Page 1

Bulletin AV-1-FAFM

Series FAFM Fan Inlet Air Flow Measuring Probe

Specifications - Installation and Operating Instructions

A

A

A

FAFM-D-xxxx

FAFM-S-xxxx

7/8

[22.23]

INLET FLOW VIEW SECTION A-A

L

3-1/8

[79.38]

APPLICATION DIAGRAM

12

[304.80]

3-5/8

[92.20]

MODEL FAFM-D

The Model FAFM Fan Inlet Air Flow Measuring Probes use

evenly distributed total and static pressure measuring points to

deliver an accurate measurement of flows in a fan inlet. The Air

Flow Measuring Probes can be completely installed from outside

of the fan making it ideal for when proper duct locations are

unavailable. With its lightweight and durable construction in

addition to its ease of installation, this product lends itself to being

used in the HVAC industry.

B

D

1

[25.40]

1/16

[1.63]

5/16

[7.70]

MOUNTING PLATES TO

BE BENT TO FIT INLET

Ø3/8

[9.53]

L

A

B

INLET FLOW VIEW

APPLICATION DIAGRAM

4

[101.60]

L = Fan Inlet Dia.

MOUNTING PLATES TO

BE BENT TO FIT INLET

MODEL FAFM-D

SECTION B-B

1/16

[1.98]

R3/16

[4.76]

SPECIFICA T IONS

Wetted Materials: Aluminum with clear anodized finish.

Accuracy: ±2% (Note: Field Calibration May Be Required).

Max. Temperature: 400ºF (204ºC).

Minimum Design Flow: 400 fpm (2.03 m/sec).

Maximum Design Flow: 12,000 fpm (60.96 m/sec).

Process Connections: 1/4˝ NPT female.

D

3/4

[19.05]

There are two versions of the model FAFM fan inlet air flow probes

to choose from depending on the depth of the fan inlet.

INSTALLATION

For fan inlets with depth less than 3-1/2˝ (8.89 cm): Please

order a fan inlet probe with an “S” suffix. This probe has a

diameter of .375˝ (.95 cm). It employs one total flow measuring

tube and one static measuring tube. Each probe is covered with

an extruded aluminum anodized coat. Each measuring tube has

multiple sensing points.

When you unpack the Model FAFM Fan Inlet Air Flow

Measurement Probe ensure that there is no visible damage from

shipping. Inspect each sensing point on the probes to ensure that

they are not filled with debris from shipping. If there is obvious

shipping damage, the probe must be replaced prior to use to

avoid inaccurate measurements. Please contact Dwyer

Instruments, Inc. if it is necessary to replace your air flow

For fan inlets with depth greater than 3-1/2˝ (8.89 cm):

measurement probe.

Please order a fan inlet probe with a “D” suffix. This probe has a

diameter of 3-1/2˝ (8.89 cm). It employs extruded aluminum

anodized coated probes with both total and static sensors on

each tube.

DWYER INSTRUMENTS, INC.

