Page 1

Bulletin F-GFT2

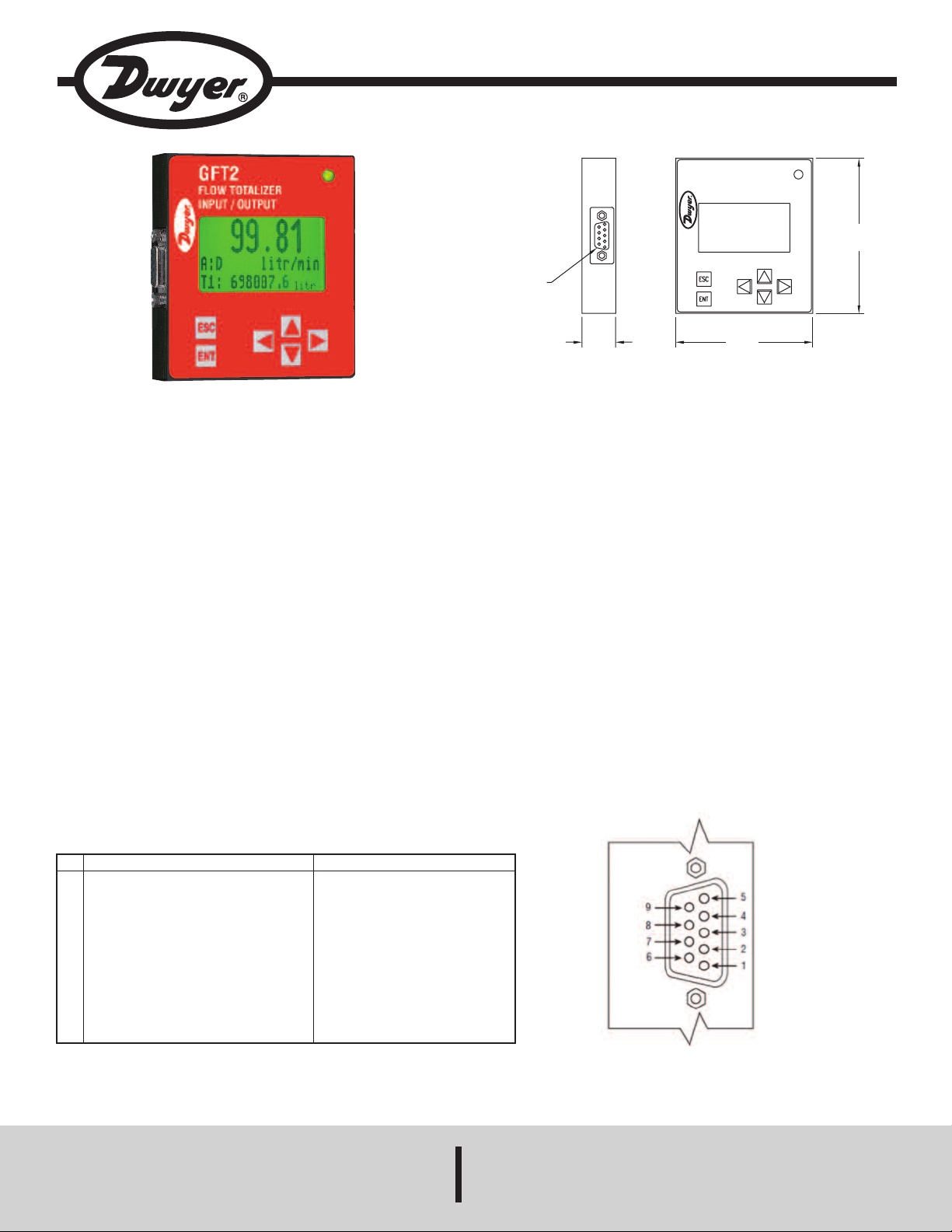

9-PIN FEMALE

I/O PORT

4

7/64

[

18.8]

3

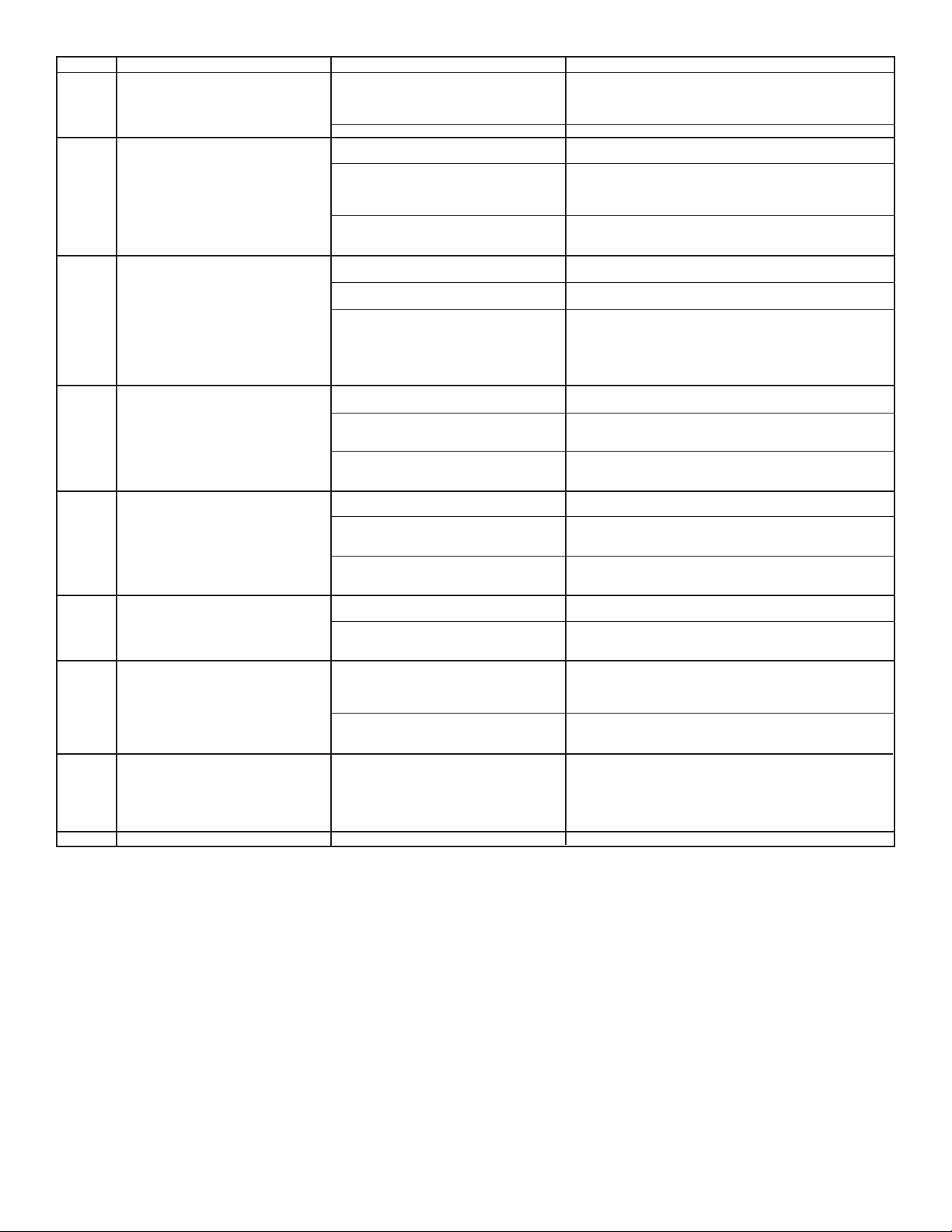

[

76.2]

3-13/32

[86.36]

GFT2

F

LOW TOTALIZER

INPUT/OUTPUT

STATUS

Series GFT2 Flow Totalizer

Specifications - Installation and Operating Instructions

he Series GFT2 Flow Totalizer is a microcontroller driven device designed to

T

linearize the flow meter and controller flow curve plus display the instantaneous

flow rate, total, and accumulated total. The totalizer is intended to be used with

analog flow meters and controllers with analog 0 to 5 VDC, 0 to 10 VDC, or 4 to

20 mA interface. RS-232 or RS-485 digital interface is available.

EATURES

F

Up to 47 different volumetric and mass flow engineering units (including user-

•

defined)

• User adjustable LCD back light and contrast level

• Compact design for unit mount, panel mount, wall mount, or field mount

applications

• Low and high flow alarms with programmable action delay.

• Free configuration and mounting utility software

• 0.51˝ (13 mm) LCD digits

Unpacking the Totalizer

The Totalizer was packed in a sturdy cardboard carton. Inspect the package for

possible external damage from shipping. Open the carton carefully and inspect for

any sign of concealed shipping damage. When unpacking make sure that all

hardware is included. The hardware should include:

(1) GFT2

(1) CD with Utility Software and operating manual

(1) Mounting Bracket with 4 screws

Safety Instructions

The GFT2 is not intended for use in life support applications or where

malfunctioning of a device may cause personal injury. When adjusting or servicing

the GFT2, take special precaution to prevent inadvertent damage to the integral

solid state circuitry.

Electrical Connection

Function

Pin

Power Supply, Common

1

Power Supply, Positive

2

RS-232 RX, Optional RS-485 (+)

3

Analog Input (+), PV Input

v4

Analog Output (+), PV set point

5

RS-232 Signal GND (RS-485 GND Optional)

6

RS-232 TX, Optional RS-485 (-)

7

Analog Input/Output reference

8

common for pins 4 and 5)

9

5VDC reference input (for 5 to 10 VDC only)

Table 1

Note

Power Input

Power Input 12 to 26 VDC

Communication

(RS-232 is input, RS_485 input/output)

Input

Output

Communication Reference

Communication

(RS-232 is output, RS-485 input/output)

SPECIFICATIONS

nput Analog Range: 0 to 5 VDC, 0 to 10 VDC, or 4 to 20 mA.

I

ccuracy: ±0.1% FS.

A

perating Temperature: 14 to 158°F (-10 to 70°C).

O

Power Supply: 12 to 26 VDC.

Weight: 0.3 lbs (125 g)..

