Page 1

Bulletin P-PTGD

Series PTGD Differential Pressure Piston-Type Gage

Specifications - Installation and Operating Instructions

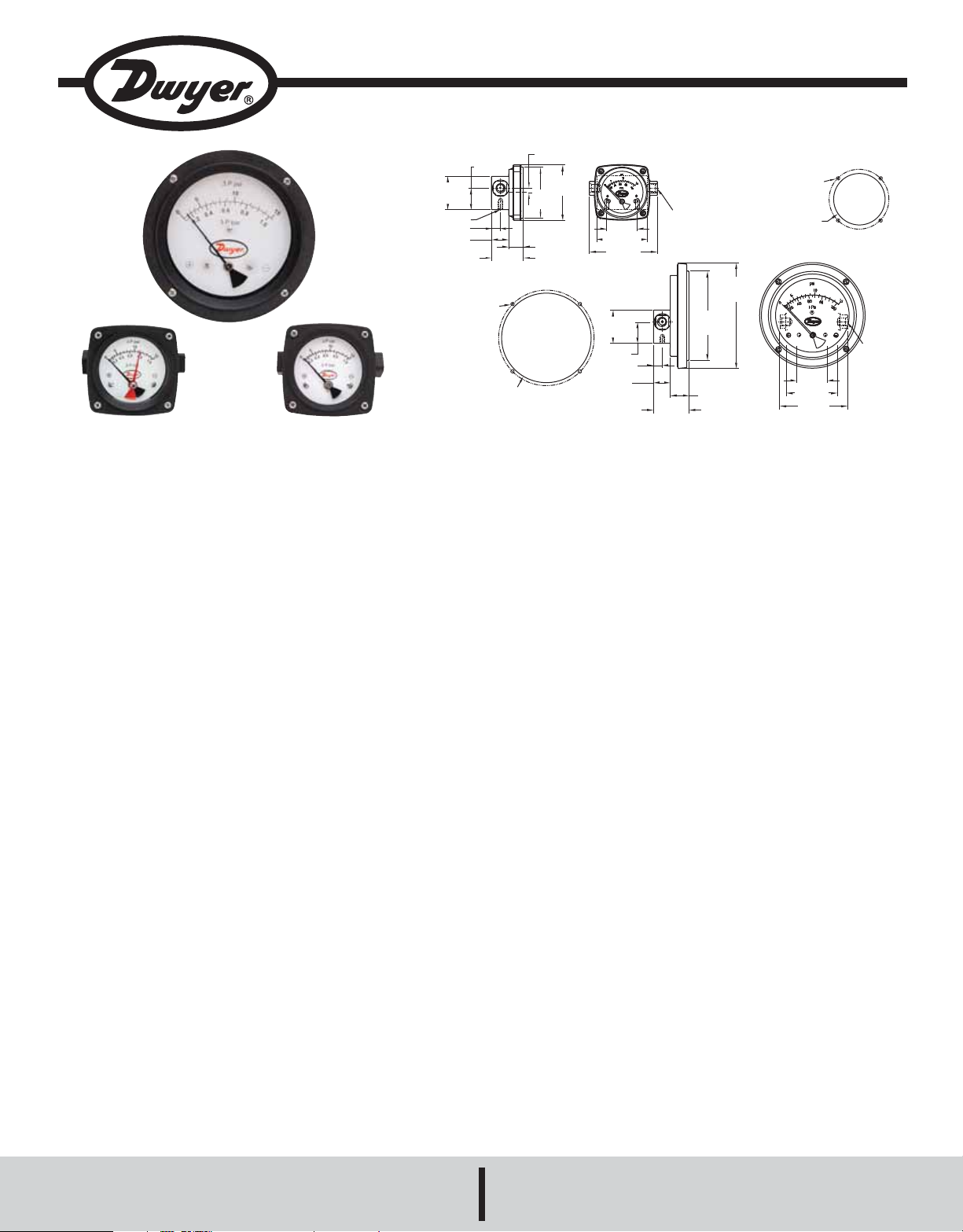

1-4

1-7/8

[47.60]

[6.50]

3-3/32

[83.00]

3

[76.20]

7/8 [22.00]

HIGH LOW

1-13/16

[46.00]

3[76.00]

3-31/32

[101.00]

1-31/32

[50.00]

7-9/32

[32.20]

1/2 [12.60]

1 [25.20]

EQUALLY SPACED ON A

ø3-1/2 [ø88.90] BOLT CIRCLE

1/4˝ NPT

BOTH ENDS

6-7/32

[157.93]

5-1/4

[133.30]

1-3/32 [28.10]

2-1/8

[54.00]

4X ø3/16 [ø5.16]