Please note that Model FAFM Fan Inlet Air Flow Measurement

Probes should be installed in portion of the fan inlet with the

smallest diameter.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

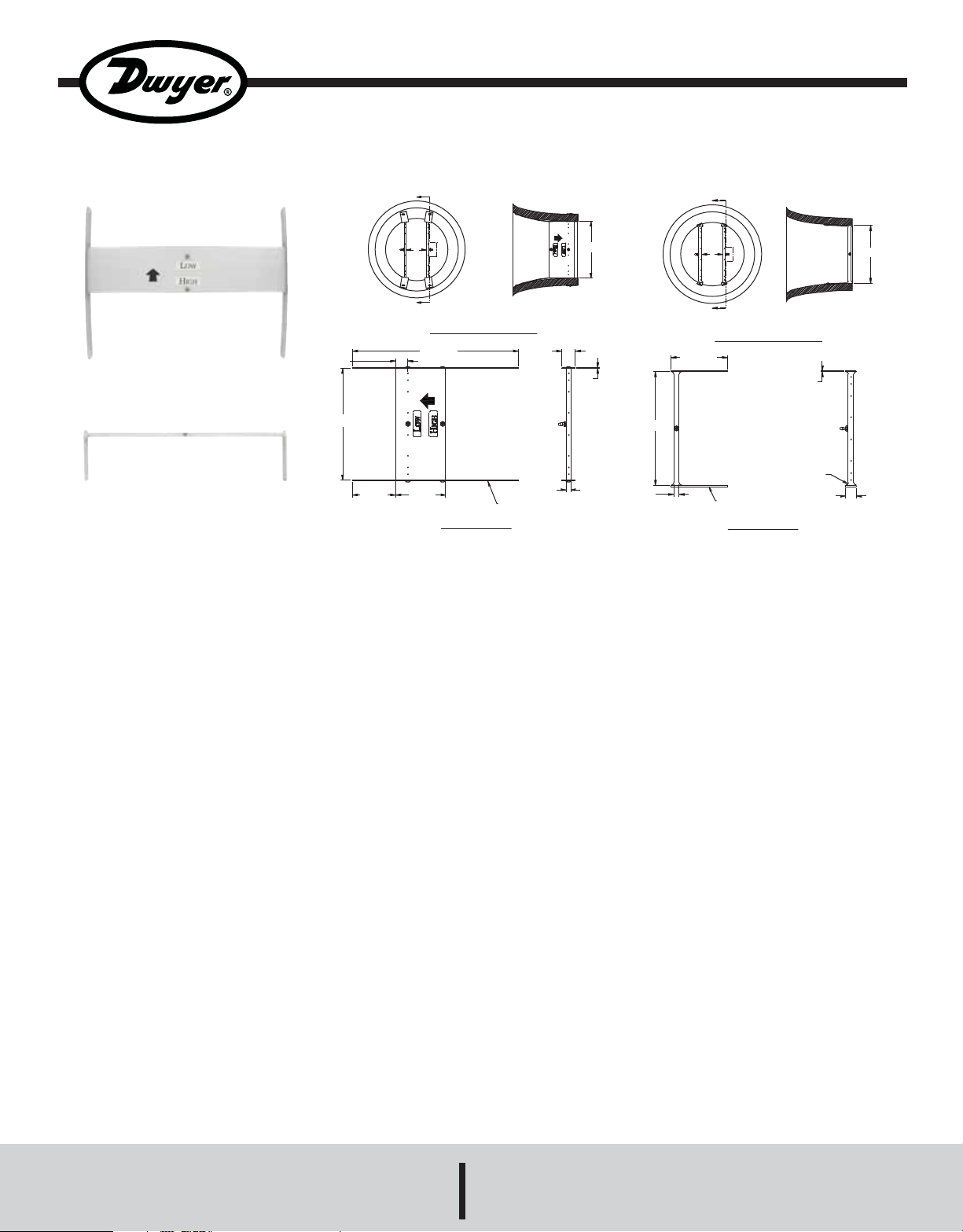

These units are meant to be installed running parallel to each other

as shown in figures 1 and 2.

Figure 1

To install the Model FAFM Fan Inlet Air Flow Measuring Probe

please refer to the following instructions:

1. Drill a minimum of two (2) holes into mounting plates.

2. Slide Model FAFM Fan Inlet Air Flow Measuring Probe Halves

into smallest diameter of the fan inlet.

3. Once in the smallest inlet diameter, push the probe to the

outside of the smallest inlet diameter and screw or rivet into

place using a minimum of two (2) screws or rivets per FAFM

half.

Note: The FAFM Air Flow Measurement Probe should be installed

with the holes in all probes visible from the outside of the fan.

4. Tee the two high and low connections to create one high and

one low output signal.

5. For double inlet fans tee all of the high and low connections to

create one high and one low output signal.

6. Connect the high and low outputs to a differential measurement

device such as a differential pressure transmitter.

CALIBRA TION

Sometimes field calibration may be required if the probe is installed

in a bad location i.e. immediately downstream of an elbow. In or der

to calibrate, you must either perform a traverse of the duct or a

sum of the air registers and compare this with the FAFM output.

Then, you must make the correction to the effective area in the

computer to make up for the error.

