Page 1

Bulletin J-24

Particu late Moni toring Sys te m s

PMT

Particulate Transmitter

PMT Series

INSTALLATION & OPERATING

MANUAL

Dwyer Instruments, Inc.

102 Indiana Highway 212

P.O. Box 373

Michigan City, IN 46361 USA

Telephone 800-872-9141

www.dwyer-inst.com

Page 2

Particulate Monitoring Systems Installation & Operati ng Manual

I. Technical Support & Return Procedure

Dwyer Instruments, Inc. provides industry leading technical support for all product lines. The

technical support department is staffed with a team of engineering professionals.

Areas of assistance provided by the Technical Support department include:

• Product Installation

• General Operation

• Application Specific

• Routine Calibration

• EPA Compliance

• Performance Upgrades and Add-On Features

To ensure the best and most efficient technical support please be prepared with the following

information prior to contacting Dwyer Instruments, Inc. If it is determined that the component must be

returned for evaluation/repair, a Return Material Authorization number will be issued. You must

include the RMA number on the packing slip and mark the outside of the shipping container.

• Company Name ________________________________________

• Product Model Number ________________________________________

• Product Serial Number ________________________________________

• Date of Installation ________________________________________

• Reason for Return ________________________________________

Dwyer Instruments Technical Support may be reached by:

Phone: (800) 872-9141

Fax: (219) 872-9057

E-Mail: tech@dwyer-inst.com

Hours of Operation: 8AM – 5PM Central Standard Time

• Any control unit or particulate sensor that was exposed to hazardous materials in a process

must be properly cleaned in accordance with OSHA standards and a Material Safety Data

Sheet (MSDS) completed before it is returned to the factory.

• All shipments returned to the factory must be sent by prepaid transportation.

• All shipments will be returned F.O.B. factory.

• Returns will not be accepted without a Return Material Authorization number.

Document No. 209-1026-E ii ©2007

Page 3

Particulate Monitoring Systems Installation & Operati ng Manual

II. Notifications

This document contains important information necessary for proper operation of the product.

It is strongly urged that all users of the product read this manual in its entirety. All instructions

should be followed properly and any questions that arise should be discussed with Dwye r

Instruments, Inc .

Any use or distribution of this document without the express consent of Dwyer Instruments,

Inc. is strictly prohibited. Any reproduction is prohibited without written permission.

In no event will Dwyer Instruments, Inc. be liable for any mistake, including lost profits, lost

savings, environmental compliance costs or other incidental or consequential damages arising

out of the use or inability to use this manual, even if advised of the possibility of such da mages,

or an y claim b y any oth er par ty.

Identifies information about practices or circumstances that can lead to personal

injury or death, property damage, or economic loss.

Warning statements help you to:

• Identify a hazard

• Avoid a hazard

• Recognize the consequences

Identifies information that is critical for successful application and

IMPORTANT

Identifies information, sections or statements in this manual that apply to

understanding of the product.

approved hazardous area systems, regulations or installation.

Document No. 209-1026-E iii ©2007

Page 4

Particulate Monitoring Systems Installation & Operati ng Manual

III. Approvals and Certifications

CE Conformant

The Electronics and Particulate Sensors conform to the appropriate country standards and

governing regulations listed below:

EN 55011/2002 Limits and methods of measurement of radio interference

characteristics of industrial, scientific and medical equipment. Group

1, Class A.

EN61000-6-2/2001 Electromagnetic compatibility – Generic immunity standard Part 6-2:

Industrial environments.

EN61000-4-2/2000 Electrostatic discharge (ESD), 4kV contact discharge, 8kV air

discharge, 4kV horizontal and vertical coupling planes.

EN61000-4-3/2002 Radiated electromagnetic fields, 10V/m, 80-1000Mhz.

AC line isolation for the Particulate Transmitter must be provided by an

external isolating DC power supply with CSA or UL marking. No power

supply is provided with or sold as an accessory.

CSA Certified

This Particulate Monitoring system is certified by the Canadian Standards Association (to

US and Canadian Standards) for use in hazardous locations as is specified below:

Hazardous Locations

Class I, Division 2 Groups A, B, C, and D

Class II, Division 2 Groups F, G

Class III

Document No. 209-1026-E

iv ©2007

Page 5

Particulate Monitoring Systems Installation & Operati ng Manual

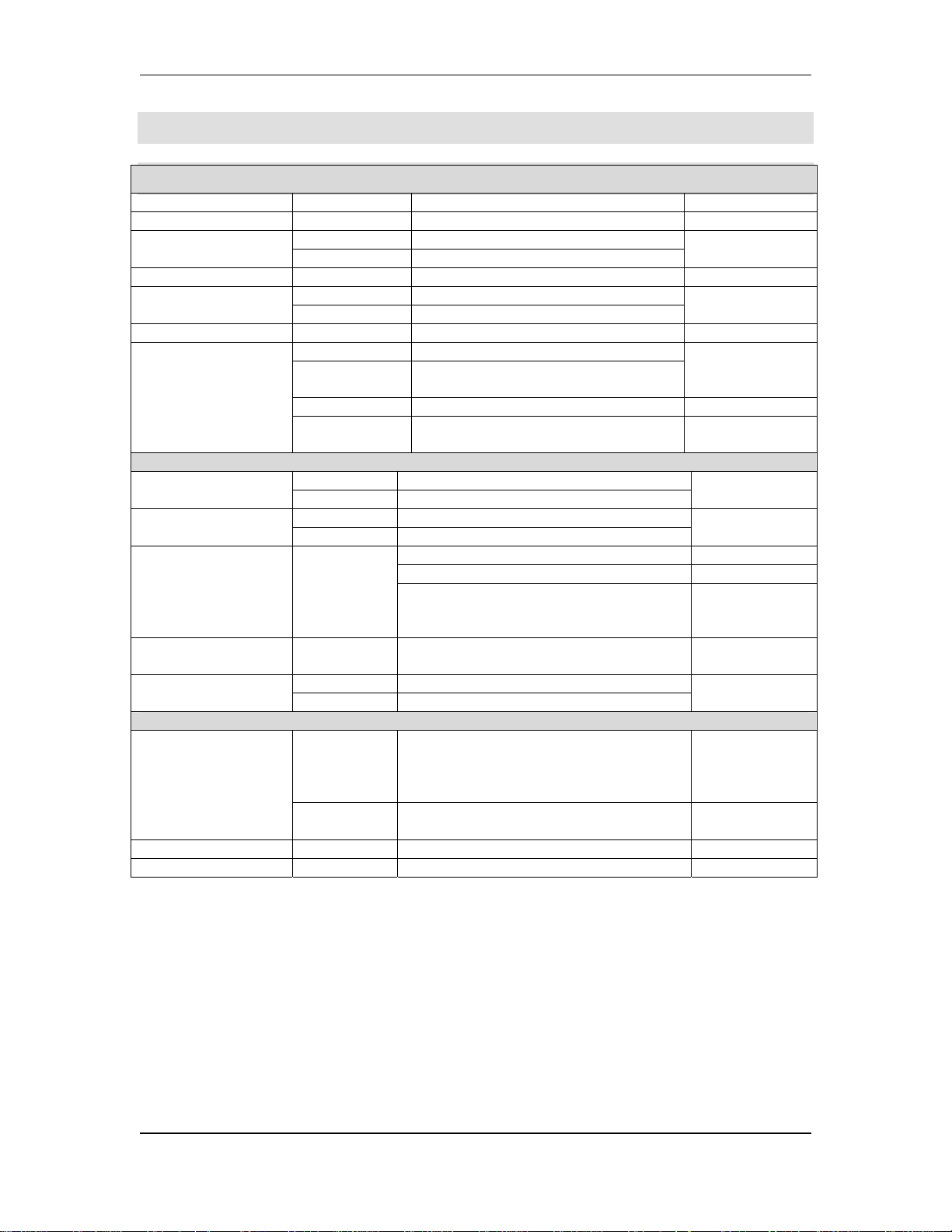

IV. Specifications

ELECTRICAL

PARAMETER DETAIL SPECIFICATION NOTE

Measurement Units picoamperes (pA) 1 x 10 ⎯ ¹² Amp

Standard 10.0pA – 5000pA Measurement Range

Optional 5.0 and 0.5pA – 5000pA

Accuracy ± 5% of Range Full Temp Range

Operating -15F to +160F (-25C to +70C) Ambient Temperature

Range

Digital Filtering Range Ajustable 0.5 Sec – 60 Sec

4-20mA Output

Process Temperature

Range

Pressure Range Operating Full Vacuum to 10PSI Other, consult

Particle Concentration

(Approximate Guide)

Particle Velocity 300 ft/min. (91 m/min.) and Higher

Particle Size 0.3 Micron and Higher

Storage -40F to +185F (-40C to +85C)

Isolation 500VDC Process to Loop

Output

Compliance

Scale Linear or Logarithmic

pA Range 0-100, 0-500, 0-1000, 0-5000 Linear

Standard ½” NPT Mount Mounting

Optional Tri-clamp, Flange

Sensor Teflon over Stainless Materials

Body Stainless Steel

Operating

Type Painted Cast Aluminum Enclosure

Rating NEMA 4X (IP 66)

OPERATING and APPLICATION RANGE

10.0pA

5.0pA

Optional

0.5pA

Optional

Max. RLoad = (Vsupply–18V)/0.02A

(24VDC = 300Ohm Rload Max.)

0.5–500, 5–5000 Logarithmic

MECHANICAL

-40F to +250F (-40C to +120C)

-40F to +450F (-40C to +232C)

-40F to +800F (-40C to +427C) two piece

At least 10.0-5000 mg/m³

At least 0.004 to 2.0 gr/cf

At least 5.0 – 5000 mg/m³

At least 0.002 to 2.0 gr/cf

At least 0.5 to 500 mg/m³

At least 0.0002 to 0.2 gr/cf

Other, consult

factory

configuration

only

factory

Visible

Barely Visible

To Visible

Barely Visible

To Invisible

Document No. 209-1026-E

v ©2007

Page 6

Particulate Monitoring Systems Installation & Operati ng Manual

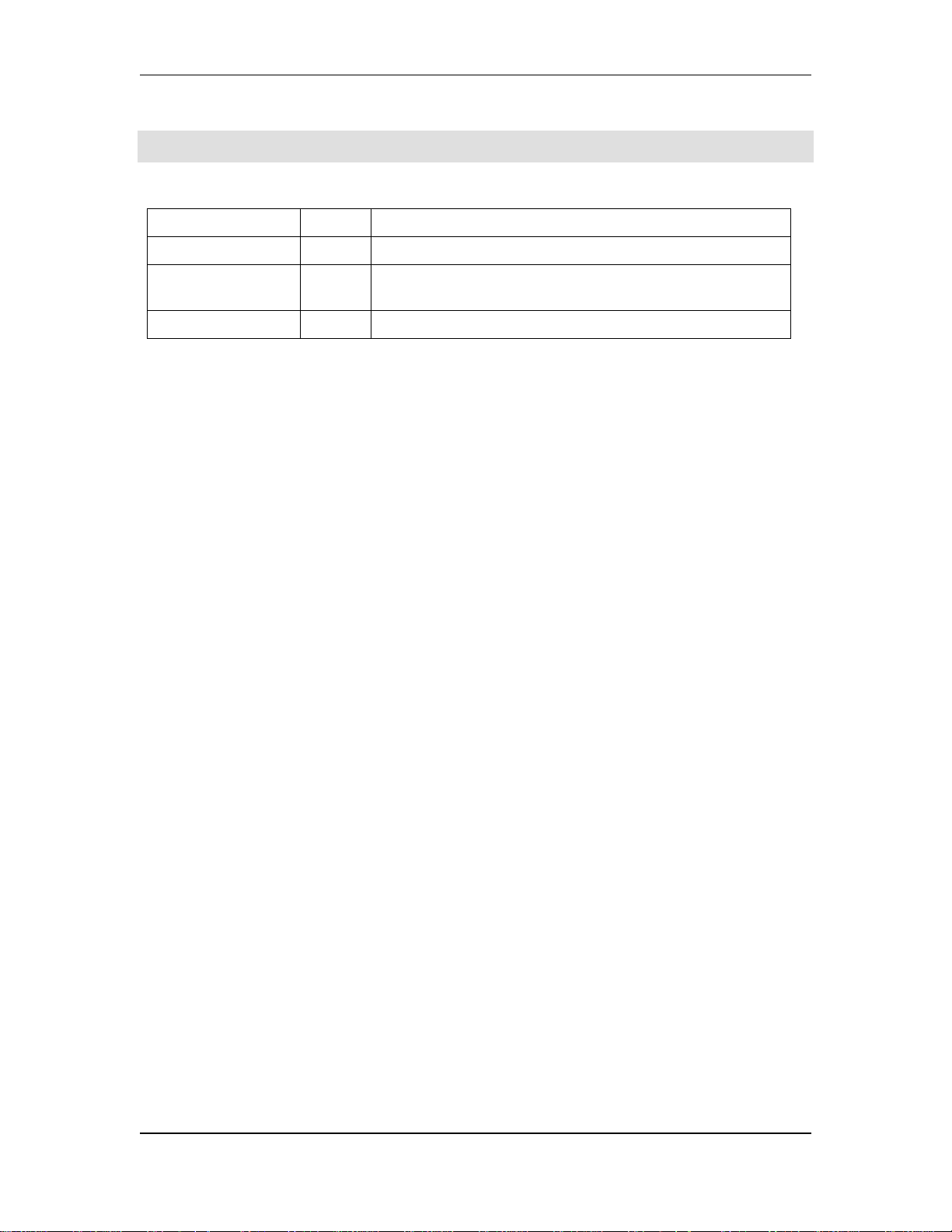

V. Installation Drawings

Drawing Number Sheets Description

225-1032 2 Installation Drawing

225-1036 1 High Temperature / High Pressure Particulate Flow Sensor

Installation Drawing

Document No. 209-1026-E

vi ©2007

Page 7

Particu late Monitoring Sys te m s Installation & Operating Manual

TABLE OF CONTENTS

Safety...............................................................................................................................................2

1.

