Page 1

Bulletin F-FLST

Series FLST Duct Mounted Airflow Measurement Station

Specifications - Installation and Operating Instructions

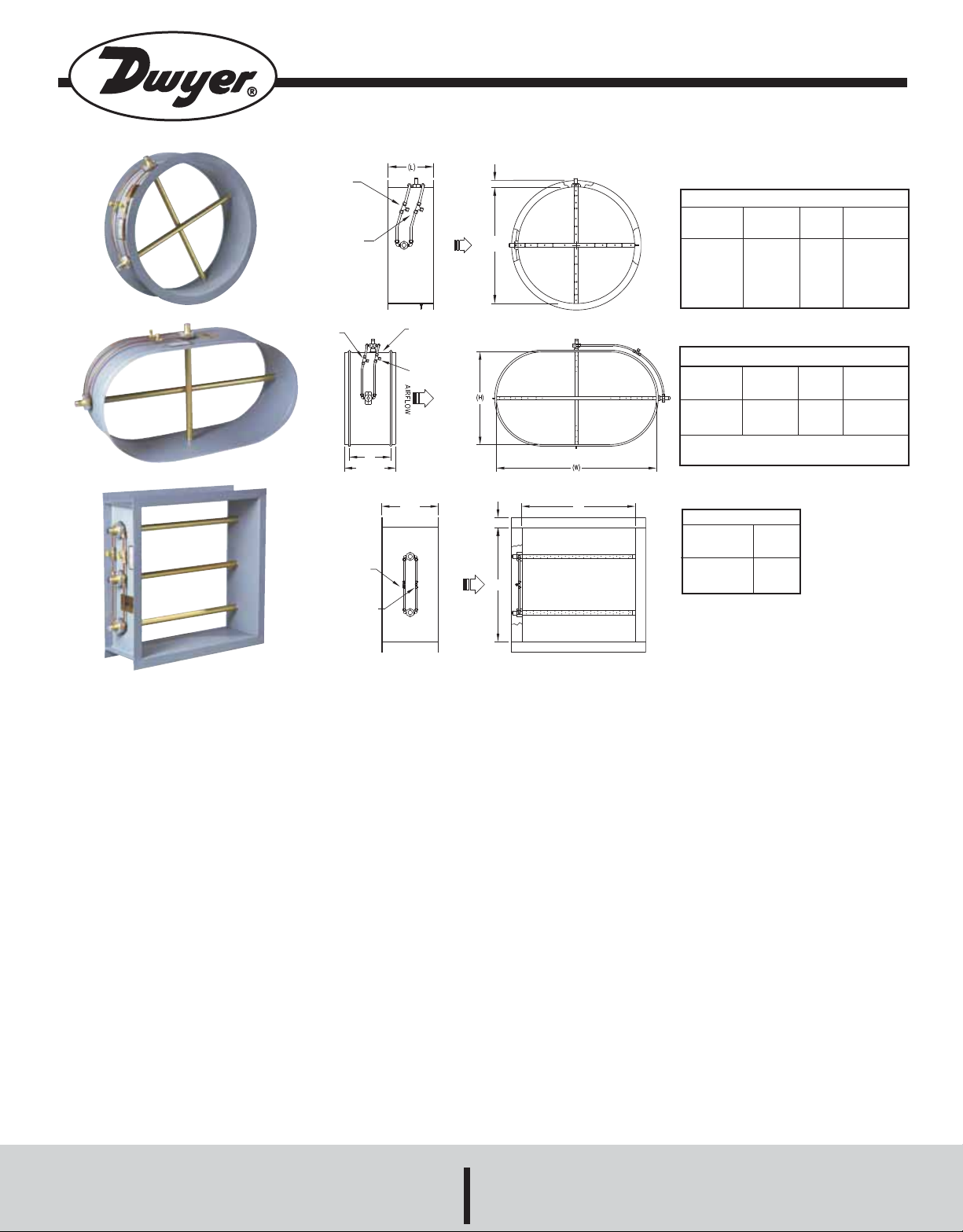

TOTAL PRESSURE

(T.P.) TAKEOFF

STATIC PRESSURE

(S.P.) TAKEOFF

TOTAL PRESSURE

(T.P.) TAKEOFF

TOTAL PRESSURE

(T.P.) TAKEOFF

STATIC PRESSURE

(S.P.) TAKEOFF

(L)

