Page 1

BULLETIN TE-PHP

VACUUM

FOR

PUSH

8-25/64

[213]

7-21/64

[186]

3-1/64

[80] MAX

1-1/4

[32]

1/4 NPT(F)

PRESSURE PORT

4-7/8

[124]

VACUUM

FOR

PUSH

1

7

5

6

2

3

4

8

9

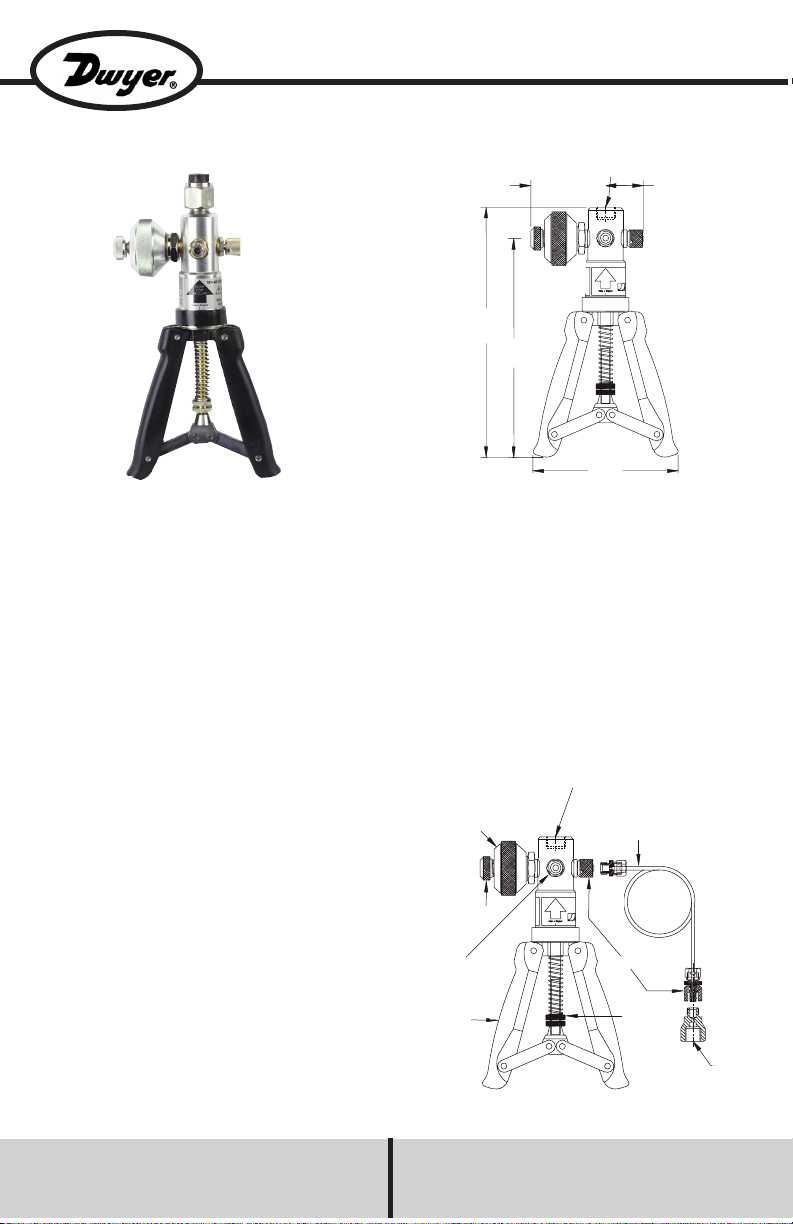

Model PHP Pneumatic Hand Pump

Specifications – Operating Instructions

Model PHP Pneumatic Hand Pump verifies

calibration of pressure transmitters, switches,

controllers, indicators, and recorders. The Model

PHP is a hand operated pump for sourcing

pressure and vacuum. Use in conjunction with an

analog or digital gage for a complete calibration

system.

The unit provides output pressures up to 600 psi

(40 bar) or vacuum down to -28.5˝ Hg (-0.960 bar).

The reliable pump reaches 100 psi in 4 strokes.

Model PHP is fitted with a fine adjustment valve

for precise volume control and an adjustable

stroke to provide over pressure protection.

Model PHP includes a 39˝ (1 m) hose with a 1/4˝

female NPT quick fit connector. The optional

service kit includes seals, O-rings, retaining

screws and an allen key.

Figure 1 Key:

1. Pressure port - NPT female connection to

take master instruments. E.g. Digital/Analog gage.

