Page 1

Bulletin # F-41-FS

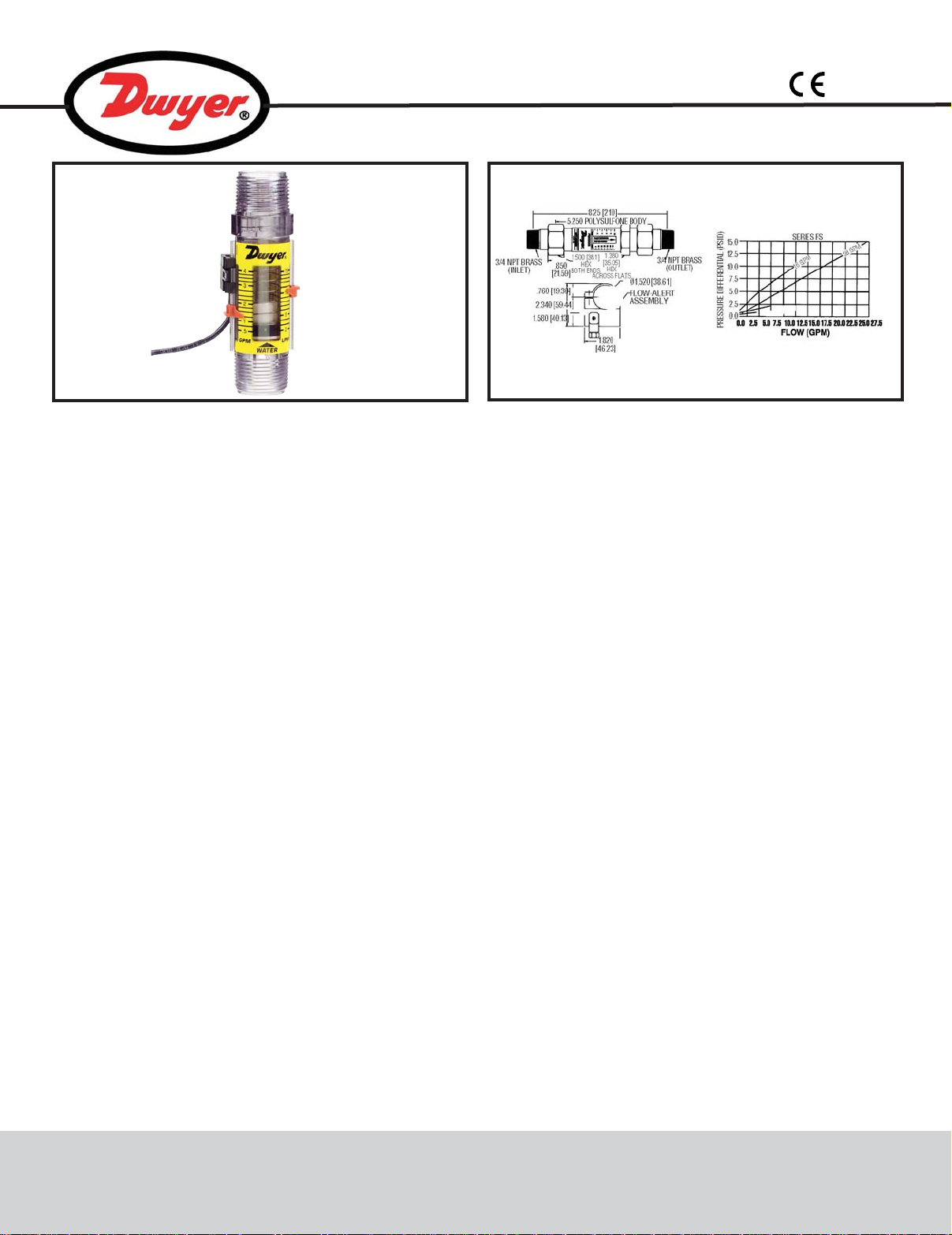

Series FS Flowmeter with Limit Switch

Specifications - Installation and Operating Instructions

DESCRIPTION

Industrial

rugged, low cost, and simple to install. The Series FS

offers visual flow rate indication and an adjustable flow

alarm to open or close AC electrical circuits, trigger

warning lights, or activate other process control

equipment. Operating within ±5% of full scale accuracy,

the Series FS can be installed vertically or horizontally

without installing any special plumbing. The Series FS is

constructed of high impact resistant polysulfone. This

series offers excellent structural integrity against operating

pressures up to 325 psi (22.4 bar) for liquids and 125 psi

(8.6 bar) for gases. The Series FS can withstand fluid

temperatures up to 250°F (121°C) and is compatible with a

wide range of chemicals.

Direct-Reading Series FS Flowmeters are

OPERATING PRINCIPLE

The Series FS is a piston-type variable area flow meter

that uses a sharp-edged annular orifice formed between

an open-centered piston and tapered metering cone. the

piston is held in a “no flow” position at the base of the

cone by a precision retention spring. Flow through the

meter creates a pressure differential across the piston

orifice, moving the piston against the spring. Piston

movement and orifice area are proportional to the rate of

flow. Therefore, the greater the rate of flow, the further the

piston moves along the tapered metering cone. The flow