(L + 2.5˝)

.25˝ RADIUS

BEADED EDGE (TYP)

STATIC PRESSURE

(S.P.) TAKEOFF

(L=5˝)

AIRFLOW

AIRFLOW

(F)

DIMENSIONS

CIRCULAR FLANGE

STATION

(D)

SIZE “D”

8˝ - 15˝

16˝ - 44˝

45˝ - 72˝

73˝ & OVER

FLANGE

THICKNESS

.064˝

.064˝

.188˝

.188˝

FLANGE

SIZE “F”

1˝

1-1/2˝

1-1/2˝

2˝

CASING

LENGTH “L”

6˝

6˝

10˝

12˝

OVAL FLANGE (OPTIONAL)

CASING

FLANGE

SIZE “F”

1-1/2˝

2˝

FLANGE

SIZE

1-1/2˝

1-1/2˝

LENGTH “L”

6˝

8˝

STATION

WIDTH “W”

UP TO 44˝

OVER 44˝

NOTE: All oval flow stations without flange have a

casing length of 5˝.

(W)

(F)

RECTANGULAR FLANGE

FLANGE

THICKNESS

.064˝

.188˝

STATION SIZE

“H” OR “W”

8˝ - 72˝

(H)

73˝ & OVER

The Series FLST Airflow Measurement Station consists of single or

multiple airflow elements, factory mounted and pre-piped in a casing

designed for flanged connection to the ductwork. Standard materials consist of a G90 galvanized casing and 6063-T5 anodized aluminum flow sensors, suitable for most HVAC applications.

The airflow averaging element, utilized in the FLST, is a head type device,

which generates a differential (velocity) pressure signal similar to the orifice,

venturi, and other head producing primary elements. The FLST is constructed so that strategically located sensing ports (based on duct size)

continually sample the total and static pressures, when inserted normal to

flow. The total pressures sensed by the upstream ports are continually

averaged within the element in an isolated chamber. The static sensing

ports (located where the influence of the velocity head is zero) are averaged

in a second isolation chamber. Multiple elements are manifolded together

for connection to a differential measurement device (gage, transmitter, etc.)

for flow measurement and indication purposes.

SPECIFICATIONS

Accuracy: Within 2% of actual flow when installed in accordance with

published recommendations.

Velocity Range: 100 to 10,000 fpm (0.51 to 51 m/s).

Wetted Material: Elements 6063-T5 anodized aluminum; Casings 16 ga

G90 galvanized steel.

Temperature Limits: Galvanized Casings and Aluminum Elements

350°F (177°C) continuous operation (in air) 400°F (204°C) intermittent

operation (in air).

Humidity: All Airflow Stations 0 to 100% non condensing.

Process Connections: 1/4˝ compression fittings.

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

Circular Flange Dimensions

Station

Size

6˝ - 15˝

16˝ - 44˝

45˝ - 72˝

73˝ & Over

Circular Stations

Standard circular airflow measuring stations include a 16 gage galvanized

casing with attached 90° connecting flanges as listed above.

Flange

Thickness

0.064˝

0.064˝

0.188˝

0.188˝

Flange

Size

1˝

1-1/2˝

1-1/2˝

2˝

Casing

Length “L”

6˝

6˝

10˝

12˝

Oval Flange Dimensions (Optional)

Station

Size

Up to 48˝

Over 48˝

Oval Stations

Standard oval airflow measuring stations include a 18 gage galvanized

casing, 5 inches long between beads with 1-1/4 inch connecting sleeve

on each end (7-1/2 inch overall length). Actual O.D. dimensions are 1/4

inch less than specified duct I.D. dimensions.