2. Fine adjustment valve.

3. Pressure release valve.

4. Pressure/Vacuum selector.

5. Adjustable stroke for varying maximum

pressure output (over pressure protection).

6. NPT adaptor set.

7. Flexible hose to item under test.

8. Knurled ‘quick-fit’ connectors.

9. Pump Handles.

SPECIFICATIONS

Output Ranges: -28.5˝ Hg to 600 psi

(-0.960 to 40 bar).

Process Connection: 1/4˝ female

NPT (quick fit).

Gage Connection: 1/4˝ female NPT.

Materials: Nickle plated brass,

anodized aluminum, and nylon.

Weight: 1.4 lbs (0.65 kg).

Fig. 1

Phone: 219/879-8000 www.dwyer-inst.com

Lit-By Fax: 888/891-4963

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361,U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

DESCRIPTION OF KEY ITEMS:

Hose/Adaptors

The hoses (7) and adaptors (6) are fitted by

simply screwing them into the connectors (8) by

turning the knurled nut on the connector fully

anti-clockwise.

Release Valve (3)

This can be used to reduce or release the

pressure in the system. The rate of pressure

reduction is dependent upon the degree of

rotation when opening the valve. Minimal force

is required to seal the system.

Volume Control (2)

The pressure generated can be finely adjusted

by turning the fine adjustment valve (2) either

clockwise or anti-clockwise to increase or

decrease pressure accordingly.

Over Pressure Protection (5)

To adjust the maximum output pressure of the

system turn the nuts (5) to increase or decrease

the stroke length.

IMPORTANT

Under no circumstances should the fine

adjustment valve (2) be wound back beyond

the red line indicator on the body. Should this

occur, then the pressure must be released from

the system before attempting to re-engage the

fine adjustment valve.

Pressure/Vacuum Selection (4)

Press the selector (4) as indicated on the label

to engage the desired mode. Ensure that the

release valve (3) is open before changing mode.

Note:

The system should only be used for

pressurizing small volumes due to its small

displacement. If the system has not been used

for a period of time, it could be difficult to

operate on the first stroke. The cylinder has

been lightly greased on assembly but, if

additional lubrication should ever be required,

then apply a minimal amount to the inside of

the cylinder.

Access is via the three retaining screws located

under the black collar.

WARNING: Do Not Connect To External

Pressure Source.

GUIDELINES FOR USE:

1. Calibration/Comparison against Analog

gauge

1.1 Fit a Test Gage to the top of the test system

(1), and correct seal.

Note: The retaining nut should be screwed fully

down but needs to be no more than finger tight

as seal is achieved by O-ring.

1.2 Connect item under test using appropriate

adaptor and sealing (6) at the end of the flexible

hose (7) or directly to body.

Note: Adaptors tightened to a maximum torque

of 15 Nm.

1.3 Screw fine adjustment valve (2) fully

clockwise.

1.4 Screw fine adjustment valve (2) 4 - 6 full

turns anti-clockwise.

1.5 Screw pressure release valve (3) fully

clockwise, tightening to ensure good seal.

1.6 Operate handles (9) until the pressure is

close to that finally required. Ensure handles

are fully squeezed together on each stroke

to achieve maximum pressure output.

1.7 Wind the fine adjustment valve (2) clockwise

to increase pressure or anti-clockwise to

decrease pressure until required pressure is

reached.

Note: The pressure may settle for up to 30

seconds after increasing pressure due to

thermodynamic effects, settling of seals and

expansion of the flexible hose.

Caution: NEVER screw the fine adjustment

valve (2) beyond the red line indicator.

1.8 Reductions in pressure can also be

achieved by careful use of the pressure release

valve (3).

1.9 Vacuum is achieved using the above

procedure and having the changeover valve (4)

pushed completely towards the vacuum

position. Note: release pressure before

changing mode.

2. Fault Investigation

In the event that the system appears to lose

pressure then the procedure above should be

repeated ensuring new seals are used, adaptors

are tightened sufficiently and the pressure

release valve (3) is tightened firmly.

Note: The connections to the hand held test

system are sealed with O-ring or bonded seals

and should not leak. The pipe to body

connection can be checked but tightened no

more than 2 Nm.

DO NOT attempt to tighten the other fittings to

the test system as this could lead to damage of

sealed joints. When testing for leaks it may be

noticed that air is drawn in or expelled from

around the changeover valve. This is normal

and should cause no concern.

©Copyright 2003 Dwyer Instruments, Inc Printed in U.S.A. 5/03

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361,U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Lit-By Fax: 888/891-4963

Loading...

Loading...