1.1 Applicable Use.......................................................................................................................... 2

1.2 General..................................................................................................................................... 2

1.3 Hazardous Area Systems........................................................................................................... 3

2. Introduction.................................................................................................................................... 4

3. Comp onent Description.................................................................................................................. 5

3.1 One-p iece Config uration............................................................................................................ 5

3.2 Two-piece Configuration with Remote Electronics ....................................................................5

3.3 Particulate Sensor/Probe............................................................................................................ 6

3.4 Smart Transmitter Modu le.........................................................................................................6

3.5 Coaxial Cable for Particulate Sensor .......................................................................................... 6

3.6 Sensor Test Port (Non -Hazardous Areas Only) ..........................................................................6

4. Particulate Sensor Installation........................................................................................................7

4.1 Location.................................................................................................................................... 7

4.2 Mounting....................................................................................................................... ........... 8

4.3 Senso r Te mperature Considerations........................................................................................... 9

5. Control Unit Installation...............................................................................................................10

5.1 Location.................................................................................................................................. 10

6. Smart Transmitter Wiring............................................................................................................ 11

6.1 Groun ding ............................................................................................................................... 11

6.2 4-20mA Wiring....................................................................................................................... 11

6.3 Sensor Cable Installation – T wo piece config u r ation onl y......................................................... 12

7. Startup .......................................................................................................................................... 13

7.1 4-20mA Loop Ch eck...............................................................................................................13

7.2 System Zero Check .................................................................................................................14

8. Interpreting Readings and Adjusting 4-20mA Range..................................................................17

8.1 Fabric Filter (Baghouse) Applications...................................................................................... 17

8.2 Alarm Levels for Fabric Filter Applications............................................................................. 18

8.3 4-20mA Output Range Adjustment .......................................................................................... 20

8.4 Time-constant Adjustment....................................................................................................... 21

9. Routine Maintenance....................................................................................................................22

10. Troubleshooting............................................................................................................................ 23

11. Spare Parts.................................................................................................................................... 24

Documen t No. 210- 1015-F Page 1 ©2007

Page 8

Particu late Monitoring Sys te m s Installation & Operating Manual

1. Safety

1.1 Applicable Use

These particulate monitor systems ar e not designed for use as a functional safety device and do not

carry a SIL rating. The device m ust not be used as part of a safety syst em or as an input signal to a

safet y system. Th ese monitors ar e designed for general proce s s and envir onmental monitoring.

1.2 General

This apparatus is available with various agency approvals as noted in the approvals section. All

versions of this device have been designed to comply with EN 61010, safety requirements for

elec tric al equipment for measu rement, control a nd laboratory use, and are s u p plied in a safe co ndition.

Before beginning an in stallation the following safety precautions and all precaution s throughout this

manual and in the ins tallation dr awings mu st be followed.

AREA CLASSIFICATION

• Before installing any device confirm area classification requirements. Do

not install any device that is not tagged as suitable for the required area

classificati on .

• WARNING – Substitution of components may impair suitability for

Division 2 hazardous loc ations.

PROCESS AND AMBIENT CONDITIONS

• Before installing any device, confirm ambient temperature, process

temperature and process pressure requirements. Do not install any device

that is not tagged as suitable for the required temperatures and pressures.

Confirm compatibility of the wetted and non -wetted materials.

INSTALLATION PERSONNEL AND SERVICE

• Only appropriately licensed and trained professionals should perform the

mechan ical and el ectrical ins tallation.

• This device does not contain field serviceable components other than th e

line fuse. Only factory personnel can perform service on this equipment.

• For operator safety and to prevent ignition of flammable or combustible

atmospher es always disconnect power before servicing.

GROUNDING AND FUSING

• Before applying power to the instrument, you must connect the sensor

housing and remote electronics housing (two piece configuration) to a

pr ope r ear th ground. Th e se n sor hous in g is con n ect e d t o ea rth ground usi n g

the ext ernal groun d screw. Th e remot e electr onics h ousing is connect ed to

earth ground through the dedicated ground screw inside the housing.

Groundin g to the neutral conductor of a single-phase circuit is not sufficient

protection.

• Only fuses with the required current, volt age and specified type should be

used. D o n ot u s e r ep aired fuses or short-cir cu ited fuse hol d er s .

Documen t No. 210- 1015-F Page 2 ©2007

Page 9

Particu late Monitoring Sys te m s Installation & Operating Manual

REGULATORY CODES

• Installation and operation must adher e to all national and local codes.

1.3 Hazardous Area Syste ms

Systems approved for use in hazardous areas include nameplates indicating that they are suitable for

inst allation in hazard ou s areas. The nameplate lists allowable hazardous areas and T code ratings as

well as approval agen cy markings. Do n ot in stall any device that is not tagged as suitable for the

area classifica tion.

Section s or st at emen ts in thi s man ua l tha t a pply to a pproved ha zar dous ar ea syst ems or in s tall ati on s

are designated with the following symbol. Designation for use in hazardous areas does not make the

system su itable for use as a function al safety device.

HAZARDOUS AREAS

• WARNING – Substitution of components may impair suitability for

Division 2 hazardous loc ations.

• Installation mu st be in accord ance with ANS I /I S A RP1 2 .6 and Nati onal

Electric Code ANSI/NFPA 70, Article 504

• Do not connect or disconnect components unless power has been

disconnected.

• Designation for use in hazardous areas does not make the system

suit able for use as a fun ctional sa fety device.

Documen t No. 210- 1015-F Page 3 ©2007

Page 10

Particulate Monitoring Systems Installation & Operati ng Manual

2. Introduction

A Parti culate Mon itorin g System con sist s of a contr ol unit, a par ticul ate sensor and a sen sor coaxia l

cable. Applications include continuous emissions monitoring, baghouse filter leak detection and

process particulate flow monitoring. Types of particulate include both solid particulates (dusts,

powders, granulars, and pellets) and liquid particulates (mists). Various control unit models and

sensors are pr ovided to match the application an d process monitoring needs.

Principle of Operation

Particulate Monitoring Systems employ a highly reliable technology based on induction. A sensor

probe is mounted in an airflow stream such as a pipe, duct or stack (for small tubing an inline nonintr usive ring sen sor is employed). As particul ate flows near and over the sen sing element, m inute

electr ical cur rents ar e induced in th e sensor an d transfer red to th e control unit by a coa xial cable. A

microprocess or filter s and pr ocesses the signal into a normalized, absolute output that is linear to the

mass concentrat ion of particu late.

_ MASS CORRELATION

IMPORTANT

It is important to note that the above relation between instrument units (pA) and

actual mass (mg/m

appropriate model and range and for providi ng a general indic ation of the typic al

particulate levels monitored. For a true correlation between (pA) and actual

mass (mg/m

must be performed for each application and a recommended model and

detection level must be ordered. It is also important to note th at the accuracy of

such correlations is application dependent and produces the best results with

consistent particulate and process conditions. The user must follow proper

procedures and must understand the typical accuracy of such correlation

techn iques. Consult factor y for details.

