Page 1

BULLETIN E-90-706

Model PM706 Temperature Panel Meter

Specifications– Installation and Operating Instructions

DESCRIPTION

Model PM706 Digital Temperature Meter monitors and

displays temperature measurements using a Type K thermocouple input. Meter features dual adjustable set points with 1A

relays and a selectable 4-20 mA or 0-10 VDC output signal.

View alarm settings by depressing the tactile alarm button on

the front panel. The bright red LED display has a floating decimal point and displays temperature in ˚F or ˚C. Meter is

equipped with overrange indication to alert operator of an

open thermocouple or faulty connections. Sealed front panel is

rated to NEMA 12 to protect against dust and fluids.

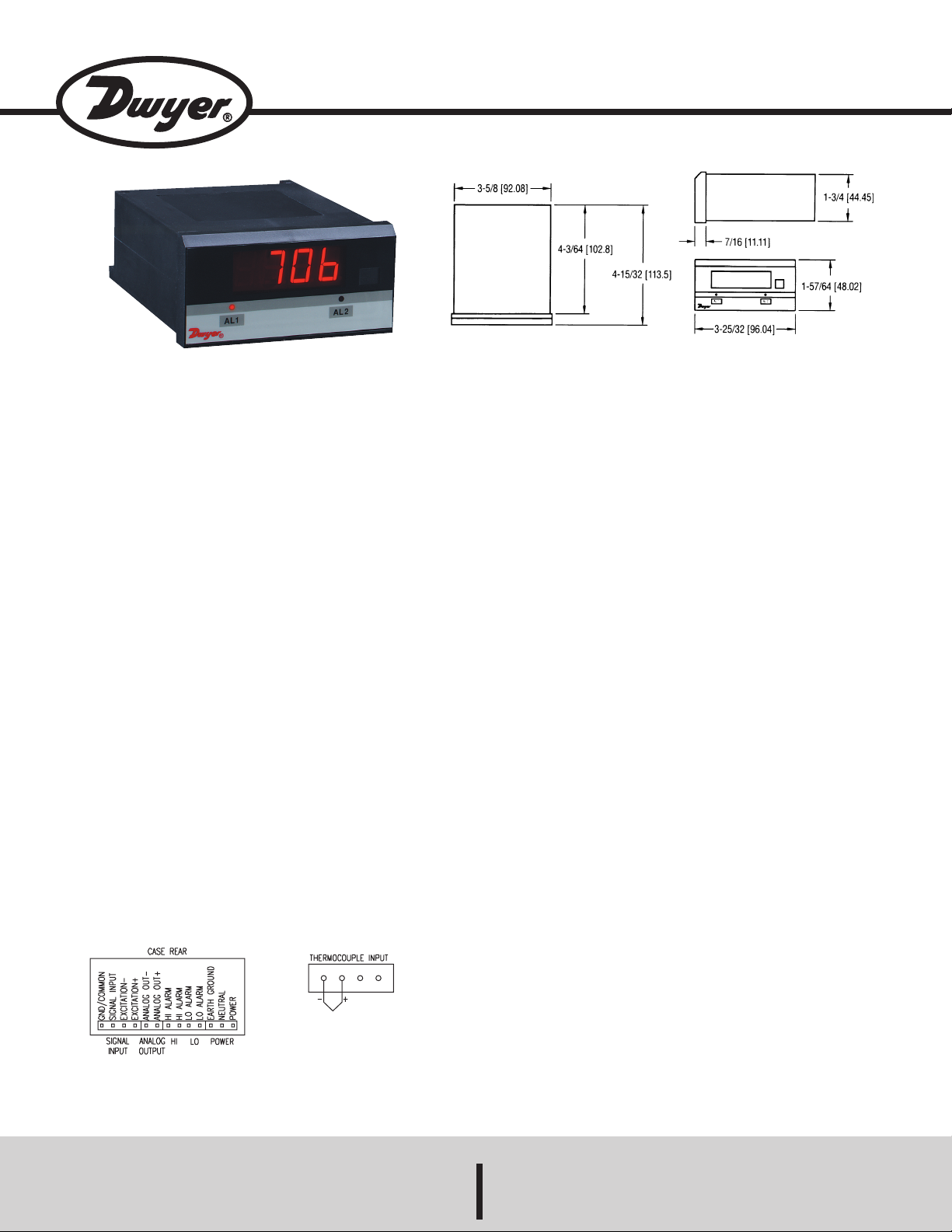

Installation and Connections

The panel requires a 1.73 x 3.62 (44 x 92mm) panel cut out

with minimum radius corners. Maximum panel thickness of

5/16 (4mm).