“D” Connector

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

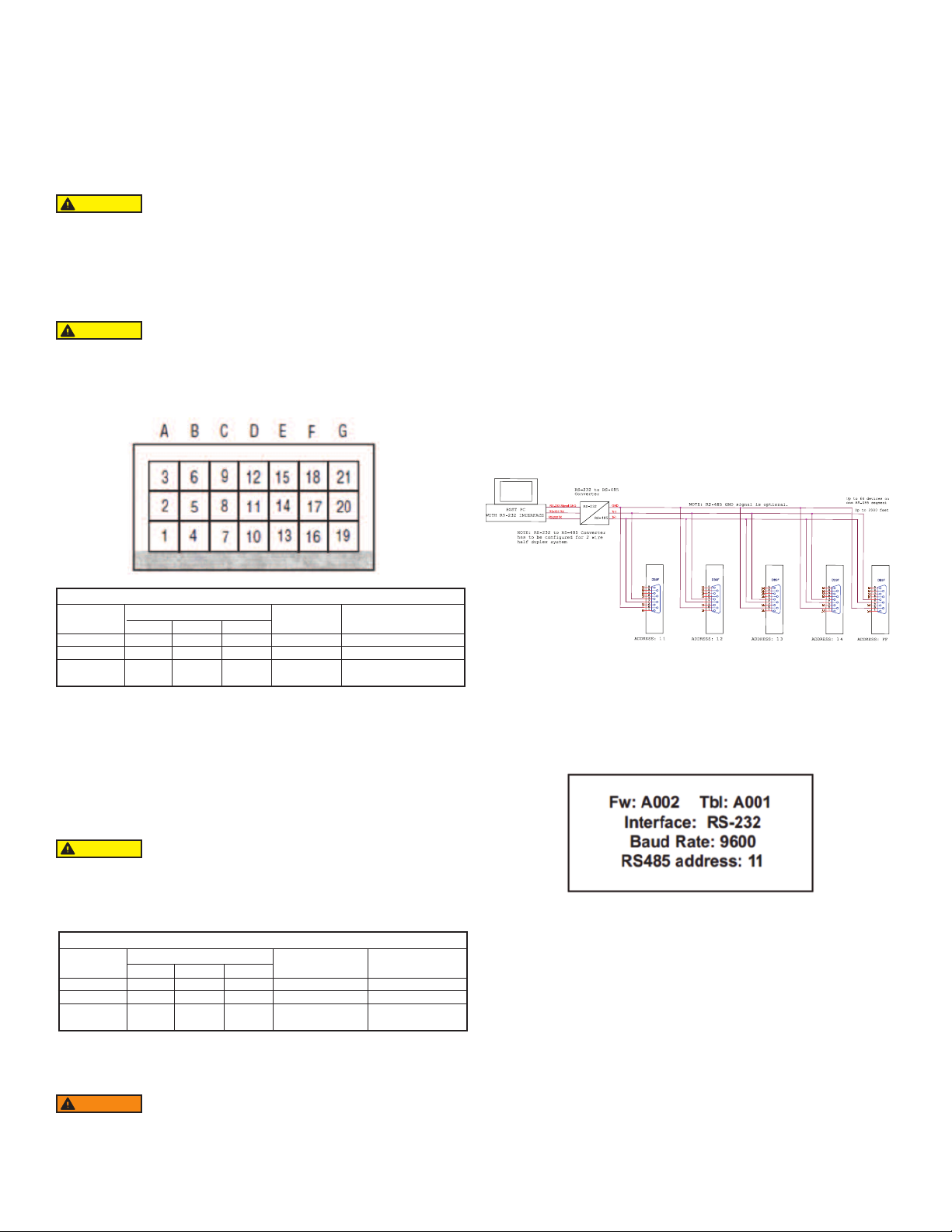

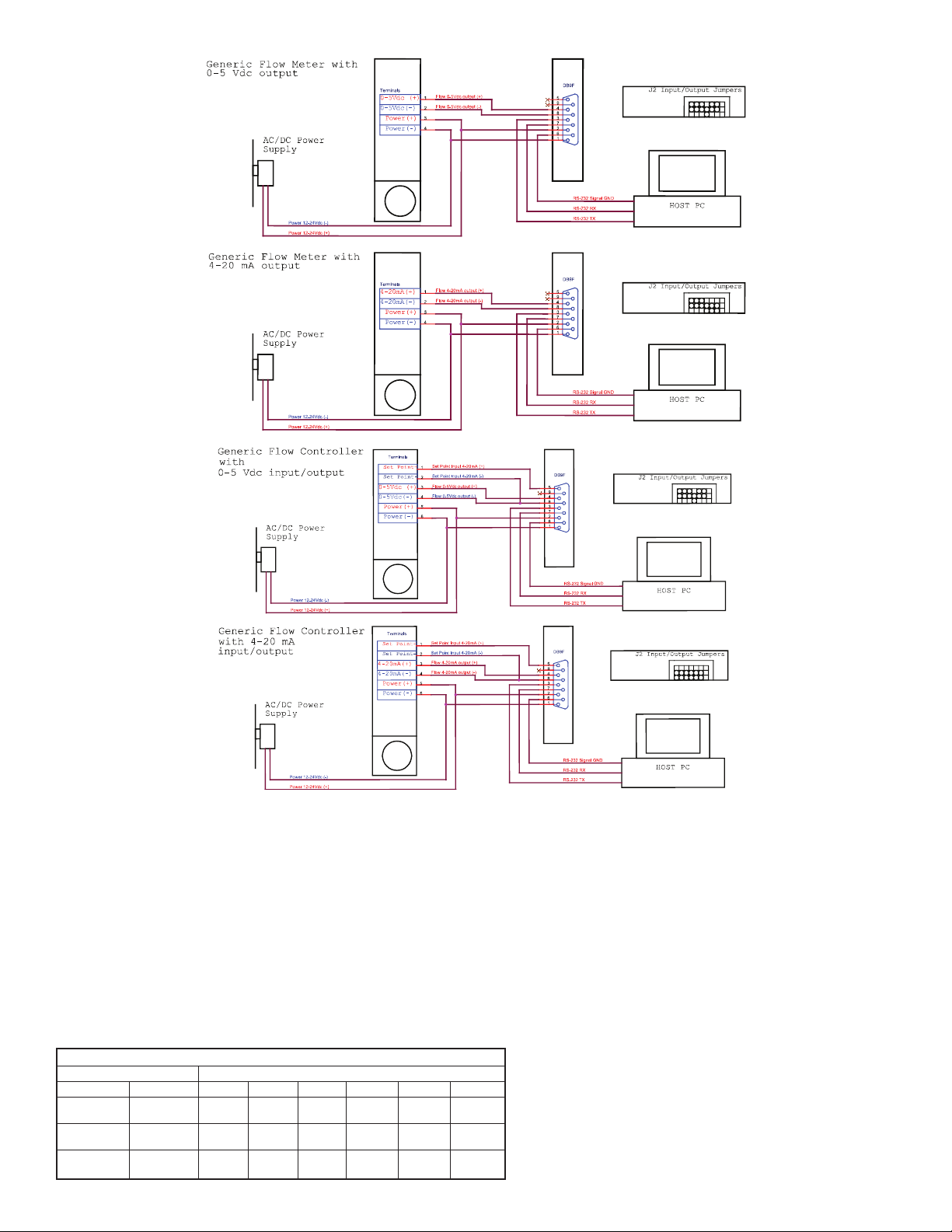

he power supply (PS), process variable (PV) input, set point (SP) control output, and

G

F

T2

#

1

G

F

T2

#

2

G

F

T2

#

3

G

F

T2

#

4

G

F

T2

#

N

T

erial communication interface signals are connected to the GFT2 via miniature 9 pin

s

emale “D” connector.

f

Power Supply Connections

The power supply requirements for the GFT2 are: 12 to 26 VDC, (unipolar power

upply).

s

C Power (+) --------------- Pin 4 of the 9 pin “D” connector

D

C Power (-) --------------- Pin 8 of the 9 pin “D” connector

D

AUTION

C

-Do not apply power voltage above 28 VDC. Doing so will

cause device damage or faulty operation.

-Make sure power is OFF when connecting or disconnecting any cables or wires in

he system.

t

ower Variable (PV) Input Signal Connections

P

epending on jumper J2 configuration, input signal can be set to 0 to 5, 0 to 10VDC,

D

or 4 to 20 mA.

S-232 Serial Communication Interface Connections

R

he digital interface operates via RS-232 and provides access to all applicable

T

nternal configuration parameters and data.

i

The settings for the RS-232 communication interface are:

Baud rate: default 9600 baud

Stop bit: 1

ata bits: 8

D

arity: None

P

low control: None

F

The RS-232 Communication Interface Connection must establish a crossover

connection form the PC host connector to the “D” connector.

RS-232 RX: Pin 2 on the host PC DB9 connector - Pin 7 of the 9 pin “D” connector

TX-)

(

S-232 TX: Pin 3 on the host PC DB9 connector - Pin 3 of the 9 pin “D” connector

R

RX-)

(

S-232 Signal GND: Pin 5 on the host PC DB9 connector - Pin 6 of the 9 pin “D”

R

connector

CAUTION

ated values shown in the specifications in Table 2. Failure to do so might cause

r

amage to this device. Be sure to check if the wiring and the polarity of the power

d

hen connecting the external signals to the input terminals,

W

lways check actual jumper J2 configuration. Do not exceed the

a

supply and PV signals are correct before turning the power ON. Wiring error may

cause damage or faulty operation.

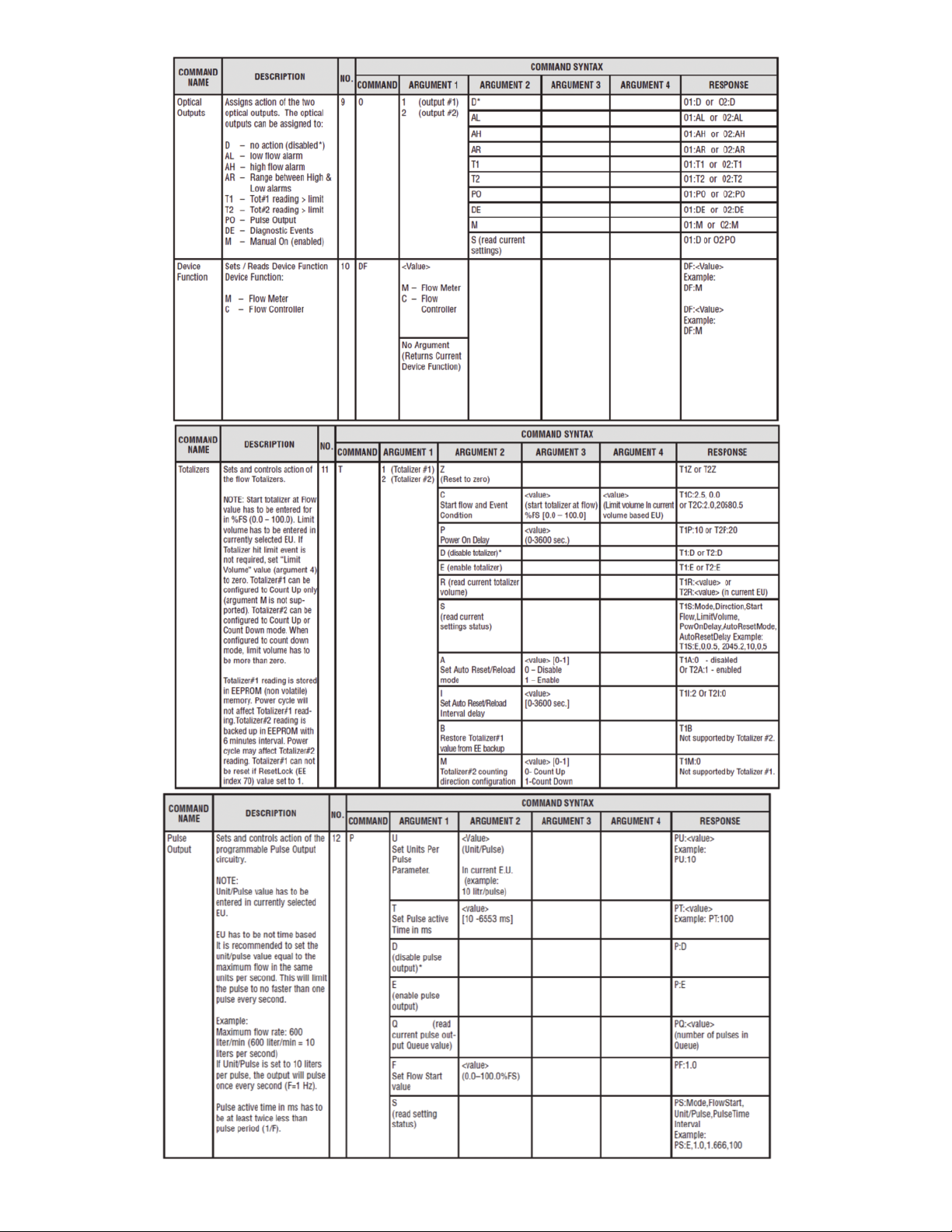

Maximum Rated Values for PV Input Signals

PV Input

Type

0 to 5 VDC

0 to 10 VDC

4 to 20 mA

J2 Jumper Configuration

J2D

10 to 11

11 to 12

10 to 11

J2E

14 to 15

14 to 15

13 to 14

17 to 18

17 to 18

16 to 17

J2F

Maximum

Signal Level

≤6 VDC

≤11 VDC

≤25 mA

Note

249 Ω Passive, Not

Isolated Current Input

Table 2

DC Power (+) --------------- Pin 4 of the 9 pin “D” connector

DC Power (-) --------------- Pin 8 of the 9 pin “D” connector

Set Point (SP) Output Signal Connections

Set Point (SP) output signal connection is only required if the GFT2 is mated to the

flow controller and will be used as a source for Set Point control signal. Depending on

the jumper J2 configuration, the SP output signal can be set to 0 to 5, 0 to 10 VDC or

4 to 20 mA.

RS-485 Communication Interface Connection:

he RS-485 converter/adaptor must be configured for: multidrop, 2-wire, half duplex

T

ode (see Figure 6). The transmitter circuit must be enabled by TD or RTS

m

depending on which is available on the converter/adapter). Settings for the receiver

(

circuit should follow the selection made for the transmitter circuit in order to eliminate

echo.