ø3-1/32 [ø76.99]

PANEL CUTOUT

HIGH LOW

1-13/16

[46.00]

3 [76.00]

3-31/32

[101.00]

1-9/32

[32.20]

1-31/32

[50.00]

2X 1/4˝ UNC

1/2 [12.60]

1 [25.20]

4X ø3/16 [ø5.16]

EQUALLY SPACED

ON A ø5-5/8 [ø142.85]

BOLT CIRCLE

ø5-9/32 [ø133.97]

PANEL CUTOUT

1/4˝ NPT

BOTH ENDS

The Series PTGD Differential Pressure Piston-Type Gage

can be

used to measure the pressure drop across filters, strainers, pump performance testing, and heat exchanger pressure drop monitoring. Its simple,

rugged design possesses weather and corrosion resistant gage front with a

shatter resistant lens. The Series PTGD contains a piston-sensing element

which provides different differential pressure ranges with full-scale accuracies

of ±2%. Constructed with aluminum or 316SS and available with two 1/4˝

FNPT end connections, the Series PTGD provides over-range protection rated

to 3000 PSIG (200 bar) or 6000 PSIG (400 bar) depending on model.

Inspection

Before installation check the name plate on each instrument against the

receiving paperwork and the intended application for correct part number, materials of construction, working pressure, dial range, etc. Inspect

for shipping damage and if damaged, report it immediately.

INSTALLATION

The Series PTGD is calibrated and tested prior to shipment and is ready

for immediate installation. Use of the following installation procedures

should eliminate potential damage and provide optimum trouble free

operation.

1. Process Connections: 1/4˝ FNPT are provided as standard. There

are two connections on the housing identified as “HI” and “LO” for high

pressure and low pressure. Be sure to get these plumbed to the proper

connections on your system. Improper connection will not damage the

instrument but it will not function properly. Flexible tubing is recommended to minimize the effect of possible vibration.

2. Instrument Location: On liquid service, the instrument should be

mounted below the process connections to facilitate self-bleeding. On

gas service, it should be located above the process connections to promote self-draining. If the process contains particulates, a “pigtail” loop or

drop leg (manometer “U-tube” configuration) in the tubing will minimize

the possibility of it migrating into the instrument. Shielded cable is recommended for control loop wiring.

3. Panel Mounting: Gages with 2-1/2˝ dials can only be mounted

through the rear of the panel. Make the proper panel cutouts as shown

in figure above. Remove the (4) bezel screws. Insert the screws through

the front of the panel and into the gage bezel. Tighten the screws

securely, alternating in a diagonal pattern.

SPECIFICATIONS

Service: Compatible gases and liquids.

Wetted Materials: Gage body: Aluminum or 316 SS; Piston: Aluminum

or 316 SS; Spring: 302 SS; Seals: Buna-N (standard); PTFE, Ceramic

Magnet; Dial Case: Nylon 6 30% glass filled gage case.

Window: Acrylic.

Accuracy: ±2% FS ascending.

Pressure Limits: 3000 psi (206 bar) for aluminum body; 6000 psi (413

bar) for SS body.

Size: 2.5˝ (63 mm) or 4.5˝ (115 mm).

Mounting Orientation: Mount in any position.

Process Connections: 1/4˝ female NPT end connections standard;

1/4˝ female NPT back or bottom connections available. All styles available with 1/4˝ BSP.

Weight: Aluminum: 2.5˝ .88 lbs (399 g); 4.5˝ 1.35 lbs (612 g); Stainless

Steel: 2.5˝ 1.75 lbs (794 g); 4.5˝ 2.3 lbs (1.04 kg).

Gages with 4-1/2˝ dial should be mounted from front of the panel. Make

the cutout as indicated in above figure. Insert the (4) panel mounting

studs, finger tight into the metal inserts located in the rear of bezel. Insert

the gage through the panel aligning the panel mounting studs with the

holes in the panel. Install the (4) M4 nuts onto the studs and tighten

securely.

TROUBLESHOOTING

A. Check for proper hook up. High to “HI” low to “LO”.

B. Make sure that certain block valves are open.

C. If A & B check out correctly, loosen high-pressure line to determine if

there is pressure to the instrument.

D. Verify that the gage is not in an electromagnetic/magnetic

environment, i.e., close proximity to high current power lines.

MAINTENANCE

The Series PTGD Differential Pressure Gages are not field serviceable

and should be returned if repair is needed. (Field repairs should not be

attempted and may void warranty). Be sure to include a brief description

of the problem plus any relevant application notes. Contact customer

service to receive a return goods authorization number before shipping.

©Copyright 2009 Dwyer Instruments, Inc. Printed in U.S.A. 12/09 FR# R1-443804-00

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...