Page 1

Bulletin P-HADP

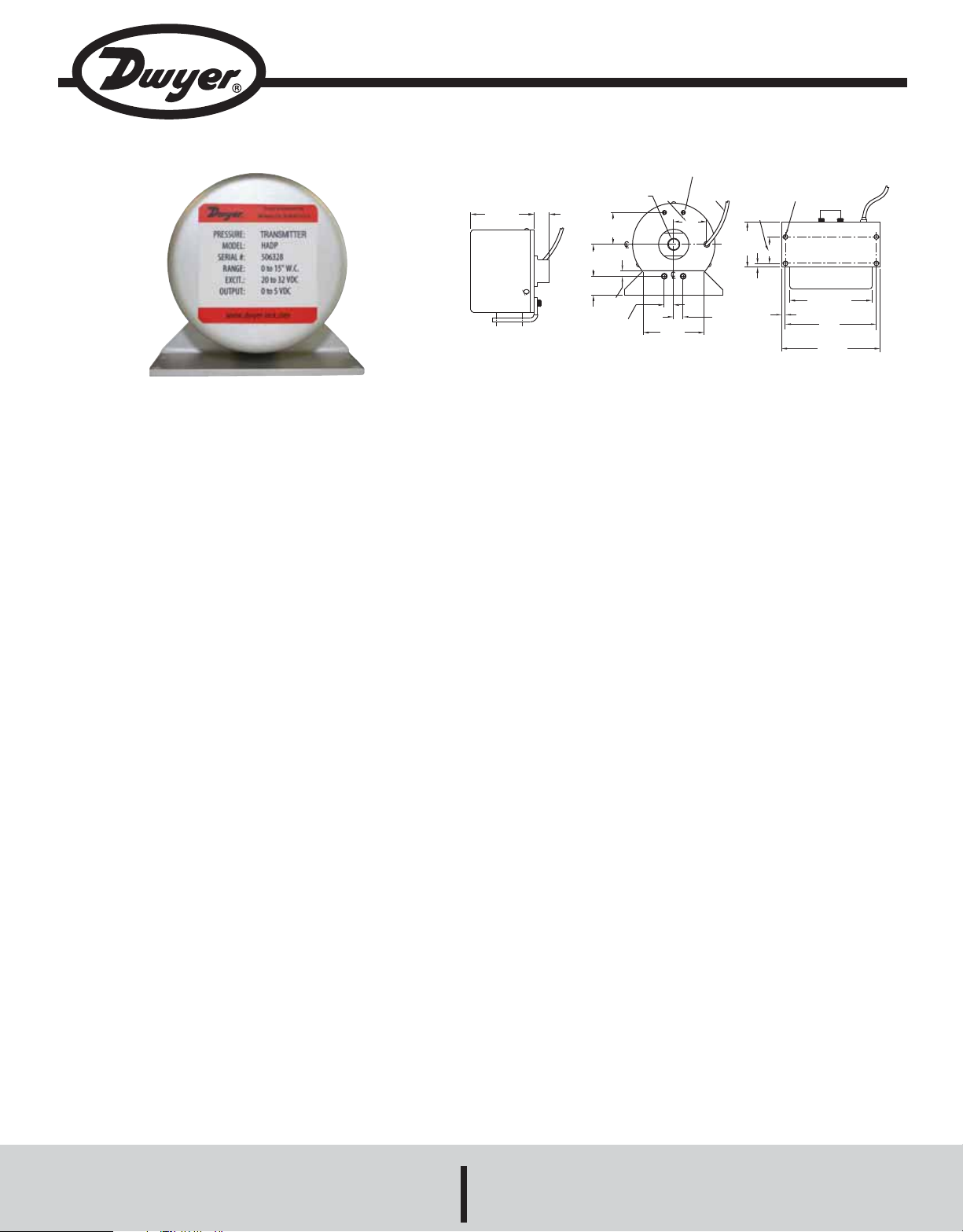

Series HADP High Accuracy Differential Pressure Transmitter

Specifications - Installation and Operating Instructions

4x 6-32UNC-2B

7/64 [2.78] MIN FULL THRD

1-3/32

2-3/32

[53.18]