3

or gr/cf) is just an approximate guide for selecting the

3

or gr/cf), a gravimetric correlation such as an isokinetic sample

Documen t No. 210- 1015-F Page 4 ©2007

Page 11

Particulate Monitoring Systems Installation & Operati ng Manual

3. Component Description

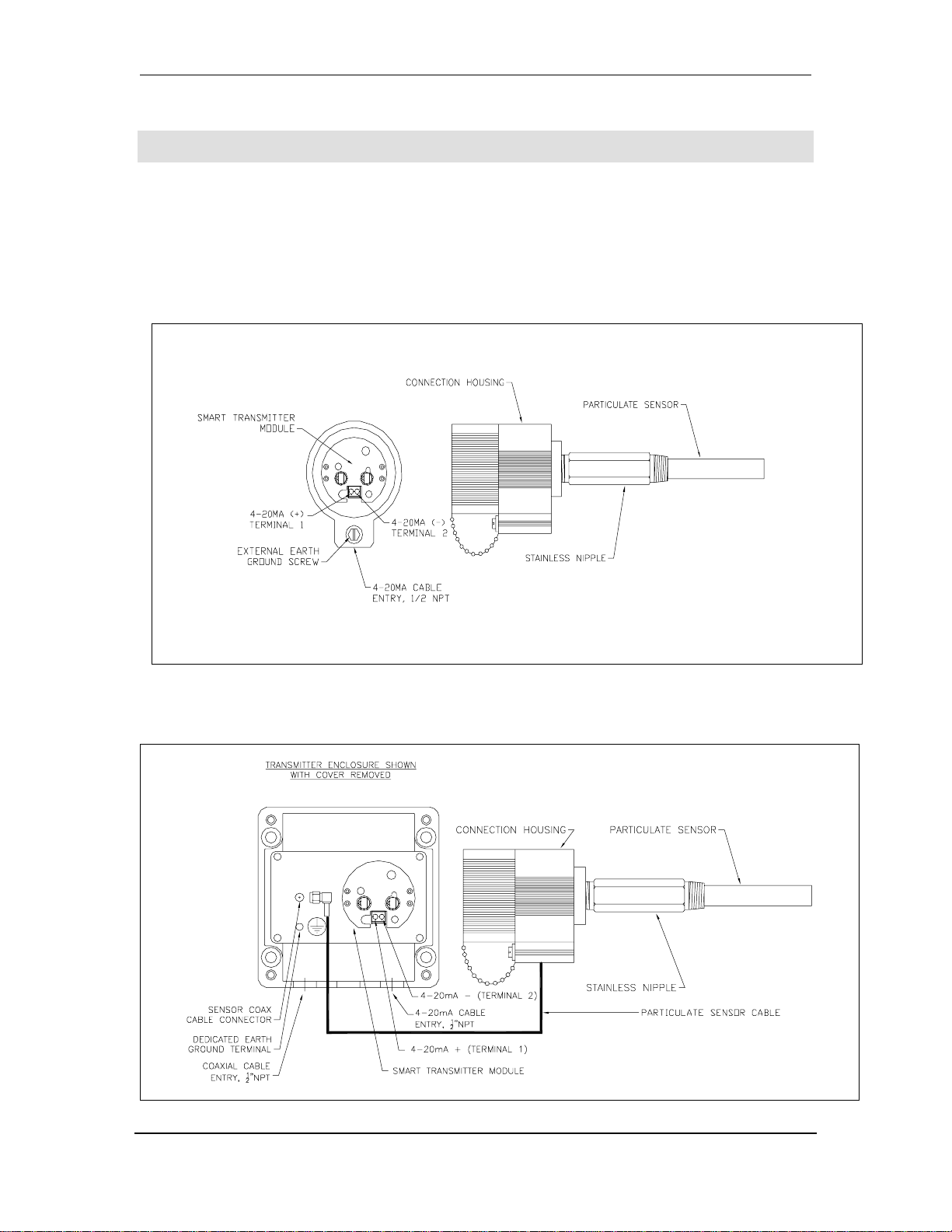

One and two pi ece vers ion s of t h e par ti cula t e tran smit t er ar e ava ila ble wi th var ious pr obe lengths and

mounting configurations. The standard configuration features the smart transmitter module integrated

directly into the sensor connection housing. A two-piece configuration incorporates a separate

enclosu re for th e smar t transmitt er module, a remote sensor/probe and an in terconnect ing cable.

3.1 One-piece Configuration

(Example only, mounting and probe length variable)

3.2 Two-piece Configuration with Remote Electronics

(Example only, mounting and probe length variable)

Documen t No. 210- 1015-F Page 5 ©2007

Page 12

Particulate Monitoring Systems Installation & Operati ng Manual

3.3 Particulate Sensor/Probe

The particulate sensor consists of a stainless probe with a non-con ductive protective layer or coating,

a stainless steel nipple/moun t and the sensor housing. It is a very rugged assembly that is virtually

maint enan ce-fr ee. It does n ot req uire sp ecial ali gnment , is not a ffect ed by n orm al vibr ati on and does

not require cleaning.

3.4 Smart Transmitter Module

The smart transmitter module processes the signals induced into the pr obe, quantifyin g and digitally

filtering them in to an absolute measurement of pA (picoamps). The pA reading is tr ansmitted over a

4-20mA current loop for remote mon itoring with a control system, PLC, panel meter, recorder etc. It

is important that the 4-20mA signal be con verted back into pA at the monitor ing location to enable

evaluating the instrument output rea dings properly. Electrical isolati on is provided between the 420mA loop and the pA measurement circuitry. This isolation provides immunity to ground loop and

power supply/plc analog input card grounding possibilities.

The smart transmitter module is located directly inside the particulate sensor housing for one-piece

configurations. For two-piece configurations the smart transmitter module is located in a separate

TYPE 4X enclosure.

3.5 Coaxial Cable for Particulate Sensor

The cable that connects the particulate sensor to the control unit is a high-quality coaxial cable

specifically desi g ned for the system. Maximum length i s 30 0 ft (91m). Do not use substitute cable.

This ca bl e is requir ed for two-piece con fi g urati ons only.

3.6 Sensor Test Port (Non-Hazardous Areas Only)

The test port is not a necessary component to operate the system, but it is r ecommended. It is a

1/8”NPT x 3” pi pe nipple used to introduce particulate int o the process to perform a natural response

check. The nippl e is s cr ew ed into or welded to the pipe/ d u ct up stream of the sensor. Par ticles are

injected into the flow stream to simulate a natural increase in particle flow. It is primarily intended for

use at negative pressure locations in fabric filter outlet ducting so that wh en the cap is removed line

suction will enable par ticles to be sucked into the flow. A test port is not recommen ded for hazardous

area app lications.

Location: A test port should be in stalled in a negative pressure location. It must be located upstr eam

of the sens or s o par t i cu la t e ca n fl o w very nea r an d around th e s en s or . It sh ou l d be l oca t ed a t le a st 3 ft

(1 m) upstr eam of the sensor and it should be located on the same side of the duct as the sensor so

particles can pass very near and around the sensor. If possible locate the test port at ground level.

Mounting: Th e test port is either screwed into a 1/8 inch NPT threaded hole, or welded in position.

(Note: A foot or so of tubi n g can be con n ect ed t o th e nip pl e to ma ke it eas y to dr aw par ti cl es out of a

conta iner. Only a pinch of particu late at a time is n eed ed for a respon se ch eck.)

_ TEST PORT INSTALLATION

IMPORTANT

• Installation of a sensor test port enables checking the response to an actual

increase in particulate.

Documen t No. 210- 1015-F Page 6 ©2007

Page 13

Particulate Monitoring Systems Installation & Operati ng Manual

4. Particulate Sensor Instal lation

The following applies for both one and two piece configurations.

4.1 Location

The foll o wi ng factors should be cons idered when d etermining the sensor l oca tion:

Area Classifica t ion

Flow conditions

Ambient & Process Tem p eratures

Process Pressur e

Electrical (Faraday) shi elding

Atmospheric shielding (in the case of ducts and stacks open to atmosph er e)

Access for install at i on and service

INSTALLATION PERSONNEL

• Only appropriately licensed professionals should install this product.

• For operator safety and to prevent ignition of flammable or combustible

atmospher es always disconnect power before servicing.

• WARNING – Substitution of components may impair suitability for

Division 2 hazardous loc ations.

SENSOR LOCATION

• Before installing the sensor, confirm ar ea classification r equirements. Do

not install any device that is not tagged suitable for the required area

classification. The sensor may be installed in the following areas:

o Class I, Division 2, Groups A, B, C, D

o Clas s II, Division 2, Groups F, G

o Class III

o Any ordinary location

• Before i n stal l ing th e sensor , con firm am bien t t emp erat ur e req uir em ent s. Do

not install any device that is not tagged as suitable for the required

temperatures or pressures. Confirm compatibility of wetted an d non-wetted

materials.