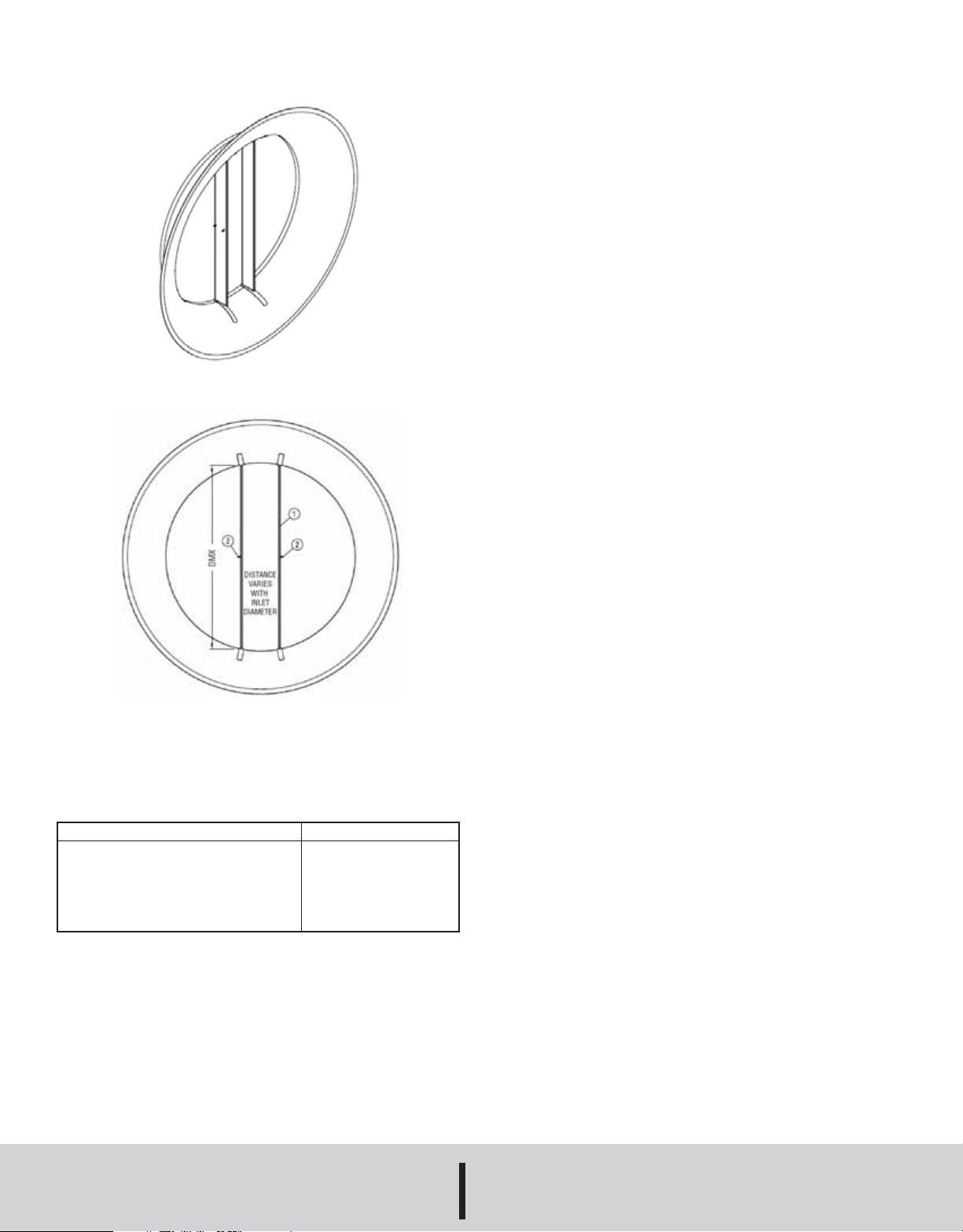

Figure 2

To determine how far apart the two halves of the FAFM should be

placed, consult the chart below.

Fan Inlet Diameter

6"-9" (10.16 cm-22.86 cm)

10"-14" (25.4 cm-35.56 cm)

15"-20" (38.1 cm-50.8 cm)

21"-24" (53.34 cm-60.96 cm)

25" (63.5 cm) and up

Probe Separation

3" (7.62 cm)

4” (10.16 cm)

5" (12.7 cm)

6" (15.24 cm)

8” (20.32 cm)

MAINTENANCE

Upon final installation, the device should be checked once a year

for a build up of dirt or debris that can be common in an HVAC

system. Also check the mounting stability once a year. Other than

this no routine maintenance is required. The FAFM model is not

field serviceable and should be returned if repair is needed (field

repair should not be attempted and may void warranty). Be sure

to include a brief description of the problem plus any relevant

application notes. Contact customer service to receive a return

goods authorization number.

©Copyright 2008 Dwyer Instruments, Inc. Printed in U.S.A. 9/08 FR# R1-443658-00

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...