rate is measured by the viewing the red indicator ring

mounted on the piston relative to a graduated flow scale

affixed to the outer surface of the flow meter body.

MECHANICAL INSTALLATION

CAUTION: DO NOT OVER TIGHTEN THE THREADS ON

THE PLASTIC BODY. Overtightening the NPT threads may

cause fracturing of the plastic flowmeter body. The

flowmeter is constructed of polysulfone and remains

stable to 210°F (99°C). DO NOT EXPOSE FLOWMETER

PHYSICAL DATA

Accuracy: ±5% Full Scale.

Repeatability: 1.0%.

Set Point: Adjustable 0 to

100% FS.

Pressure Limits: 325 psi (22.4

bar)

Temperature Limits: 250°F

(121°C).

Supply Voltage: 115 VAC, 140

VAC max.

TO OPEN FLAMES OR EXCESSIVE HEAT. The meter may

melt, crack, or distort. Some pipe dope formulas will react

adversely with polysulfone. Use Teflon

material is necessary.

The Series FS can be mounted in any plane of orientation.

Horizontal or vertical mounting does not effect flowmeter

accuracy. The inlet and outlet of the flowmeter should be

aligned, particularly when high temperature, high

pressure, or a combination of both may be encountered.

Install the flowmeter in the direction of the indicating

arrow on the scale. The Series FS Flowmeter does not

require lengths of straight pipe at the inlet, or outlet, to

stabilize flow through the meter. These meters can

tolerate particles that normally will jam other flow controls.

If large amounts of particulates are encountered, a 200

mesh or 74 million micron filter is recommended.