RS-485 T(-) or R(+) pin 7 of the 9 pin “D” connector (TX-)

S-485 T(+) or R(-) pin 3 of the 9 pin “D” connector (RX+)

R

S-485 GND (if available) pin 6 of the 9 pin “D” connector

R

Figure 1 RS-485 Multidrop Half Duplex Two Wire System

LCD Key-Pad Operation: Data Entry and Configuration

Display Indications:

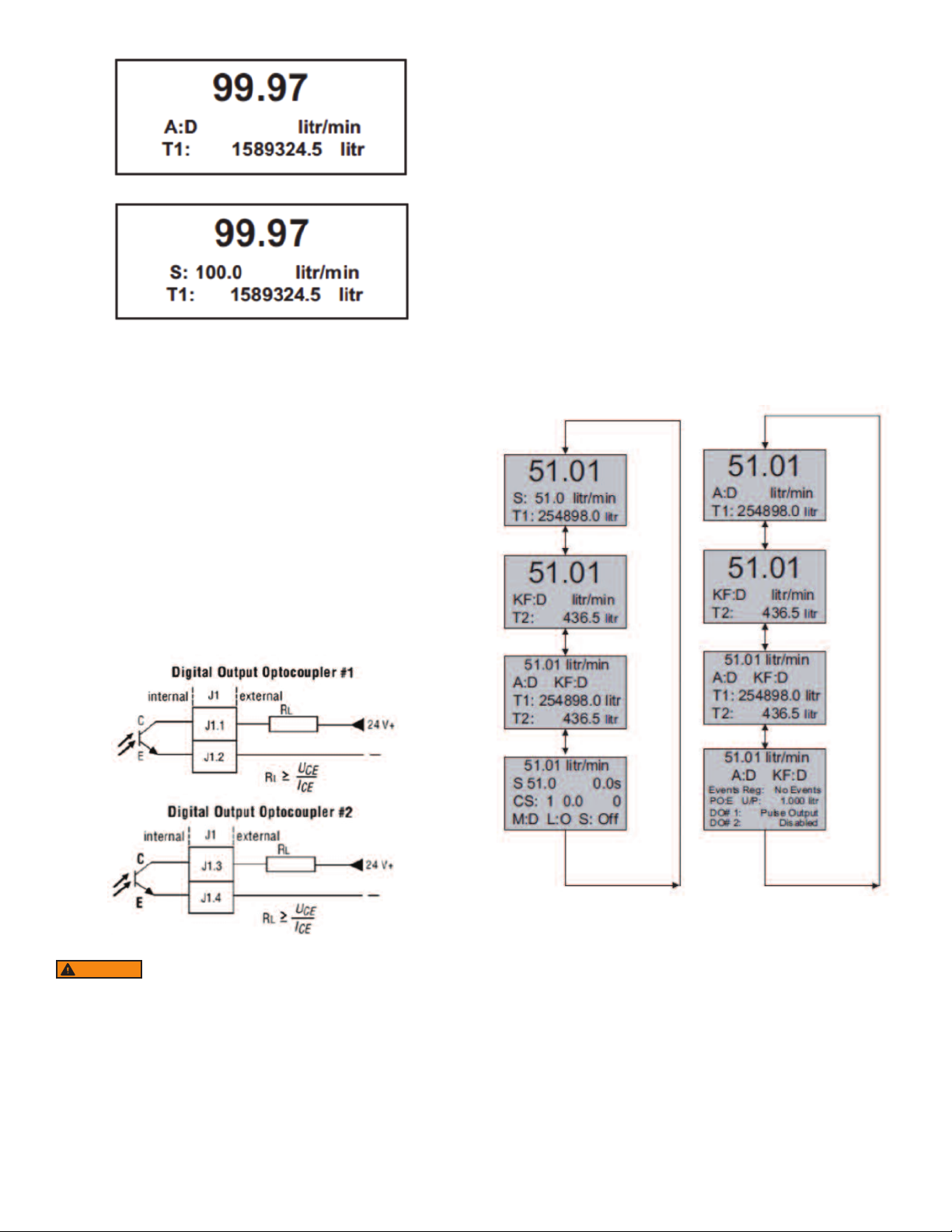

Initially, after the power is first turned on, the banner screen is shown for 2 seconds,

then the device firmware and EEPROM data base table revisions on the first line,

communication interface type on the second line, baud rate and RS-485 hexadecimal

address value on the third and fourth lines are shown for another 2 seconds.

Subsequently, the actual process information (PI) is displayed.

CAUTION

When connecting the load to the output terminals always check

actual jumper J2 configuration. Do not exceed the rated values

shown in Table 3. Failure to do so might cause damage to this device. Be sure to

check if the wiring and the polarity of the power supply and SP signals are correct

before turning the power ON. Wiring error may cause damage or faulty operation.

Do not connect external voltage source to the SP output terminals.

Maximum Rated Load Impedence for SP Output Signals

SP Output

Type

0 to 5 VDC

0 to 10 VDC

4 to 20 mA

J2 Jumper Configuration

J2A

2 to 3

2 to 3

1 to 2

J2B

5 to 6

5 to 6

4 to 5

J2C

8 to 9

8 to 9

7 to 8

Maximum

Load Impedence

≤1000 Ω

≤5000 Ω

≤900 Ω

Note

Self powered

(non-isolated)

Table 3

DC Power (+) --------------- Pin 5 of the 9 pin “D” connector

DC Power (-) --------------- Pin 8 of the 9 pin “D” connector

WARNING

The 4 to 20 mA current loop output is self-powered (non-

isolated). Do NOT connect an external voltage source to the

output signals.

Figure 2

Based on configuration (device function as flow meter or flow controller), different

parameters may be displayed in the Process Information (PI) screen by pressing the

UP or DN pushbuttons.

Process Information screens can be configured to be static or dynamic. Using the

Screen mask settings, the user can enable (unmask) or disable (mask) up to 4

different process information combinations (see Figure 6). In static mode the UP

button pages through the PI screens in the forward direction, the DN button pages

through the PI screens in the reverse direction. When the last PI screen is reached,

the firmware “wraps around” and scrolls to the initial PI once again.

In the Dynamic display mode, firmware initiates automatic screen sequencing with

user-adjustable screen Cycle Time. When the last PI screen is reached, the firmware

“wraps around” and scrolls to the initial PI screen once again.

NOTE: Actual content of the LCD screen may vary depending on the model and

device configuration.

Page 3

igure 3 - Initial PI Screen (Flow Meter)

F

djusting the Set Point using local LCD/Keypad: Current Set Point value is

A

isplayed on the second line of the main PI screen, next to the ‘S’ character. See

d

igure 7.

F

Pressing the ENT button while in the PI screen will activate Set Point adjustment

mode. The first character of the Set Point value will start to flash. Use the UP or DN

button to increase/decrease digit value from 0 to 9. Use RIGHT or LEFT buttons to

ove the cursor to another digit position. When desired Set Point value is entered,

m

se the ENT button to accept the new Set Point value. If in the end of the Set Point

u

alue entry the ESC button is pressed instead of ENT, the original Set Point value

v

ill be restored and Set Point adjustment mode will be deactivated. To exit form the

w

Set Point adjustment mode before Set Point value is accepted, press ESC button.

NOTE: Since the Set Point value entered via local LCD/keypad is stored in the non

olatile memory (EEPROM), it will be executed on the next device power up event.

v

OTE: If Program Set Point mode is enabled and the program is running, the Set

N

Point value can be changed at any moment by the execution of the next active step.

Figure 4 - Initial PI Screen (Flow Controller)

When GFT2 device is set as the last device on the RS-485 bus segment, and 220

Ohm bus termination is required, set jumper J2G to position 19-20. This will result

in connection 220 Ohm resistor between RS-485 (+) and (-) terminals.

igital and Pulse Optically-Isolated Outputs and Connections

D

FT2 is equipped with two programmable digital optically-isolated outputs. Each

G

utput can be assigned to any one of many different system events or configured

o

as pulse output.

Digital optically-isolated outputs use dedicated 4 position 3.5 mm male terminal

block header J1 located on the top side of the GFT2 enclosure . (Mated interface

onnector: Tyco Electronics P/N 284510-4)

c

ptocoupler #1 - Terminal J1 (pins 1 and 2):

O

Plus (+) (passive) Terminal J1 pin 1

Minus (-) (passive) Terminal J1 pin 2

Optocoupler #2 – Terminal J1 (pins 3 and 4):

Plus (+) (passive) Terminal J1 pin 3

Minus (-) (passive) Terminal J1 pin 4

Controlling Set Point value using Program Set Point Mode:

In order to activate the Programmed Set Point:

. Program Set Point mode has to be enabled.

1

. Program Loop parameter has to be set to desired value (On/Off).

2

. Program Run parameter has to be set to “On”.

3

Figure 5

WARNING

limits for voltage and current: 2V < UCE < 40 V, 0.2 mA < ICE < 150 mA.

Set Point Control (only for devices set as controller)

When the GFT2 is configured as controller it can be used to control the set point

value for mated flow controller using the analog output interface. The set point

value can be adjusted locally using the LCD/ keypad, remotely via RS-232/RS-485

digital interface, or can be programmed in advance using user preset programs of

up to sixteen steps (Program Set Point Mode).

NOTE: Before applying power and process signals, make sure the input/output

jumpers are installed in the correct position (see Figure 6).

Optically-isolated outputs require application of external DC

voltage across terminals. Do not exceed maximum allowed

Figure 6

Page 4

igure 7

F

As shown in the above picture, the program run parameter can be toggled “On” and

“Off” by pressing RIGHT and LEFT keypad buttons while PI screen 4 is active. If

he Program Run status parameter set to “Off”, the program execution will pause

t

nd current SP value will freeze until the Program Run status parameter is set to

a

On”.

“

NOTE: While Program Set Point mode is running, the current Set Point value also

can be changed from local LCD/keypad and digital RS-232 communication

interface. In this case, new Set Point value will be kept only until the next

uccessive program step will be executed.

s

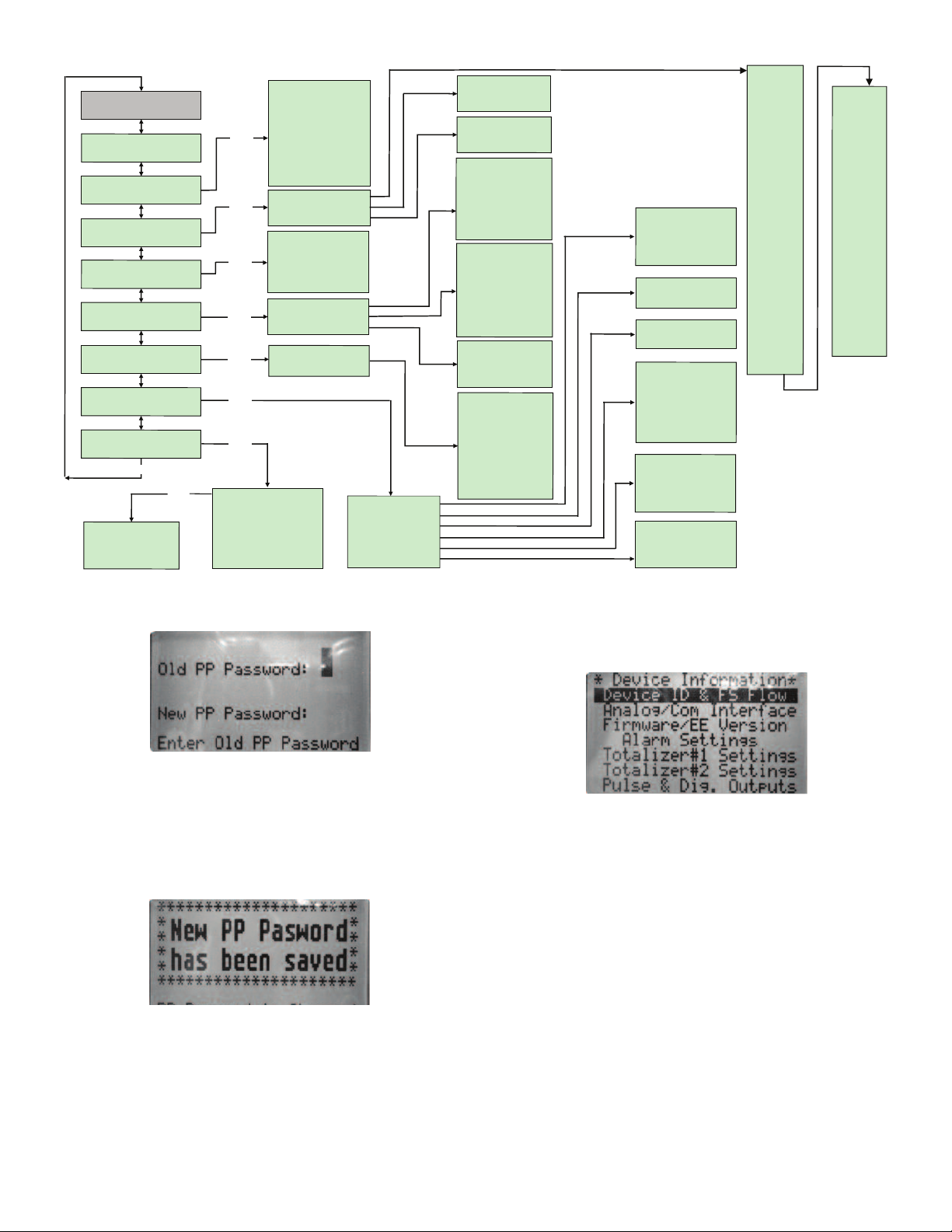

enu Structure

M

The diagram on the Figure 10 gives a general overview of the standard top-level

display menu structure when running firmware version A001. The ESC pushbutton

is used to toggle between the Process Mode (PI screens) and the Setup menus.

