Page 1

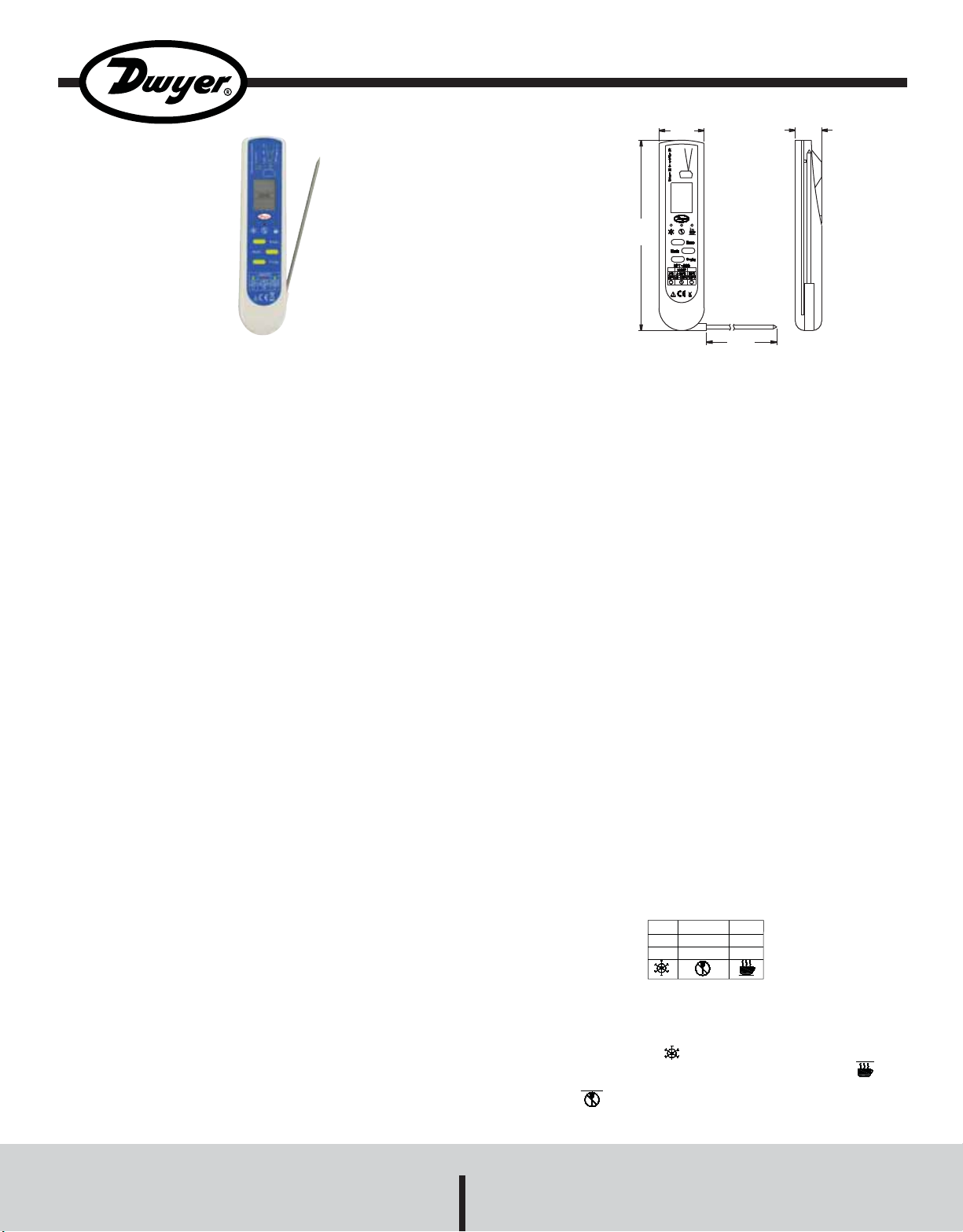

Model FST-300 Food Service Infrared Thermometer

Specifications - Installation and Operating Instructions

Bulletin T-16

The Model FST-300 Infrared Thermometer is designed to monitor tem-

peratures in the food service industry. The thermometer has both an infrared sensor and an immersion probe to safely monitor surface and

product temperatures. The quick HACCP zone display gives visual indication when products are within a safe storage temperature range for both

hot and cold food products. The Model FST-300 also has a built-in white

light to illuminate the measurement area.

OPERATING INSTRUCTIONS

Infrared Measurements

Simply aim the thermometer at the target and press the “SCAN” key to display the surface temperature.

Probe Measurements

Simply insert the probe into the desired area and press the “PROBE” key

to display the probe temperature on the bottom LCD display. The temperature will be measured for 4 minutes continuously. Pressing the “PROBE”

key during measurements will hold the current reading.

1-1/2

[38.1]

6-5/16

[160.34]

SPECIFICATIONS

Range: Infrared Sensor: -67 to 482°F (-55 to 250°C); Probe Sensor: -67

to 626°F (-55 to 330°C).

Ambient Operating Temperature: 32 to 122°F

(0 to 50°C).

Accuracy: ±1.1°F (0.5°C).

Resolution: 0.5°F (0.2°C).

Distance to Spot: 2.5:1 optics ratio.

Emissivity Range: 0.95 Default – adjustable 0.1 to 1.0.

Battery Life: 18 hours continuous use (auto power off after 15 seconds).

Weight: 3.5 oz (98.1 g).

Agency Approvals: CE.