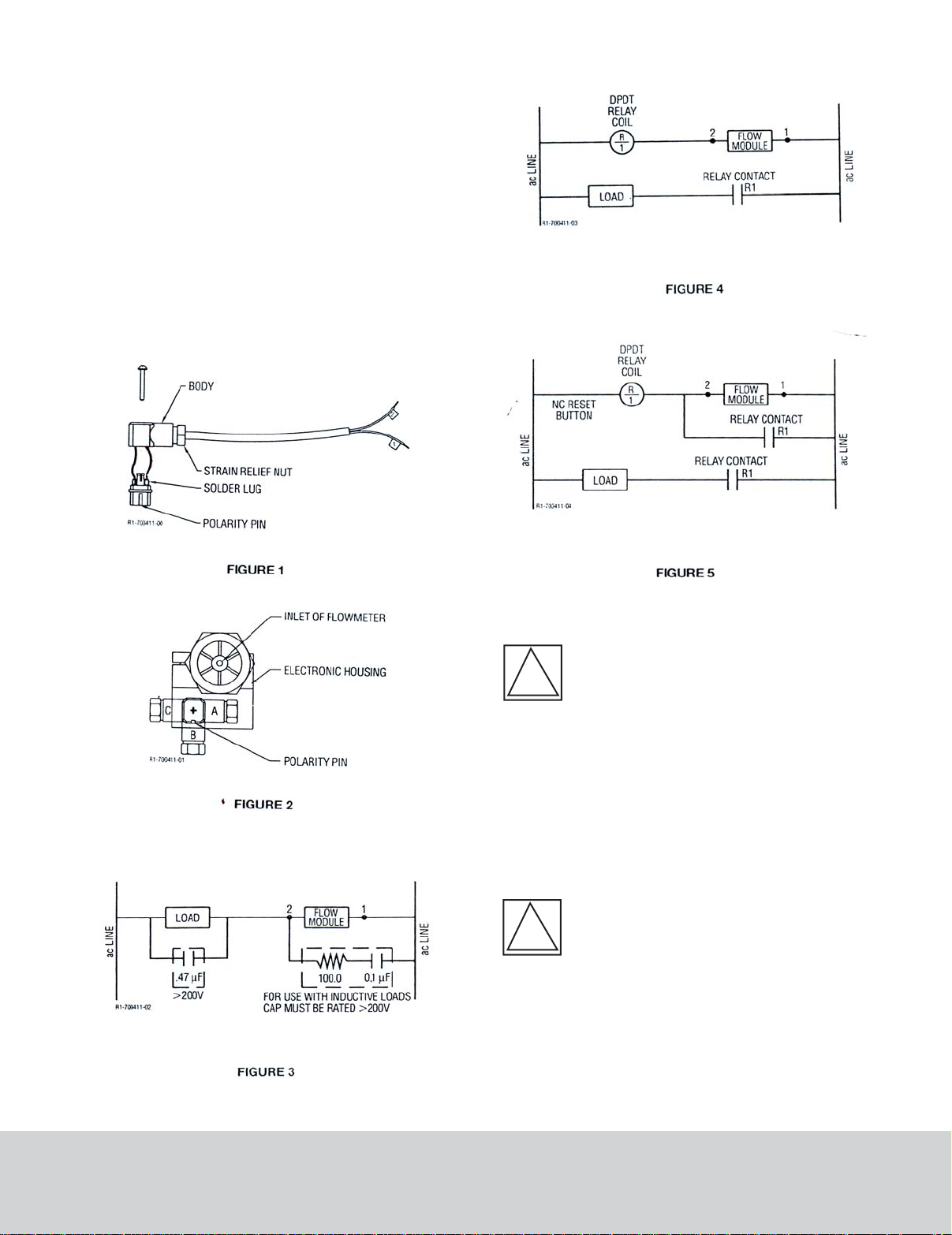

A separate four conductor female connector is supplied

with the limit switch assembly. The connector must be

disassembled to solder wired onto it. See Figure 1. the

Connector has four solder lugs labeled 1, 2, 3, and 4.

Te rminals 3 and 4 are not used. It should be noted before

reassembly, which wire is connected to which solder plug.

Color coding or labeling the wires is advised. Secure

On-State Current: 0.02 to 1.0

A AC.

Connections: 1˝ male NPT

Polysulfone or

Brass.

Flow Scale: Calibrated at 1.0

specific gravity @ 70°F (21°C).

Wetted Materials: Polysulfone

body, Barium Ferrite, Stainless

Steel spring and retaining

rings.

3

/4˝ male NPT

®

tape as if sealing

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

wires to solder lugs and determine the orientation A, B, or

!

!

C, snap the connector back together, pull excess wires

out of strain relief, and tighten strain nut. Plug into electric

housing and secure with screw.

ELECTRICAL INSTALLATION

The module can only switch loads that consume between

2.5 and 90 watts, or have 5000Ω to 150Ω impedence

respectively. If the load draws less than 2.5 watts, a 0.47

uF loading capacitor is required. This capacitor will

increase the power consumption and ensure complete

conduction. See Figure 3. Wiring according to Figure 3

will provide conduction over 15-20% of full scale, above

or below the flow rate set point. For loads greater than 90

watts, see Figures 4 and 5.

