Page 1

Series FDT Flush Diaphragm Transmitter

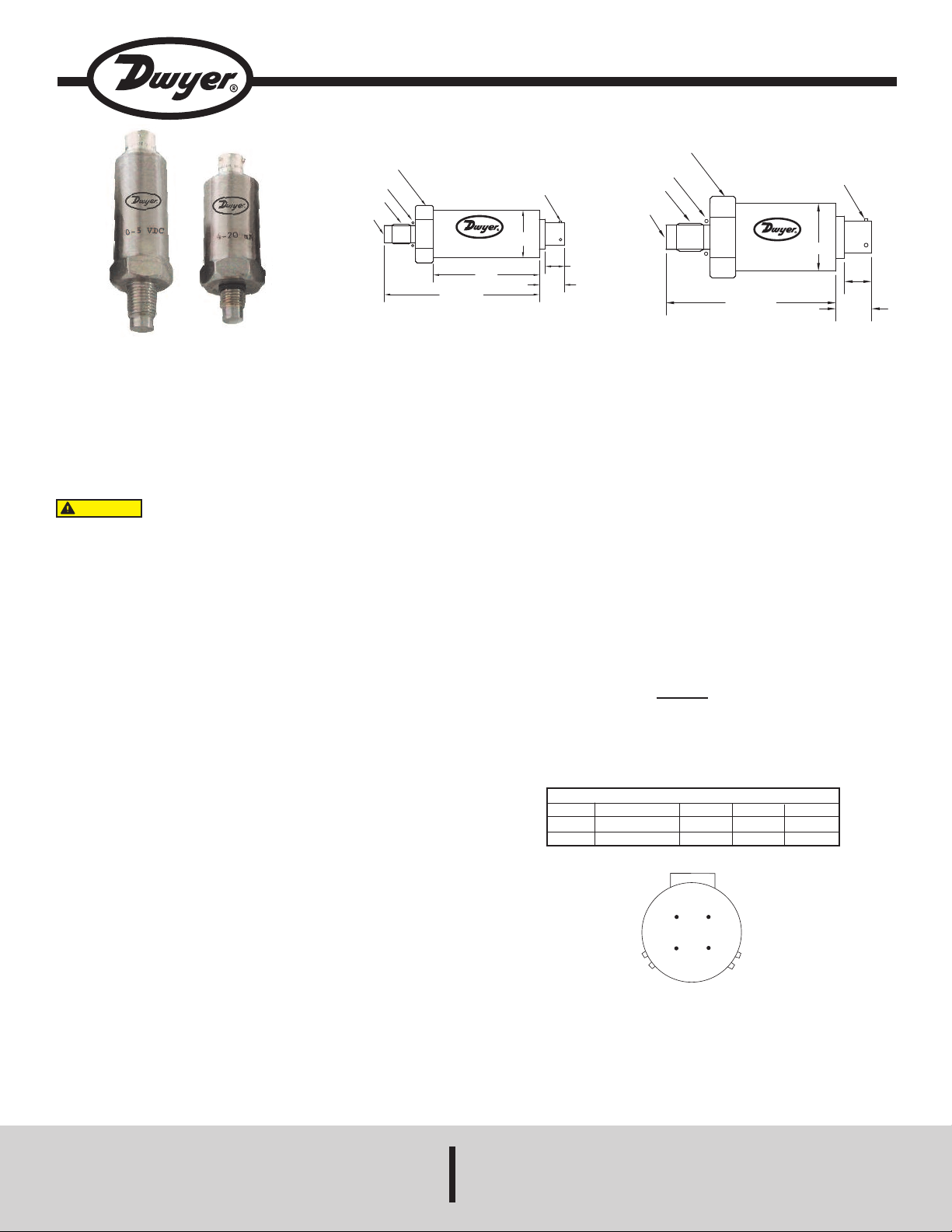

7/16-20 UNF

1.00

FLUSH

DIAPHRAGM

0.525

0.400

BENDIX 4 PIN

CONNECTOR

DTIH-8-4PN

1˝ HEX

VITON O-RING

2.250

3.25(REF)

0-5 VDC

0 - 5 or 0 - 10 VDC MODEL

7/16-20 UNF

FLUSH

DIAPHRAGM

VITON O-RING

2.50(REF)

0.400

1.00

1˝ HEX

0.525

BENDIX 4 PIN

CONNECTOR

DTIH-8-4PN

4 - 20 MA

A

D

B

C

Specifications - Installation and Operating Instructions

he Series FDT Flush Diaphragm Transmitter is designed for highly cyclical

T

conditions. This unit has a non-oil filled sensor element that provides resistance to

temperature fluctuations. Manufactured from a solid piece of steel, the sensing

diaphragm can withstand the most abrasive/cyclical applications. Unit performs

well in high cyclical environments with the presence of water-hammering or

piking.

s

lush feature greatly reduces chance of leakage. Tough materials allow the unit to

F

ithstand harsh process conditions. Advanced manufacturing techniques, extreme

w

environmental burn-in, and thorough residual stress relieving procedures ensure

unit will maintain its high performance standard over time.

