Page 1

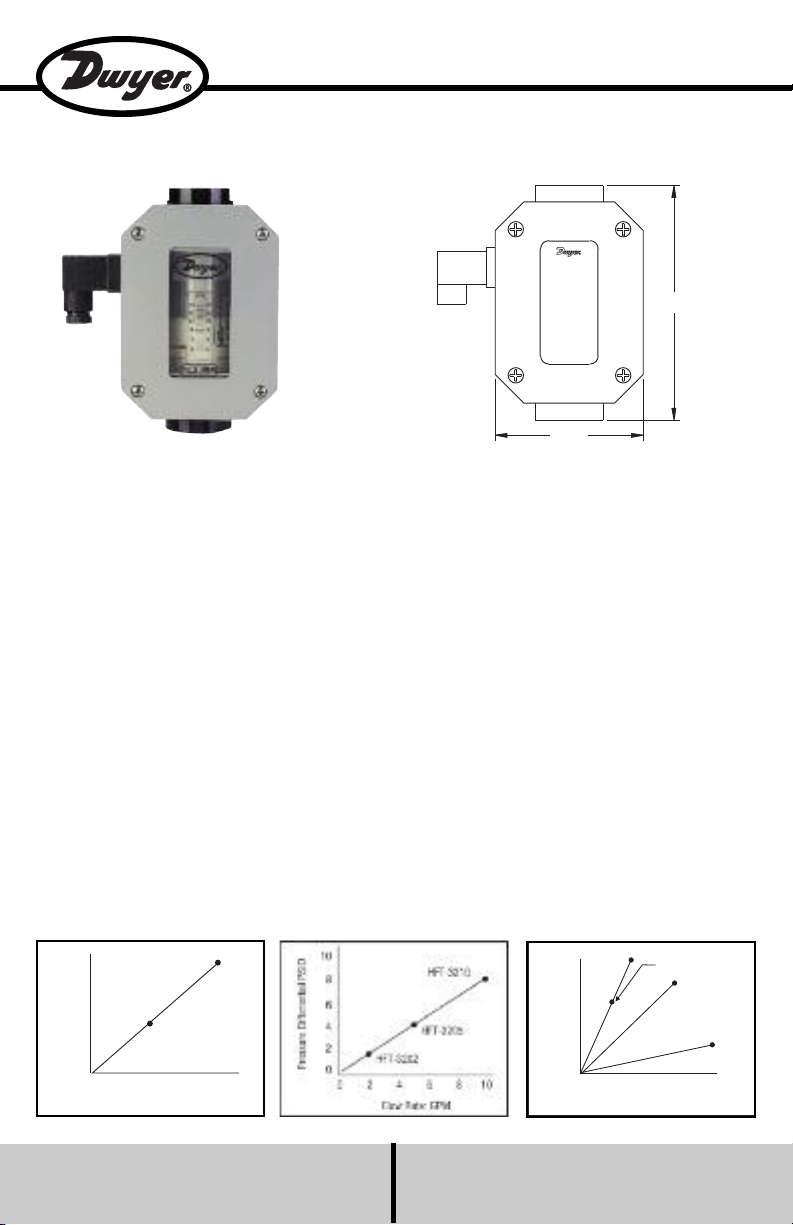

BULLETIN F-HFT

4.500

7.125

2.0

1.5

1.0

0.5

0

Pressure Differential PSID

HFT-1123

HFT-1112

Flow Rate: SCFM @ 100 PSIG

0 5 10 15 20 25

Flow Rate: GPM

Pressure Differential PSID

HFT-23 20

HFT-23 15

HFT-24 40

HFT-25 50

12

10

8

6

4

2

0

0 10 20 30 40 50

Series HFT Flow Transmitters

Specifications – Operating Instructions

Series HFT Flow Transmitters are typically used to

transmit a signal proportional to flow rate to a process

control computer, a PLC, a recorder, or a panel-mount

display. The Flow Transmitters are used as the primary

input device to record flow rates through hydraulic and

pneumatic systems. The universal output transmitter

circuit employed by the Series HFT Flow Transmitter is

capable of producing output signals of 4-20mA, 0-5

VDC, and 0-2000 Hz square wave pulse. A 1-5 VDC

signal may be obtained from the 4-20 mA signal by

placing a 249 Ω resistor in parallel with the receiver.

SPECIFICATIONS

Service: Compatible gases or liquids.

Wetted Materials: Body: Aluminum, brass or 304 SS;

Seals: Buna-N or Fluoroelastomer; Magnet: PTFE

coated Alnico; Other internal parts: 304 SS.

Viscosity Limit: 500 SSU.

Accuracy: ±4% FS over entire range; ±2.5% over

center third of the measuring range.

Repeatability: ±1% of full scale.

Response Time: <100 msec.