CAUTIONS

WARNING: Due to incompatibility,

Polysulfone flow meters SHOULD

NOT be used for monitoring the

following fluids: ACETONE, ALCOHOL,

BENZENE, CARBON DISULFIDE, FREON 11,

KEROSENE, LIQUID PROPANE, NAPHTHA,

AND PERCHLOROETHYLENE.

Other chemicals may also be incompatible with

Polysulfone. When in doubt, the meter should be tested in

a non-critical application under low pressure conditions to

determine compatibility. Also note that some chemicals

become more aggressive when heated. An acceptable

application may become unsafe at elevated temperatures.

CAUTION: These flowmeters are unidirectional devices. The piston acts as a check

valve to block flow in the reverse direction,

causing an excessive pressure differential

which could result in damage to internal

components.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 3

CAUTION: Consult the factory before using

!

any polysulfone meters to monitor the

following fluids: AMMONIA, ETHYLENE

GLYCOL 50/50, PHOSPHATE ESTER,

PHOSPHATE ESTER BASE, PHOSPHORIC

ACID.

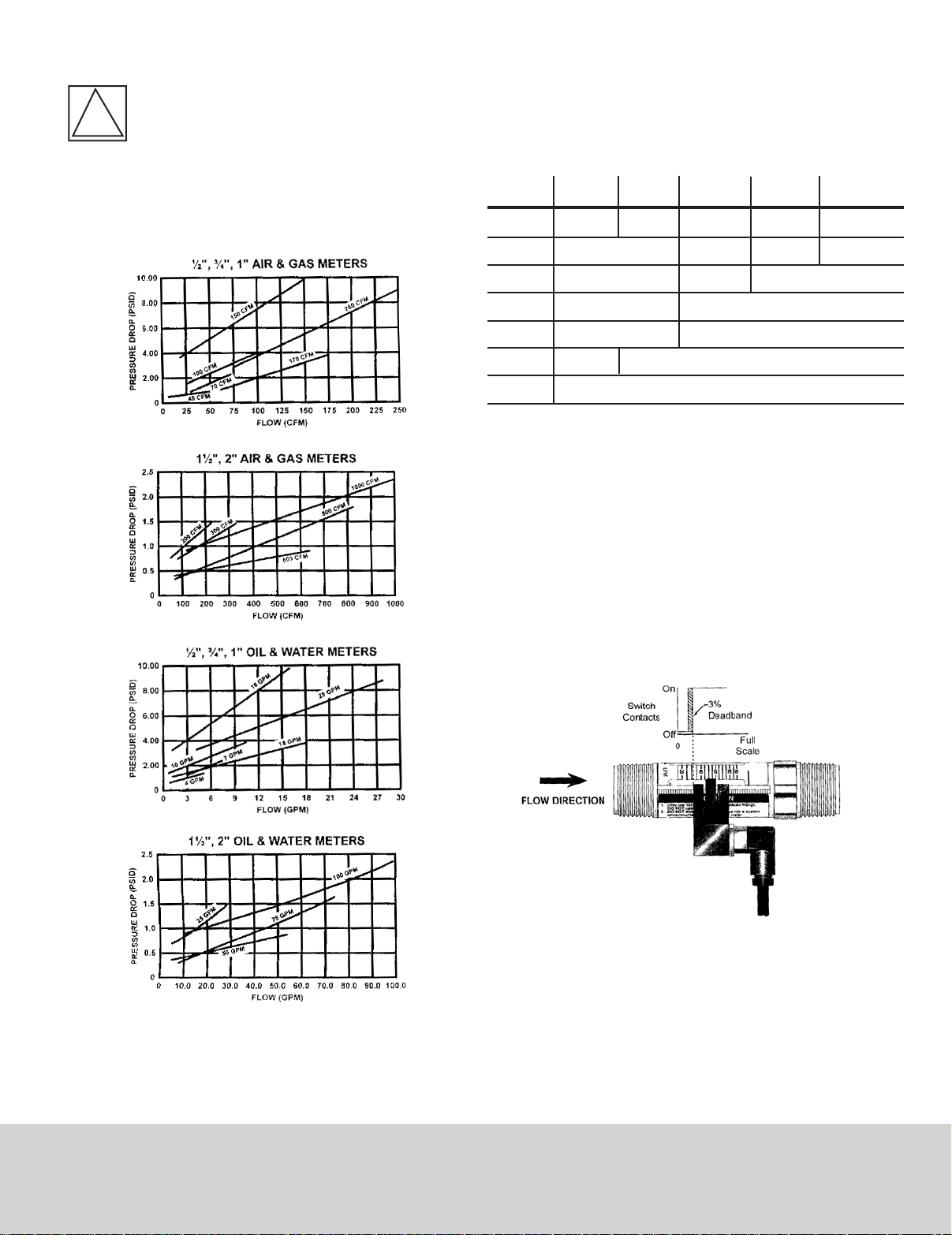

PRESSURE DROP

FLOW-ALERT SWITCH OPTIONS

NOTE: All flow-alert switches are magnetically triggered.

Magnets cannot be added to the basic flow meter so it

is not possible to add a switch to the basic meter if it

was not originally ordered with the switching magnet.

SWITCH SPECIFICATIONS

Specifications AC Latching DC Latching

Operating

Voltage

Operating

Current

Contact

Rating

Operating

Tem p .

Cable

Certification

Enclosure

Rating

115 VAC ±10%

1A @ 30 VDC 0.5 @125 VAC

32 to 158°F (0 to 70 °C)

N/A

10-30 VDC

25 mA max

Resistive Load

Not Included

Reed Switch

Form-A (N.O.)

1A @ 200 VDC

Resistive Load

NEMA 12 &13 (IP65)

Reed Switch

Form-B (N.C.)

N/A

N/A N/A

32 to 250°F (0 to 125 °C)

3 ft., 24 ga 2 conductor PVC Jacket

Reed Switch

Form-C (SPDT)