• For hazardous areas, a maximum ambient temperature of the particulate

sensor enclosure must not be exceeded. Refer to the Temperature

Considerations section for full details.

Documen t No. 210- 1015-F Page 7 ©2007

Page 14

Particulate Monitoring Systems Installation & Operati ng Manual

It is essent ial for th e pip e/duct to pr ovide a n el ectri cal (Far aday) sh iel d for t he sen sor. It is ther efore

required that the pipe, duct or stack is metal and earth grounded (small inline tubing sensors provide

their own section of metal pipe wh ich also must be grounded). Consult the factory when insertion

probe style sensors are to be in stalled in non-conductive pipes, ducts such as plastic or fiberglass.

The particulate sensor must be installed in a position where the flow is reasonably laminar and the

particulate is evenly distributed. The ideal position is where the pipe/duct is straight an d free of items

such as valves, damp ers or ot her fl ow obst ruct ions for a length of 4 diam e ters or longer. Horizontal or

vertical sections are acceptable. For basic flow/no flow detection it is not necessary to select a

location with a long straight section if access has to be sacrificed dramatically. For trending and

measur em ent the n eed for a s tra igh t sect i on and lamin ar flow in creases. Th e par ti cul ate s en sor sh oul d

be positioned with approximately two thirds of the straight section upstream of the sensor and on e

third downstream. The particulate sensor should be located in the center of the pipe/duct. If the

pipe/ducting is square it should be located in the center of one of the sides. In either case, be sure the

position is such that the tip of the sensor reaches the midpoint or beyond. Always use good

engineering sense and be sure th e s ensor will interact with a r easonable rep resentat ion of the flow.

For emissions detection applications such as baghouses or cartridge collectors, good locations are

generally found upstream of the blower. Th e particulate sensor can be located downstream of the

blower but not too cl ose to the stack outlet. There must be sufficient duct downstream of the sensor to

provid e adeq uat e electr ical and atmosp her ic shi eldin g. Th e sensor shoul d be locat ed up strea m of an y

sampling ports by at least two feet. It is not necessary that the sensor be in th e same section of the

duct/stack as the sampling ports. Particulate sampling por ts require fully-developed laminar flow and

longer straight sections.

Extreme vibration should be avoided .

_ ATMOSPHERIC AND ELECTRICAL SHIELDING OF SENSOR

IMPORTANT

• It is essen tial for the pipe/duct to provide an electrical (Faraday) shield for

the sensor. The pipe/duct or stack should be metal with a high quality earth

ground. Consult the factory for non-conductive pipes/ducts such as plastic

or fiberglass. (Small in-line sensors for small tubing provide their own

section of metal pipe, which al so must be grounded).

• When the sensor is placed in a stack/duct choose a location away from

atmosph ere so wind driven atmospheric particulate or rain does not flow

over the sensor and so ex ternal electrical noise cannot affect operation.

• Do not p lace the sen sor where th e pipe/duct i s corroded or cr acked whi ch

may allow water droplets to create signals as th ey flow by.

4.2 Mounting

The foll o wing types of process moun ts are availa bl e for the stan dard probe style sensors:

NPT, Quick-Clamp an d AN S I fl ange.

Inline sensors for small tubing are supplied with swage lock or other tube connections to mount inline

with metal or plastic tubing.

Installation drawings of each mounting type can be found in the appendix.

Documen t No. 210- 1015-F Page 8 ©2007

Page 15

Particulate Monitoring Systems Installation & Operati ng Manual

4.3 Sensor Temperature Considerations

The sensor may be ordered with one of three process t em peratur e ranges:

1. -40ºF to 250ºF (-40ºC to 121ºC)

2. -40ºF to 450ºF (-40ºC to 232ºC)

3. -40ºF to 800ºF (-40ºC to 426ºC)

Note: For the process temperatures in the range of 233ºC - 426ºC, a high temp probe must be used.

The max imum allowab le ambie nt te mp erature at sensor housing is 70ºC .

Table: T Code Rating for Sensor

Process Temperature Does Not Exceed

Maximum Ambi en t

70ºC (160ºF) T6 T4 T2C T1* T1*

75ºC (167ºF) 125ºC (257ºF) 225ºC (437ºF) 325ºC (617ºF) 426ºC (800ºF)

Documen t No. 210- 1015-F Page 9 ©2007

Page 16

Particulate Monitoring Systems Installation & Operati ng Manual

5. Control Unit Installation

The following applies for two-piece configurations only.

5.1 Location

The foll o wi ng factors should be cons idered when d etermining the control unit locati on :

Area Classifica t ion

Ambient Tempera ture

Locate at a position that is convenient for setup and operation

Mount at eye level

Mount to a flat sur face in a vertical orientation

Do not mount to surfaces with excessive heat or vibration

INSTALLATION PERSONNEL

• Only appropriately licensed professionals should install this product.

• For operator safety and to prevent ignition of flammable or combustible

atmospher es always disconnect power before servicing.

• WARNING – Substitution of components may impair suitability for

Division 2 hazardous loc ations.

CONTROL UNIT LOCATION

• Before i nsta lling the contr ol unit, confirm area cl assi fication requir ements.

Do not install any device that is not tagged suitable for the r equired area

classificati on. The control unit may be in stalled in the following areas:

o Class I, Division 2, Groups A, B, C, D

o Clas s II, Division 2, Groups F, G

o Class III

o Any ordinary location

• Before installing the control unit, confirm ambient temperature

requirements. Do not install any device that is not tagged as suitable for the

required temperature.

• For h azardous ar eas, a maxim um am bient tempera ture of th e contr ol unit

enclosu re must not be exceed ed. Refer to th e Temperatur e Consid erations

section for full details.

• Do not l ocate the con trol unit in or n ear sources of very high elect rical n oi se

such as a Variable Fr equency Drive (VFD) or Motor Control Center. Locate

the con trol unit at least 10 feet fr om thes e sources an d, if possibl e, power

the con trol unit fr om a separate power s ource.

Mounting: Mounting holes are in tegrated into the enclosure base. Mounting hardware should be

capable of supporting five times the control unit weight. Re fer installation drawings for dimensions.

Documen t No. 210- 1015-F Page 10 ©2007

Page 17

Particulate Monitoring Systems Installation & Operati ng Manual

6. Smart Transmitter Wiring

6.1 Grounding

Proper gr ounding is essential to ens ure reliable opera t ion and op e rat or safet y.

CONTROL UNIT GROUNDING

For One-Piece configurations:

• Connection to protective ground is made through the process mount.

Protective earth ground connection to external ground screw must be

ins talle d when m ounted to non-metal lic or ungrounded process.

For Two-Piece configurations:

• Connection to protective ground is made through the process mount.

Protective earth ground connection to external ground screw must be

ins talle d when m ounted to non-metal lic or ungrounded process.

• The remote electronics housing is connected to a separate earth ground

through an internal groun d screw. Grounding to the neutral conductor of a

single phase circuit is not suffi cient prot ection.

6.2 4-20mA Wiring

An appr opriatel y li censed electrician mu st perform all el ectrical connections.

CONTROL UNIT WIRING

• All wiring must be rated 250V minimum. Analog 4-20mA wire should be

22 AWG stranded shielded twisted pair, Belden 88761 or equi valent.

• Ana log 4-2 0mA cabl e shiel d shou ld be ter minat ed to ear th groun d in th e

PLC/ DCS/ panel meter cabinet. The shielded wire should be terminated to

gr ound at one end only, ne ver at both end s .

