORY” by

pressing the

SETUP page.

Press the

“PARAMETER MEMORY” screen is

displayed. To return to the “SITE

SETUP” screen, press the

or

ENT

key, and the

key on the SITE

ESC

key.

SITE SETUP

PARAMETER MEMORY

PIPE PARAMETER

ZERO ADJUST

RESPONSE SET

SITE SETUPSITE SETUP

CALIBRATION

CUT OFF

TOTALIZE

--- SENSOR SPACING ---

126.7mm

MANUAL ZERO

0 s e c

0 . 0 0 0 m/s

ENT

SITE SETUP

ESC

SAVE

No

1

2

3

4

5

6

7

8

9

10

LOAD NAME

SITE NAME

MODE

LOAD NAME

SAVE

w Move the cursor to “MODE” and press

ENT

the

key. The mode selection

screen will appear.

ENT

When pressing the

key after mode

selection, the relevant mode is

determined.

No

1

2

3

SITE SETUP

4

5

6

7

8

9

10

MODE

SITE NAME

SAVE

LOAD

DELETE

Stores the contents

of setting in memory.

Reads out the

contents of setting.

Deletes the contents

of setting.

e To select “SAVE” or “LOAD”, select a name (No.) of a site by using the cursor and press the

ENT

key. So, this function enables you to save and load the data.

Note) When using the “SAVE” function, it is

necessary to enter “SITE NAME” in

advance.

The name set in the “SITE NAME” given on

page 6-3, “PIPE PARAMETER” is saved.

r When selecting “DELETE”, select the site name

(No.) by using the cursor, and press the

ENT

key, so the data will be deleted. Be careful since

95-06-27 13:12

MODE

SAVE

SGP 1'

No

SGP 1'SGP 1'

1

SGP 1 1/4'

2

SGP 1 1/2'

3

SITE SETUP

SGP 2'

4

SGP 2 1/2'

5

SGP 3'

6

SGP 3 1/2'

7

SGP 4'

8

SGP 5'

9

SGP 6'

10

LOAD NAME

SITE NAME

Indicates the

read name.

registered pipe parameter data are deleted.

