Page 1

Bulletin V-HBAV

TM

W.E. ANDERSON

Model No: #HBAVXXXX

Power Supply:

Torque:

Time:

W.E. ANDERSON

A DIV. OF DWYER INSTRUMENTS, INC.

102 INDIANA HWY 212, MICHIGAN CITY, IN 46360

Phone: 219-879-8000

Email: info@dwyer-inst.com

www.dwyer-inst.com

Made In China

A

B

C

D

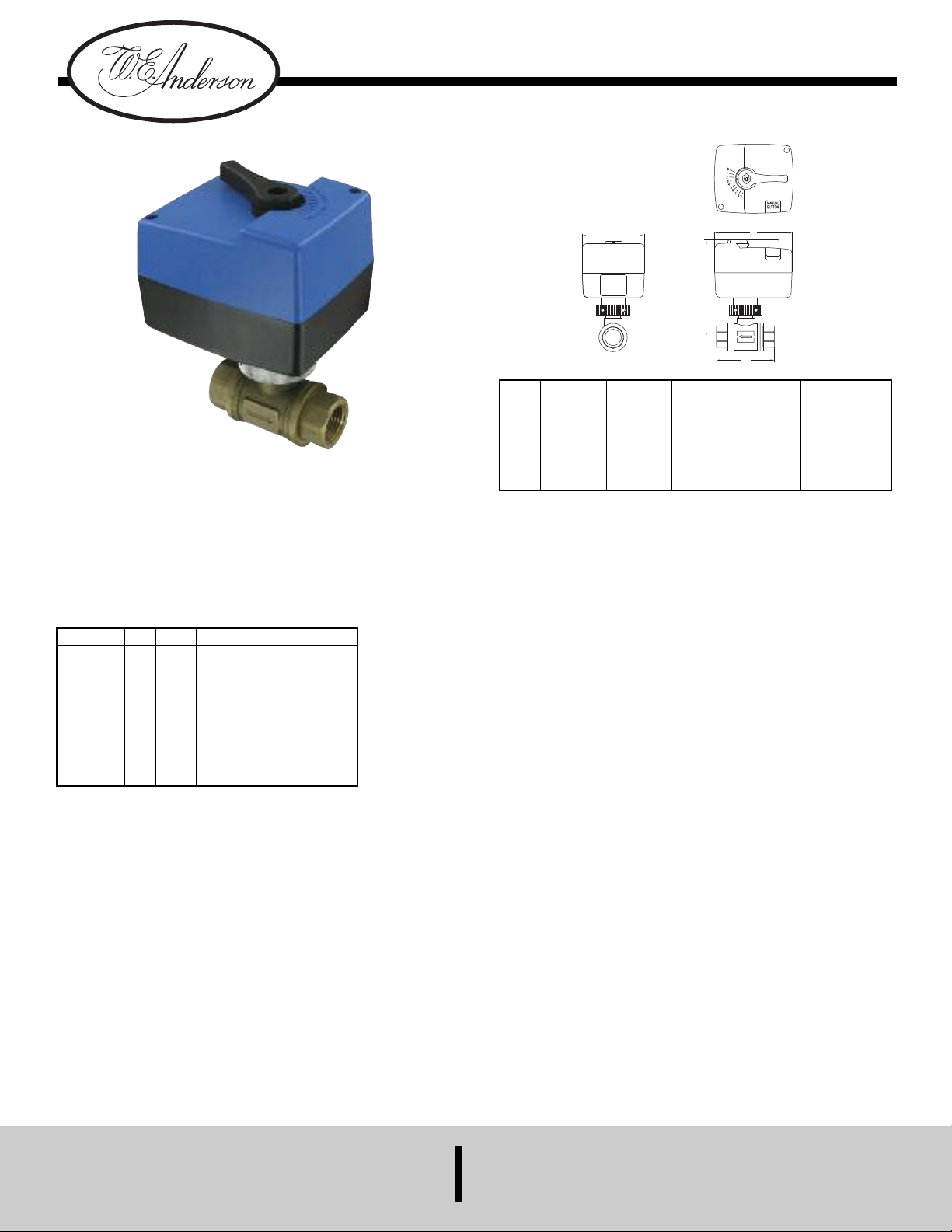

Series HBAV Two-Way Detachable Electric Ball Valve

Specifications - Installation and Operating Instructions

The Series HBAV is an electrical ball valve ideal for flow control in hot

and cold water HVAC systems. These valves are typically used in

conjunction with air conditioning systems, heating systems, water

treatment and production industries. The HBAV is electrically driven

open and/or closed via a bidirectional AC motor. The electrical valve

offers a detachable actuator with position switches and indicator. The

HBAV is available with modulating or floating actuators.