N/A

0.25A @ 175 VDC

Resistive Load

CE

N/A

N/A

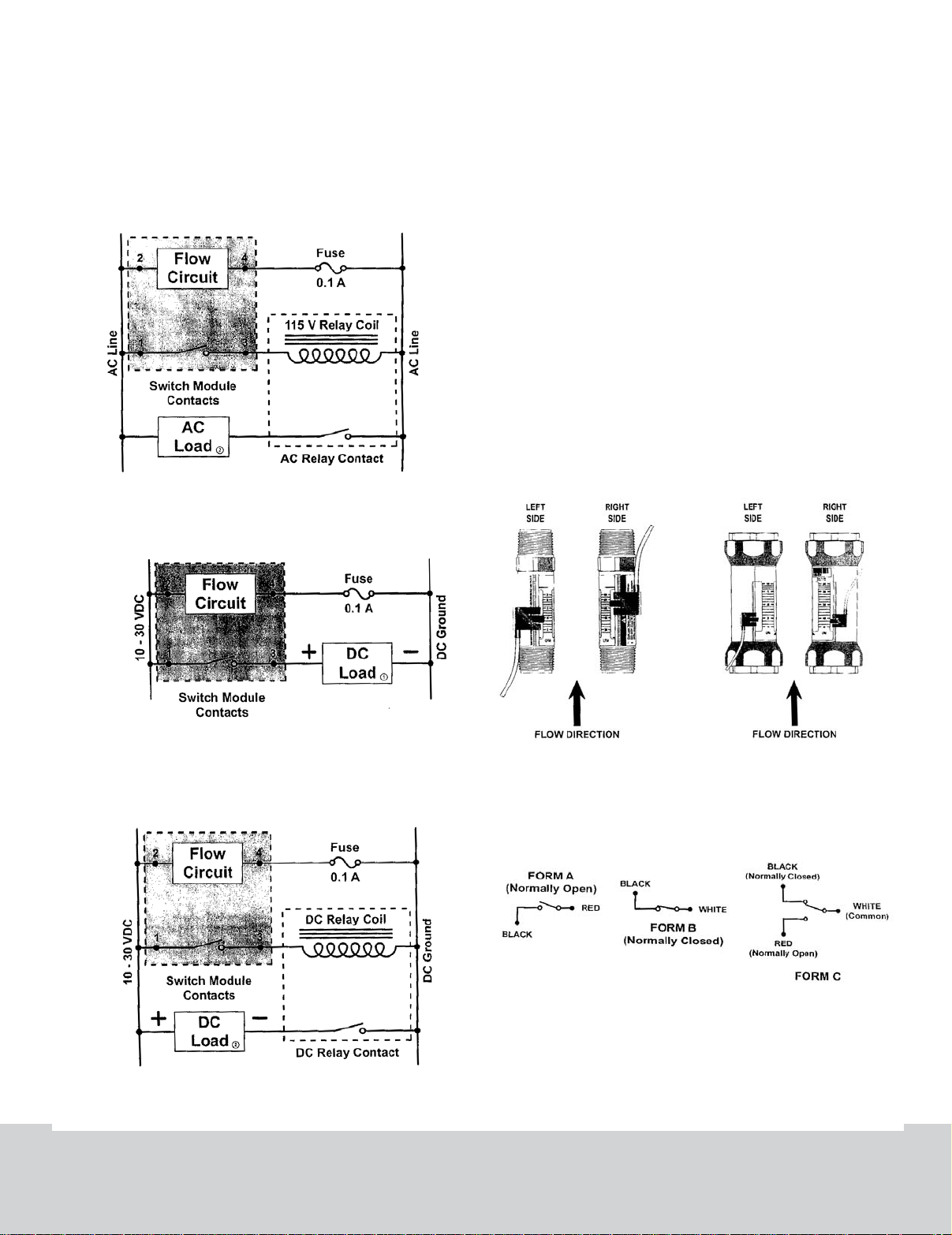

FLOW-ALERT LATCHING LIMIT SWITCH

The AC and DC powered low alert modules consist of

relay circuit housed in a sealed polypropylene enclosure.

The modules have a normally open dry relay contact that

can be used to directly control alarms, warning lights, and

relays or can be used to interface to a PLC. The relay will

be latched on as the magnet inside the flow meter passes

by the module and remained latched on until the magnet

passes in the other direction or power is interrupted (See

Figure 5). The set point is adjustable from 0 to 100% of

full scale. Flow meters can be equipped with one latching

limit switch, either AC or DC.

Figure 5

Latching Switches

FLOW-ALERT REED LIMIT SWITCH

The reed switch alert modules are available in three

forms. They are: Form A (Normally Open), Form B

(Normally Closed), and Form C (SPDT). Reed switches are

housed in a sealed polypropylene enclosure for

environmental protection. the reed switch modules do not

provide a latching function like the AC and DC powered

units. When the magnet inside the flow meter comes

within proximity of the module, the reed switch will

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 4

change state (See Figure 6). The set point is adjustable

from 0 to 100% of full scale. Two reed switch flow alerts

may be installed on a single flow meter but one must be

set for activation on increasing flow and the second must

be set for activation on decreasing flow.

Figure 6

Reed Switches

DC Switch

Figure 8

AC Switch

Latching Flow-Alert Switch Installation,

Operation and Adjustment

1. Install the switch on the flow meter by placing the

adjustment arms over the serated rail from the rear of the

meter by pushing down. The direction of the connector

and cable assembly indicate whether the switch will

activate on increasing flow, connector and cable pointing

up, or on decreasing flow, connector cable pointing down.

(See Figure 7.)

2. The connector has four solder lugs labeled: 1, 2, 3 and 4.

Soldering wires to the terminals first requires disassembly of

the connector as shown in Figure 8. Figure 9 depicts the

specific wiring pinouts for each style of latching switch. It

should be noted BEFORE reassembly which wire is

connected to which solder lug. Color coding or labeling the

wires is advised.

