Page 1

MODEL FC-1000 ELECTRIC FAN SPEED CONTROL

Specifications - Installation and Operating Instructions

Bulletin E-39

The Model FC-1000 Electronic Fan Speed Control is designed to yield pre-

cise modulation of the speed of a motor. Popular 0-10 VDC input works with

most process controllers eliminating the need for more expensive dampers,

damper actuators, and linkages while improving the overall energy efficiency of

the system. This compact unit offers a field selectable hard start feature which

will initiate hard start of the motor when it recieves an input signal of 1.0 VDC or

greater for increased application flexibility. To simplify mounting, there are separate conduit openings for the low and high voltage connections. This UL recognized unit offers built in radio frequency interference (RFI) suppression and

voltage surge protection exceeding IEEE C62.41 standards.

This low cost unit enables variable control of ventilation fans, condenser fan

speed control and interface with VAV box controllers. When the fan speed control is combined with any Dwyer®2-Wire transmitter, Love Model 16A process

controller and some single faced motors up to 1 HP approved by the manufacturer for speed control applications, it provides a low cost alternative to many

damper actuated systems. Model FC-1000 fan speed controls are designed for

use only as operating controls. Where an operating control failur e would result in

personal injury and/or loss of property , it is the responsibility of the installer to add

devices (safety, limit controls) or systems (alarm, supervisory systems) that protect against, or warn of, control failure. A Dwyer®Series 1900 differential power

switch and Series AN14 indicating annunciator are recommended to warn

against fan motor burnout or other system failures.

Caution: The FC-1000 may be used only with single-phase motors approved

by the manufacturer for speed control applications.

COMPATIBLE MOTORS*

MANUFACTURER

A.O. Smith

A.O. Smith

Century

Emerson

Fasco

Franklin Electric

G.E.

G.E.

G.E.

G.E.

G.E.

*This list is intended to be used only as an initial guideline. Final selection

will depend upon the equipment’s suitability with the Model FC-1000 and

the selected motor under load.

MFG. MODEL NO.

F48SX6V14

F48SX6V18

8-161183-02

K55HXCPT-9963

U26BI

1501760400PRI

5KCP39PGC499S

5KCP48GT505

5KCP48TG1505

5KCP49ZG157AS

5KCP39SGH979S

ELECTRICAL RATING

1 HP, 200-230/277 VAC

6/10 HP, 200-230/277 VAC

1 HP, 200-230/277 VAC

1/2 HP, 108-230/277 VAC

1 HP, 200-230/277 VAC

1 HP, 108-230/277 VAC

3/4 HP, 230/277 VAC

3/4 HP, 230/277 VAC

3/4 HP, 230/277 VAC

3/4 HP, 230/277 VAC

3/4 HP, 230/277 VAC

SPECIFICATIONS

Line Voltage Range: 120-277 VAC, 50/60 Hz

Full Load Amp Rating: 9.8 @120 VAC, 9.3 @ 208 VAC,

8.0 @240 VAC, 6.9 @277 VAC.

Locked Rotor Amp Rating: 24.0.

Low Voltage Input: 24 VAC, Class 2.

Input Signal Voltage: 0-10 VDC.

Signal Input Impedance: 10K ohms.

Transient Protection: 320 V surge suppression (exceeds

IEEE C62.41 Standards).

Wiring Connections:

Signal and low voltage input: 1/4” quick connects.

Line Voltage: 10-32 screw terminals.

O

Temperature Range: -40 to 131

F (-40 to 55OC).

Construction (case): Cold rolled steel.

Enclosure: NEMA 1.

Mounting: Vertical only; four holes for #10 screws.

Weight: 1 lb, 11 oz (.77 kg).