33/64

[13.1]

[26.99]

1-1/16

[26.99]

5/8

[15.88]

1-1/16

3/16

[4.76]

1/8-27

NPT PORT

5/16

[7.94]

[27.78]

2

[50.8]

CABLE

2´ LONG

5/16

[7.94]

1-1/2

[38.1]

[22.23]

1/8

[3.18]

1/8

[3.18]

7/8

4x Ø5/32 [Ø3.97]

MOUNTING HOLES

Ø2-47/64

[69.45]

3

[76.2]

3-1/4

[82.55]

The Series HADP transmitter has been carefully calibrated before shipment

to you, and it should be handled with the same care given any precision

instrument. Pressure range and dimensions are reported on the applicable

specifications bulletin.

Ambient Conditions

Do not submerge in liquids, use in ambient conditions corrosive to

anodized aluminum, subject to spray or dripping, or use in a high

vibration environment. The transmitter is very slightly sensitive to

acceleration in the pressure fitting axis. Installation is recommended in

the vertical position, with the pressure port downward. This position

minimizes damage from drippage of pressure system piping.

Installation of Pressure Fittings

Your transmitter is designed for most accurate operation when

subjected to pressures within the designated pressure range. Refer to

the specifications for proof pressure limits. Subjection to excessive

pressure voids the warranty. Do not overpressure.

Standard sealants such as pipe tape generally are satisfactory. For the

most sensitive pressure ranges, excessive high torquing of a metal

pressure fitting may cause slight zero shift which may be trimmed out

using the zero adjustment. Use of a plastic fitting often shows no

noticeable zero shift. The torquing effect does not appreciably affect

linearity or sensitivity. The wrench flat on the Series HADP should be

used when installing the positive pressure fitting.

SPECIFICATIONS

Service: Compatible non-conducting

air/gas.

Wetted Parts:

Positive (high) Pressure Port:

Gases compatible with SS, hard

anodized 6061 aluminum (Buna-N

O-ring);

Reference (low) Pressure Port:

Anodized aluminum, alumina

ceramics, gold, fluorocarbon

elastomer sealant & Buna-N O-ring.

Accuracy: <±0.14% FS.

Stability: <±0.1% FS over 6 months @

70°F (21°C).

Pressure Limits: See Model Chart.

Temperature Limits:

Operating: 0 to 175°F

(-18 to 71°C);

Storage: -65 to 250°F

(-53 to 121°C).

Compensated Temperature Range:

30 to 150°F (-1 to 65°C).

Thermal Effect: <±1.0% FS / 100°F.

Power Requirements: 17 to 42 VDC.

Output Signal: 4 to 20 mA for current

models, 0 to 5 VDC for voltage models.

Zero and Span Output:

Zero output: Factory set to within

±0.07 mA;

Span (FS) output: Factory set to

within ±0.07 mA.

Loop Resistance:

Minimum supply voltage (VDC) = 17

+ 0.02 x Resistance of receiver plus

line;

Maximum supply voltage (VDC) =

42 + 0.004 x Resistance of receiver

plus line.

Zero and Span Adjustments: None.

Response Time: <5 msec.

Current Consumption: <30 mA.

Electrical Connections: 2 ft multi-

conductor cable.

Process Connections: 1/8˝-27 NPT

internal (both positive and negative

ports).

Mounting Orientation: Pressure port

90° parallel to ground.

Thermal Effects: Max. zero: ±1.0

(±1.8); %FS / 100°F (100°C) max.

Weight: 8 oz (227 g).

Agency Approval: CE.