Pin

Function

1

Relay (NO)

2

DC +

3

Relay Common

4

DC -

Figure 9

Pin

Function

1

Relay (NO)

2

AC Supply

3

Relay Common

4

AC Supply

AC - WIRING CONFIGURATIONS

Warning: All wiring should be made in

accordance with the National Electrical Code

and must conform to any applicable state and

!

local codes.

3. After securing the wires to the solder lugs, a

determination of, “Which direction should the body of the

connector face?” needs to be made. Before snapping the

conductors back into the connector body, see Figure 10.

Figure 7

Figure 10

1 - AC Conventional Connection (Figure 11):

Note1: Load must be within specified contact rating range. 1 A

@ 30 VDC/500 mA @ 125 VAC.

4. After selecting direction A, B, or C, snap connector back

together, pull the excess wire out of the strain relief, and

tighten the strain relief nut.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Figure 11

Page 5

2 - AC Conventional Secondary Connections

(Figure 12):

Figure 12 demonstrates a secondary (slave) relay with a

115 VAC coil integrated with the AC switch module. This

combination allows switching of loads up to the rating of

the relay contacts.

3 - DC Conventional Connection (Figure 13):

Figure 12

Operation, and Adjustment

Warning: All wiring should be made in accordance with

the National Electrical Code and must conform to any

applicable state and local codes.

Figure 13 depicts the correct switch orientation to ensure

secure engagement of the adjustment locking mechanism.

The drawing assumes the flow scale points to the front.

1) Install the switch on the flow meter by placing the

adjustment arm over the serrated rail from the bottom of

the meter and pushing up for 1/2, 3/4, and 1 inch meters

or pushing down from the top on 1-1/2 and 2 inch meters.

Each meter will accept up to two reed switches and the

switch(es) for 1/2, 3/4, and 1 inch meters must be

installed before the meter is plumbed into the system.

2) Flow-Alert reed switches are available in three

configurations, Form A (Normally Open), Form B (Normally

Closed), and Form C (SPDT). Wire color codes and switch

configurations are shown in Figure 16.

4 - DC Conventional Secondary Connections

Figure 13

(Figure 14):

Figure 15

Figure 16

Figure 14

Flow-Alert Reed Switch Installation,

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 6

SWITCH ADJUSTMENT

After the flow meter has been installed and the switch

wired, the flow rate at which the switch will activate must

be adjusted. Figure 17 shows the activation zone for the

latching switches and Figure 16 shows the activation zone

for the reed switch variation.

1) With fluid running through the meter set the flow to the

rate you wish the switch to activate.

2) Gently move the switch adjustment tab(s) outward until

the switch body is free to slide up or down on the

serrated rail.

3) Move the switch into position until the switch activates.

4) Release the switch adjustment tab(s) to lock the switch

into position.

Warning - Fail-safe operation - If the flow

meter and switch are to be installed in a critical

application be sure the system is fail-safe. The

!

switch should be wired such that any switch

failure will stop the system. Failure to fail-safe the system

may lead to system damage and/or injury to personnel.

FLUID CORRECTION - LIQUIDS

Standard Flow

Standard liquid flow scales are calibrated in gpm and lpm

at 0.876 specific gravity for petroleum-based fluids and

1.0 s.g. for water and water-based fluids. For field

conversion of the standard scale to other fluids, see

ammonia example listed below.

Special Flow Scales

Special scales are available for liquids and gases in any

measurement unit, and other fluid viscosities and/or

specific gravities.

Viscosity Effect (SUS/cSt)

This variable area design utilizes a precision molded,

sharp-edged orifice and biasing calibration spring that

assures operating stability and accuracy over the wide

viscosity range common to many fluids. Generally, high

flow models provide good accuracy over a viscosity range

of 40 to 500 SUS (4.2 to 108 cSt).

Density Effect (specific gravity)

Any fluid density change from stated standards has a

square-root effect on meter accuracy. Special scales can

be supplied if actual specific gravity decreases accuracy

beyond application limits.

Corrections for more or less dense fluids can be made to

standard scales using correction equations as follows.

