Page 1

Series PDWS

PADDLE WHEEL FLOW

SENSOR INSTRUCTIONS

F-PDWS

Page 2

TABLE OF CONTENTS

GENERAL INFORMATION

General Information

Features, Specifications ........................................................................................................Page 3

Installation

Insertion Depth, Distorted Flows, Fitting Installation, Meter Installation, Positioning the Meter......................Page 4

Straight Pipe Recommendations .............................................................................................................

Page 5

Full Pipe Recommendations ..........................................................................................................Page 6

Connection Diagrams

RTI/BAT, Connecting to PLC's..............................................................................................................Page 7

Operation

Minimum Flow, Flow Range Table, Calibration (“K-Factor”), Field Calibration..................................................Page 8

Maintenance

Rotor Replacement, Signal Troubleshooting, Sensor Replacement .............................................................Page 9

Parts Explosion

Parts List ......................................................................................................................................................Page 10

Troubleshooting

Problems, Probable Causes, To Check, To Repair ..................................................................................Page 11

The PDWS Series are impeller (or “paddlewheel”) insertion meters designed for use with a wide variety of liquids in pipe sizes

1/2" to 8". Sensors are available in brass, 316 stainless steel,

PVC, and polypropylene. Bodies are machined from a solid rod

for maximum precision. High-quality jewel bearings and nickelbound tungsten carbide shafts are used for extreme low friction

and long life. Low-ow performance is good, although other

Dwyer Instruments Inc. ow meters are recommended where

extremely low ows are being measured.

The rotation of the rotor is detected by a non-drag Hall-effect

sensor. Output is a current-sinking pulse (square wave), which

can be sent long distances (up to 2,000 feet) without a transmitter. This signal can be connected directly to PLC's, counters,

and computer cards, as well as a variety of Dwyer Instruments

Inc. controls and displays.