Flange

Thickness

0.064˝

0.188˝

Flange

Size

1-1/2˝

1-1/2˝

Casing

Length “L”

6˝

8˝

Rectangular Flange Dimensions

Station Size

8˝ - 72˝

73˝ & Over

Rectangular Stations

Standard rectangular airflow measuring stations include a 16 gage galvanized casing, 5 inches long, with formed integral 90° connecting flanges

as listed above.

Flange Size

1-1/2˝

2˝

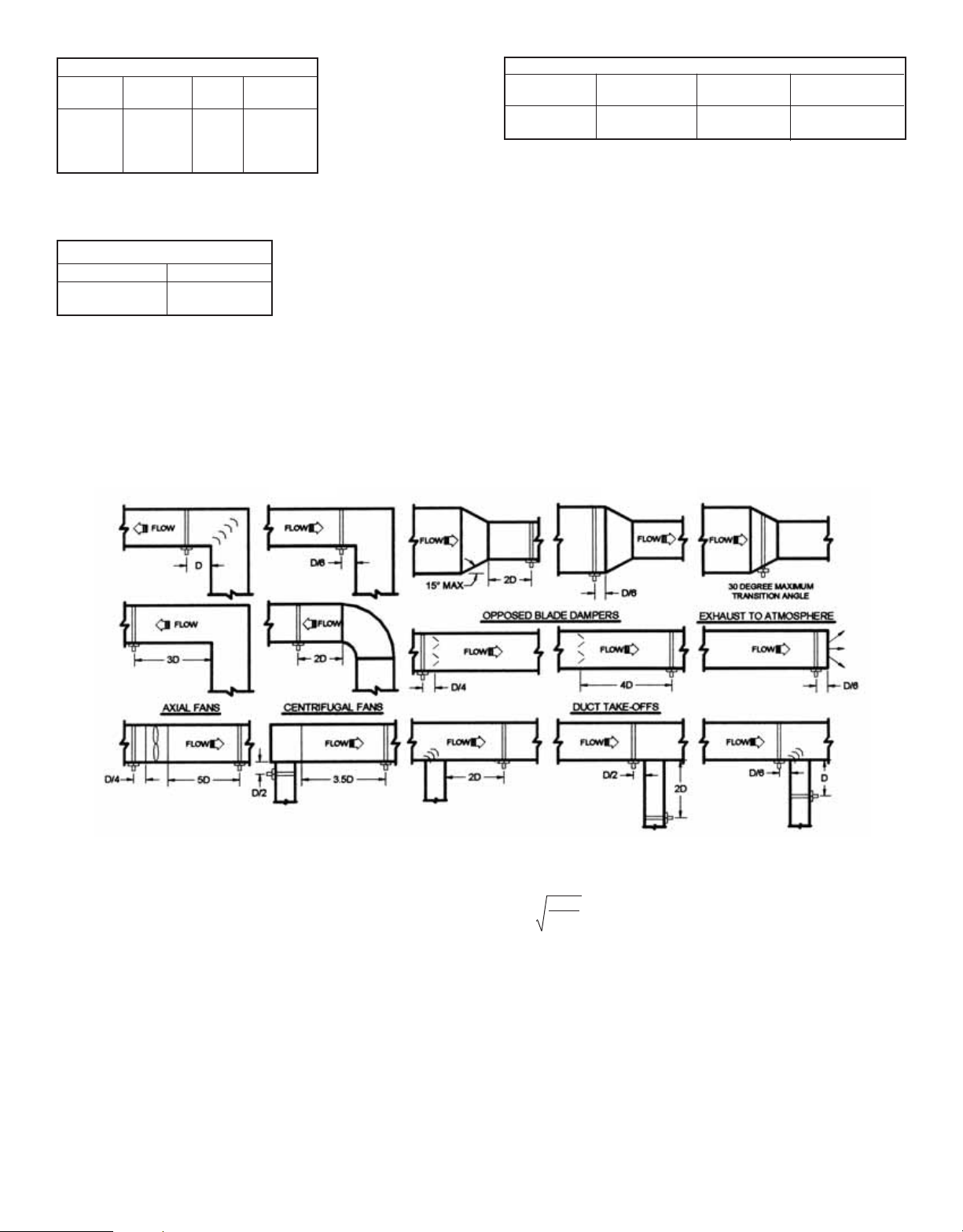

ELBOWS

INSTALLATION

The elements may be installed in any duct configuration. However, the

accuracy of the installation is dependent on the flow conditions in the

duct. The minimum installation requirements for the elements based upon

a uniform velocity profile approaching the duct disturbance for flow rates

less than 2,500 fpm are shown below. Add one duct diameter to the

installation requirements shown below for each additional flow rate of

1000 fpm. These are not ideal locations. It is always best to locate the elements as far as possible from all duct disturbances, with upstream disturbances being the most critical consideration.

