Page 1

Bulletin P-PFG2

C

L

E

A

N

C

H

A

N

G

E

D

I

R

T

Y

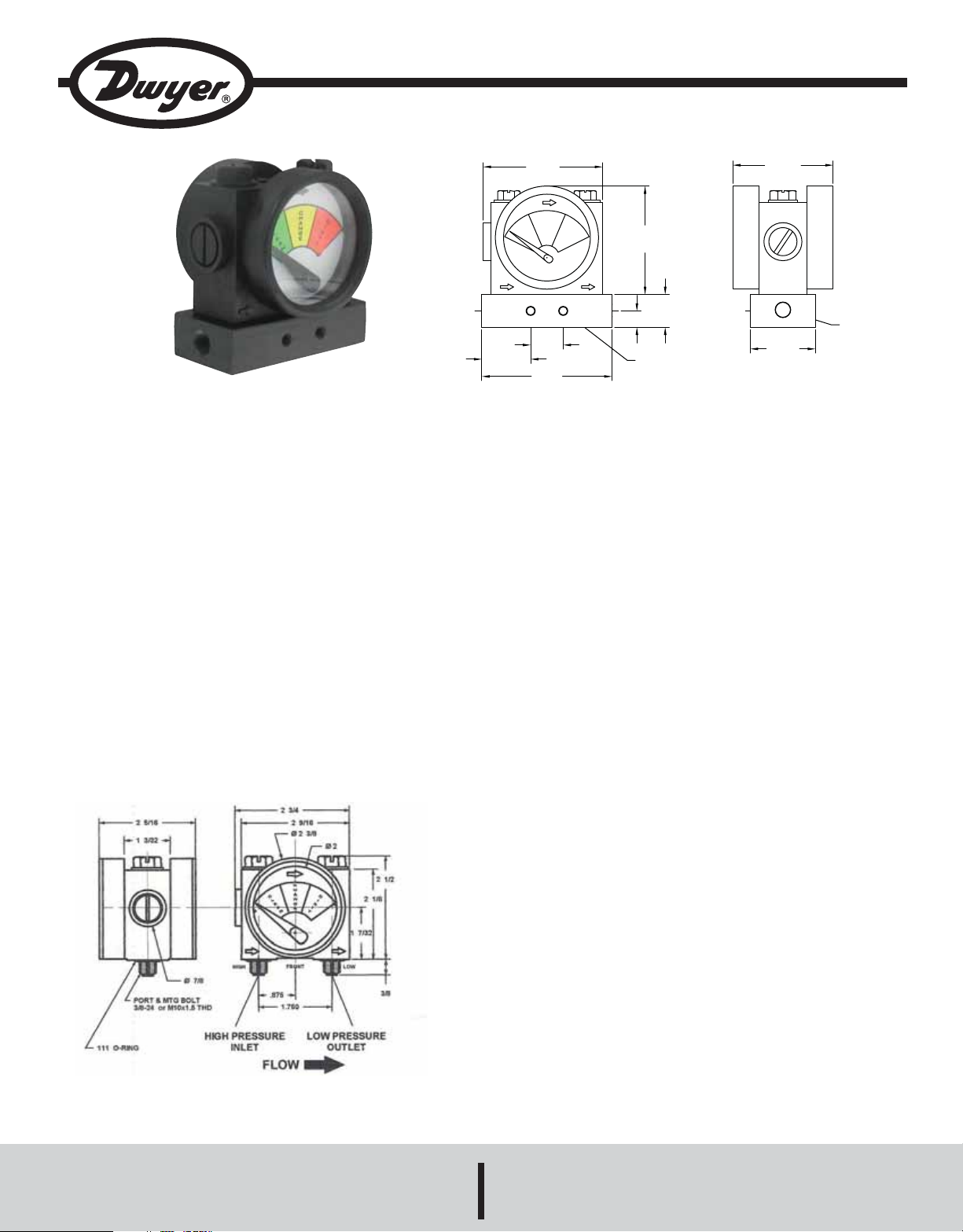

HIGH PORT

1-1/8

[28.58]

3

[76.20]

3/4

[19.05]

2X #10-32 UNF

MOUNTING HOLES

LOW PORT

3/4

[19.08]

3/8 [9.37]

2-1/2

[63.50]

2-3/4

[69.85]

2-5/16

[58.74]

1-1/2

[38.10]

2X 1/8 NPT

CONNECTION

Series PFG2 Process Filter Gage

Specifications - Installation and Operating Instructions

The Series PFG2 Process Filter Gage is designed for determining the state of an

in-line filter. The differential pressure indicator determines the pressure drop on

either side of a filter through its 1/8˝ female NPT pressure connections, and relates

the value to one of three zones: clean (green), change (yellow), or dirty (red). The

Series PFG2 is perfectly suited for filter applications, line loss, valve drop, and

many other differential pressure applications where a simple indicator is needed.

MOUNTING

The Series PFG2 features two #10-32 UNF threaded holes in its mounting block

for easy mounting. The holes are 3/4˝ apart and located at the same level as the

end process connections. The direction of process flow is indicated on the dial,

with the arrow pointing to the low pressure port. In order to change the high and

low pressure connections, simply remove the indicator from the mounting base

and rotate 180°. Retighten the plastic bolts to 20 to 25˝ pounds of torque. By

removing the mounting block, the PFG2 can be directly mounted through the

outlet/inlet connections on the bottom of the unit.

MAINTENANCE

Upon final installation of the Series PFG2 Process Filter Gage, no routine

maintenance is required. A periodic check of system calibration is recommended.

The Series PFG2 is not field serviceable and should be returned if repair is

needed (field repair should not be attempted and may void warranty). Be sure to

include a brief description of the problem plus any relevant application notes.

Contact customer service to receive a return goods authorization number before

shipping.

PFG2 WITHOUT MOUNTING BASE

SPECIFICATIONS

Service: Liquids/gases compatible with SS, GFN, and fluoropolymer.

Wetted Materials: Aluminum, SS, glass filled nylon, and fluoropolymer.

Accuracy: ±5% F.S.

Maximum Temperature: 200°F (93°C).

Maximum Pressure: 300 psig (20.7 bar).

Materials:

Body: Glass filled nylon;

Mounting Block: Aluminum;

Lens: Polyester;

Elastomers: Fluorocarbon.

Process Connection: 1/8˝ female NPT.

Mounting Orientation: Any orientation with 10-32 threaded holes 3/4˝ apart.

Dimensions: 3.25˝ H x 3˝ W x 2.31˝ D.

Weight: 9.6 oz (272.2 g).

©Copyright 2010 Dwyer Instruments, Inc. Printed in U.S.A. 9/10 FR# R1-443837-00

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Loading...

Loading...