• The coaxial cable must be in conduit that is separ ate from all oth er circuits

for t wo pi ece configurations.

Conduit openings are provided in the bottom of the enclosure to route wiring into the enclosure.

Never drill new conduit openings in the side or top of the en closure as a bad conduit seal may allow

water to enter the enclosure.

Documen t No. 210- 1015-F Page 11 ©2007

Page 18

Particulate Monitoring Systems Installation & Operati ng Manual

6.3 Sensor Cable Installation – Two piece configuration only

Connection: Prior to making coaxial cable conn ections review th e followin g routing in structions.

IMPORTANT

_ PARTICULATE SENSOR COAXIAL CABLE ROUTING

• The sensor cable must be installed in conduit that is separate from all other

wiring.

• The cabl e sh oul d be r ou ted from th e part i cula te s en sor t o the c ontrol unit in

a pa th t hat avoid s hi gh vi brat ion, hea t over 394 °F (200°C) and an y stron g

magn etic or electrical field s.

• The cabl e should be locat ed at least 18 in (46 cm) away from an y po wer

lines (conduit), motors, frequency drives and other sources of electrical

inter ference throughout its entire path .

• The cabl e shou ld be i nsta lled in metal lic con duit . At th e process en d, use a

section of shielded flex conduit that is 1 to 2 times the probe length to ser ve

as a ser vice loop.

The coa xi a l ca ble i s c on n ected t o th e con t r ol un it by a coa x con n ector a nd is connected t o th e sen s or

by two ring terminal s . The connect ors are normally supplied pre-assem bl ed to the cable.

Once t he cable h as been r outed, in sert th e coax conn ector int o the contr ol unit enclosur e leavin g a

very small service loop as specified in the installation drawing shown in the appendix. A larger

service loop should be used at the sensor en d, typically 1 to 2 times the sensor len gth. Any small

amount of extra cable length should be pulled into the near est junction box and NOT left in the sensor

housing or in th e control unit enclosure. If th ere is a signi fi cant amoun t of extra cable (many fe et), the

cable sh ould be sh orten ed at th e sensor end and the sen sor end connector s should be re-assem bled

using factory-supplied connectors and instructions.

IMPORTANT

_ COAXIAL CABLE INSIDE THE CONTROL UNIT

• A ferrite suppressor is located on the sen sor coaxial cable near the coax

connector and must remain inside the control unit enclosure.

• The red cable in sulation must extend a minimum of 6 in (15 cm) into the

coax cabl e conduit .

• Do not l eave any excess ca bl e in the control unit or sensor housin g .

Insid e the particulate sensor encl osu re, attach the coax cable as in di cated in the sensor drawing. Wh en

connecting the br aided shield, ensure it does not touch the surge voltage protection assembly. Do not

leave exc es s cable in side the sensor housing.

Documen t No. 210- 1015-F Page 12 ©2007

Page 19

Particulate Monitoring Systems Installation & Operati ng Manual

−

N

7. S tartup

7.1 4-20mA Loop Check

Upon initial installation the 4-20mA loop connection should be tested. Monitor the transmitter’s mA

output with a multimeter connected in ser ies with the 4-20mA loop or monitor the PLC r egister or

mea s urin g device.

Step 1: Check the transmitter’s 4mA output by settin g the output range switch to the “4mA Test”

position . The output should be 3.9mA – 4.1mA. If th e output is not within the range specified, check

the following:

Output = 0mA – check for proper termination of all wires, check for proper connection of

multimeter, ensure l oop power supply is on.

Output not between 3.9mA - 4.1mA - ensure loop voltage measured across the transmitter input

terminals is 18 – 28VDC.

Step 2: Verify the rea ding at the recor d ing device (PLC, etc.) is reading the equ ivalent of 4mA .

Step 3: Check the transmitter’s 20mA output by s etting the output range switch to the “20mA Test”

position . The output should be 19.9mA – 20.1mA. If the output is not within the range specified,

check the following:

Output not between 19.9mA – 20.1mA – ensure loop voltage measured acr oss the transmitter

inpu t termin als i s 18 - 28VDC. If th e loop volt ag e is with in th e all owable r an ge, ens ure tha t the

extern al loop i mped ance d oes not ex ceed th at all owed for loop c omplian ce. Calcu late ma ximum

allowable external loop impedance (Rmax) as follows:

)(0.14)(

=Ω

R

)max(

mA

ote: I f a mult imeter i s connected i n the ser ies curr ent loop,

its impedance will be added to that of the plc/dcs analog in put

impedance.

Step 4: Verify the rea ding at the recor d ing device (PLC, etc.) is rea ding the equivalent of 20m A .

vdcvdcVloop

)(0.20

Documen t No. 210- 1015-F Page 13 ©2007

Page 20

Particulate Monitoring Systems Installation & Operati ng Manual

7.2 System Zero Check

The System Zero Check is used at insta llation t o confirm proper installation and for tr ou bl es hootin g .

SAFETY

• Always disconnect power to the control unit before making any wiring

changes at eith er the control unit or sensor as well as when making any

mount ing changes or r eplacing an y component.

• Do not remove the sensor (even when power is disconnected) from a

running process if it will in any way compromise personnel or plant safety.

• Plant safety procedures must be followed at all times while perfor ming any

equip ment check or maintenan ce.

System Zero Check

1. Shut the process off, sto pp ing flow completely , inc lu ding all airflow not just

particulate flow. The slightest amount of flowing particles can create a

signal. If process flow cannot be stopped, the particulate sensor can be

removed from the process and installed in a grounded test pipe to create a

shielded, no flow condition.

2. Let the system stabilize for 2-3 minutes.

3. Monitor the transmitter’s mA output. Its scaled value should be well below

its specified minimum detection level. If the system passes this chec k then it

is assured that ther e ar e no false signals entering the system.

If th e system z er o ch eck is not s uccess ful , each comp on ent of th e system sh oul d

be checked individ u ally, in the fol lowing or d er :

1. Control Unit Zero Check

2. Coaxi al Cable Zero Ch eck

3. Sensor Zero Check

Documen t No. 210- 1015-F Page 14 ©2007

Page 21

Particulate Monitoring Systems Installation & Operati ng Manual

Control Unit Zero Check

1. Disconn ect power to the con trol unit.

2. For a t wo piece con figur ation, open the enclosu re cover an d unscrew th e

coaxia l cable conn ector from th e control un it. Leave th e connect or inside

the con tr ol uni t en closu r e. Make s ur e th e conn ect or does n ot sl ip down in to

the conduit. The one piece configuration requires only that the “Zero

Button ” be pres sed a n d hel d aft er open ing th e encl osure cover t o gener a te a

zero test reading.

3. Close the enclosure cover.

4. Re-apply power to the control unit and allow the reading to stabilize for 1-2

minutes.

5. Monitor the transmitter’s mA output. Its scaled value should be well below

its specified minimum detection level. If the control unit passes this check,

there are no false signals entering the control unit. For one piece

configuration s the mA output should be monitored while the zero button is

pressed and held.

Pass:

1. Discon nect power from the control unit.

2. Open th e enclosu re cover and re-a ttach th e coaxial ca ble conn ector to th e

control unit.

3. Close the enclosure cover and proceed to th e Coax ial Cable Zero C heck.

Fail:

1. If a zer o r eadin g cann ot be obt ain ed, cl ose th e encl osur e cover an d con tact

the factory for fur ther assistance.