AUTION

C

designed for 120 or 240 volt AC operation. Use only on 8 to 38 VDC.

INSTALLATION

Location

Select a location where the temperature of the transmitter will be between -40 and

200°F (-40 to 93°C). Distance from the receiver is limited only by total loop

resistance. The tubing or piping supplying pressure to the unit can be practically

any length required but long lengths will increase response time slightly.

Do not exceed specified supply voltage ratings. Permanent

damage not covered by warranty will result. This device is not

ulletin E-FDT

B

PECIFICATIONS

S

Service: Compatible liquids and gases, adhesives, slurries, materials that can

harden, or where a pressure cavity is not desired.

Wetted Materials: 316 & 15-5 SST.

Accuracy: ±0.5% FSO (includes non-linearity, hysteresis, and repeatability).

tability: ≤ ±0.25% FSO per year.

S

emperature Limits: -40 to 200°F (-40 to 93°C).

T

ompensated Temperature Limits: 0 to 170°F (-18 to 77°C).

C

Pressure Limit: 150% FS; Burst: 200% FS.

Thermal Effect: ±1.5% FSO over compensated range.

Power Requirements: 8 to 38 VDC.

Output Signal: FDT-A: 4 to 20 mAdc; FDTV: 0 to 5 VDC.

esponse Time: <1mS.

R

Loop Resistance: FDT-A: 0-1.5 Ω; FDT-V: ≤ 100 Ω.

Electrical Connections: Bendix 4 pin.

Process Connection: 7/16-20 UNF Male Flush Diaphragm. Optional 1/4” male

NPT.

Enclosure Rating: NEMA 4x (IP66).

Mounting Orientation: Mount in any position.

Weight: 2 oz (57 g).

Agency Approvals: CE.

Position

The transmitter is not position sensitive. However all standard models are originally

calibrated with the unit in a position with the pressure connection downward.

Although they can be used at other angles, for best accuracy it is recommended

that units be installed in the position calibrated at the factory.

Pressure Connection

Use a small amount of plumbers tape‚ thread tape or other suitable sealants to

prevent leaks. Be sure the pressure passage inside the port is not blocked.

Electrical Connections

Units must “see” the proper excitation to perform within specifications. Insufficient

power may prevent the unit from providing the full rated output at the full rated

pressure. Electronics can be damaged by electric surges. Surge arresters are

suggested for applications where surges are possible. Mechanical isolation may

receiver load resistance (RL) for the DC power supply voltage available is

expressed by the formula:

RL Max = Vps - 8

20 mA DC

Shielded cable is recommended for control loop wiring.

VOLTAGE (0 to 5 V) OUTPUT OPERATION

(Other output contact the factory) See Fig. A for connection of the power supply,

transmitter and receiver.

Standard Wiring

MODEL

FDT-V

FDT-A

OUTPUT

0-5 VDC 3 Wire

4-20 mAdc

Power(+)

Pin A

Pin A

Power(-)

Pin B

Signal(+)

Pin C

Pin B

Fig. A

also be required. Electrical termination must be made in a NEMA 4 enclosure.

Care must be taken to prevent migration of fluid into the cable jacket. Unless

otherwise specified, the unit’s electronics should not be exposed to temperatures

above 250°F.

Note: Wrench only on the wrench flats for mounting or removing the unit. Do not

use the housing or electrical termination for wrenching. The pressure cavities of

FDT series unless otherwise specified are manufactured with 15-5 and 316

stainless steels and are suitable for use with all media compatible with those

materials. Foreign objects should not be introduced into the pressure cavity. Units

must be protected from exposure to transient pressure spikes and pressures over

their rated proof pressure range.

CURRENT (4 to 20 mA) OUTPUT OPERATION

An external power supply delivering 8 to 38 VDC with minimum current capability

of 40 mA DC (per transmitter) is required to power the control loop. See Fig. A for

connection of the power supply, transmitter and receiver. The range of appropriate

©Copyright 2012 Dwyer Instruments, Inc. Printed in U.S.A. 11/12 FR# R1-443432-00 Rev.2

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

MAINTENANCE

After final installation of the pressure transmitter and its companion receiver, no

routine maintenance is required. A periodic check of system calibration is

suggested. The Series FDT transmitters are not field reparable and should be

returned if repair is needed (field repair should not be attempted and may void

warranty). Be sure to include a brief description of the problem plus any relevant

application notes. Contact customer service to receive a return goods authorization

number before shipping.

Phone: 219/879-8000 www.dwyer-inst.com

Loading...

Loading...