4-1/2

[114.3]

7/8

[22.23]

Minimum or Maximum Reading

The thermometer will display the minimum or maximum reading for the

period in which measurements were taken in the minimum or maximum

mode.

For minimum measured temperature, press the “SCAN” button to turn on

the unit. Press the “MODE” key once so that min is flashing at the top of

the LCD display. Press and hold the “SCAN” key to take measurements.

Only the minimum temperature measured will be displayed.

For maximum measured temperature, press the “SCAN” button to turn on

the unit. Press the “MODE” key twice so that max is flashing at the top of

the LCD display. Press and hold the “SCAN” key to take measurements.

Only the maximum temperature measured will be displayed.

Continuous Monitoring

The lock mode is used for continuously monitoring temperatures for up to

60 minutes or until the “SCAN” key is pressed.

To enter the lock mode, press the “SCAN” key once to turn on the unit.

Press the “MODE” key three times so that lock is flashing at the top of the

LCD. Press the “SCAN” key once to start taking measurements.

Engineering Units

The thermometer can measure in °F or °C. To change the units, press the

“SCAN” key once to turn on the unit. Press the “MODE” key four times

until the unit descriptor is flashing. Press the “SCAN” key once to change

the units.

Emissivity

The emissivity is preset at the factory at 0.95. It can be adjusted from 0.10

to 1.00 (display reading 10E to 100E). Changes should only be carried out

by experienced personnel.

To change the emissivity, press the “SCAN” key to turn on the unit. Press

the “MODE” key five times until the top display changes to read the

emissivity. Press the “SCAN” key to adjust the emissivity in 0.01 (1E)

increments. Press the “MODE” key to accept the new emissivity reading.

Hazard Analysis and Critical Control Point Zone Display (HACCP)

HACCP

4°C

4-60°C

40°F

40-140°F

The HAACP zone display is present to give a quick reference as to whether

the measured temperatures are in the safe zone for hot or cold products.

The Green LED with the “ ” icon represents a safe condition for

refrigerated products below 40°F (4°C). The Green LED with the “ ” icon

represents a safe condition for hot foods above 140°F (60°C). The Red

LED with the “ ” icon represents unsafe food conditions between 40 to

140°F (4 to 60°C).

60°C

140°F

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

LCD Error Messages

The thermometer incorporates visual diagnostic messages as follows.

Hi Lo: Hi or Lo is displayed when the temperature being measured is

outside of the settings of HAL and LAL.

NOTICE

It is important to turn the thermometer off before replacing the battery

otherwise the thermometer may malfunction. Dispose of used battery

promptly and keep away from children.

Er2: Displays when the thermometer is exposed to rapid changes in the

ambient temperature.

Er3: Displays when the ambient temperature exceeds 32°F (0°C) or

122°F (50°C). The thermometer should be allowed plenty of time (minimum

30 minutes) to stabilize to the working/room temperature.

For all other error messages it is necessary to reset the thermometer. To

reset it, wait for the instrument to turn off, remove the battery and wait for

a minimum of one minute, reinsert the battery and turn it on. If the error

message remains please contact the Dwyer Customer Service department

for further assistance.

Batteries

The thermometer incorporates visual low battery indication as follows.

Battery OK: Measurements are possible.

Battery Low: Battery needs to be replaced, measurements are still

possible.

Battery Exhausted: measurements are not possible.

1. When device is in use, do not look directly into the laser

beam - Permanent eye damage may result.

2. Use extreme caution when operating the laser.

3. Never point the device towards anyone’s eyes.

4. Keep out of reach of all children.

NOTICE

The readings may be affected if the unit is operated within radio frequency

electromagnetic field strengths of approximately 3 volts per meter, but the

performance of the instrument will not be permanently affected.

1. Do not twist / rotate the probe in the wrong direction.

2. Excess stress may cause the probe to break.

3. Following a high temperature measurement, the probe

may be hot.

4. The probe may cause harm / injury when open. Keep

probe back when not in use.

5. To prevent damage to the probe, do not exceed the

measurement temperature range.

6. To avoid electrical shock, do not use this instrument

when voltages at the measurement surface exceed 24V

AC or DC.

Storage and Cleaning

The sensor lens is the most delicate part of the thermometer. The lens

should be kept clean at all times, care should be taken when cleaning the

lens using only a soft cloth or cotton swab with water or medical alcohol.

Allowing the lens to fully dry before using the thermometer. Do not

submerge any part of the thermometer . The thermometer should be stor ed

at room temperature between -4 and 149°F (-20 to 65°C).

When the low battery icon indicates the battery is low, the batteries should

be replaced immediately with AAA, 1.5V batteries using the following

steps.

Replacing Batteries

Probe

1. Remove the rubber screw cover and screw from the battery cover.

2. Lift the battery cover to access batteries.

3. Replace batteries observing polarity marked on unit.

4. Close the battery cover.

5. Replace screw and rubber screw cover.

Infrared Lens

White Light

Rubber Screw Cover

(Screw’s location)

Battery Cover

MAINTENANCE

A periodic check of the system calibration is recommended. The Model

FST-300 is not field serviceable and should be returned if repair is needed

(field repair should not be attempted and may void warranty). Be sure to

include a brief description of the problem plus any relevant application

notes. Contact customer service to receive a return goods authorization

number before shipping.

©Copyright 2008 Dwyer Instruments, Inc. Printed in U.S.A. 11/08 FR# R5-443627-00 Rev. 1

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...