Page 1

Bulletin L-FSW2

4-45/64

[119.50]

4

-23/64

[

110.83]

8-23/64

[212.50]

5/8

[16.00]

Series FSW2 Free-Floating Cable Float Switch

Specifications - Installation and Operating Instructions

he Series FSW2 Free-Floating Level Switch is a mercury-free self

T

ounterweighted floating switch designed for the automation of pumps, specifically

c

filling and draining of tanks, wells, and reservoirs. The FSW2 body is free of any

irregularities making it ideal for use in sewage water applications. The

polypropylene body consists of a double airtight chamber with high-pressure melted

polypropylene re-injection sealing to ensure a perfect seal against infiltration. Cable

angers are available to suit a variety of mounting applications. Featuring CE

h

pproval and optional cables available that include higher chemical compatibility,

a

igh temperature durability, oil resistance, and drinking water suitability. Contact

h

factory for piggyback plug option, and cable length options ranging from 10 to 70 ft

(3.04 to 21.34 m).

INSTALLATION

The basic operating principle of the FSW2 is very simple. As fluid level rises the

micro-switch located inside the FSW2 is counter-balanced in such a way that it

generates a flipping action in the position of the switch. When fluid level decreases

the float starts in an inverted state then positions correctly. This change in position

generates a signal that can be used to actuate a motor or signal an indicator alarm.

To ensure the proper function of the FSW2, it is necessary to secure the electric

cable inside the tank or well as illustrated in Figure 1. The length of the cable

measured between the fixture point and the body of the FSW2 should be a

minimum of 6 in (15 cm). It is essential to ensure that there are no obstructions in

the FSW2 operational area before operation. During operation, adjustments to

the FSW2 cable must not be made under any circumstances, due to the fact

that any unwanted cable connections made while the FSW2 is immersed in water

can lead to electric shock.

There is a hanging bracket accessory option available (A-459), for wire

arrangement. The bracket allows the cable of the FSW2 to be held in place at the

top of the tank.

Note: The Series FSW2 is self counterweighted and can be used without the need

of additional counterweight, clamp, or bracket. The previous are means to simplify

installation and aid in organizing the use of multiple float switches.

ELECTRICAL CONNECTIONS

The Series FSW2 features a variety of different cable options. One of these options

includes the selection between SPST and SPDT. SPST, single pole single throw,

allows a single operating function with the choice of operation on increasing level

(NC/filling) or operation on decreasing level (NO/ emptying), depending on the

model selection. SPDT, single pole double throw allows for operation of both

increasing and decreasing level, depending on the connections made between the

terminals of the micro-switch and the cable. SPDT, which is a four-conductor cable