FEATURES

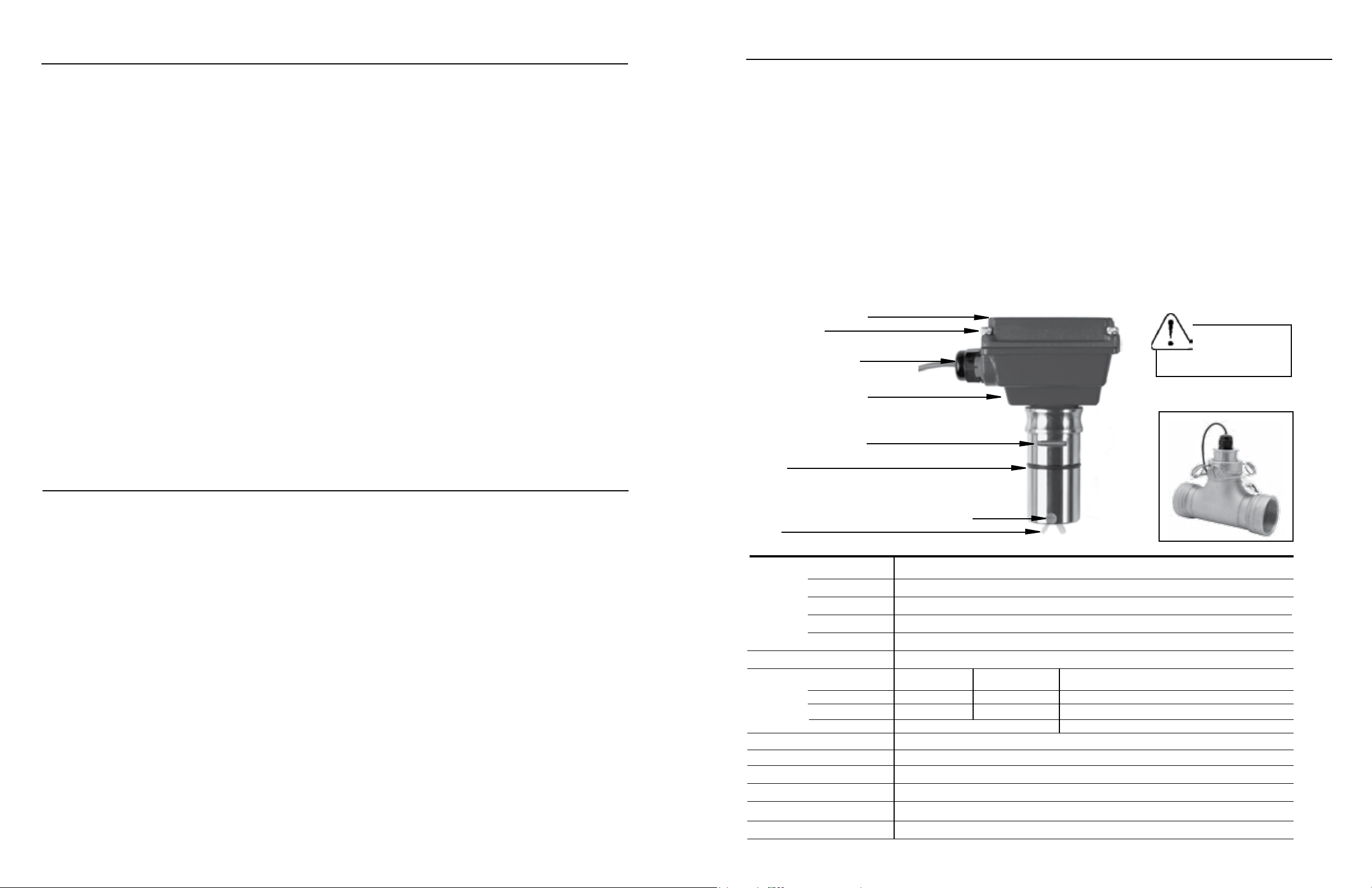

Cover or Optional Module

Housing Screw

(connect ground to one)

Cable-Seal Strain Relief

Lower Housing (optional)

PDWS meters are ideal for chemical proportioning applications.

If no display is required, a simple divider such as the PWD

provides adjustable pump pacing. For rate and total display,

the Series RTI (loop powered) ow indicator can be mounted

directly on the Series PDWS meter, or remotely on a wall or

panel. The Series BAT blind analog transmitter can be used to

convert to a 4 to 20 mA output.

The Series PDWS require special ttings that ensure correct

depth placement in the pipe. Fittings come in a variety of ma-

terials for compatibility with specic applications. Tee ttings

are individually wet-calibrated at the factory and marked with

the K-factor (pulses per gallon). Saddle ttings must be eld-

installed on the pipe and do not come wet-calibrated. K-factors

for saddles are based on factory-testing. Please see Series PWF

for appropriate ttings.

Caution: Clip(s)

must be installed

before use.

High Pressure Model

TABLES AND DIAGRAMS

Specifications, Features ...............................................................................................................Page 3

Distorted Flows, Positioning the Meter .............................................................................................Page 4

Straight Pipe Recommendations .................................................................................................

Full Pipe Recommendations ...........................................................................................................Page 6

Connections Diagrams .......................................................................................................................Page 7

Flow Range Table, K-Factor Number on Tee Fitting, K-Factor Chart, Pressure vs. Temp Chart...................Page 8

Rotor and Sensor Replacement .............................................................................................................Page 9

Parts Explosion, Parts List ........................................................................................................................Page 10

Troubleshooting............................................................................................................................................Page 11

Page 2

Page 5

Retaining Slot (for U-Clip)

For easy installation at correct depth setting

O-Ring

Jewel Bearings for superior low-ow performance

Rotor

SPECIFICATIONS*

Materials Sensor Body

Rotor

Shaft

Bearings

O-Ring

Rotor Pickup

Maximum

Pressure

High Pressure

Flow Range

Accuracy

Signal

Power

Maximum Current

Cable

*Specications subject to change

Temperature

Brass, 316 Stainless Steel, PVC, or Polypropylene

PVDF

Nickel-bonded tungsten carbide (Ceramic optional)

Ruby jewel

EPDM (Fluoroelastomer optional)

GMR (Giant Magnetoresistive) Sensor

Brass 316 SS PVC or Polypropylene

(See Pressure vs. Temp. Chart)

200 PSI (14 bar) 250 PSI (17 bar) 175 PSI (12 bar) @ 75˚ F

Not Available 400 psi (28 bar) Not Available

200˚F (93˚C) 130˚F (55˚C)

0.3 to 30 ft/s

+/- 1.5% of full-scale

Hall-effect current sinking pulse

6-24 Vdc, 2 mA

20 mA

#22 AWG, 3 Cond, 18' (maximum 2000’ run)

Page 3

Page 3

INSTALLATION

INSTALLATION

Insertion Depth. The PDWS Series are xed-depth meters

that must be used with matched ttings appropriate to the

application and pipe size. This ensures that the ow sensor

is installed at the correct insertion depth to measure the av-

erage ow velocity of the stream.