Output Signal: 4-20 mA; 0-5 V; 1-5 V.

Temperature Limits: 170°F (76°C).

Note: Refer to Series HF In-Line Flow Monitor, Bulletin

F-55, “Installation and Operating Instructions” for

installation, operation, and cleaning instructions for the

basic flow monitor cartridge (included). The following

instructions are specifically for the Series HFT circuitry

for transmitting a proportional output signal.

Pressure Limits: See Chart.

Power Requirements: 12-35 VDC.

Enclosure Rating: NEMA 4X (IP65).

Shipping Weight: 1/4 to 1/2˝ female NPT Models: 3

lb (1.4 kg); 3/4 to 1˝ female NPT Models: 4.5 lb (2.0

kg); 1-1/2˝ female NPT Models: 12 lb (5.4 kg).

PRESSURE DIFFERENTIAL VS. FLOW RATE

1/4˝ FEMALE NPT

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

1/2˝ FEMALE NPT

Phone: 219/879-8000 www.dwyer-inst.com

3/4˝, 1˝ & 1-1/2˝ FEMALE NPT

Page 2

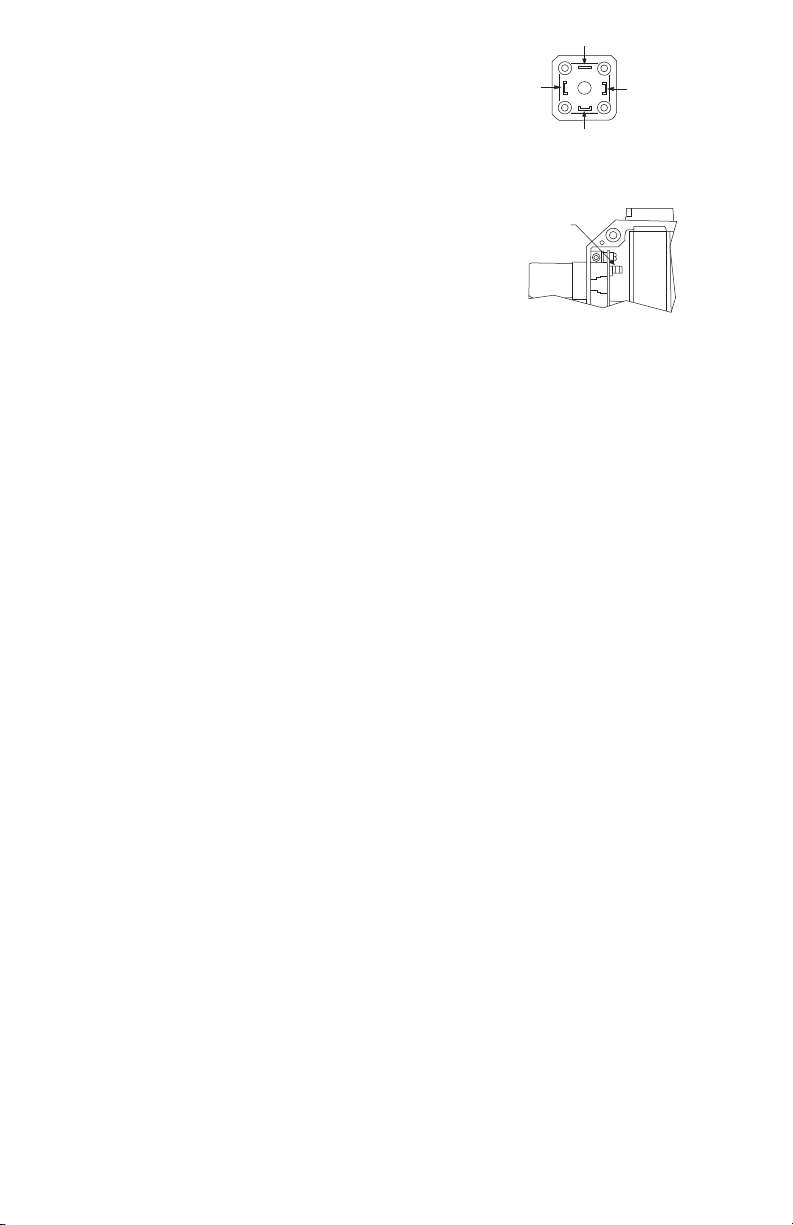

Selecting the Output

NO CONNECTION

G

2

3

1

PIN #1

+12-35 VDC

PIN #2

4-20 mA OUT

ELECTRICAL CONNECTIONS - 4-20 mA

Illustration 2

NO CONNECTION

PROGRAMMABLE JUMPER

IN POSITION CLOSEST

TO METER OUTLET

JUMPER POSITION - 4-20 mA

Illustration 3

The user may choose between reading a 0-2000 Hz

square wave pulse, a 0-5 VDC analog signal, or a two-

ire 4-20 mA analog signal by connecting to the

w

ppropriate pins on the 4-pin DIN connector and by

a

lacing the programmable jumper in the appropriate

p

position for the desired output. An analog 1-5 VDC

output may also be obtained by configuring the unit for

the two-wire 4-20 mA output and then placing a 249 Ω

resistor in parallel with the receiver. The exact output

ins and jumper positions that correspond to each

p

utput are discussed later in this manual.