TRANSITIONS

Notes:

Round Ducts:

D = Duct diameter

Rectangular Ducts:

D = 4HW

π

H = Duct height

W = Duct width

Page 3

FLST RESISTANCE to AIRFLOW

FLST SPECIFICATION GUIDE

1. Provide where indicated and/or scheduled airflow traverse elements

capable of continuously monitoring the fan or duct air volumes they serve.

2. Each element shall be designed and built to comply with, and provide

results in accordance with, accepted practice for duct system traversing as

defined in the ASHRAE Handbook of Fundamentals, AMCA publication

#203, as well as the Industrial Ventilation Handbook. The number of sensing ports on each element, and the quantity of elements utilized at each

installation, shall comply with ASHRAE Standard #111 for equal area duct

traversing.

3. Each airflow measuring element shall contain multiple total and static

pressure sensing ports placed along the leading edge of the cylinder. The

static pressure chamber shall incorporate dual offset static taps on opposing sides of the averaging chamber, so as to be insensitive to flow angle

variations of as much as ±20 degrees in the approaching airstream.

4. The airflow traverse elements shall be capable of producing steady, nonpulsating signals of true total and static pressure, with an accuracy of 2%

of actual flow for operating velocities as low as 100 feet per minute (fpm).

Signal amplifying sensors requiring flow correction (K factors) for field calibration are not acceptable.

5. The airflow traverse elements shall not induce a measurable pressure

drop, greater than 0.18 inch at 4,000 fpm. The units sound level within the

duct shall not be amplified, nor shall additional sound be generated.

6. The probes shall be manifolded together in a 16 gauge galvanized steel

duct section with 90 degree undrilled flanges, fabricated to the duct size,

and shall contain multiple airflow traverse elements interconnected as herein before described.

Installation Considerations

1. Primary flow elements shall be installed in strict accordance with the

manufactures published requirements and with ASME guidelines affecting

non-standard approach conditions. These elements serve as the primary

signals for the airflow systems; it shall be the responsibility of the contractor to verify correct installation to assure that accurate primary signals are

obtained.

2. An identification label shall be placed on each unit casing listing model

number, size, area, and specified airflow capacity.

7. Where primary flow elements are located outside of the manufacturer’s

published installation guidelines the manufacturer shall be consulted, and

approve of any special configurations, such as air equalizers and/or additional and strategically placed measuring points, as may be required.

8. Where the stations are installed in insulated ducts, the airflow passage

of the station shall be the same size as the inside airflow dimension of the

duct. Station flanges shall be sized to facilitate matching connecting ductwork.

Page 4

Engineering Reference Table

V = Velocity in feet per minute Pv = Velocity Pressure in inches H

Velocity Versus Velocity Pressure

2

O

V

180

190

200

210

220

230

240

250

260

270

280

290

300

310

320

330

340

350

360

370

380

390

400

410

420

430

440

450

460

470

480

490

500

510

520

530

540

550

560

570

580

590

600

610

Pv

0.0020

0.0023

0.0025

0.0027

0.0030

0.0033

0.0036

0.0039

0.0042

0.0045

0.0049

0.0052

0.0056

0.0060

0.0064

0.0068

0.0072

0.0076

0.0081

0.0085

0.0090

0.0095

0.0100

0.0105

0.0110

0.0115

0.0121

0.0126

0.0132

0.0138

0.0144

0.0150

0.0156

0.0162

0.0169

0.0175

0.0182

0.0189

0.0196

0.0203

0.0210

0.0217

0.0224

0.0232

Above Pv Values are Based on Standard Air Density of 0.075 lbm ft3which is Air at 68°F. 50% Relative Humidity, and 29.92˝ Hg.