UP and DN buttons must be used to move through the menu items. When the last

item in the menu is reached, the menu “wraps around” and scrolls back to the

beginning of the menu items list. Similarly when the first menu item is highlighted

and UP button is pressed, the menu “wraps around” and scrolls down to the end of

the menu items list.

All process configuration parameters settings are password protected. In order to

access or change them, Program Protection should be disabled. Each time the

device is powered up, the Program Protection is enabled automatically. By default

,device is shipped from the factory with Program Protection (PP) password set to

Zero (PP Disabled). If PP password is set to Zero (Disabled), entering PP password

is not required and a following screen will appear when Program Protection menu

item will be selected. (See Figure 8).

ressing the UP or DN button to select the Disabled option and then the ENT

P

utton to save settings will disable program protection.

b

f PP password is set to any value more than Zero, the firmware will prompt with

I

“Enter PP Password” (see Figure 9). User must enter up to 3 digits program

protection code in order to be able to access password protected menus. Once the

correct password is entered, Program Protection is turned off until the unit is

owered up again.

p

Figure 9

Parameter Entry

There are two methods of data entry:

. Direct numerical number entry.

1

. Tabular Input from a table menu.

2

If the menu with direct numerical entry is selected, use the UP or DN button to

increase/decrease digit value from 0 to 9. Use the RIGHT or LEFT button to move

the cursor to another digit position. When the desired value is entered, use ENT

button to accept (save in the EEPROM) the new value.

OTE: During data entry, the input values are checked for acceptability. If data is

N

ot acceptable, it is rejected and a message indicates that the new data has not

n

been accepted.

If the menu with tabular entry is selected, the available menu options can be set

with the UP or DN buttons and are accepted by pressing the ENT button.

Submenu “Change PP Password”

In order to get access to “Change PP Password” menu, program protection must

be disabled. If PP password is set to Zero (Disabled), entering PP Password is not

required and PP can be disabled from “Program Protection” menu (see Figure 3).

If PP Password is set to any value more than Zero, the firmware will prompt with

“Enter PP Password” (see Figure 9). User must enter program protection code

(up to 3 digits). If PP password is lost or forgotten, contact Dwyer Instruments.

Figure 8

Page 5

Once “Change PP Password” menu is selected, the following screen will appear:

P

ro

g

ram

P

ro

t

a

c

t

i

o

n

(P

P

)

C

h

an

g

e

P

P

Pa

s

s

wo

r

d

D

e

v

ic

e

In

fo

r

ma

ti

o

n

E

n

g

U

n

i

ts

&

K

-

F

a

c

to

r

T

o

ta

l

iz

e

r

S

et

ti

n

g

s

O

p

t

Ou

tp

u

t

S

et

ti

n

g

s

G

e

n

e

r

a

l

S

e

tt

i

ng

s

D

evice

D

iagn

o

stic

A

la

r

m

Se

t

ti

n

g

s

*

*

*

*

*

M

a

i

n

M

e

n

u

*

*

*

*

*

U

p

/

D

n

E

ven

t R

egis

ter M

en

u

A

na

log In

p

ut count

s

A

nal

og Outp

ut V

alu

e

LCD

B

ack

Ligh

t S

e

t.

P

uls

e O

utpu

t Qu

eue

CP

U

T

e

m

peratur

e

D

evice

D

iagn

o

stic

O

p

t

O

u

t

p

u

t

#

1

S

e

t

O

p

t

O

u

t

p

u

t

#

2

S

e

t

T

o

ta

li

ze

r

#

1

To

ta

l

i

ze

r

#

2

P

u

l

se

O

u

tp

u

t

Fl

o

w

A

l

a

r

m

M

o

d

e

L

o

w

Fl

o

w

A

la

r

m

H

i

g

h

Fl

o

w

A

l

a

r

m

Fl

o

w

A

l

a

r

m

D

e

l

a

y

Fl

o

w

A

l

a

r

m

L

a

t

ch

M

e

a

su

r

i

n

g

U

n

its

U

se

rD

e

f

i

n

e

d

U

n

its

K

-

Fa

cto

r

S

e

t

tin

g

s

D

e

vi

ce

ID

&

FS

Fl

o

w

A

n

a

l

o

g

/C

o

m

In

te

rfa

c

e

Fi

rm

w

a

re

/E

E

V

e

r

sio

n

A

l

a

rm

S

e

t

tin

g

s

T

o

ta

li

ze

r

#

1

S

e

t

tin

g

s

T

o

ta

li

z

e

r

#

2

S

e

t

tin

g

s

P

u

l

se

&

Di

g

.

O

u

t

p

u

ts

M

a

te

d

D

e

vic

e

In

f

o

G

e

n

e

r

a

l S

e

tt

in

g

s

D

i

sp

la

y

M

o

d

e

S

cre

e

n

C

ycl

e

T

i

m

e

S

cr

e

e

n

M

a

sk

D

i

sp

la

y

B

a

ck

L

i

g

h

t

D

i

s

p

la

y

C

o

n

tra

s

t

Fl

o

w

M

e

te

r

Fl

o

w

Co

n

t

r

o

ll

e

r

B

a

u

d

Ra

te

S

e

t

tin

g

s

R

S

-

4

8

5

B

u

s A

d

d

r

e

s

s

Fu

ll S

ca

l

e

R

a

n

g

e

L

o

w

Flo

w

C

u

t-o

ff

Fl

o

w

P

o

w

e

r

U

p

D

e

l

a

y

Fl

u

id

S

td

.

D

e

n

sit

y

A

n

a

lo

g

O

u

tp

u

t

C

a

l

.

A

n

a

lo

g

I

n

p

u

t

Ca

l.

P

i

lot C

a

l.

T

im

e

r

S

ignal

Con

dit

. M

ode

NR

F Nu

m

. of Sam

ples

NR

F T

im

e In

terva

l

A

ver.Fi

lter Dam

ping

Flow

Lin

earize

r M

ode

P

rogram

S

P

M

ode

P

S

P

Lo

o

p M

ode

P

S

P

S

t

eps M

a

sk

P

S

P

S

t

eps S

et

tings

T

o

t

a

l

ize

r #

1

M

o

d

e

T

o

t

#

1

Fl

o

w

S

ta

r

t

T

o

t

#

1

A

ctio

n

V

o

l

.

T

o

t

#

1

P

o

w

e

r

O

n

De

l

a

y

T

o

t

#

1

A

u

t

o

R

e

se

t

T

o

t

#

1

A

u

to

Re

s D

e

l

a

y

R

e

se

t

T

o

t

a

liz

e

r #

1

T

o

t

a

l

ize

r #

2

M

o

d

e

T

o

t#

2

C

o

n

fi

g

u

r

a

tio

n

T

o

t

#

2

Fl

o

w S

ta

r

t

T

o

t

#

2

A

ctio

n

V

o

l

.

T

o

t

#

2

P

o

w

e

r

O

n

D

e

l

a

y

T

o

t

#

2

A

u

to

R

e

lo

a

d

T

o

t

#

2

A

u

to

Re

l

D

e

la

y

R

e

se

t

T

o

t

a

liz

e

r #

2

P

u

l

s

e

O

u

t

p

u

t

M

o

d

e

P

u

l

se

F

lo

w

S

t

a

r

t

[U

n

i

t

]/

P

u

lse

P

u

l

se

A

c

t

i

v

e

T

i

m

e

D

i

sa

b

le

d

L

o

w

F. A

la

r

m

H

i

g

h

F.

A

l

a

rm

F. R

a

nge H

-

L

Total#

1

E

vent

T

otal#2

E

vent

P

ulse O

utput

D

iagnos

tic

M

anua

l

On

U

D

U

n

i

t

K

-

F

a

cto

r

U

D

U

n

i

t

T

im

e

B

a

se

U

D

U

n

i

t

Use

D

e

n

si

t

y

K

-F

a

c

t

o

r M

o

d

e

I

n

t

.

K

-

Fa

c

to

r

In

d

e

x

U

se

r

D

e

f

'

d

K

-

Fa

cto

r

%

F

S

m

l

/s

e

c

m

l

/

m

i

n

m

l

/

h

r

m

l

/

d

a

y

l

i

t

r

/

s

e

c

l

i

t

r

/

m

i

n

l

i

t

r

/

h

r

l

i

tr

/

d

a

y

m

^

3

/

s

e

c

m

^

3

/

m

i

n

m

^

3

/

h

r

m

^

3

/

d

a

y

f

^

3

/

s

e

c

f

^

3

/

m

i

n

f

^

3

/h

r

f

^

3

/

d

a

y

g

a

l

/s

e

c

g

a

l

/m

i

n

g

a

l

/

h

r

g

a

l

/

d

a

y

g

r

a

m

/

s

e

c

g

r

a

m

/

m

i

n

g

r

a

m

/

h

r

g

r

a

m

/

d

a

y

k

g

/

s

e

c

k

g

/

m

i

n

k

g

/

h

r

k

g

/d

a

y

l

b

/

s

e

c

l

b

/

m

i

n

l

b

/

h

r

l

b

/

d

a

y

M

t

o

n

/

m

i

n

M

t

o

n

/

h

r

I

g

a

l

/s

e

c

I

g

a

l

/m

i

n

I

g

a

l

/

h

r

I

g

a

l

/

d

a

y

M

i

l

L

/

m

i

n

M

i

l

L

/h

r

M

i

l

L

/d

a

y

b

b

l

/s

e

c

b

b

l

/m

i

n

b

b

l

/h

r

b

b

l

/

d

a

y

U

s

e

r

E

n

t

E

ven

t R

eg. S

tatus

E

ven

t Latch

M

ask

E

ven

t R

eg. M

ask

R

e

s

et E

ven

t R

eg.

D

isplay S

etting

s

D

e

vice F

unction

C

om

m

u

nica

tio

n S

e

tt.