Remove the two retaining clamps by loosening and removing

their screws.

Feed the meter housing through the panel and re-fit the

clamps, holding them close to the meter housing as the

screws are tightened.

Tighten the screw sufficiently to retain the meter in the panel.

DO NOT OVER TIGHTEN THE SCREWS, otherwise the

threads in the case will strip.

Ensure the available input power is of the correct level, and is

fused at no more than 0.5A, filtered if on the same leg as heavy

switch gear, and is provided with an adequate clean ground.

Ensure any signal cabling is secured and kept clear of high

Figure 1: Wiring Connections

PHYSICAL DATA

Signal Input: Type K Thermocouple.

Signal Type: Single ended, negative wire connected to meter com-

mon.

Temperature Range: -148 to 1999˚F (-100 to 1200˚C).

Accuracy: ±2% at 23˚C ambient.

Resolution: 1˚F/˚C.

Read Rate: 2.5 readings/sec.

Setpoints/Alarms: One setpoint active below reading (internally

reconfigurable to above reading) and one setpoint active above

reading. Active condition indicated by LED indication.

Setpoint Adjustment: Set points adjustable by 20 turn potentiometers by removal of front cover. 0 to 2000 counts, adjustable

within 5 counts or better.

Setpoint Hysteresis: 3(0) counts max hysteresis built in to each

setpoint.

Setpoint Viewing: By depression of front panel accessible

switches. Indication agrees within ±5(0) counts of actual setpoint

level.

Analog Output: Factory configured non-isolated output 4-20mA,

8V maximum compliance or 0-10VDC 1kohm minimum load. Span

output set for 0-1000(0) counts, internally adjustable over 500(0) to

2000(0) count span. Accuracy ±1% ±(0.2mA or 0.2V) over operating conditions. Adjustable range of output is -10% to 100% of F.S.

Relay Output: One normally open below duty contact output per

setpoint. 1A @ 250VAC/30VDC resistive load capacity.

Ambient Temperature Effect: +0.01% of rdg, -0.05˚ per degree.

Temperature Coefficient: ±100 ppm/˚C.

Sensor Wire Effect: 0.01˚C power ohm per conductor.

Broken Sensor: Display flashes overrange for open circuitry input.

Sensor Wire Current: 0.5µA.

Overrange Indication: Display flashes.

Operating Temperature Range: 32 to 122˚F (0 to 50˚C).

Storage Temperature Range: -4 to 185˚F (-20 to 85˚C).

Humidity Range: 0 to 80%, non-condensing.

Power Supply: 115/230 VAC, ±10%, 50/60 Hz.

Power Consumption: 7 W.

Common Mode: Signal common to power ground 1500V peak

DC to 60 Hz. 354V IEC spacing.

Housing: 8 DIN, NEMA 12.

Display: 7 segment red LED 14.2mm high. Decimal point posi-

tioning by internal solder switch. Negative polarity indication by

center segment of left hand display. Alarm indication by 3mm

round red LED displays.

Weight: 1 lb. (500 g).

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, ,U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Lit-By Fax: 888/891-4963

Page 2

current switching cables.

Note the relay outputs of the meter are light duty only and do

not incorporate snubber networks.

Check that the input supply is disconnected at source before

wiring up the meter.