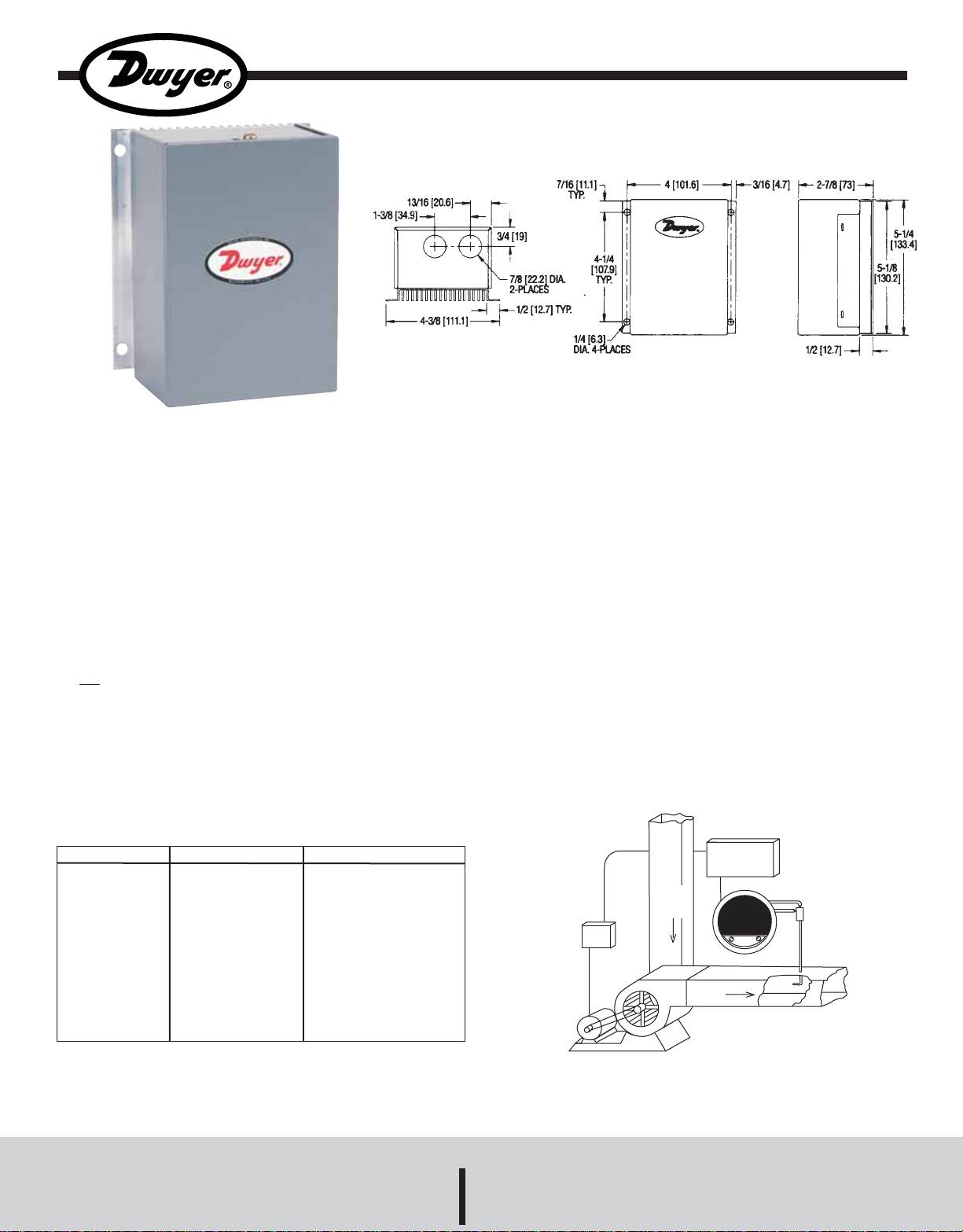

Love Model 1600

Process Controller

Return

Model FC-1000

Fan Speed

Control

Variable

Speed

Motor

Air

Air Flow

Fan

Series 641

Air Velocity

Transmitter

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

INSTALLATION

Maintaining operating temperatures within the listed product ratings is

necessary for proper operation. The FC-1000 control should be mounted

with the cooling fins in a vertical position without obstructions that may

prevent air flow through the fins. Do not mount the FC-1000 where the

control is exposed to excessive heat. For maximum ambient temperature

ratings, refer to the Temperature Range in the Specifications Section.