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

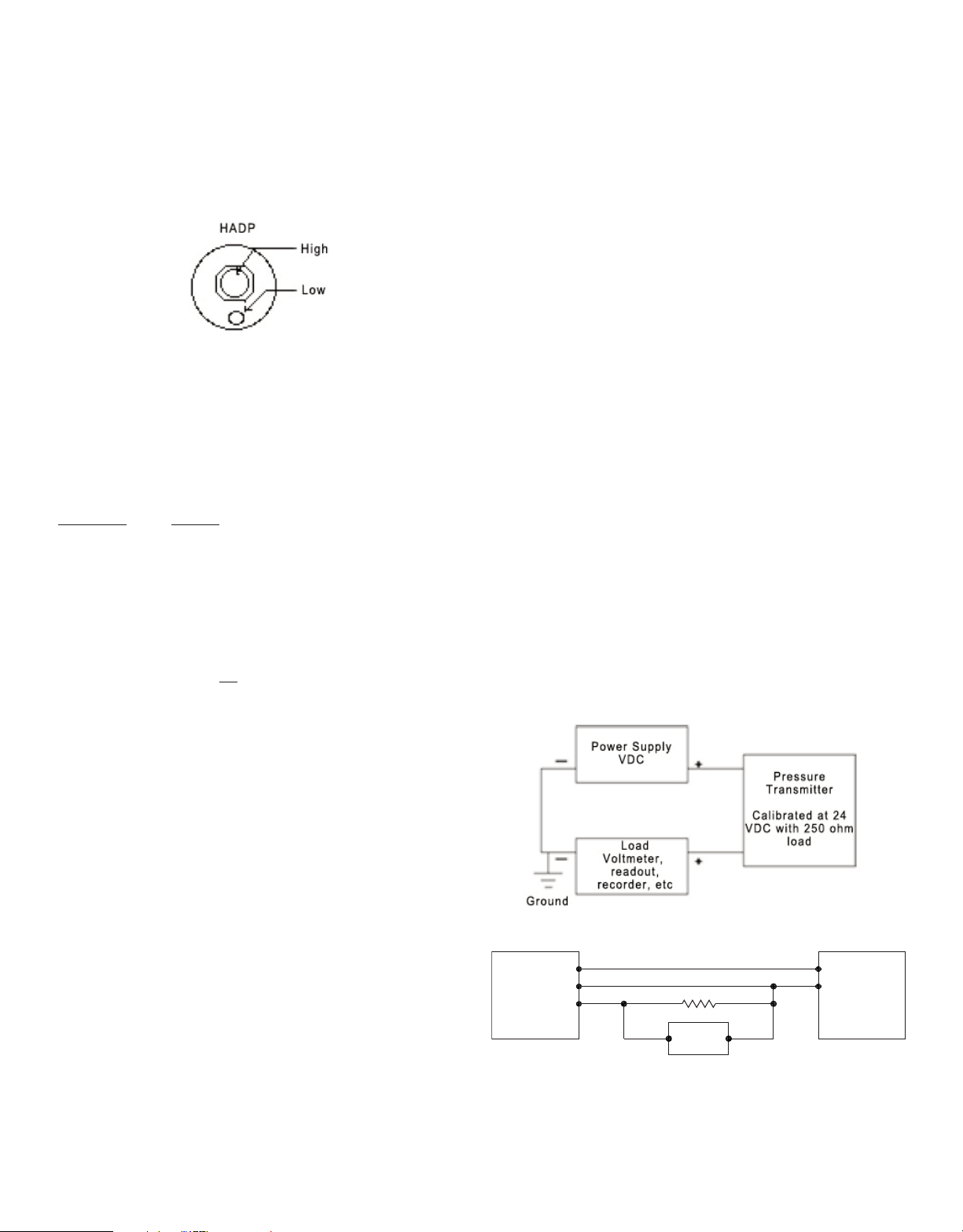

A. Positive Pressure Fitting and Media Compatibility

PRESSURE

TRANSMITTER

POWER SUPPLY

RECEIVER

+

–

+ –

Series HADP: 1/8˝-27 NPT internal fitting

For use with gases compatible with stainless

steel, hard anodized 6061 aluminum, Buna N

“O” ring.