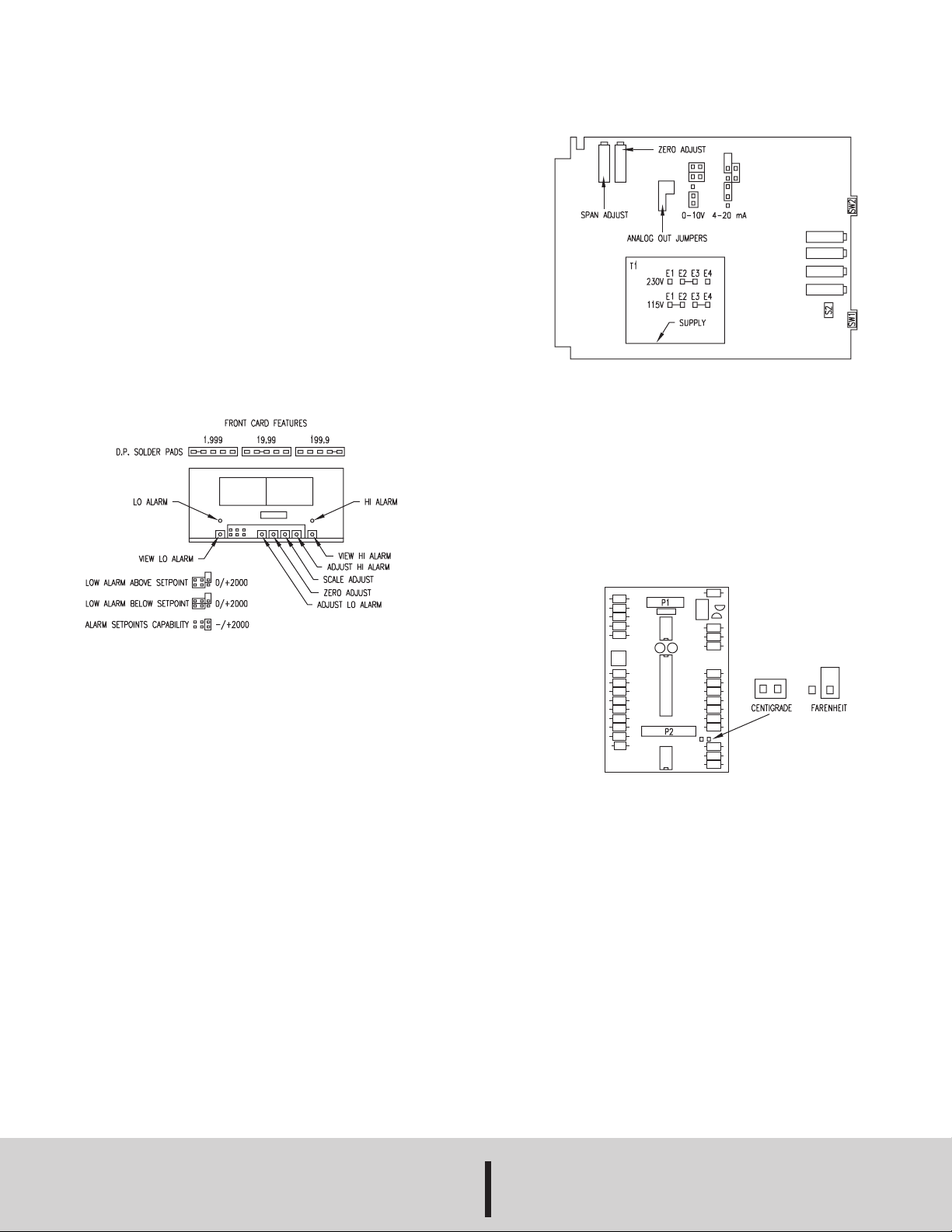

Adjustments

Trimming span and zero and adjustment of alarm setpoints is

by means of potentiometers inside the front of the meter. See

figure 2. The front cover must be pried off to gain access to the

controls.

The span and zero adjustments on temperature meters should

not need to be changed from their factory settings, unless

significant sensor lead resistances are involved.

If the alarm setpoints are not required, they should be set to

beyond +2000(0) counts, and the low alarm configured to be

active above the setpoint.

Jumper Switches: Analog Output Signal

To change from standard 4-20mA output to 0-10V, three

jumper switches on the input board must be changed.

Location of the analog out jumpers is shown on figure 3.

Figure 3: Analog Out Jumpers

Jumper Switches: ˚F or ˚C

There is only one configuration switch; this is located at the

front end of the small signal input card. See figure 4.

Close the switch for ˚C and leave open for ˚F. Re-calibration will

be required if the jumper position is changed. Two known

temperatures will need to be monitored close to zero and

800˚C, either directly, or using a thermocouple/RTD simulator

and the zero and the span adjustments re-trimmed.

Figure 2: Front Card Features

Internal Jumper Switches

Access to the internal jumper switches requires the removal of

the unit from its case. These changes should be made, if

required, prior to the installation of the units.

Ensure the power is removed. Unplug all rear panel connectors

and unscrew the small retaining screw at the bottom rear of the

case. Pry off the front cover and carefully slide the printed

circuit board from the case.

Reverse the procedure after the changes are made, ensuring

the retaining screw is not over tightened.

Access to the analog output jumper switches requires the

removal of the input conditioner card, which can be pulled off

the main board. CAREFULLY PULL THE INPUT BOARD

STRAIGHT UP OFF THE BOARD. Carefully replace the card by

lining up pins in sockets and gently pushing towards main

board after configuration.

©Copyright 1999 Dwyer instruments, Inc Printed in U.S.A. 10/99 FR# R1-440679-00

Maintenance

After final installation of the Model PM-706 Temperature Panel

Meter, no routine maintenance is necessary. These panel

meters are not field serviceable and should be returned to the

factory, freight prepaid, if repair is needed. Be sure to include

a clear description of the problem plus any application information available.

Figure 4: Thermocouple Jumpers

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, ,U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Lit-By Fax: 888/891-4963

Loading...

Loading...