Coaxial Cable Zero Check (Two Piece Confi gurat i on Only)

1. Disconn ect power to the con trol unit.

2. Open the sensor enclosure cover and disconnect the coaxial cable center

conduct or from th e sensor pr obe end. Do n ot disconn ect the coaxia l cable

shi eld. Do not r emove the probe fr om the pr ocess. Lea ve the coaxi al cabl e

center conductor ring terminal hanging in free space within the sensor

enclosure (do not isolate it with tape) and close the cover.

3. Re-apply power to the control unit and allow the reading to stabilize for 1-2

minutes.

4. Monitor the transmitter’s mA output. Its scaled value should be well below

its specified minimum detection level. If the coaxial cable passes this ch eck

then there are no fal s e s i gn als entering the coaxial cable.

Documen t No. 210- 1015-F Page 15 ©2007

Page 22

Particulate Monitoring Systems Installation & Operati ng Manual

Pass:

1. Disconn ect power to the con trol unit.

2. Open the sensor enclosure cover and re-attach the coaxial cable center

conductor to the s e nsor probe end.

3. Close the sensor en closure cover and proceed to the sensor zero check.

Fail:

1. Check cable insta llation and routing in struction s in the Instal lation s ection

of this manual for proper cable installation. Make an y changes necessary.

2. Cont act the factor y for fu rther ass istance.

Once th e contr ol unit an d coaxial cable zer o have been checked, p roceed to t he Sen sor Zero Ch eck.

To per form the sen sor zer o check the proc ess flo w must be stoppe d or a sensor test pip e (avai labl e

from Factory) or length of metal pipe will be needed (4”-6” diameter pipe or larger). The pipe should

be at least 3 in (8 cm) longer than the probe itself and must be grounded. The length of pipe will serve

as an el ectrical sh ield for the pr obe while it is out of the process.

Sensor Zero Check

1. Do not remove the sensor from a running process if it will in any way

compr om ise personn el or plant safety procedures.

2. Disconn ect power to the con trol unit.

3. Remove t he sensor from th e process and insert it into the gr ounded m etal

test pipe.

4. Re-apply power to the control unit and allow the reading to stabilize for 1-2

minutes.

5. Monitor the transmitter’s mA output. Its scaled value should be well below

its specified minimum detection level. If the sensor passes this check there

are no false signals from the sen s or .

Pass:

1. Disconn ect power to the con trol unit.

2. Remove the sensor from the grounded test pipe and re-insert into the

process.

Fail:

1. Cont act the factor y for fu rther ass istance.

When p erforming a zero check, keep in mind that it may be acceptable to consi d er a small fa lse signal

negligible. For example if the baseline readings are 100pA and a system zero offset of 1pA was

found, this is only a 1% affect on the normal readings. If using the devi ce for basic flow/no flow

detection or basic emissions detection, this would n ot be significant.

Documen t No. 210- 1015-F Page 16 ©2007

Page 23

Particulate Monitoring Systems Installation & Operati ng Manual

8. Interpreting Readings and Adjusting 4-20mA Range

8.1 Fabric Filter (Baghouse) Applications

Particulate flow is very dynamic in nature, thus the output signal is also usually very dynamic. This is

more often the case with fabric filter and dust collection exhaust monitoring applications where filter

emissions and filter cleaning systems can cause wide ranging variations in the particulate levels.

When monitoring downstream of fabr ic filter, it is often possible for the difference between baseline

readings and peak readings following cleaning cycles, to vary by a factor of 10 or even 100. This is

the reason for the log arithmic ou tput (lin ear ou t put is also easily selected ) .

The logarithmic scale provides the ability to simultaneously monitor and resolve the baseline and

peak readings. It is not uncommon to have baseline readings of less than 10pA while at the same time

peak readings may be over a hundred or more.

Particulate levels listed below are typical for new or well maintained bag or cartridge filter dust

collection system. Many factors, other than generic bag wear may contribute to high particulate levels

including but n ot limited to: Improper filter installation, bad tube sheet seals, improper filter media

for process conditions, high differential pressure or a lack of a filter cake buildup.

PARTICULATE READING GUIDE FO R FABRIC FILTERS

IMPORTANT

• The guide below is only an approximate guide for modern, highly-efficient baghouses

• With large r or old er bagh ouses, readings can be sign ifica ntly h igher than th e ra nges shown bel ow

• Shaker and reverse air baghouses will have higher peak readings as compar ed to pulse jet

• Readings tend to be higher when new filters are installed and a filter cake has yet to form

• With sm all cartrid ge filters, th e r eadings tend to be a t the lower en d of the ranges

• Readings tend to also be lower with highly-efficient filter media such as Gore-Tex® fabric (Gore-

Tex is a reg istered tr ademark of W.L. G ore & Associat es .)

Typical Readings and Guide for New Efficient Fabric Filters

AVERAGE

BASELINE READINGS

1 – 10 pA Less than 50pA No signi ficant emissions

10 – 100 pA Less than 500pA On set of emissions

100 – 1000pA Greater than 500pA Significant emission s present

PEAK READINGS

(after cleaning cycle)

FILTER CONDITION

Documen t No. 210- 1015-F Page 17 ©2007

Page 24

Particulate Monitoring Systems Installation & Operati ng Manual

8.2 Alarm Levels for Fabric Filter Applications

In fabr ic filter applications it is common to use alarms for indicating sustained high r eadings. Internal

alarms are not included in 4-20mA l oop powered transmitter products. Alarming for loop powered

transmitter products is typically a part of an external system such as a PLC or Plan t Wide Control

System.

It is recommended to set two separate alarm levels. One alarm sho u ld be set based on the av erage base

line r eading and another alarm sh ould set based on the peak readings followin g cleaning cycle s .

Normal ly, Al arm # 1 is used for det ectin g su stain ed incr eases in th e base lin e rea ding . For ex ampl e a

baghouse that has new, highly-efficient filters may have an average baselin e reading of 10-20pA. It

would then be recommend to set the baseline alar m at 30-50pA with an alarm delay time that was

long en ough so th at cl ean ing cycle pea ks di d n ot act i vat e the basel i n e alar m . Ea ch a p pli cati on ca n be

different (for example much higher rea d in gs are possible with lar g er, older baghouses) a nd each plant

may have different operating demands in terms of how sensitive the alarms should be set. It is,

therefore, recommended to initially set the alarm as low as possible and to trend and data log the

readings over time before finalizing the settings. Correlations to stack test data can also be

incor p orated to correlate the ou tput to actual mass concen tration to set more quantitative al ar ms.

Normally, Alarm #2 is set to detect changes in the peak readings caused by the filter cleaning cycles.

Recall that as filter s just begin to tear or become porous, the momen tary puffs of particulate emissions

that normally occur just after a cleaning cycle will increase in peak height and duration (peak width).

Essentially the cleaning cycle amplifies the existence of small tear s. Thus, setting an alarm to detect

changes in the peak emissions is often r eferred to as a Pre-Visible Alarm as it is th e best, and most

reliable, approach to detecting emissions before become visible. When a sustained increase in the

baseline level occurs, particulate emissions will likely be visible and the filters should be changed

immediately. Where as, when only the peak emissions have increased, emission will likely not be

visible and there likely would be time to sch edule changing the filters (i.e. ear ly warning).

Technical assistance is ava i lable to provide suggesti ons in setting alarm levels.