9 - 2

Page 44

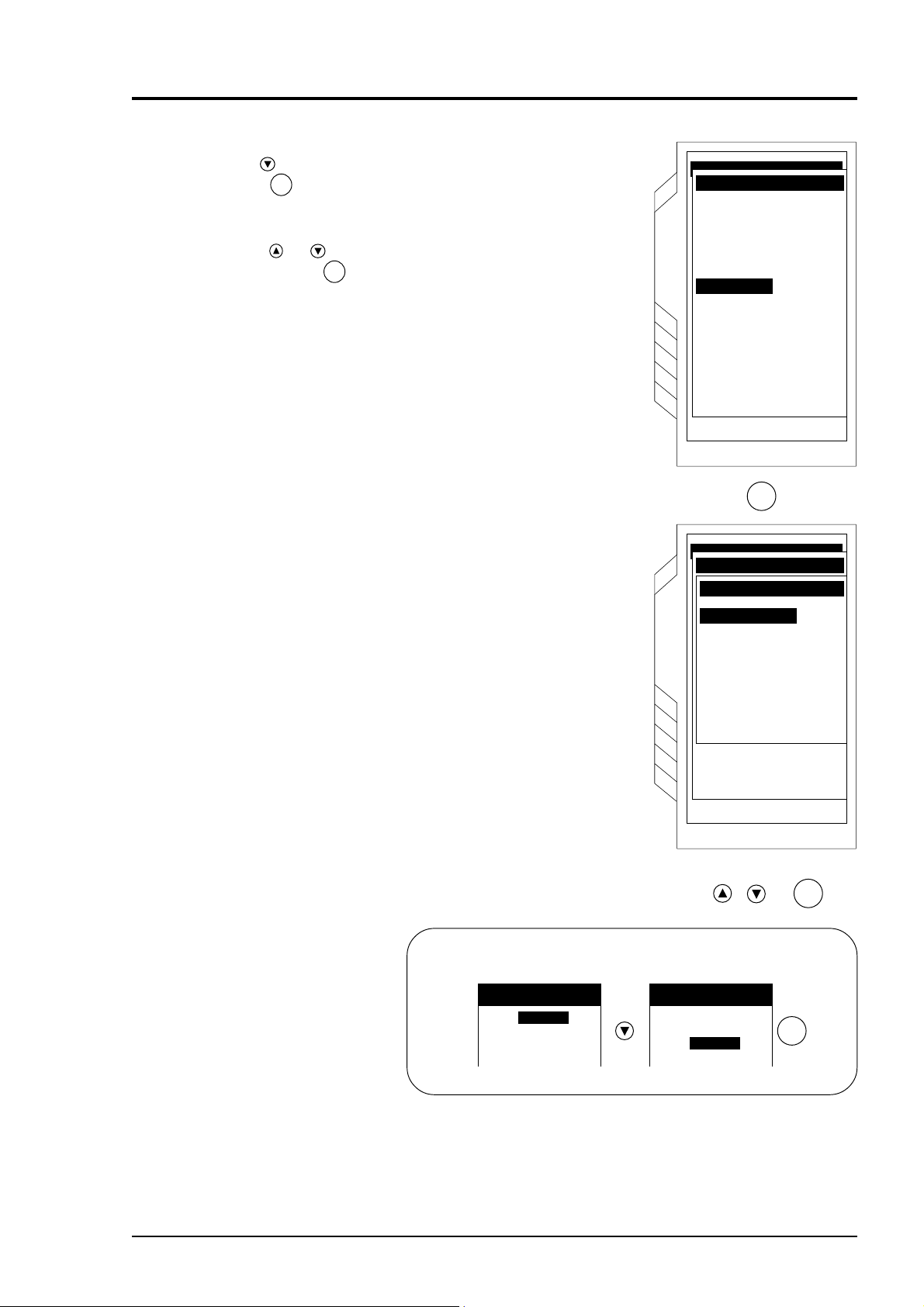

9.1.2 ZERO ADJUST: when performing zero adjustment

BULLETIN F-68

On this screen, zero point is adjustable.

Operation

q Select “ZERO ADJUST” by the

ENT

the

key. The zero adjustment screen will appear.

w Select ZERO ADJUST, and press the

or

ENT

adjustment to be specified is carried out.

• [Manual zero]

Perform zero adjustment in situation where the flow is

stopped.

The measurement indication should be at zero when the

ENT

key is pressed.

This zero calibration operation should be performed

after stopping flow.

• [Clear]

Calibration is performed without stopping flow.

Calibration value by MANUAL ZERO is cleared.

CAUTION

When PIPE P ARAMETER or measurement method

(page 9-17) is changed, perform zero adjustment.

key and press

key. Zero

SITE SETUP

PARAMETER MEMORY

PIPE PARAMETER

RESPONSE SET

SITE SETUP

CALIBRATION

CUT OFF

TOTALIZE

---

SENSOR SPACING

0.0mm

SITE SETUP

ZERO ADJUST

SITE SETUP

MANUAL ZERO

ZERO ADJUST

MANUAL ZERO

CLEAR

MANUAL ZEROZERO ADJUST

0 s e c

0 . 0 0 0 m/s

---

9.1.3 RESPONSE SET : when changing output response

The response time of output is to be set here. (range: 0 to 99

sec)

This function is used when stabilizing the output or responding

to the high velocity.

[Operation]

key on the SITE SETUP page and select

q Press the

“RESPONSE SET”. Press the

moves to the set item, enabling you to set the response

time.

w Move the digit by pressing the

numeric values by using the

press the

or

ENT

key for setting.

ENT

key, and the cursor

or

key and enter

or

key. After entry,

63%

Flow rate

Response time

SITE SETUP

PARAMETER MEMORY

PIPE PARAMETER

RESPONSE SET

SITE SETUP

CALIBRATION

CUT OFF

TOTALIZE

---

SENSOR SPACING

0.0mm

Time

MANUAL ZEROZERO ADJUST

50 s e c

0 . 0 0 0 m/s

---

9 - 3

Page 45

9.1.4 OUTPUT CORRECTION: when calibrating measured value (out-

BULLETIN F-68

put calibration function)

This function enables you to set

Calculation of output value

correction values.