V

620

630

640

650

660

670

680

690

700

710

720

730

740

750

760

770

780

790

800

810

820

830

840

850

860

870

880

890

900

910

920

930

940

950

960

970

980

990

1000

1010

1020

1030

1040

1050

Pv

0.0240

0.0247

0.0255

0.0263

0.0272

0.0280

0.0288

0.0297

0.0305

0.0314

0.0323

0.0332

0.0341

0.0351

0.0360

0.0370

0.0379

0.0389

0.0399

0.0499

0.0419

0.0429

0.0440

0.0450

0.0461

0.0472

0.0483

0.0494

0.0505

0.0516

0.0528

0.0539

0.0551

0.0563

0.0575

0.0587

0.0599

0.0611

0.0623

0.0636

0.0649

0.0661

0.0674

0.0687

The equation for converting air volume (Q) into velocity (V) and velocity pressure (Pv) is:

V

1060

1070

1080

1090

1100

1110

1120

1130

1140

1150

1160

1170

1180

1190

1200

1210

1220

1230

1240

1250

1260

1270

1280

1290

1300

1310

1320

1330

1340

1350

1360

1370

1380

1390

1400

1410

1420

1430

1440

1450

1460

1470

1480

1490

Pv

0.0701

0.0714

0.0727

0.0741

0.0754

0.0768

0.0782

0.0796

0.0810

0.0825

0.0839

0.0853

0.0868

0.0883

0.0898

0.0913

0.0928

0.0943

0.0959

0.0974

0.0990

0.1006

0.1021

0.1037

0.1054

0.1070

0.1086

0.1103

0.1119

0.1136

0.1153

0.1170

0.1187

0.1205

0.1222

0.1239

0.1257

0.1275

0.1293

0.1311

0.1329

0.1347

0.1366

0.1384

V

1500

1510

1520

1530

1540

1550

1560

1570

1580

1590

1600

1610

1620

1630

1640

1650

1660

1670

1680

1690

1700

1710

1720

1730

1740

1750

1760

1770

1780

1790

1800

1810

1820

1830

1840

1850

1860

1870

1880

1890

1900

1910

1920

1930

Pv

0.1403

0.1422

0.1440

0.1459

0.1479

0.1498

0.1517

0.1537

0.1556

0.1576

0.1596

0.1616

0.1636

0.1656

0.1677

0.1697

0.1718

0.1739

0.1760

0.1781

0.1802

0.1823

0.1844

0.1866

0.1888

0.1909

0.1931

0.1953

0.1975

0.1998

0.2020

0.2040

0.2065

0.2088

0.2111

0.2134

0.2157

0.2180

0.2203

0.2227

0.2251

0.2274

0.2298

0.2322

V

1940

1950

1960

1970

1980

1990

2000

2020

2040

2060

2080

2100

2120

2140

2160

2180

2200

2220

2240

2260

2280

2300

2320

2340

2360

2380

2400

2420

2440

2460

2480

2500

2520

2540

2560

2580

2600

2620

2640

2660

2680

2700

2720

2740

Pv

0.2346

0.2371

0.2395

0.2420

0.2444

0.2469

0.2494

0.2544

0.2595

0.2646

0.2697

0.2749

0.2802

0.2855

0.2909

0.2963

0.3017

0.3073

0.3128

0.3184

0.3241

0.3298

0.3356

0.3414

0.3472

0.3531

0.3591

0.3651

0.3712

0.3773

0.3834

0.3897

0.3959

0.4022

0.4086

0.4150

0.4214

0.4280

0.4345

0.4411

0.4478

0.4545

0.4612

0.4681

V

2760

2780

2800

2820

2840

2860

2880

2900

2920

2940

2960

2980

3000

3020

3040

3060

3080

3100

3120

3140

3160

3180

3200

3220

3240

3260

3280

3300

3320

3340

3360

3380

3400

3420

3440

3460

3480

3500

3520

3540

3560

3580

3600

3620

Pv

0.4749

0.4818

0.4888

0.4958

0.5028

0.5099

0.5171

0.5243

0.5316

0.5389

0.5462

0.5536

0.5611

0.5686

0.5762

0.5838

0.5914

0.5991

0.6069

0.6147

0.6225

0.6304

0.6384

0.6464

0.6545

0.6626

0.6707

0.6789

0.6872

0.6955

0.7038

0.7122

0.7207

0.7292

0.7378

0.7464

0.7550

0.7637

0.7725

0.7813

0.7901