B. Reference Pressure Fitting and Media Compatibility (Differential

pressure measurements only.)

Notes:

(1) Differential pressure models can be used to measure gage pressure

by leaving the reference port open to atmosphere.

(2) Line Pressure refers to pressure applied to both high and low sides

of the sensing device simultaneously. Refer to the product data sheet

to determine maximum differential pressure and overpressure limits.

Electrical Information for Standard 24 VDC Excitation Pressure

Transmitters (nominal)

Connections

Cable Lead Function

White Positive Excitation

Yellow Positive Output

Brown Negative Output

Black Negative Excitation - (to circuit ground)

Case Shield

Electrical

The electrical circuit is equivalent to a 4 terminal network, which can be

grounded at only one point, either at the negative excitation or the negative

signal output lead, but must not be commoned or grounded at more than

one point.

The pressure transmitter must be operated with the case connected either

to the negative excitation terminal or to the negative output terminal.

Failure to do this may result in damage to or unsatisfactory operation of the

unit. This connection may be made by connecting shield and black

(negative excitation) leads or alternately by connecting the shield and

brown (negative output) leads together. Best shielding against noise will be

obtained by connecting the shield and negative excitation (black) leads.

Electrical

Operation is from a ±24 VDC supply (common return grounded), and

provides you with the negative signal output lead also at the common

ground potential. Thus many transmitters can be operated from one power

supply into single-ended loads. Circuit is reversed voltage protected for at

least 5 minutes. Internal transient suppression network is provided for short

duration transients to 150 volts.

Grounding

For general usage and best results (lowest noise) grounding of the

shield/case to the black lead is recommended.

Power Supply Advice

This transmitter has been designed to operate from a ±24 VDC source.

The ±24 V is 24 V above the common power return-lead, and the -24 V is

24 V below the common power return lead.

All three power leads must be connected. The transmitter will not function

if just the +24 V and -24 V leads are connected to the power source.

To avoid circuit damage due to excessive voltage, the positive supply

voltage should be held within the range of +15 V to +20 V (+22 V to +30

V), and the negative supply voltage should be held within the range of -10

V to -20 V (-10 V to -24 V).

Electrical Information for 4 to 20 mA Pressure Transmitter

Electrical

The circuit is designed to operate as a true 2-wire 4 to 20 mA pressure

transmitter.

Connection

The transmitter has two electrical leads. These may be connected for

current flow in either direction, without change in performance or damage.

We suggest that the electrical cable shield be connected to the system loop

circuit’s ground, thereby improving electrical noise rejection.

Wiring 4 to 20 mA Output

The circuit has internal protection:

Reversed excitation voltage for at least 5 minutes.

Short-circuit or signal output leads.

Short duration power line transients up to 150 volts.

Note on long cable use:

In some instances, use of long cables (several hundred feet length) may

introduce enough cable capacitance into the circuit to cause output

oscillations. If encountered, this oscillation may be eliminated by

connecting a 100 ohm resistor (1/8th watt or larger) in series to each of the

output leads at the end of the 2 ft transmitter cable. These series resistors,

of course, add to the output resistance.

Wiring 0 to 5 VDC Output

Page 3

Adjustments for Zero and Sensitivity

Adjustments for Voltage Output Pressure Transmitters (cover must

be removed)

CAUTION

Zero Pressure Output

Can be adjusted to zero by potentiometer as shown in diagram. Unit

factory adjusted to zero output (±10 mV).

Sensitivity (span)

Can be adjusted by potentiometer as shown on outline diagram. Unit

factory adjusted to order specifications.

Linearity - DO NOT TOUCH

Factory adjusted for best linearity. Touching any adjustments other than

zero output or sensitivity may necessitate recalibration.

Note: Sensitivity (span) adjustment is not recommended unless a

primary pressure standard (dead weight tester, etc.) is available for use

as a reference.