D

e

vice C

alibrati

on

S

ignal C

on

dition

er

P

rogram

S

et P

oin

t

E

nt

E

n

t

E

n

t

E

n

t

E

n

t

E

n

t

E

n

t

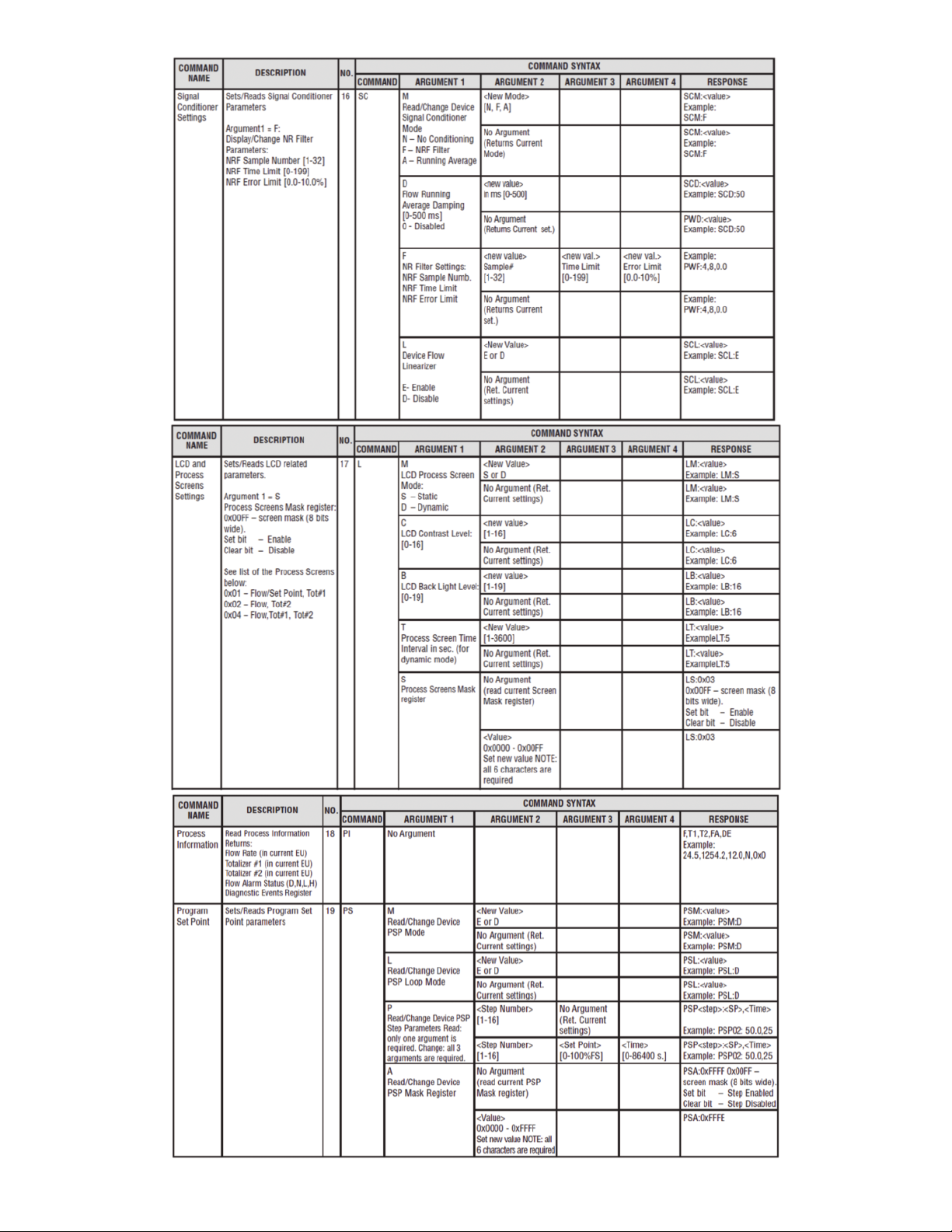

Figure 11

Figure 12

In order to protect device configuration parameters when changing the PP

password, the old PP password must be entered.

NOTE: By default, the device shipped from the factory with Program Protection

(PP) password set to Zero (PP Disabled).

Once old and new passwords are entered, the firmware will prompt with a

confirmation message (see Figure 12) that the new password has been saved.

Figure 10

Submenu “Device Information”

This submenu contains information about the device’s main configuration

parameters. These items are informational only, not password-protected, and can

not be changed (read only).

Submenu “Measuring Units”

Use the “Engineering Units and K-Factor Menu” to navigate to “Measuring Units”

menu option. This option allows configuration of the flow meter/controller with the

desired units of measurement. These are global settings and determine what

appears on all process information screens and data log records. Units should be

selected to meet each particular metering need. A total of 47 different volumetric

and mass based engineering units are supported (See Table 4).

NOTE: Program the Measuring Units first because subsequent menus may be

based on the units selected. Once Flow Unit of Measure is changed, the Totalizer’s

Volume based Unit of Measure will be changed automatically.

Fi

gur

e

1

3

Page 6

ubmenu “User-Defined Units”

S

n addition to conventional flow units, user-defined flow engineering units may be

I

elected. Use the “Engineering Units and K-Factor Menu” to navigate to the “User

s

efined Units” menu option. This option enables user-defined configuration of any

D

engineering unit required for process measurement.

The following three parameters are available for this function:

. UD Unit volume K-Factor (defined in Liters)

1

. UD Unit time base (defined in Seconds)

2

. UD Unit use density (units with or without density support)

3

Before using User-Defined Unit, make sure the proper conversion factor of the new

unit with respect to one liter is set (the default entry is 1.00 Liter). Also, proper time

base values for User-Defined Units must be set.

he following selections are available: 1 second, 60 seconds (1 minute), 3600

T

econds (1 hour), 86400 seconds (1 day). The default entry is 60 seconds. If a

s

mass based User-Defined Unit is desired, then “UD Unit Use Density” parameter

must be set to “YES”. The default entry is “NO”, so Fluid STD Density parameter is

not used for flow rate calculation.

low Rate

umber

N

F

ngineering

E

nits

U

1

2

3

4

5

6

7

8

9

0

1

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

%FS

ml/sec

l/min

m

ml/hr

ml/day

itr/sec

l

litr/min

litr/hr

litr/day

^3/sec

m

m^3/min

m^3/hr

m^3/day

f^3/sec

f^3/min

f^3/hr

f^3/day

gal/sec

gal/min

gal/hr

gal/day

gram/sec

gram/min

gram/hr

gram/day

kg/sec

kg/min

kg/hr

kg/day

lb/sec

lb/min

lb/hr

lb/day

Mton/min

Mton/hr

lgal/sec

lgal/min

lgal/hr

lgal/day

MilL/min

MilL/hr

MilL/day

bbl/sec

bbl/min

bbl/hr

bbl/day

User

Table 4: Supported Engineering Units List

otalizer

T

ngineering

E

nits

U

%s

ml

l

m

ml

ml

itr

l

litr

litr

litr

^3

m

m^3

m^3

m^3

f^3

f^3

f^3

f^3

gal

gal

gal

gal

gram

gram

gram

gram

kg

kg

kg

kg

lb

lb

lb

lb

Mton

Mton

lgal

lgal

lgal

lgal

MilL

MilL

MilL

bbl

bbl

bbl

bbl

User

escription

D

Percent of full scale

Mililiter per second

ililiter per minute

M

Mililiter per hour

Mililiter per day

iter per second

L

Liter per minute

Liter per house

Liter per day

ubic meter per second

C

Cubic meter per minute

Cubic meter per hour

Cubic meter per day

Cubic feet per second

Cubic feet per minute

Cubic feet per hour

Cubic feet per day

Gal per second

Gal per minute

Gal per hour

Gal per day

Grams per second

Grams per minute

Grams per hour

Grams per day

Kilograms per second

Kilograms per minute

Kilograms per hour

Kilograms per day

Pounds per second

Pounds per minute

Pounds per hour

Pounds per day

Metric Ton per minute

Metric Ton per hour

Imperial Gal per second

Imperial Gal per min

Imperial Gal per hour

Imperial Gal per day

Million Litr per minute

Million Litr per hour

Million Litr per day

Barrel per second

Barrel per minute

Barrel per hour

Barrel per day

User Defined

ubmenu “K-Factors Settings”

S

onversion factors relative to Nitrogen are convenient to use when flow

C

eter/controller mated to GFT2 is calibrated for Nitrogen and another gas is

m

equired to be measured/controlled.

r

Conversion factors relative to Nitrogen, for up to 22 common gases, are stored in

the GFT2. In addition, provision is made for a user-defined conversion factor.

onversion factors may be applied to all units of measure (except %FS unit) via

C

CD/Keypad or serial communication interface.

L

he following three parameters are available for this function:

T

K-Factor Mode: Disable, Internal Index, User-Defined (default Disabled)

Internal K Factor Index: 1 – 22 (from internal K-Factor table)

User-Defined K-Factor: 0.001 – 999.9 (default value is 1.000)

OTE: The conversion factors will not be applied for % FS engineering unit.

N

Submenu “Alarm Settings”

GFT2 provides the user with a flexible alarm/warning system that monitors the Fluid

Flow for conditions that fall outside configurable limits, as well as visual feedback

for the user via the LCD or via an optically-isolated output. The Flow Alarm has

everal attributes which may be configured by the user via LCD/Keypad or serial

s

ommunication interface. These attributes control the conditions which cause the

c

larm to occur and to specify actions to be taken when the flow rate is outside the

a

specified conditions.

Depending on the GFT2 function configuration (flow meter or controller) there are

two Alarm algorithms. If GFT2 is configured as flow meter, flow Alarm conditions

ecome true when the current flow reading is equal to or higher/lower than

b

orresponding values of high and low flow Alarm levels. If GFT2 is configured as

c

low controller, flow Alarm conditions become true when difference between Set

f

Point value and current flow reading is equal or higher/lower than corresponding

values of High and Low Flow Alarm levels.

Alarm actions can be assigned with preset Delay Interval (0-3600 seconds) to

activate the optically-isolated output (separate for High and Low alarm). Latch

Mode control feature allows each optical output to be latched on or follow the

corresponding alarm status.

The following settings are available for Flow Alarm (see Figure 10):

a) Flow Alarm Mode (Tabular entry)

This function determines whether Flow Alarm is Enabled or Disabled. The following

sections are available: Enabled or Disabled. The default entry is Disabled. Alarm

Mode selections can be set with the UP and DN buttons and are accepted by

pressing ENT button.

b) Low Flow Alarm (Numerical entry)

The limit of required Low Flow Alarm value can be entered in increments of 0.1%

from 0 – 100% FS.

If a Low Alarm occurs and one of the two optional outputs is assigned to the Low

Flow Alarm Event, the optically-isolated output will be activated:

1) For Flow Meter Function: when the flow is less than the Low Flow Alarm value.

2) For flow controller function: when the absolute difference between Set Point

value and actual flow reading is equal or more than the Low Flow Alarm value and

Actual Flow value is less than Set Point value.

The Low Flow Alarm condition is also indicated on the corresponding Process

Information Screen displaying L character.

NOTE: For Flow Meter function, the value of the Low Flow Alarm must be less than

the value of the High Flow Alarm

c) High Flow Alarm (Numerical entry)

The limit of required High Flow Alarm value can be entered in increments of 0.1%

from 0 – 100% FS. If a High Alarm occurs and one of the two optical outputs is

assigned to the High Flow Alarm Event, the optically-isolated output will be

activated for:

a) Flow Meter function: when the flow is more than the High Flow Alarm value.

b) Flow Controller function: when absolute difference between Set Point value and

Actual Flow reading is equal or more than the High Flow Alarm value and actual

flow value is more than Set Point value.

The High Flow Alarm condition is also indicated on the corresponding Process

Information Screen by displaying H character.

NOTE: For Flow Meter function, the value of the High Flow Alarm must be more

than the value of the Low Flow Alarm.

Page 7

) Flow Alarm Action Delay (Numerical entry)

d

he Flow Alarm Action Delay is a time in seconds that the Flow Rate value remain

T

above the high limit or below the low limit before an alarm condition is validated.

s

alid settings are in the range of 0 to 3600 seconds (default value is 0, no delay).