0.7990

0.8080

0.8170

V

3640

3660

3680

3700

3720

3740

3760

3780

3800

3820

3840

3860

3880

3900

3920

3940

3960

3980

4000

4050

4100

4150

4200

4250

4300

4350

4400

4450

4500

4550

4600

4650

4700

4750

4800

4850

4900

4950

5000

5050

5100

5150

5200

5250

Pv

0.8260

0.8351

0.8443

0.8535

0.8627

0.8720

0.8814

0.8908

0.9002

0.9097

0.9193

0.9289

0.9386

0.9483

0.9580

0.9678

0.9777

0.9876

0.9975

1.0226

1.0480

1.0737

1.0997

1.1261

1.1527

1.1797

1.2070

1.2346

1.2625

1.2907

1.3192

1.3480

1.3772

1.4066

1.4364

1.4665

1.4969

1.5276

1.5586

1.5899

1.6216

1.6535

1.6858

1.7184

V

5300

5350

5400

5450

5500

5550

5600

5650

5700

5750

5800

5850

5900

5950

6000

6050

6100

6150

6200

6250

6300

6350

6400

6450

6500

6550

6600

6650

6700

6750

6800

6850

6900

7000

7100

7200

7300

7400

7500

7600

7700

7800

7900

8000

Pv

1.7512

1.7844

1.8180

1.8518

1.8859

1.9204

1.9551

1.9902

2.0256

2.0613

2.0973

2.1336

2.1702

2.2071

2.2444

2.2819

2.3198

2.3580

2.3965

2.4353

2.4744

2.5139

2.5536

2.5937

2.6340

2.6747

2.7157

2.7570

2.7986

2.8406

2.8828

2.9253

2.9682

3.0549

3.1428

3.2319

3.3223

3.4140

3.5069

3.6010

3.6964

3.7930

3.8909

3.9900

Where

V = Q

PV = V 2 x p

A

MAINTENANCE

Since the sensing elements have no moving parts, only periodic cleaning

may be required. The sensing elements should be inspected for fouling of

the sensing holes as part of an annual preventative maintenance program.

Installations having viscous airborne particles may require more frequent

inspection. If the sensing holes on the elements have become fouled or

plugged, the following procedure is recommended. Caution, all instru-

ments must be isolated (removed) from the sensing lines prior to

performing the following cleaning procedure.

[

[

C

V = Velocity in fpm C = 1096.7

Q = Flow in efm p = Density of air in lb/ft

A = Area in ft

2

Pv = Velocity pressure in inches H2O

3

Cleaning: In applications where the sensing elements are subject

to viscous contaminants it is recommended that the surface be

washed with a cleaning agent. The cleaning agent used must be

suitable for use on the type of material the sensing element is constructed of (i.e. aluminum, stainless steel, etc.)

The Series FLST Duct Mounted Airflow Measurement Station is

not field serviceable and should be returned if repair is needed

(field repair should not be attempted and may void warranty). Be

sure to include a brief description of the problem plus any relevant

application notes. Contact customer service to receive a return

Backpurging: Connect clean/dry compressed air, set at a maximum

pressure of 25 psi, to the output pressure ports (total and/or static) of the

sensing element being cleaned. While purging the sensing element, wipe

the surface of the cylinder with a cloth or brush to loosen and remove all

contaminate buildup.

goods authorization number before shipping.

©Copyright 2009 Dwyer Instruments, Inc. Printed in U.S.A.1/09 FR# R1-443414-00 A Rev. 1

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...