o

Wiring

4-20 mA output connections:

Input Voltage: The supply voltage must be between 12

and 35 VDC. The maximum resistance that may be

placed within the current loop is given by the following

formula:

R

max

= 50(Vs- 12)

Where:

R

max

= the maximum resistance that

may be placed in the current loop (Ω).

V

s

= the value of the supply voltage (VDC)

Note: Although the signal conditioning circuit does have

integral over-current protection, it is recommended that

the circuit be protected with a 0.25 amp fuse.

Wiring Instructions:

(Refer to Illustrations 2 & 3)

1) Move the programmable jumper on the signal

conditioning board into the position closest to the

meter’s outlet, as shown in Illustration 3.

2) Connect the positive DC power source (+12 to +35

VDC) to terminal #1 on the DIN connector.

3) Connect terminal #2 of the DIN connector to the

positive current input on the receiving device.

4) If the power source does not originate from the

receiving device, the negative side of the power

supply must be connected to the signal ground of the

receiving device.

5) If the transmitter is operating properly, the green

LED on the signal conditioning board will illuminate

dimly at zero flow and will increase in intensity as

flow increases.

0-5 VDC output connections:

Wiring Instructions:

(Refer to Illustrations 4 & 5)

1) Move the programmable jumper on the circuit board

into the position closest to the meter’s inlet, as

shown in Illustration 5.

2) Connect the positive voltage source (+12 to +35

VDC) to terminal #1 of the DIN connector.

3) Connect terminal #2 of the DIN connector to the

negative side of the DC voltage source.

4) Connect terminal #3 of the DIN connector to the 0-5

VDC input of the receiving device.

5) If the power source does not originate at the

receiving device, a wire will need to be connected

between the negative side of the voltage source and

the signal ground of the receiving device.

6) If the transmitter is operating correctly, the green

LED on the circuit board will illuminate brightly when

power is applied to the unit.

Note: The input impedance (resistance) of the receiving

device must not be lower than 100 Ω or non-linearities

may result. Lower impedance will not damage the

transmitter.

Page 3

0-2000 Hz pulse output connections:

NO CONNECTION

G

2

3

1

PIN #1

+12-35 VDC

PIN #2

DC GROUND

ELECTRICAL CONNECTIONS - 0-5 VDC

Illustration 4

PIN #3

0-5 VDC OUTPUT

PROGRAMMABLE JUMPER

IN POSITION CLOSEST

TO METER INLET

JUMPER POSITION - 0-5 VDC

Illustration 5

G

2

3

1

NO CONNECTION

PIN #2

1-5 VDC OUT

ELECTRICAL CONNECTIONS - 1-5 VDC

Illustration 8

PIN #1

+17-35 VDC

NO CONNECTION

249 OHMS

TO SIGNAL

GROUND

PROGRAMMABLE JUMPER

IN POSITION CLOSEST

TO METER OUTLET

JUMPER POSITION - 1-5 VDC

Illustration 9

"G" PIN

0-2000 Hz OUTPUT

G

2

3

1

PIN #1

+12-35 VDC

PIN #2

DC GROUND

ELECTRICAL CONNECTIONS - 0-2000 Hz PULSE OUT

Illustration 6

NO CONNECTION

PROGRAMMABLE JUMPER

IN POSITION CLOSEST

TO METER INLET

JUMPER POSITION - 0-2000 Hz PULSE OUT

Illustration 7

Wiring Instructions:

(Refer to Illustrations 6 & 7)

1) Move the programmable jumper on the circuit board

into the position closest to the meter’s inlet, as

shown in Illustration 7.

2) Connect the positive voltage source (+12 to +35

VDC) to terminal #1 of the DIN connector.

3) Connect terminal #2 of the DIN connector to the

negative side of the DC voltage source.

4) Connect the “G” terminal of the DIN connector to the

pulse input of the receiving device.

5) If the power source does not originate at the

receiving device, a wire will need to be connected

between the negative side of the voltage source and

the signal ground of the receiving device.

6) If the transmitter is operating properly, the green

LED on the circuit board will illuminate brightly when

power is applied to the unit.

-5 VDC output connections:

1

iring Instructions:

W

Refer to Illustrations 8 & 9)

(

1) Move the programmable jumper on the signal

conditioning board into the position closest to the

meter’s outlet, as shown in Illustration 9.