Model

HBAV0212

HBAV0214

HBAV0224

HBAV0312

HBAV0314

HBAV0324

HBAV0412

HBAV0414

HBAV0424

Cv

4.5

4.5

4.5

7.0

7.0

7.0

11.2

11.2

11.2

Size

1/2˝

1/2˝

1/2˝

3/4˝

3/4˝

3/4˝

1˝

1˝

1˝

Supply Voltage

120 VAC

24 VAC

24 VAC

120 VAC

24 VAC

24 VAC

120 VAC

24 VAC

24 VAC

Input

Floating

Floating

Modulating

Floating

Floating

Modulating

Floating

Floating

Modulating

Size

1/2˝

3/4˝

1˝

1-1/4˝

1-1/2˝

2˝

A in [mm]

3.62 [92]

3.62 [92]

3.62 [92]

4.84 [123]

4.84 [123]

4.84 [123]

B in [mm]

3.03 [77]

3.03 [77]

3.03 [77]

3.07 [78]

3.07 [78]

3.07 [78]

C in [mm]

4.53 [115]

4.53 [115]

4.72 [120]

5.16 [131]

5.16 [131]

5.31 [135]

D in [mm]

2.68 [68]

2.68 [68]

3.23 [82

3.86 [98]

4.13 [105]

4.80 [122]

Weight lb [kg]

1.43 [0.65]

1.54 [0.70]

2.09 [0.95]

3.20 [1.45]

3.31 [1.50]

4.19 [1.90]

SPECIFICATIONS

Service: Compatible fluids.

Body: 2-way, NC.

Line Size: 1/2 to 2˝ NPT.

End Connections: Female NPT.

Pressure Limits: Max: 375 psi (25 bar); Close off: 87 psi (6 bar).

Temperature Limit:

Ambient: -22 to 158°F (-30 to 70°C);

Process: 23 to 122°F (-5 to 50°C).

Wetted Materials: Brass, SS, NBR, PTFE.

Input: Floating: 3-wire; Modulating: 4 to 20 mA (24 VAC power only).

Power Requirements: 120 VAC or 24 VAC, 50/60 Hz, single phase.

Power Consumption: Floating: 3 to 5 VA; Modulating: 4 VA.

Electrical Connection: 18 AWG.

Cycle Time (per 90°): 1/2 to 1˝: 45 sec.; 1-1/4 to 2˝: 50 sec.

Enclosure Rating: NEMA 1 (IP10).

Housing Material: Plastic, nylon, and polyoxymethylene.