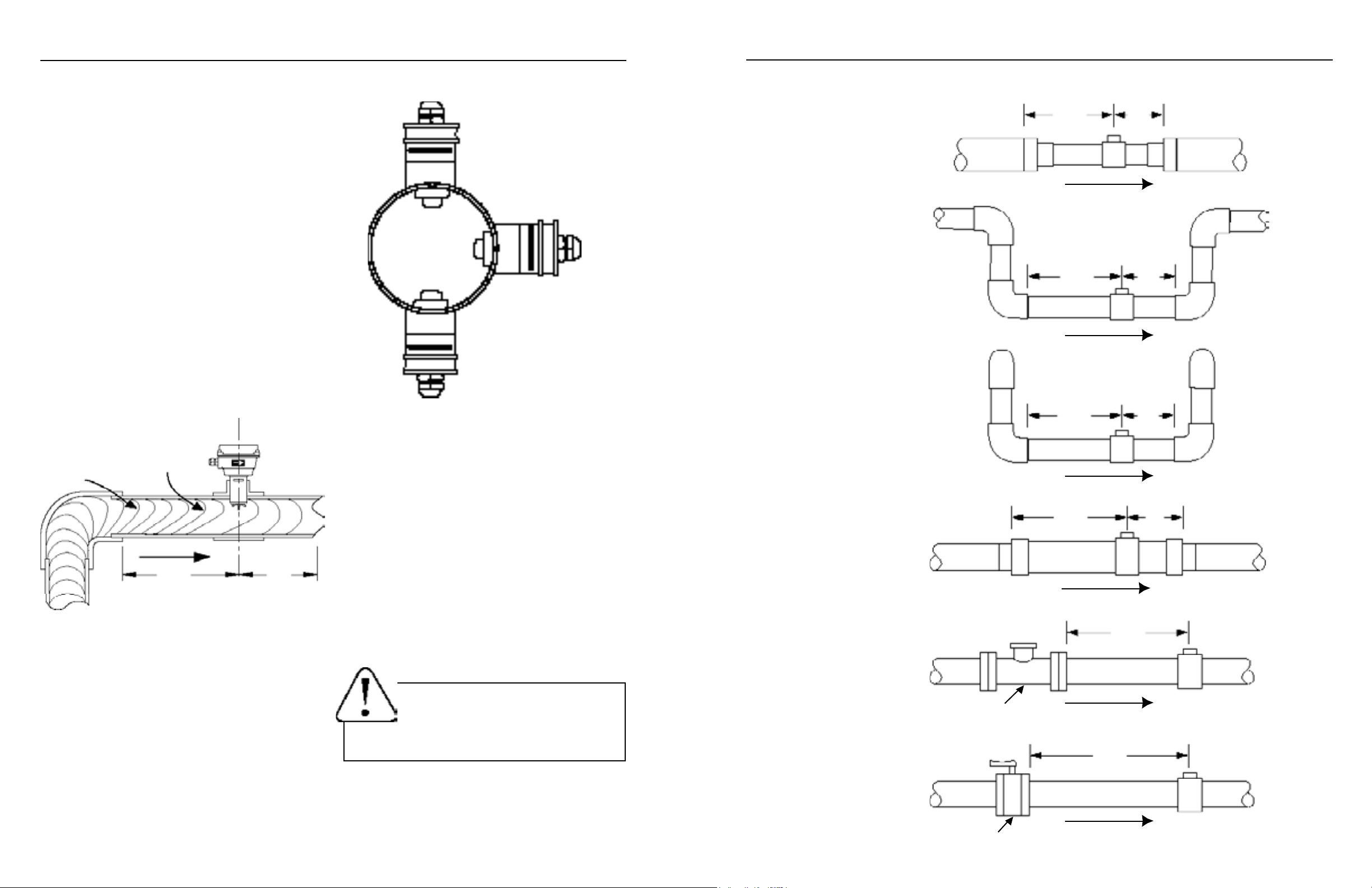

Straight Pipe. Straight pipe of at least 10 diameters up-

stream and ve diameters downstream of the meter is

strongly recommended for proper accuracy. This is neces-

sary because the shape of the velocity prole changes as the

rate increases around an elbow; placing the meter too near

the elbow causes a distorted reading. Additional straight run

may be needed under specic adverse circumstances (see

next page).

If you can’t provide enough straight run to smooth out the

velocity prole, some decrease in accuracy may result. This

does not mean the meter’s reading is meaningless, however.

In some applications (e.g., control system, valve operation)

a repeatable reading may be more important than a highly

accurate one.

POSITIONING THE METER

Okay, if no air in pipe

BEST

Okay, if no sediment in pipe.