TURN OFF EXCITATION POWER DURING COVER

REMOVAL OR REPLACEMENT

Adjustments for Current Output Pressure Transmitters (cover must

be removed)

Zero Pressure Output

Zero output can be adjusted ±0.2 mA about the nominal 4 mA. The zero

adjustment is the potentiometer shown in the diagram. Changing zero

will not change span.

Sensitivity (span)

Sensitivity can be adjusted approximately ±5 mA from the nominal 16

mA full scale span. The sensitivity adjustment potentiometer is located

as shown in the diagram and may be adjusted without affecting linearity

calibration.

Linearity - DO NOT TOUCH

Factory adjusted for best linearity. Touching any adjustments other than

zero output or sensitivity may necessitate recalibration.

Note: Sensitivity (span) adjustment is not recommended unless a

primary pressure standard (dead weight tester, etc.) is available for use

as a reference.

MAINTENANCE

Upon final installation of the Series HADP Differential Pressure

Transmitter, no routine maintenance is required. A periodic check of

system calibration is recommended. The Series HADP is not field

serviceable and should be returned if repair is needed (field repair should

not be attempted and may void warranty). Be sure to include a brief

description of the problem plus any relevant application notes. Contact

customer service to receive a return goods authorization number before

shipping.

Page 4

Chart A

Model

HADP-UV-00

HADP-UV-01

HADP-UV-02

HADP-UV-03

HADP-UV-04

HADP-UV-05

HADP-UC-00

HADP-UC-01

HADP-UC-02

HADP-UC-03

HADP-UC-04

HADP-UC-05

HADP-BV-08

HADP-BV-09

HADP-BV-10

HADP-BV-11

HADP-BV-12

HADP-BV-13

HADP-BC-08

HADP-BC-09

HADP-BC-10

HADP-BC-11

HADP-BC-12

HADP-BC-13

Model

HADP-UV-06

HADP-UV-07

HADP-UC-06

HADP-UC-07

HADP-BV-14

HADP-BV-15

HADP-BC-14

HADP-BC-15

Range in w.c.

0 to 0.5

0 to 1

0 to 2.5

0 to 5

0 to 15

0 to 30

0 to 0.5

0 to 1

0 to 2.5

0 to 5

0 to 15

0 to 30

0 to ±0.25

0 to ±0.5

0 to ±1

0 to ±2.5

0 to ±7.5

0 to ±15

0 to ±0.25

0 to ±0.5

0 to ±1

0 to ±2.5

0 to ±7.5

0 to ±15

Range psid

0 to 5

0 to 10

0 to 5

0 to 10

0 to ±2.5

0 to ±5

0 to ±2.5

0 to ±5

Max Pressure

High

5 psi

7 psi

10 psi

20 psi

50 psi

50 psi

5 psi

7 psi

10 psi

20 psi

50 psi

50 psi

5 psi

7 psi

10 psi

20 psi

50 psi

50 psi

5 psi

7 psi

10 psi

20 psi

50 psi

50 psi

75 psi

100 psi

75 psi

100 psi

75 psi

100 psi

75 psi

100 psi

Max Pressure

Low

2.5 in w.c.

5 in w.c.

12.5 in w.c.

25 in w.c.

75 in w.c.

150 in w.c.

2.5 in w.c.

5 in w.c.

12.5 in w.c.

25 in w.c.

75 in w.c.

150 in. w.c.

2.5 in w.c.

5 in w.c.

12.5 in w.c.

25 in w.c.

75 in w.c.

150 in w.c.

2.5 in w.c.

5 in w.c.

12.5 in w.c.

25 in w.c.

75 in w.c.

150 in w.c.

25 psi

50 psi

25 psi

50 psi

25 psi

50 psi

25 psi

50 psi

Note: HADP-XV-XX is for voltage, and HADP-XC-XX is for current.

©Copyright 2010 Dwyer Instruments, Inc. Printed in U.S.A. 12/10 FR# R1-443858-00

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...