2) Connect the positive voltage (+17 to +35 VDC) to

terminal #1 of the DIN connector.

3) Connect terminal #2 of the DIN to the 1-5 VDC input

of the receiving device.

4) Connect one lead of a 249 Ω resistor to Terminal #2

as shown in Illustration 8. Connect to the other lead

to signal ground.

5) If the power source does not originate at the

receiving device, a wire will need to be connected

between the negative side of the voltage source and

the signal ground of the receiving device.

6) If the transmitter is operating properly, the green

LED on the circuit board will illuminate dimly at zero

flow and will increase in intensity as flow rate

increases.

Page 4

ser Adjustments

G

PM

5

5

4

4

3

3

2

2

1

1

PROGRAMMABLE JUMPER

DIN CONNECTOR

4-20 mA OFFSET ADJUST

4-20 mA SPAN ADJUST

0-5 VDC SPAN ADJUST

SIGNAL CONDITIONING CIRCUIT

FLOW INDICATOR LINE

FOLLOWER

SENSOR ASSEMBLY

FLOW RATE SCALE

NEMA 4X ENCLOSURE

Illustration 10

U

he 4-20 mA, 0-5V, and 0-2000 Hz square wave outputs

T

on the Flow Transmitter are all factory calibrated. User

adjustment should be unnecessary and any adjustment

of the potentiometer on the signal conditioning board is

strongly discouraged. If one of the outputs does fall out

f calibration, the following procedure may be used to

o

ecalibrate the unit.

r

) Turn off the flow through the system.

1

2) Connect between +12 and +35 VDC to pin 1 of the

DIN connector. Connect terminal 2 of the DIN

connector to the negative terminal of the DC supply.

3) Move the programmable jumper on the signal

onditioning board into the position closest to the

c

ensor’s inlet, as shown in Illustrations 5 & 7.

s

) Connect the positive terminal of a voltmeter to pin 3

4

of the DIN connector. Connect the negative terminal

to pin 2 of the DIN connector.

5) Gradually increase the flow through the system until

the flow rate indicated on the printed flow rate scale

reaches full-scale (the highest value printed on the

scale).

6) Adjust the 0-5 VDC Span potentiometer until a

reading of 5.00 VDC is obtained on the voltmeter.

7) Turn off the flow through the system and remove the

voltmeter.

8) Move the programmable jumper on the signal

conditioning board into the position closest to the

sensor’s outlet, as shown in illustrations 3 and 9.

9) Disconnect pin 1 of the DIN connector from the

positive terminal of the DC power supply.

10) Connect the positive terminal of an ammeter to the

positive terminal of the DC power supply. Connect

the negative terminal of the ammeter to pin 1 of the

sensor’s DIN connector.

11) Adjust the 4-20 mA Offset potentiometer (see

Illustration 1) until a reading of 4.00 mA is obtained

on the ammeter.

12) Gradually increase the flow through the system until

the flow rate indicated on the printed flow rate scale

reaches full-scale (the highest value printed on the

scale).

13) Adjust the 4-20 mA span potentiometer (see

Illustration 1) until a reading of 20.00 mA is obtained

on the ammeter.

14) Gradually decrease the flow through the system until

a value equal to 50% of full-scale is obtained on the

sensor’s flow rate scale. Verify a reading of between

11.92 and 12.08 mA.

©Copyright 2012 Dwyer Instruments, Inc. Printed in U.S.A. 5/12 FR# R1-443343-00 Rev. 3

DWYER INSTRUMENTS, INC.

Symptom: The green LED does not illuminate when

power is applied.

Remedy:

1) Recheck the wiring diagram for the communication

protocol that is being used and verify that the wiring

is correct.

2) Verify that the DC supply that is being used is

capable of producing at least 12 VDC.

3) Make sure that the cable that is soldered to the DIN

connector inside of the sensor enclosure is plugged

into the connector opposite to the programmable

jumper.

Symptom: The readings obtained from the

electronic output do not agree with the readings

shown on the printed flow rate scale.

Remedy:

1) Make sure that the programmable jumper is in the

correct position for the communication protocol that

is being used.

Symptom: The green LED illuminates, but no

readings are obtained from the sensor’s electronic

output.

Remedy:

1) Re-check the wiring diagram for the communication

protocol that is being used and verify that the wiring

is correct.

2) Make sure that the cable from the sensor assembly

is plugged into the connector on the signal

conditioning board located near the sensor inlet.

Symptom: When the flow rate in the system

changes, the follower and electronic output do not

respond.

Remedy:

1) Remove the flow sensor from the system and

inspect the internals to see if anything has caused

them to become jammed. Make sure that the 200

mesh, 74 micron filtration requirement of the flow

sensor is being observed.

Phone: 219/879-8000 www.dwyer-inst.com

Troubleshooting Chart

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...