STRAIGHT PIPE RECOMMENDATIONS

(X = diameter)

Reduced Pipe

Two Elbows In Plane

10X

5X

PDWS

5X10X

PDWS

DISTORTED FLOWS

Faster Flow

Causes Meter

Distorted

To Read High

Flow Prole

FLOW

10X

Diameter Minimum

(See Below)

Diameter Minimum

5X

(See Below)

Fitting Installation. Stainless steel and brass ttings have

female pipe threads, requiring the appropriate male thread-

ed ttings. Saddle ttings require a hole to be cut in the

pipe (recommended hole size is 1-3/4”). Before cutting into

the pipe, observe the drawing below to choose your meter

orientation.

PVC Fittings. A PVC tting is usually installed by solvent

welding. PVC tees are supplied with some upstream straight

pipe, less than the recommended straight pipe requirements. It is not advisable to connect directly to the end of

these ttings with a ow disturbing device (valve, elbow), but

rather add straight pipe to the end of these ttings to meet

the straight pipe requirements for your application.

Meter Installation. After the meter tting is installed in the

pipeline, the meter can be installed in the tting. Press the

meter into the tting as far as it will go. Retain the meter in

place by inserting the u-pin. The pin can be installed from

either side. It may be necessary to rotate the probe back

and forth slightly to start the pin into the slots on the probe.

Slide the pin in as far as it will go.

Caution: Never remove the u-clip retainer when

the pipe is under pressure. Always remove

pressure from the pipe before you attempt to

remove the meter. Removal under pressure

may result in damage or serious injury.

Two Elbows, Out Of Plane

Expanded Pipe

Spiral Flow

Propeller Meter

20X

20X

5X

PDWS

5X

PDWS

30X

PDWS

50X

Page 4

Swirling Flow

Partially Open

Buttery Valve

PDWS

Page 5

Page 4

INSTALLATION

CONNECTION DIAGRAMS

FULL PIPE RECOMMENDATIONS

Possible Problem:

Allows air pockets to form at sensor

PDWS

Better Installation:

Ensures full pipe

PDWS

SERIES RTI/BAT

Figure 1

PLC's and Controls

PDWS

Possible Problem:

Post-valve cavitation can create air pocket

PDWS

Possible Problem:

Air can be trapped

Caution: These ow sensors are not recommended for installation down-

stream of the boiler feedwater pump where installation fault may expose the

ow sensor to boiler pressure and temperature. Maximum recommended

temperature is 130°F (Plastic), 200°F (Metal).

PDWS

Better Installation:

Keeps pipe full at sensor

PDWS

Better Installation:

Allows air to bleed off

Page 6

Page 7

Page 5

OPERATION

MAINTENANCE

Minimum Flow. As with any other ow sensor, there is a rate

below which the Series PDWS sensor cannot read. Check the

ow rate table below for the minimum ow rate detectable by

the sensor for a given pipe size.

Flow Range (GPM)

1/2" 3/4" 1"

Min 0.28 0.5 0.8 1.9 3.1 6.9 12 27 46.8

Max 28 50 80 190 314 691 1190 2700 4680

1-1/2"

2" 3" 4" 6" 8"

Calibration (“K-factor”). The K-factor represents the number of

pulses per gallon the meter produces during a ow test. This

number must be entered into your electronic control to make

it read properly. If the PDWS Series meter is ordered with a

tee tting, it is factory-calibrated in the Series PWF tting and

the K-factor is indicated on the side (see below).

Find Your K-Factor Here

PRESSURE VS. TEMPERATURE PVC/Polypropylene)

If a saddle or weld-type tting has been ordered, see the

table below to determine the proper K-factor.

PDWS SERIES K-FACTORS

FOR SADDLE & WELDOLET FITTINGS

3" 4" 6" 8"

PVC/

Steel

Sch. 40

PVC/

Steel

Sch. 80

Stainless

Steel

(10S)

Stainless

Steel

(10S)

Copper

Tubing

(Type L)

Copper

Tubing

(Type K)

Brass

Pipe

Duct.

Iron

(Class

52)

28.92 16.790 7.412 4.275

32.368 18.591 8.215 4.684

25.614 14.996 6.747 3.926

28.920 16.790 7.412 4.275

31.386 17. 8 47 7.981 4.563

32.212 18.294 8.272 4.736

29.033 17.009 7.268 4.254

23.548 15.282 6.913 3.485

Caution: Never remove the u-clip retainer

when the pipe is under pressure. Always

remove pressure from the pipe before attempting to remove the meter. Removal

under pressure may result in damage or

serious injury.

Rotor Replacement. It is unusual for a rotor to require replacement due to damage sustained in normal service. More

commonly, the meter is dropped while it is out of the pipe.