Measured

[Settable range of zero point:

value

-1.000 m/s to 1.000 m/s]

[Settable range of span:

0 to 200%]

0

Correction

Zero point shift

[Operation]

q To open the “CALIBRATION” screen, press the

key on the SITE SETUP page and

or

select “CALIBRATION”. Then, press the

ENT

key.

Set span value

×

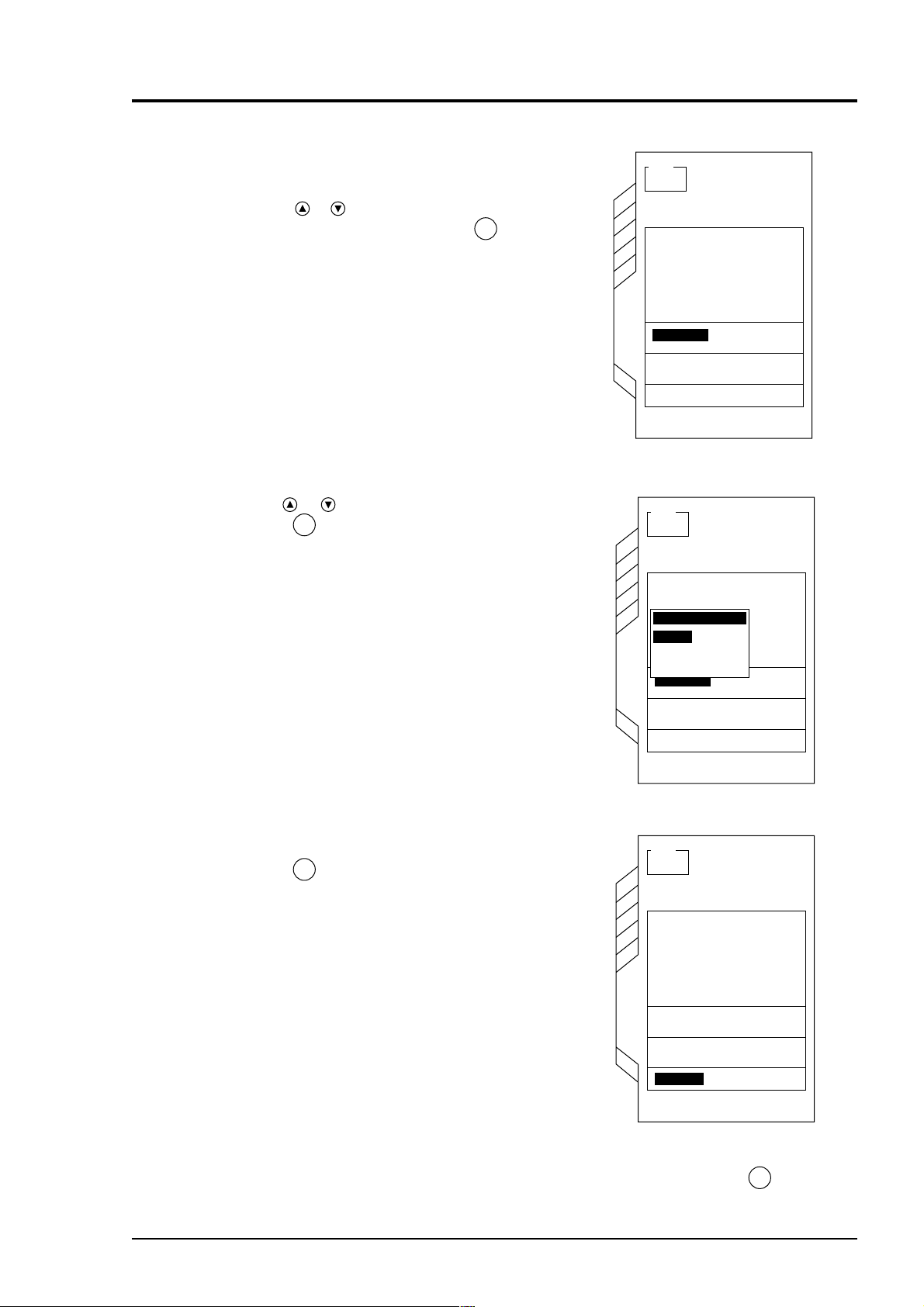

100