V

e) Flow Alarm Action Latch (Tabular entry)

The Flow Alarm Action Latch settings controls the Latch feature. If optically-isolated

utput is assigned to the Flow Alarm Event, in some cases, the Flow Alarm Latch

o

eature may be desirable.

f

he following settings are available: Disable or Enable. By default, Flow Alarm is

T

non-latching. That means the alarm is indicated only while the monitored Flow

Value exceeds the specified set conditions.

ubmenu “Totalizer #1”

S

FT2 provides the user with two independent Programmable Flow Totalizers. The

G

otal volume of the flowing fluid is calculated by integrating the actual instantaneous

t

fluid flow rate with respect to time. Totalizer #1 (main totalizer) value is stored in the

EEPROM and saved every (1) second. In case of power interruption, the last saved

Totalizer value will be loaded on the next power on cycle, so main totalizer reading

will not be lost. Use the “Totalizer Menu” to navigate to the “Totalizer #1” menu

ption. The following settings are available for Totalizer #1 (see Figure 10).

o

) Totalizer #1 Mode (Tabular entry)

a

This option determines whether Totalizer #1 is Enabled or Disabled. The following

selections are available: Enabled or Disabled. The default entry is Disabled.

Totalizer #1 Mode selections can be set with the UP and DN buttons and are

accepted by pressing ENT button.

OTE: Before enabling the Totalizer, ensure that all totalizer settings are

N

onfigured properly. Totalizer Start values have to be entered in the currently active

c

Volumetric or Mass flow engineering unit. The Totalizer will not totalize until the

Process Flow Rate becomes equal to or more than the Totalizer Start value.

Totalizer Event values must be entered in currently active volume or mass based

engineering units. If the Totalizer Event at preset total volume feature is not

required, set Totalizer Event value to zero (default settings).

igure 14

F

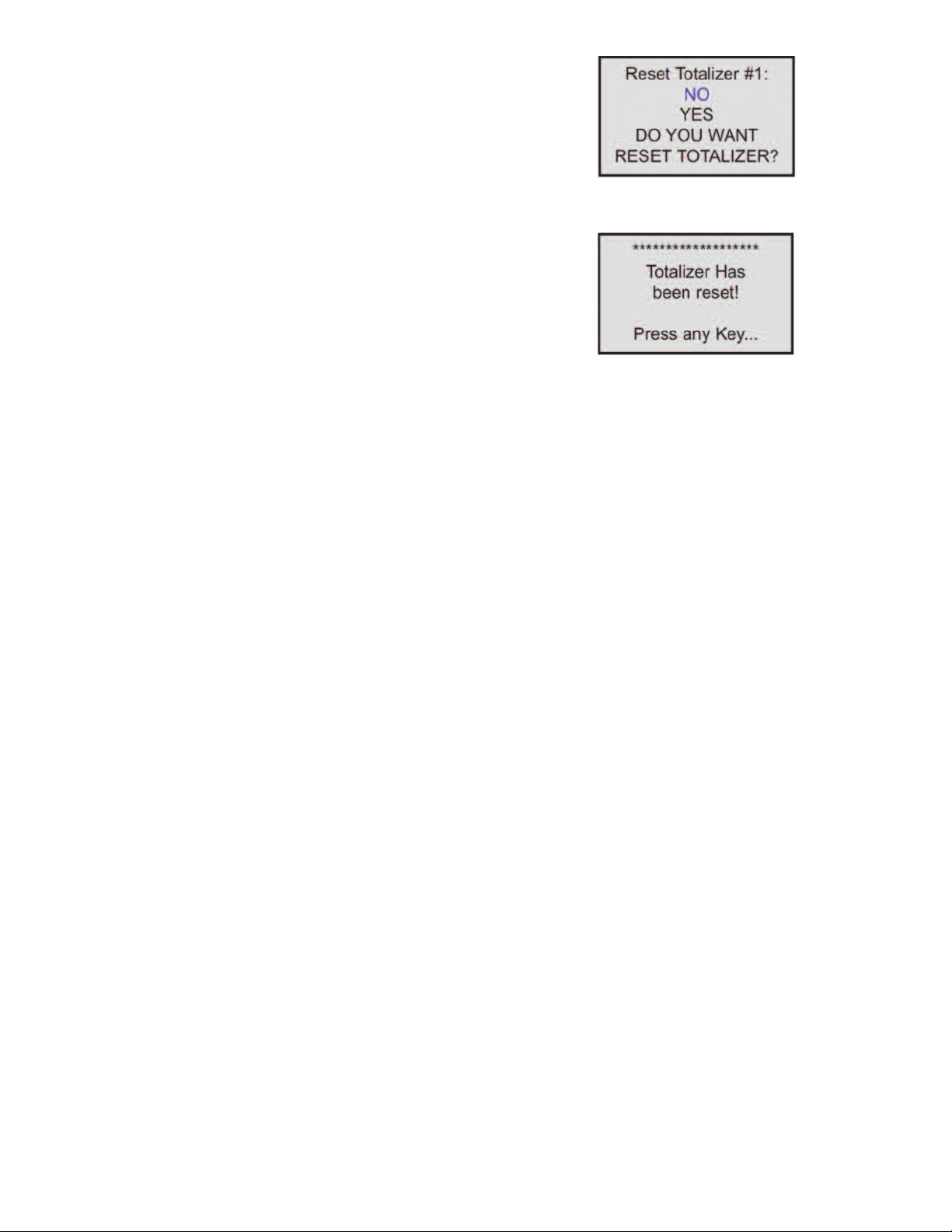

nce the “YES” option is selected, Totalizer #1 will be reset and the following

O

onfirmation screen will appear:

c

Figure 15

Submenu “Totalizer #2”

he Totalizer #2 (pilot totalizer) value is stored in the flow meter volatile memory

T

SRAM) and saved every 100 milliseconds (0.1 second). In case of power

(

nterruption, the Totalizer #2 volume will be lost (reset to zero). It is preferable to

i

use Totalizer #2 for short term process flow calculation (for example: batch

processing). Use the “Totalizer Menu” to navigate to “Totalizer #2” menu option. The

following settings are available for Totalizer #2 (see Figure 10):

) Totalizer #2 Mode (Tabular entry)

a

his option determines whether Totalizer #2 is Enabled or Disabled. The following

T

elections are available: Enabled or Disabled. The default entry is Disabled.

s

Totalizer #2 Mode selections can be set with the UP and DN buttons and are

accepted by pressing ENT button.

b) Totalizer #1 Flow Start (Numerical entry)

This option allows the totalizer to start at a present flow rate. The Totalizer #1 will

not totalize until the process flow rate becomes equal to or more than the Totalizer

#1 Flow Start value. The limit of required Totalizer #1 Flow Start value can be

entered in increments of 0.1% from 0 to 100% FS.

c) Totalizer #1 Action Volume (Numerical entry)

This option allows the user to activate preset required action when the totalizer

reaches a preset volume. Totalizer #1 Action Volume value must be entered in

currently active volume/mass based engineering units. Totalizer #1 action event

becomes true when Totalizer #1 reading is more or equal to preset "Totalizer #1

Action Volume”. If the Totalizer #1 Action at preset total volume feature is not

required, set “Totalizer #1 Action Volume” value to zero (default settings).

d) Totalizer #1 Power On Delay (Numerical entry)

Sometimes it is convenient to start the Totalizer only after specified power up delay

interval. Most of the mass flow meters and controllers require some warm up time

from the power up event in order to stabilize process variable output and get

accurate reading. “Totalizer #1 Power On Delay” option allows set specified time

interval which must elapse from the device power up event before Totalizer will be

activated. Valid settings are in the range of 0 to 3600 seconds (default value is 0,

no delay).

e) Totalizer #1 Auto Reset (Tabular entry)

This option allows to automatically reset Totalizer #1 when it reaches preset Action

Volume value. This feature may be convenient for batch processing, when

predefined volume of the fluid must be repeatedly dispensed into the process. The

following selections are available: Enabled or Disabled.

The default entry is Disabled. Totalizer #1 Auto Reset selections can be set with the

UP or DN buttons and are accepted by pressing ENT button.

f) Totalizer #1 Auto Reset Delay (Numerical entry)

This option may be desirable when “Totalizer #1 Auto Reset” feature is enabled.

Valid settings are in the range of 0 to 3600 seconds (default value is 0, no delay).

g) Reset Totalizer #1 (Numerical entry)

The Totalizers #1 reading can be reset by selecting “Reset Totalizer #1” menu

option. A typical display with Totalizer #1 Reset screen is shown in Figure 14.

NOTE: Before enabling the Totalizer, ensure that all Totalizer settings are

configured properly. Totalizer Start values must be entered in currently active

Volumetric or Mass flow engineering unit. The Totalizer will not totalize until the

process flow rate becomes equal to or more than the Totalizer Start value. Totalizer

Event values must be entered in currently active volume or mass based

engineering units. If the Totalizer Event at preset total volume feature is not

required, then set Totalizer Event value to zero (default settings).

b) Totalizer #2 Configuration (Tabular entry)

Totalizer #2 can be configured to count up or down. When configured to count

down, be sure “Totalizer #2 Action Volume” parameter is set to the desired value of

more than zero. In this case Totalizer #2 Action Event will be activated when the

totalizer counts down to zero. The following selections are available: Count UP or

Count DN. The default entry is Count UP. Totalizer #2 configuration selections can

be set with the UP and DN buttons and are accepted by pressing ENT button.

c) Totalizer #2 Flow Start (Numerical entry)

This option allows the start of the totalizer at a preset flow rate. The Totalizer #2 will

not totalize until the process flow rate becomes equal to or more than the Totalizer

#2 Flow Start value. The limit of required Totalizer #2 Flow Start value can be

entered in increments of 0.1% from 0 -100%FS.

d) Totalizer #2 Action Volume (Numerical entry)

This option allows the user to activate preset required action when totalizer reaches

a preset volume when totalizer configured to count up, or zero value when totalizer

configured to count down. Totalizer #2 Action Volume value must be entered in

currently active volume/mass based engineering units. When set to count up,

Totalizer #2 Action Event becomeS true when the totalizer #2 reading is more or

equal to preset “Totalizer #2 Action Volume”. If the Totalizer#2 Action at preset total

volume feature is not required, set “Totalizer #2 Action Volume” value to zero

(default settings).

NOTE: When Totalizer #2 is configured to count down, be sure “Totalizer #2 Action

Volume” value is set to any value more than zero.

e) Totalizer #2 Power On Delay (Numerical entry)

Sometimes it is convenient to start Totalizer only after specified power up delay

interval. Most of the mass flow meters and controllers require some warm up time

from the power up event in order to stabilize process variable output and get

accurate reading. “Totalizer #2 Power On Delay” option allows set a specified time

interval which must elapse from the device power-up event before Totalizer will be

activated. Valid settings are in the range of 0 to 3600 seconds (default value is 0,

no delay).

Page 8

) Totalizer #2 Auto Reload (Tabular entry)

f

his option allows to automatically reset/reload Totalizer #2 when it reaches preset

T

ction Volume value (when configured to count UP

A

o count Down

t

predefined volume of the fluid must be repeatedly dispensed into the process. The

following selections are available: Enabled or Disabled. The default entry is

Disabled. Totalizer #2 Auto Reload selections can be set with the UP and DN

uttons and are accepted by pressing the ENT button.

b

) Totalizer #2 Auto Reset Delay (Numerical entry)

g

his option may be desirable when “Totalizer #2 Auto Reload” feature is enabled.

T

Valid settings are in the range of 0 to 3600 seconds (default value is 0, no delay).

h) Reset Totalizer #2 (Numerical entry)

otalizers #2 reading can be reset by selecting “Reset Totalizer #2” menu option. A

T

ypical display with Totalizer #2 Reset screen is shown below.

t

Once “YES” option is selected, the Totalizer #2 will be reset and the following

onfirmation screen will appear.

c

. This feature may be convenient for batch processing when

)

igure 16

F

or zero value (when configured

)

he outputs can be made to switch when a specified event occurs (e.g. when a Low

t

r High Flow Alarm limit is exceeded or when the Totalizer reaches a specified

o

alue) or it may be directly controlled by user.

v

The user can configure each optical output action from 9 different options:

• Disabled: No Action (output is not assigned to any events and is not energized)

• Low Flow Alarm

High Flow Alarm

•

Range between High and Low Flow Alarm settings

•

Totalizer #1 reading exceed set limit

•

Totalizer #2 reading exceed set limit

•

• Pulse Output function

• Diagnostic: Output will be energized when any of the Diagnostic or System events

are active

Manual On Control: Output will be energized until Disabled option will be selected.

•

y default, both optically-isolated outputs are disabled.