1. For maximum heat dissipation, locate the FC-1000 where air passes

through the cooling fins.

2. Mount the control where it can be conveniently wired to the power

supply and motor.

WIRING

CAUTION: Disconnect the power supply before the wiring connections

are made to avoid possible electrical shock or damage to the equipment.

Make all wiring connections using copper conductors only. All wiring must

be in accordance with the National Electrical Code and local regulations.

For maximum electrical ratings, refer to the Specifications Section.

CAUTION: The FC-1000 must be connected to suitable earth ground.

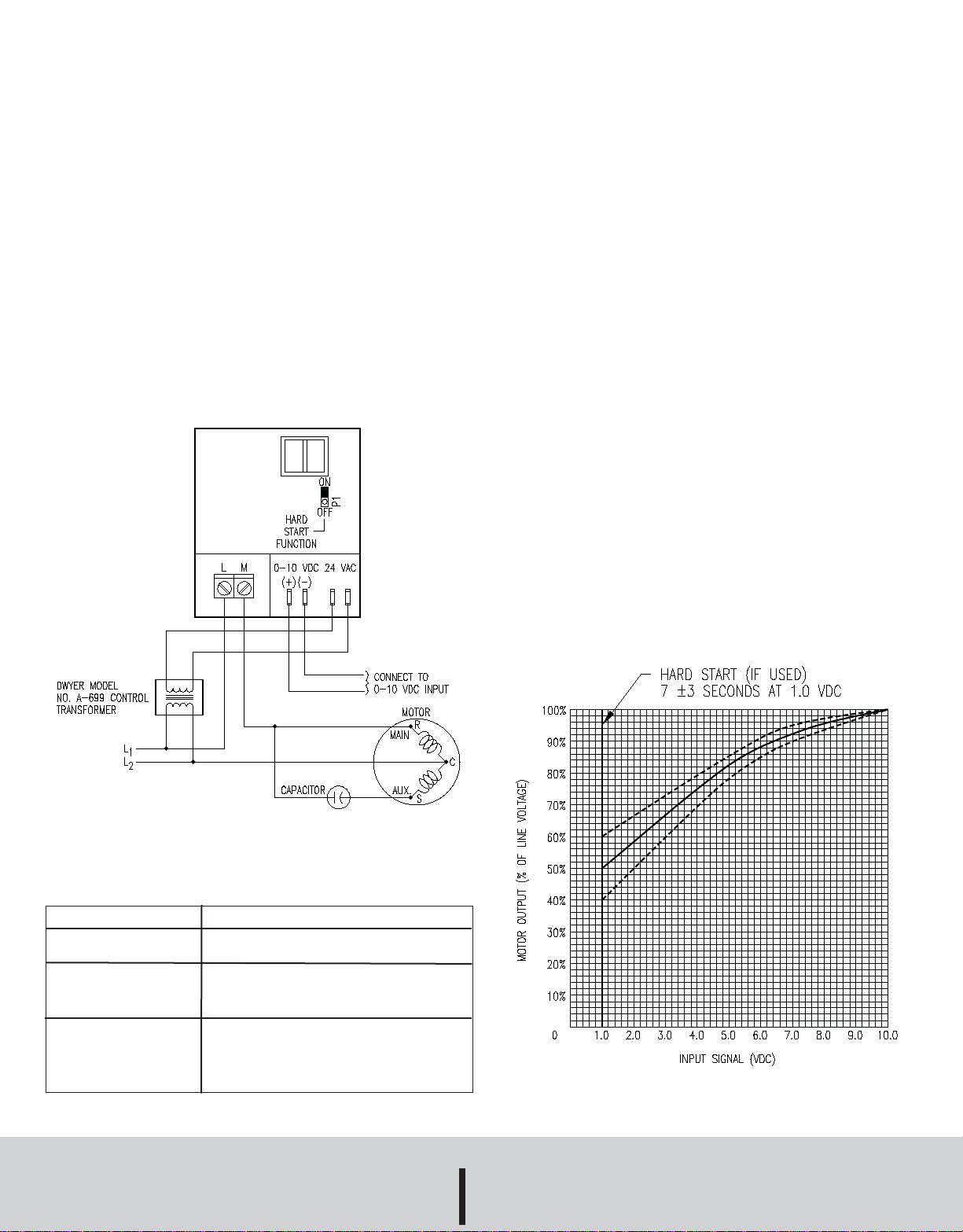

Consult wiring diagram (Fig. 1) for proper wiring.

ADJUSTMENTS

Model FC-1000 controls come factory set. There are no field adjustments

available.

CHECKOUT PROCEDURE

Before applying power, make sure installation and wiring connections are

according to job specifications.

After necessary adjustments and electrical connections have been made,

put the system in operation cycle before leaving the installation.

SELECTABLE HARD START/CONTROL OPERATION

Hard start means that the control will apply 90-100% of the line voltage

to the motor for a period of 7 (±3) seconds. After the specified time (7

seconds) for the hard start feature has elapsed, the control output will

revert to a level relative to the input signal (see fig. 2). If the input signal

remains at 1.0 VDC the control output to the motor will remain at

minimum speed. If the input signal is less than 1.0 VDC, the control

output will be zero (0). A built in time delay of 10 seconds will occur

between each hard start. If the Model FC-1000 has an input signal of 1.0

VDC or greater within this 10 second time period, the motor will restart

but it will not hard start.

The hard start feature is selected by a movable two pin jumper located in