(ground option) or a three-conductor cable (without ground option), has one lead

that is common, one that is normally open (NO), and the other that is normally

closed (NC), for the proper connections of these conductors please refer to the

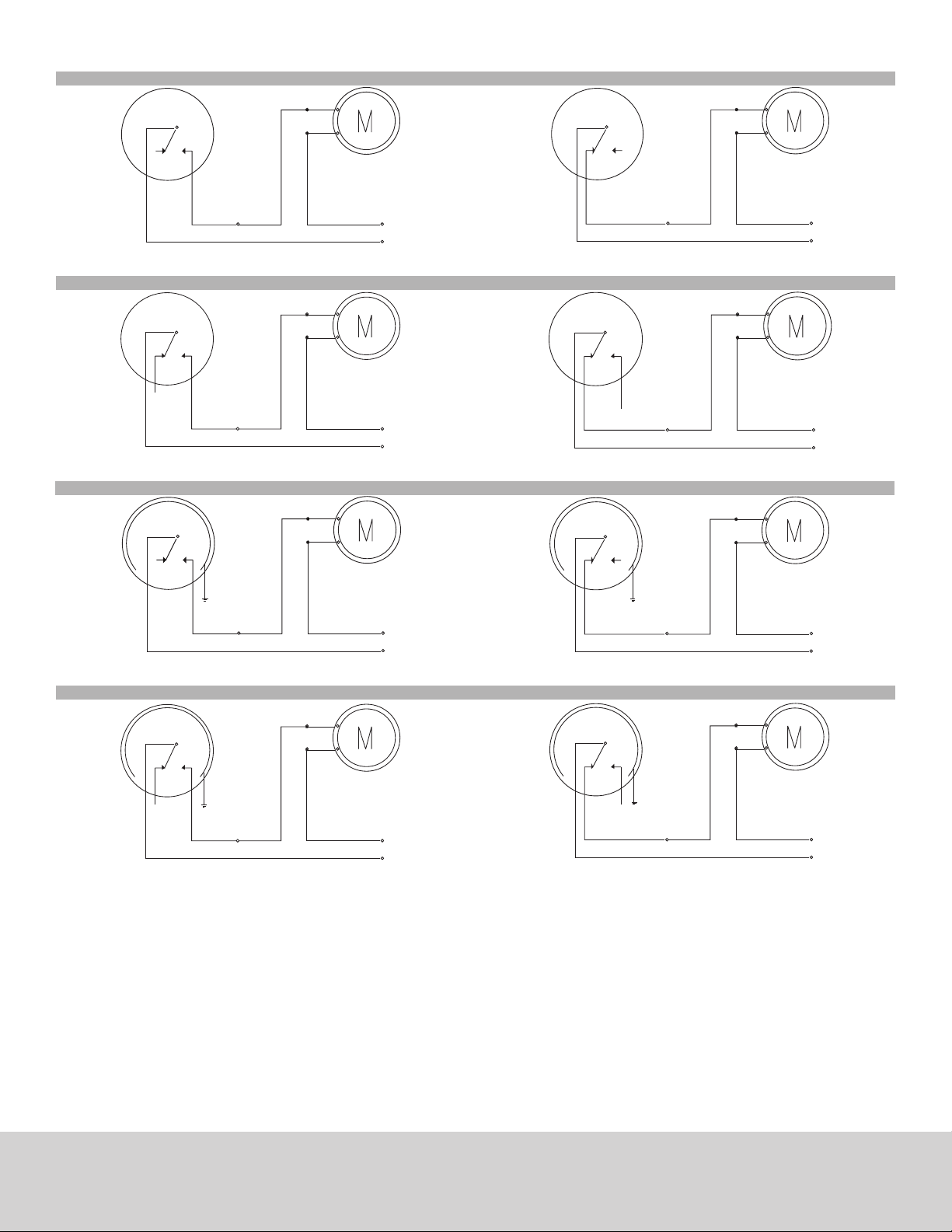

wiring diagrams in Figures 2 to 9.

PECIFICATIONS

S

ervice: Compatible liquids, slurries.

S

Wetted Materials:

Housing: Polypropylene;

Cable: FSW2-XXNX-XX: Neoprene;

perating Temperature: 32 to 122°F (0 to 50°C).

O

Pressure Limits: 29 psi (2 bar).

Enclosure Rating: IP68.

Switch Type:

FSW2-0XXX-XX: SPST;

FSW2-CXXX-XX: SPST;

FSW2-DXXX-XX: SPDT.

Electrical Rating: 10 (3) A @ 250 VAC.

Mounting Orientation: Vertical.

Shipping Weight:

Housing: 2.4 lb (1100 g);

Cable: 0.77 oz (21.27 g) per foot.

Agency Approval: CE.

the level switch. The power supply cable is an important part of the FSW2. Should

the cable appear to be damaged, discontinue use immediately and proceed to

replace the unit. The yellow/green wire found on some units is the ground wire and

must be connected to a suitable ground terminal with the dimension greater than

1mm

FSW2-XXPX-XX: PVC;

SW2-XXTX-XX: Rubber compound EM7 quality;

F

SW2-XXWX-XX: EPDM ethylene propylene;

F

NOTICE

2.

The terminal used must also be protected against accidental break.

When making the connections described above, ensure that the

maximum motor power does not exceed the values indicated on

Figure 1: Installation

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

BROWN

BLUE

L

N

COM

B

ROWN

BLUE

L

N

COM

BROWN

BLACK

L

N

COM

N.O.

N.C.

BLUE

BROWN

BLACK

L

N

COM

N.O.

N.C.

BLUE

YELLOW

G

REEN

BROWN

BLUE

L

N

COM

YELLOW

GREEN

BROWN

BLUE

L

N

COM

BROWN

BLACK

L

N

COM

N.O.

N.C.

BLUE

YELLOW

GREEN

BROWN

BLACK

L

N

COM

N.O.

N.C.

BLUE

GREEN

YELLOW

Figure 2-Emptying (NO) Function

SW2-ONXX-XX

F

igure 4-Double Function (Emptying (NO))

F

FSW2-DNXX-XX

WIRING DIAGRAMS

2 x 1 CABLE

x 1 CABLE

3

G1 CABLE

3

igure 3-Filling (NC) Function

F

SW2-CNXX-XX

F

igure 5-Double Function (Filling (NC))

F

SW2-DNXX-XX

F

Figure 6-Emptying (NO) Function

FSW2-OGXX-XX

Figure 7-Filling (NC) Function

FSW2-CGXX-XX

4G1 CABLE

Figure 8-Double Function (Emptying (NO))

FSW2-DGXX-XX

Figure 9-Double Function (Filling (NC))

FSW2-DGXX-XX

Correctly insulate any wire not in use!

MAINTENANCE & REPAIR

Inspect and clean wetted parts with water or damp cloth at regular intervals.

Disassembly or modifications made by the user will void the warranty and could

impair the continued safety of the product. If repair is required obtain a Return Goods

Authorization (RGA) number and send the unit, freight prepaid, to the address below.

Please include a detailed description of the problem and conditions under which the

problem was encountered.

Dwyer Instruments, Inc.

Attn: Repair Department

102 Indiana Hwy 212

Michigan City, IN 46361

©Copyright 2013 Dwyer Instruments, Inc. Printed in U.S.A. 11/13 FR# R3-443851-00 Rev. 2

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Loading...

Loading...