B

NOTE: Optically-isolated outputs are accessible via screw terminal header J1 and

require application of external DC voltage across terminals. See Wiring Diagrams.

ubmenu “Display Settings”

S

rocess Information screens can be configured to be static (manual control) or

P

ynamic (automatic sequencing). In the static mode pressing the UP button allows

d

the user to page through the PI screens in the forward direction, pressing DN button

pages through the PI screens in the reverse direction. When the last PI screen is

reached, the firmware “wraps around” and scrolls to the initial PI screen once again.

OTE: PI screens which are masked in the Screen Mask Register (see below) will

N

e skipped.

b

Use the “General Settings” menu to navigate to “Display Settings” menu option

(see Figure 10).

Figure 17

Submenu “Pulse Output”

The flow Pulse Output is operating independently from totalizers and, based on

configuration settings (see Figure 10), can provide pulse frequency proportional to

instantaneous fluid flow rate.

The LCD/keypad and serial communication interface commands are provided to:

• Enable/Disable Pulse Output

• Start Pulse Output at preset flow rate (0.0 – 100.0%FS.

• Configure the Unit/Pulse value (in current engineering units)

• Configure Pulse Active On Time (10 – 6553 milliseconds)

NOTE: The Pulse Output minimum Active On time is 10 milliseconds (.01 second).

The Optical Pulse Output cannot operate faster than one pulse every 100

millisecond (.1 second). A good rule to follow is to set the Unit/Pulse value equal to

the maximum flow in the same units per second. This will limit the pulse rate to no

faster than one pulse every second.

For example: Maximum flow rate = 1200 kg/min

(1200 kg/min = 20 kg/sec)

If unit per pulse is set to 1200 kg/pulse, the Optical Pulse

Output will pulse once every minute.

If unit per pulse is set to 20 kg per pulse, the Optical Pulse Output will pulse once

every second.

The Optically-Isolated Pulse Output incorporate Pulse Output queue, which

accumulate pulses if the Pulse Output is accumulating process flow faster than the

Pulse Output hardware can function. The queue will allow the pulses to “catch up”

later if the flow rate decreases. A better practice is to slow down the Pulse Output

by increasing the value in the Unit/Pulse setting in the Pulse Output menu (see

Figure 10).

The following settings are available for LCD Display:

a) Display Mode (Tabular entry)

This option determines whether Display screens are in static (manual control) or

dynamic (automatic sequencing) mode. The following selections are available:

Static or Dynamic. The default entry is: Static (manual control). Display screens

mode parameter can be set with the UP and DN buttons and are accepted by

pressing ENT button.

b) Screen Cycle Time (Numerical entry)

This menu selection defines time interval in seconds for each PI screen to be

displayed in the dynamic mode (automatic sequencing). Screen Cycle Time can be

set to any value in the range between 1 to 3600 seconds (1 hour, numerical entry).

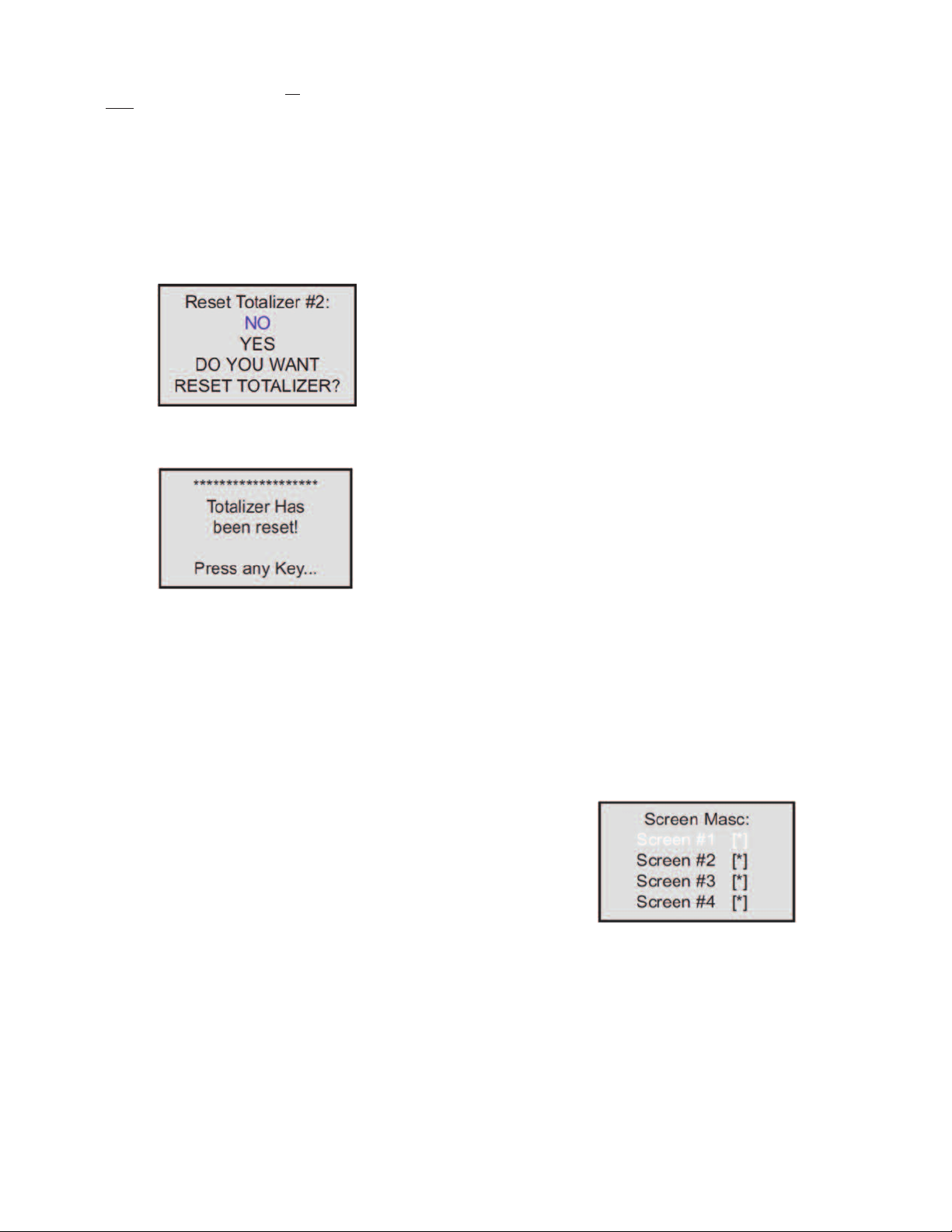

c) Screen Mask (Tabular entry)

Using Screen Mask settings the user can enable (unmask) or disable (mask) up to

4 different process variable combinations (see Figure 1). By default the unit is

shipped from the factory with all PI screens enabled. A typical display with Screen

Mask selection is shown below.

In the example shown above, all PI screens are enabled. Each PI screen assigned

Figure 18

to a corresponding bit in the PI Screen Register. In order to change PI Screen mask

settings, the user should select the desired screen using UP and DN buttons and

then press RIGHT button. The asterisk will appear/disappear on the right side of the

corresponding screen. The asterisk represents that the screen is enabled. In order

to disable the screen, the corresponding asterisk must be removed. Use the ENT

button to accept and save new PI Screen Mask settings in the device’s nonvolatile

memory.

NOTE: If Pulse Output feature is required, one of the Digital Optically- solated

outputs must be assigned to “Pulse Output” function. Pulse output signal will be

accessible via corresponding Digital Optically-Isolated output on the screw

terminal header J1 (see Wiring Diagrams).

Submenu “Opt. Outputs Settings”

Two sets of optically-isolated digital outputs are provided to actuate user-supplied

equipment. These are programmable via digital interface or LCD/Keypad such that

NOTE: PI Screen #1 cannot be disabled (unmasked).

d) Display Back Light (Numerical entry)

Using Display Back Light settings the user can adjust the desired level of the LCD

back light. The backlight has 19 different levels. Use UP and DN buttons to adjust

back light level and press ENT button to accept and save back light level settings

in the device’s nonvolatile memory.

Page 9

) Display Contrast (Numerical entry)

e

sing Display Contrast settings, the user can adjust the desired level of the LCD

U

ontrast. The contrast has 16 different levels. Use UP and DN buttons to adjust

c

ontrast level, and press ENT button to accept and save contrast level settings in

c

the device’s nonvolatile memory.

NOTE: By default, the contrast level is set to 6, which is the optimal level for room

emperature (20°C or 70°F).

t

ubmenu “Device Function”

S

his menu selection allows the selection of GFT2 function according to the mated

T

device type. If GFT2 is connected to the flow meter, then the “Meter” function must

be selected. If GFT2 is connected to the flow controller, then “Controller” function

must be selected.

OTE: Based on “Device Function” (device function as flow meter or flow

N

ontroller) settings, different parameters may be displayed in the Process

c

Information (PI) screen (see Figure 1) and different features of the GFT2 device

may be enabled or disabled (set point control only enabled when GFT2 is

configured as flow controller). Also, some features (e.g. Flow Alarm) may have

different behavior. Make sure the “Device Function” parameter is set according to

he actual device being used.

t

ubmenu “Communication Settings”

S

This menu selection allows the configuration of a serial communication interface

speed (Baud rate) and device RS-485 bus address (only applicable for optional RS485 interface). The following settings are available for “Communication Settings”

(see Figure 10).

) Baud Rate Settings (Tabular entry)

a

he Baud Rate Settings (Tabular entry) option determines device serial

T

communication interface speed (Baud rate) and can be set to one of the following:

1200, 2400, 4800, 9600, 19200, 38400, 57600, or 115200.

) Low Flow Cut-Off (Numerical entry)

b

he low flow cut-off can be selected between 0.0 and 10.0 % of the full-scale range.

T

lows less than the cut-off value are internally driven to zero and not totalized.

F

efault value of the “Low flow Cut-Off” parameter is zero (disabled).

D

c) Flow Power Up Delay (Numerical entry)

Sometimes it is convenient to start the process of the input signals after the

pecified power up delay interval. Most mass flow meters and controllers require

s

ome warm up time from the power up event in order to stabilize process variable

s

utput and get accurate reading. “Flow Power UP Delay” option allows set specified

o

ime interval, which has to elapse from the device power up event before

t

processing of the input signals will be activated. During active faze of the Power Up

Delay, the flow rate will be internally driven to zero and not totalized. Valid settings

are in the range of 0 to 3600 seconds (1 hour, default value is 0, no delay).

) Fluid Std. Density (Numerical entry)

d

he density of the flowing fluid at standard temperature and pressure conditions

T

should be in g/L. This parameter is used only when mass-based engineering units

are selected. Valid settings are in the range of 0.000001 to 10000.0 g/L. Factory set

default value is 1.25 g/L (Nitrogen).

) Analog Output Calibration

e

OTE: The analog outputs available on the GFT2 were calibrated at the factory.

N

There is no need to perform analog output calibration unless the DAC IC, output

amplifier IC, or passive components from analog output circuitries were replaced.

Any alteration of the analog output scaling variables in the EEPROM table will

VOID calibration warranty supplied with the instrument.

he GFT2 analog output calibration involves calculation and storing the off set and

T

pan variables in the EEPROM based on two calibration points (0 and 100%FS).

s

The 0 to 5 (0 to 10) VDC output has only scale variable and 4 to 20 mA output has

offset and scale variables.

By default, the device shipped from the factory with Baud rate set to 9600.

NOTE: The Baud rate set on the GFT2 device should always follow the Baud rate

of the host PC or PLC it is connected to.

b) RS-485 Bus Address (Numerical entry)

The standard GFT2 comes with an RS-232 interface. The optional RS-485

interface has two hexadecimal characters of the address, which must be assigned.

By default, each flow meter is shipped with RS-485 address set to 11 hexadecimal.

When more than one device is present on RS-485 bus, each device should have a

unique address. The two characters of the address in the hexadecimal

representation can be changed from 01 to FF.

NOTE: Address 00 is reserved for global addressing. Do not assign the global

address for any device. When command with global address is sent, all devices on

the RS-485 bus execute the command, but do not reply with an acknowledge

message.