board position P1, directly below the FC-1000’s isolation transformer (see

fig. 1). As indicated by the markings on the board, the hard start feature

is “On” when the connector is placed over the two pins which are closest

to the isolation transformer. Likewise, placement of the connector over

the two pins farthest away from the isolation transformer will turn the

hard start feature “Off.” When the hard start feature is “On,” the FC-1000

must receive an input signal of 1.0 VDC or greater in order to initiate hard

start.

FACTORY REPAIRS

In the unlikely event the Model FC-1000 should fail, the unit can be

returned to the factory for warranty repair if the warranty period has not

expired. Field repairs should not be attempted. Repairs for th Mode FC1000 in or out of warranty are done on a repair/exchange basis. Please

contact Dwyer Customer Service for a return goods authorization number

before returning the unit. All units returned for repair are to be shipped

freight prepaid, to:

Dwyer Instruments, Inc.

102 Highway 212

Michigan City, IN 46360

Attention: REPAIRDEPARTMENT

FIG. 1 PERMANENT SPLIT-CAPACITOR

CONNECTIONS TO THE MODEL FC-1000

FAN SPEED CONTROL.

OPERATIONAL SEQUENCE

VOLTAGE INPUT

Signal input of less than

1.0 VDC

Signal input of 1.0 VDC

Signal input between

1.0 and 10.0 VDC

©Copyright 2007 Dwyer Instruments, Inc. Printed in U.S.A. 8/07 FR# R6-440863-00 Rev. 1

DWYER INSTRUMENTS, INC.

MOTOR VOLTAGE(VAC, TRUE RMS)

0 volts output to motor.

Hard start (if used). 90-100% of line

voltage applied for 7 (±3) seconds after

which minimum speed will be maintained.

Motor voltage varies directly with signal

input from minimum speed to 100% of line

voltage. See figure 2 for ramp control of

output vs signal input.

FIG. 2 MODEL FC-1000 INPUT VS OUTPUT CURVE

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...