Another reason for rotor replacement is shaft wear after long

service. Rotors are easily eld-replaced.

To install a rotor, follow these steps:

1. Unscrew the threaded bearing housings to expose

the shaft ends. If bearings are being replaced,

back them completely out.

2. Remove the rotor. Put the new rotor in its place.

3. Thread in one bearing housing part way, then the

other. Take care to start the end of the shaft into

the bearing hole before tightening further.

4. Screw in bearing housings until they bottom.

Note: Do not use excessive force.

5. Check for free spin. Blowing lightly on the rotor

should result in it spinning rapidly and coasting to a

smooth stop.

Sensor Replacement. It is very unusual for a sensor to require replacement in normal use. The primary cause of sensor

failure is overvoltage (inadvertent connection of high voltage,

for example) or incorrect polarity on hookup. The sensor is

replaced by removing the strain relief, then threading out

the sensor retainer plug. Remove the entire sensor capsule

by pulling on the cable. The new sensor capsule can then be

installed. Replace the retainer plug, and then replace and

tighten the strain relief.

Sensor Replacement

1) Loosen and unthread

Strain Relief

2) Remove Sensor Retainer

Plug by inserting a

screwdriver blade into

one side of the slot and

turning

3) Remove the Sensor

Capsule by pulling on

the cable

4) Reverse the process

to replace

Page 8

Field Calibration. It is possible to eld-calibrate a Series

PDWS ow sensor to determine an accurate K-factor in the

actual installation. The reason for doing this would be to

compensate for an unusual condition, for instance, applica-

tions with higher viscosity uid (PDWS meters are calibrated

for water use) or which lack adequate straight pipe ahead of

the meter.

˚F

Signal Troubleshooting. The ow sensor has only one mov-

ing part, the rotor. If this is turning properly and there is no

signal, the magnetic sensor is not operating properly. To check

the signal, apply 12 Vdc power to the red (+) and black (-)

leads. Set a multimeter to voltage reading. Put the positive

multimeter lead on the red wire and the negative lead on the

white wire. Slowly turn the rotor. Voltage reading should swing

between -12 Volts and 0 Volts as the rotor turns. If it does

not, the solid-state magnetic sensor is not working properly.

Checking for continuity is not a useful test of these sensors.

Page 9

Page 6

PARTS EXPLOSION

TROUBLESHOOTING

SERIES PDWS PARTS LISTING

Upper Housing

1

Problem

No signal

after installation

Inaccurate

metering

Probable Cause Try...

Insufcient ow

Bad connections to control electronics

Incompatible control

Damaged or missing rotor

Failed magnetic sensor

Not enough straight pipe between meter and

severe ow disturbance

Wrong K-Factor entered

Consult Flow Range Chart

Reduce pipe size or use different

sensor

Check connections at control;

Red (+), Black (-), White (signal)

Use 6 to 24 VDC power supply

Add pull up resistor, if using currentsourcing device

Remove ow sensor from tting and check

for free spinning; replace rotor

See signal troubleshooting; replace

magnetic sensor

Move meter away from ow disturbance, or

eld-calibrate

Check tting for K-Factor, check indicator to

see if it is entered properly ("Set K" on

RTI)

Gasket

2

Lower Housing

3

Housing Screw Assembly

4

Plug, Steel

5

Plug, Plastic

6

Strain Relief

7

Sensor Retainer

8

Sensor, Low Power

9

Body

10

O-Ring, EPDM

11

Bearing Screws (2)

12

Rotor (Nickel/Carbide Shaft)

13

Rotor (Ceramic Shaft)

Rotor Repair Kit (Kynar/Carbide)

14

Rotor Repair Kit (Kynar/Ceramic)

Standard Fitting

15

Magnetic sensor failing to pick up each blade

Wrong time units on ow indicator

Remove ow sensor from pipe. If indicator

is an RTI, set K to 1.00, turn rotor slowly by

hand, indicator should count each blade;

replace sensor

If using an RTI, check left side of

display (sec, min, hr, day); change to

desired unit

High Pressure Fitting

16

Page 10 Page 11

Page 7

WARRANTY/RETURN

Refer to "Terms and Conditions of Sale" in our catalog or on

our website. Contact customer service to receive a Returns

Goods Authorization number before shipping your product

back for repair. Be sure to include a brief description of the

problem plus any relevant applciation notes.

Dwyer Instruments, Inc. • 102 Indiana Highway 212 • Michigan City, IN 46360 • USA

(P) 219.879.8868 • (F) 219.872.9057 • 1.800.872.9141 • www.dwyer-inst.com

LT-65200388-082212

08/22/2012

Loading...

Loading...