Scales

Figure 17

Figure 18

For water and water-based meters

1.0

√

Specific Gravity

For petroleum-based meters

0.876

√

Specific Gravity

Example: Measuring Gasoline with a petroleum based

meter

Fluid: Gasoline

Measured Flow From Scale: 28.5 GPM

Select (Gasoline) specific gravity from Fluid Selection

Chart.

S.G (LPG) = 0.70

Since a petroleum meter is being used, select the

petroleum-based formula.

√

1.119 (Correction Factor x 28.5 (Inducted Flow of

Gasoline = 31.88 (Actual Flow of Gasoline).

0.876

0.70

=1.119

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 7

Fluid Selection Chart

Internal

Components

Fittings

Fluid

Acetic Acid (Air Free)

Acetone

Alcohol, Butyl (Butanol)

Alcohol, Ethyl (Ethanol)

Ammonia

Benzene

Carbon Disulphide

Castor Oil

Cotton Seed Oil

Ethylene Glycol 50/50

Freon II

Gasoline

Glycerin

Kerosene

Liquid Propane (LPG)

Mineral Oil

Naphtha

Perchloroethylene

Petroleum Oil

Phosphate Ester

Phosphate Ester Base

Phosphoric Acid (Air Free)

Sea Water

Synthetic Petroleum Base

Water

Water Glycol 50/50

Water in Oil

Air

Argon (A)

Carbon Dioxide (CO2)

Freon 11 (CCI3F)

Freon 12 (CCI2F)

Helium (He)

Hydrogen (H2)

Natural Gas

Nitrogen (N2)

Oxygen (O2)

Propane (C3H8)

Specific

Gravity

1.06

0.79

0.83

0.83

0.89

0.69

1.26

0.97

0.93

1.12

1.46

0.70

1.26

0.82

0.51

0.92

0.76

1.62

0.76

1.18

1.26

1.78

1.03

1.00

1.00

1.07

0.93

1.00

1.38

1.53

4.92

4.26

0.14

0.07

0.60

0.97

1.10

1.57

Correction Factor of

Standard Scales

Oil

0.909

1.053

1.027

1.027

0.992

1.127

0.834

0.950

0.970

0.884

0.774

1.119

0.834

1.033

1.310

0.976

1.074

0.735

1.000

0.862

0.833

0.701

0.922

0.936

0.936

0.95

0.970

Water

0.971

1.125

1.089

1.089

1.060

1.204

0.891

1.015

1.037

0.945

0.828

1.195

0.891

1.104

1.400

1.042

1.147

0.786

1.068

0.921

0.891

0.749

0.985

1.000

1.000

0.967

1.037

Air/Compressed Gas

1.000

1.175

1.237

2.218

2.060

0.374

0.265

0.775

0.985

1.049

1.253

Buna N

Polysulfone

T300 Stainless

R

R

C

N

R

N

R

R

R

R

R

N

R

R

C

N

N

N

N

R

N

C

C

R

R

R

R

R

R

R

N

R

N

R

R

R

R

R

R

R

R

R

N

R

R

R

R

R

N

R

R

N

R

R

R

R

R

N

R

N

N

R

N

R

N

C

R

N

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

N

R

N

N

R

N

C

R

R

C

R

R

R

R

R

R

R

R

R

R

R

N

R

R

C360 Brass

PH157 MO Stainless

R

R

R

R

R

N

R

C

R

R

R

R

R

R

R

R

R

R

R

R

R

N

N

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

PVC - Type 1

N

R

R

N

C

R

C

R

C

R

R

N

N

N

R

C

R

N

R

R

R

N

R

C

R

R

R

R

R

R

R

R

N

N

N

N

R

R

R

N

R

N

N

R

N

R

C

R

R

R

R

R

R

R

R

R

R

R

R

R

R

N

R

N

R

R

R

N

C

R

R

R

R

R

R

R

T303 Stainless

R

R

R

R

R

N

R

C

R

R

R

R

R

R

R

R

R

R

R

R

R

N

N

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R - Recommended N - Not Recommended C - Consult Factory

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Loading...

Loading...