Weight: See table above.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

Instructions For Operation And Use

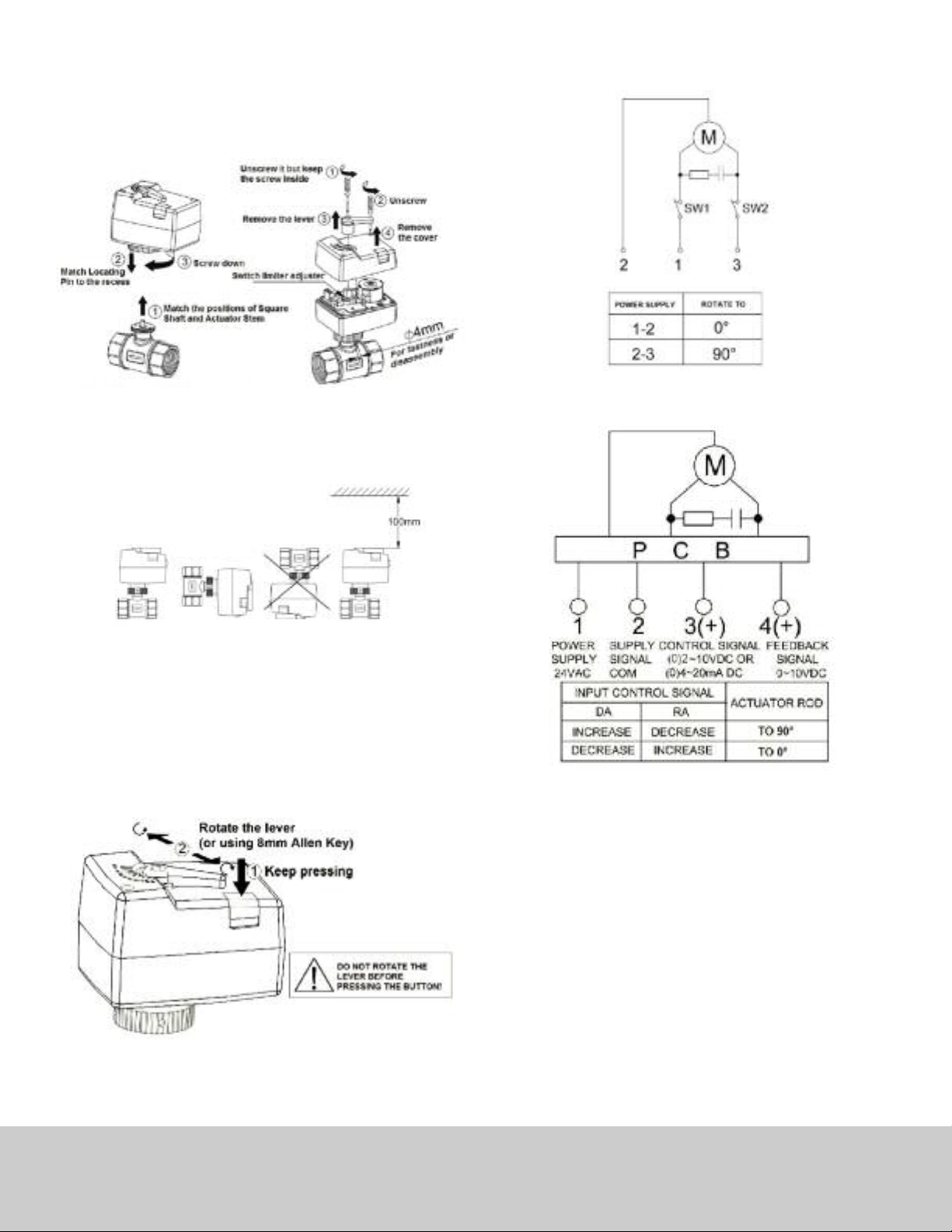

Assembly and disassembly of the actuator from the valve body is done

simply by twisting the connection between them (see Figure 1). In order to

do this properly, the actuator lever needs to be in the ‘0’ position so the

actuator stem and pins match with the corresponding hole. Use little force

to pull apart the actuator.

Figure 1

2. 3-way valves are installed by matching the pipe male connection to the

3HBAV female valve connection. Do not mount the 3HBAV upside down.

For the correct direction of the 3HBAV placement (see Figure 2).

Wiring Diagrams

FLOATING

igure 4

F

MODULATING

Figure 2

3. Manual operating lever: To move the ball valve manually, press and hold

down the manual button located on the top of the actuator (see Figure 3).

Moving the lever allows you to rotate the ball valve open or closed. When

the manual button is released, the valve is locked in that position

automatically.

Automatic operating lever: To have the ball valve rotate automatically,

install a three wire electric connection of 18 AWG into the sensor input

located under the plastic cover of the actuator.

Figure 3

Figure 5

NOTE

Modulating model sizes 1/2˝ through 1˝ include an electric cord attached on

the outside. Modulating model sizes 1-1/4˝ through 2˝ contain a 4-wire

terminal block.

MAINTENANCE/REPAIR

Upon final installation of the Series HBAV, no routine maintenance is

required. The Series HBAV is not field serviceable and should be returned

if repair is needed. Field repair should not be attempted and may void

warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on our website.

Contact customer service to receive a Return Goods Authorization number

before shipping the product back for repair. Be sure to include a brief

description of the problem plus any additional application notes.

©Copyright 2012 Dwyer Instruments, Inc. Printed in U.S.A. 5/12 FR# RB-443961-00

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...