NOTE: Do not assign the same RS-485 address for two or more devices on the

same RS-485 address for two or more devices on the same RS-485 bus. If two or

more devices with the same address are connected to the one RS-485 network, a

communication collision will take place on the bus, and communication errors will

occur.

Submenu “Device Calibration”

The Calibration Menu contains the parameters, which have to be set according to

flow meter/controller being used and according to required process conditions.

These values should be changed only by properly trained personnel. Device

Analog Output and Input calibration was performed on the factory and should not

be initiated unless recommended by factory personnel. Following settings are

available for “Device Calibration” menu selection:

a) Full-Scale Range (Numerical Entry)

The Full-Scale Range value in liter per minute (L/min) should be set equal to the

full-scale range (converted to L/min) of the device mated to GFT2. The analog input

and output will be scaled automatically to this value. For example, if Full-Scale

Range value set to 10.0 L/min and device is configured for 0-5 VDC analog input,

when 5.0 VDC is applied to GFT2 analog input the PI flow rate will indicate 100.0%

FS. (if %FS units of measure is selected).

NOTE: Failure to set Full-Scale Range parameter in L/min equal to the full-scale

range (converted to L/min) of the device mated to GFT2 may cause erroneous

readings and unexpected device behavior.

Power up the GFT2 instrument for at least 15 minutes prior to commencing the

calibration procedure. Observe analog output jumper position (see GFT2

Input/Output Configuration Jumpers) and connect the corresponding type of

measurement device to pins 5 (+) and 8 (-) of the 9-pin D-connector. Follow

firmware prompts and adjust calibration point values according to measurement

device reading. If calibration must be aborted, press ESC button. When calibration

is completed, firmware will display new offset and span values and ask, “Press ENT

button to save new calibration variables to EEPROM or ESC to abort calibration

and exit without saving.” In the end, the firmware will prompt the confirmation

message.

f) Analog Input Calibration

NOTE: The analog inputs available on the GFT2 were calibrated at the factory.

There is no need to perform analog input calibration unless the CPU IC, input

amplifier IC, or passive components from analog input circuitries were replaced.

Any alteration of the analog input scaling variables in the EEPROM table will VOID

calibration warranty supplied with the instrument.

The GFT2 analog output calibration involves calculation and storing the offset and

span variables in the EEPROM based on two calibration points (0 to 100% FS.).

The 0 to 5 (0 to 10) VDC output has only scale variables and the 4 to 20 mA output

has offset and scale variables.

NOTE: Check the actual input jumper configuration before applying any input

signal to the GFT2. Make sure the input signal does not exceed maximum allowed

level for corresponding input type (see Table 2). Do not apply voltages above 5.0

VDC unless GFT2 input was specifically configured on the factory for 0 to 10 VDC

(check actual model number and specification). Exceeding maximum allowed input

level may cause inadvertent damage to the device circuitry.

Power up the GFT2 instrument for at least 15 minutes prior to commencing the

calibration procedure. Observe the analog jumper position (see GFT2 Input/Output

Configuration Jumpers) and the connect corresponding type of calibration signal

source device to pins 4 (+) and 8 (-) of the 9-pin D-connector. Follow firmware

prompts and apply calibration point values according to the on-screen instructions.

If calibration has to be aborted, press ESC button. When calibration is completed,

firmware will display new offset and span values and ask, “Press ENT button to

save new calibration variables to EEPROM or ESC to abort calibration and exit

without saving.” In the end, the firmware will prompt a confirmation message.

g) Pilot Calibration Timer

The Pilot Calibration timer accumulates operational hours since the last time the

unit was calibrated. The smallest increment value is 0.1 hour (6 minutes). The value

of the timer may be reset by the user by pressing RIGHT button. Once RIGHT

button is pressed, the confirmation screen will appear with the “Yes” or “No” menu.

Page 10

electing “Yes” will reset the pilot calibration timer back to zero.

S

ubmenu “Signal Conditioner”

S

noise reduction filter algorithm (Running Average or Noise Reduction Filter) is

A

now available in the flow meter when pulsating flow or especially noisy signals are

encountered. The Flow Linearizer algorithm is also available when flow linearity

must be improved.

he following settings are available for “Program Set Point” (see Figure 10):

T

) Program Set Point Mode (Tabular entry)

a

This function determines whether the Program Set Point is Enabled or Disabled.

The following selections are available: Enabled or Disabled. The default entry is

Disabled. Program Set Point Mode selections can be set with the UP and DN

uttons and are accepted by pressing ENT button.

b

) Program Set Point Loop Mode (Tabular entry)

b

This function determines whether Program Set Point Loop is Enabled or Disabled.

If Loop is enabled, when program reaches the last step it wraps around and again

starts execution from the first enabled step. The following selections are available:

Enabled or Disabled. The default entry is Disabled. Program Set Point Loop Mode

elections can be set with the UP and DN buttons and are accepted by pressing

s

NT button.

E

c) PSP Steps Mask (Tabular entry)

Using PSP Steps Mask settings, the user can enable (unmask) or disable (mask)

any step in the program. If the step is masked, the program will skip it and move to

the next enabled step. By default the unit is shipped from the factory with all

rogram steps enabled (unmasked). A typical display with PSP Steps Mask

p

election is shown below.

s

he following diagnostic events are supported:

T

vent

E

Number

1

2

3

4

5

6

7

8

9

1

1

12

1

1

NOTE: Any Alarm or Diagnostic events that may have occurred (Event 0 to Event

D) are stored in the internal status register. All detected events (if corresponding bit

n the latch register is not masked) remain stored until the register is manually reset

i

by keypad or by means of the serial communication interface). If event

(

orresponding bit in the latch register is masked (disabled), the event will be

c

indicated as long as it is active (no latching). The status Alarm Event Register is

mapped to the SCRAM (volatile memory). In case of power interruption, the status

Event Register will be automatically reset.

he following settings are available for “Event Register Menu” (see Figure 10):

T

) Event Register Status (Read Only)

a

Each active Alarm event will be indicated on the LCD screen. Also, the total number

of currently active events will be displayed on the first line (header). A typical display

without active diagnostic and Alarm Events is shown below.

Diagnostic and Alarm Events Description

CPU Temperature Too High

igh Flow Alarm

H

Low Flow Alarm

Range Between High and Low

Totalizer #1 Exceed Set Event Volume Limit

otalizer #2 Exceed Set Event Volume Limit

T

Optical Pulse Output Queue Overflow

Flow Rate Above Limit

cc Power Voltage Out of Range

V

0

1

Power On Event (Power On Delay Time > 0)

3

4

erial Communication Error

S

EPROM Error

E

assword Event

P

atal Error

F

Table 5

LCD BIT Code

0

1

2

3

4

5

6

7

8

9

A

B

C

D

Figure 19

In the example shown above, all PSP Steps are enabled. Each PSP Step assigned

to a corresponding bit in the PSP Steps Register. In order to change PSP Step

mask settings, the user should select desired stop using UP and DN buttons and

then press RIGHT button. The asterisk will appear/ disappear on the right side of

the corresponding step. The asterisk represents that step is enabled. In order to

disable step, the corresponding asterisk has to be removed. Use ENT button to

accept and save new PSP Steps mask settings in device non volatile memory.

d) PSP Steps Settings (Numerical entry)

Using PSP Steps Settings menu selection, the user can assign required set point

and time values for each step in the program. A typical display with PSP Steps

Settings selection is shown below.

Figure 20

In the example shown above, Step 01 is selected. For each step there are two

parameters: set point value in % FS and time interval in seconds. In order to

change PSP Step settings user should select desired step using UP and DN

buttons and then press ENT button. The cursor in the selected (highlighted)

parameter will start flashing. Use UP, DN, LEFT, RIGHT buttons to adjust desired

value and then press ENT button to accept and save new PSP Step Settings in the

device’s nonvolatile memory.

Figure 21

A typical display with two active events is shown below.

Figure 22

If more than 7 events are displayed, the user can use UP and DN buttons to scroll

and see all indicated events. If event is not latched in the Event Latch Mask

register, it may appear and disappear from the status screen, so it will be indicated

as long as the actual event is taking place.

b) Event Latch Mask (Tubular entry)

Using Event Latch Mask settings, the user can enable (unmask) or disable (mask)

latch feature individually for each event. The event is enabled if there is an asterisk

sign [*] set on the right across corresponding event. If event is not latched (no

asterisk across corresponding event) it may appear and disappear from the status

screen, so it will be indicated as long as the actual event is taking place. By default,

the unit is shipped from factory with only one event active: 0 – CPU Temperature

too high. For all other events, the latch feature is disabled. A typical display with

Event Latch Mask selection is shown below.

Submenu “Event Register Menu”

GFT2 is equipped with a self-diagnostic Alarm Event Register which is available via

digital interface and on screen LCD indication. Use the “Diagnostic Menu” to

navigate to “Event Register Menu” menu option.

Figure 23

Page 11

n Figure 23, latch features for all events are disabled except event #0. In order to

I

hange Event Latch Mask Settings the user should select desired event using UP

c

nd DN buttons and then press RIGHT button. The asterisk will appear/disappear

a

n the right side of the corresponding event. The asterisk represents that the latch

o

feature is enabled. In order to disable latch feature, the corresponding asterisk has

to be removed. Use the ENT button to accept and save new Event Latch mask

settings in the device’s non volatile memory.

) Event Register Mask (Tabular entry)

c

sing Event Register Mask Settings user can individually enable (unmask) or

U

isable (mask) each event. The event is enabled if an asterisk sign [*] is set on the

d

right across from corresponding event. If the event is disabled, it will not be

processed or indicated in the Events Status Register, even if actual conditions for

event have occurred. By default the unit is shipped from the factory with only one

vent active: “0 – CPU Temperature too high”. All other events are disabled. A

e

ypical display with Event Register Mask selection is shown below.

t

Figure 24

In the example shown above, all events are disabled except event #0. In order to

hange Event Register Mask Settings, the user should select the desired event

c

sing UP and DN buttons and then press the RIGHT button. The asterisk will

u

ppear/disappear on the right side of the corresponding event. The asterisk

a

represents that the event is enabled. In order to disable the event, the

corresponding asterisk has to be removed. Use the ENT button to accept and save

the new Event Register Mask Settings in the device’s nonvolatile memory.

) ADC Input Counts (Read Only)

a

his menu selection provides raw, average, and filtered values of the ADC counts

T

or analog input circuitry (read only). A typical display with the ADC Input Counts

f

creen is shown below.

s

igure 27

F

) Analog Output Values (Read Only)

b

his menu selection provides information about currently selected analog output

T

configuration and DAC counts for analog output circuitry (read only). A typical

display with DAC Output Values screen is shown below.

igure 28

F

) LCD Back Light Settings (Read Only)

c

This menu selection provides information about the LCD back light level, PWM duty

cycle, and contrast (read only). A typical display with the LCD Back Light Settings

screen is shown below.

d) Reset Event Register (Tabular entry)

The Event Register can be reset by selecting “Reset Event Register” menu option.

A typical display with the Reset Event Register screen is shown below.

Figure 25

Once the “YES” option is selected, the Event Register will be reset and the

following confirmation screen will appear.

Figure 26

Submenu “Diagnostic Menu”

The Diagnostics Menu can be used for troubleshooting purposes and provides

information about the device’s internal variables. These items (except the Events

Register submenu described above) are informational only and may not be

changed (read only).

Figure 29

d) Pulse Output Queue (Read Only)

This menu selection provides information about the Pulse Output Queue. A typical

display with the Pulse Output Queue screen is shown below.

Figure 30

e) CPU Temperature (Read Only)

This menu selection provides the current value of the PCB and CPU temperature

in °C (read only). A typical display with the CPU Temperature reading is shown

below.

Figure 31

Page 12

nstallation

I

eneral Directions

G

Mounting, electrical installations, parameters configuration, startup, and

•

maintenance of this instrument may only be performed by trained personnel.

Personnel must read and understand this operating manual before performing any

installation or configuration steps.

The GFT2 device should only be operated by trained personnel. All instructions in

•

his manual are to be observed.

t

Ensure that power and all input/output signals are correctly wired up according to

•

he wiring diagram provided in this manual. The housing of the device should only

t

be opened by trained personnel.

Hardware Installation