Documen t No. 210- 1015-F Page 18 ©2007

Page 25

Particulate Monitoring Systems Installation & Operati ng Manual

_ ALARM LEVELS FOR EPA COMPLIANT LEAK DETECTION

IMPORTANT

• Alarm levels for EPA compliant leak detection such as MACT regulations should in itially be set as

low as possible unt il sufficien t trend data has been logged and all consider ations have been made.

• Do not in crease th e alarm levels without proper justification.

• Documentation of properly determined alarm levels is r ecommended as well as locking out alarm

set point adjustment except to authorized personnel.

• Consult factory for alarm set point assistance and EPA Compliance Software for advanced

alarming and alar m r ecord keeping.

Documen t No. 210- 1015-F Page 19 ©2007

Page 26

Particulate Monitoring Systems Installation & Operati ng Manual

−

−

8.3 4-20mA Output Range Adjustment

For proper selection of 4-20mA output range, both baseline and peak levels must be taken into

accoun t. The 4-20mA output range should be selected to allow accurate measurement of low baseline

signals while still allowing resolution of higher peak signals that occur during pulse-jet cleaning

cycles.

The 4-20mA analog output repr esents the linear or logarithmic equivalent of the “pA” particulate

levels. Once the analog output has been tra nsmitted to the PLC or chart recorder, it is recommended to

convert the 4-20mA signal back into pA to assist in data interpretation, alarm level determination and

historical data comparison . This can be of particular importance for EPA regulator y applications. The

follo wing two examp les show the formulas used to convert the 4-20mA signal into pA.

Logarithmic Scale (Recommended): Loga ri thm ic s calin g pr ovid es a meth od of tr an sm ittin g sign al s

such that low-level signals are expanded for increased resolution and accuracy while high-level

signals are compacted for increased signal range. Allowable ranges are 0.5-500pA and 5-5000pA.

Both ranges are three decades wide. To convert the 4-20mA logarithmic signal back into pA in the

remote plc/dcs, the followin g formula is used:

1. Scale mA input to pro p er log( 10 ) argument:

Y

=

)(00.4)( mAmAMeasured

333.5

2. Convert log(10) argume nt to pA:

Example: 0.5 – 500pA log scale with measured loop current of 9.33mA:

=

1. Scale mA input to proper log(10) argument:

Y

pAgeMinimumRanpA 10)( ∗=

)(0.4)(33.9

mAmA

Y

0.1

=

333.5

2. Convert log(10) argument to pA:

Three d ecade logar ithmic scale gives the following equ ivalent mA outputs:

4-20mA Scaling 0.5 – 500pA LOG: 4m A = 0.5 pA

9.33mA = 5.0pA

14.66mA = 50pA

20mA = 500 pA

0.1

)(0.510)(5.010)(5.0

pApApApA =∗=∗=

4-20mA Scaling 5 – 5000pA LOG: 4mA = 5.0 pA

9.33mA = 50pA

14.66mA = 500pA

20mA = 5000 pA

Documen t No. 210- 1015-F Page 20 ©2007

Page 27

Particulate Monitoring Systems Installation & Operati ng Manual

−

Linear Scale: Linear scaling provides direct, proportional, linear change in the 4-20mA output signal

over the selected pA range. Allowa ble ranges are 0-100pA, 0-500pA, 0-1000pA, and 0-5000pA. To

convert the 4-20mA linear signal back into pA in the remote plc/dcs, the following formula is used:

)(0.4)(

pA

=

mA

If unsur e where to set the linear output range, a good generic selection for fabric filters is a range that

is equal to or greater than 25 times the measur ed baseline signal. For example, if the baseline signal is

15pA, the linear range would be selected as 15pA * 25 = 375pA … choose 500pA linear range.

Resolution: The 4-20mA output i s transmitted at a resolut i on of 12 bits or 4. 88uA.

mAmAMeasured

)(0.16

)(*

pARange

8.4 Time-constant Adjustment

The particulate transmitter contains an adjustable digital filter. Particulate flow is very erratic in

nature. Filter cleanin g cycles can also cause dramatic chan ges. Setting the filter time con stant higher

(in seconds) will “smooth” out the signal. Setting the filter time constant lower (in seconds) will

incr ease th e respon siveness of the s ignal and mak e it mor e “bounc y”. Keep i n min d that setting the

filter time constant too high may r educe the ability to use peak readings to determine the onset of

filter wear.

The recommended filter time constant for fabric filters is 3.0 seconds. If the output signal is too

bouncy with this setting, the time constant should be increased until a smoother reading is obtained. If

the output sign al is steady but peak readings are not seen during the activation of the filter pulse-jet

cleaning cycle, the time constant should be decreased until the peak r eadings can be measured.

Documen t No. 210- 1015-F Page 21 ©2007

Page 28

Particulate Monitoring Systems Installation & Operati ng Manual

9. Routine Maintenance

EQUIPMENT MAINTENANCE

• Only appropriately licensed profession als should per form maintenan ce on

this pro d u ct.

• WARNING – To prevent ignition of flammable or combustible

atmospheres and for operator safety, always disconnect power before

servicing.

Particulat e Sensor: The sensor does not nor mally need any clea ning and for optima l performan ce,

rout ine cleanin g of the sensor is not recommen ded.

Transmitter Module: The transmi tter m odule is zeroed a t the fa ctor y and norm all y does not r equir e

adjustment. Zer o a d justment can be checked once ev ery 6-12 months.

Documen t No. 210- 1015-F Page 22 ©2007

Page 29

Particulate Monitoring Systems Installation & Operati ng Manual

10. T roubleshooting

The most important aspects of tr oubleshooting ar e to keep in mind the instrument is monitoring small

sign a l s. Th e q ua li t y of ca bl e c on n e ct or s sh oul d n ot be o ver l o oke d. T h e s en s or h ou sing sh oul d be k ep t

dry an d clean. Br eak all troubleshooti ng down in to the bas ic system com ponent s, the sen sor, smart

transmitter module and 4-20mA loop.

False High Signals (False Alarms)

1. When an appar ent false h igh sign al is pr esent, fir st check t he process t o be sur e the par ticulat e

level has not increased. Keep in mind that the system can detect very low levels. In filtration

appli cations th e system can detect invisi bl e particulate levels and very small emissions .

2. Check th e sen sor co ver a nd con dui t seal to be sur e th ey wer e not left op en a llowin g ra in t o enter

the housing. Check the coaxial cable (two piece configuration only) connectors using a digital

voltmeter and check for shorts. If nothing can be foun d, conduct a system zero check.

No Reading or Alar m (When Believed Necessary)

1. Increase the p artic ulate level or intro du ce particulate into the ai r stream a nd monitor for a response .

If th e system respond s properly re-eva luate the selected alarm points an d th e process cond itions.

2. If there is n o response, check for electr ical cont in u ity from the sensor to the cont rol unit end of th e

coax cabl e ( two piece configura ti on only).

3. Contact the factory for a Field Test Unit that can generate a sign al to check response and

calibration (two-piece configuration only).

Documen t No. 210- 1015-F Page 23 ©2007

Page 30

Particulate Monitoring Systems Installation & Operati ng Manual

11. Spare Part s

Item Details Part No.

Control Unit/Transmitter Control Unit/Transmitter Family Refer to Product Label

Particulate Sensor Variable Lengths & Connections Refer to Product Label

Particulate Sensor Cable Coax, SMA x Ring Lugs CCA-Feet

Documen t No. 210- 1015-F Page 24 ©2007

Page 31

Particulate Monitoring Systems Installation & Operati ng Manual

Notes:

Documen t No. 210- 1015-F Page 25 ©2007

Page 32

Page 33

Page 34

Loading...

Loading...