Page 1

MAINTENANCE/REPAIR

Regular maintenance of the total system is recommended to assure sustained

optimum performance. These devices are not field repairable and should be

returned to the factory if recalibration or other service is required. After first

obtaining a Returned Goods Authorization (RGA) number, send the unit freight

prepaid to the following. Please include a clear description of the problem plus

any application information available.

Dwyer Instruments, Inc.

Attn: Repair Department

102 Highway 212

Michigan City, IN 46360

Important Points!

Product must be maintained and installed in strict accordance with the National Electrical Code and Dwyer product catalog and instruction bulletin. Failure

to observe this warning could result in serious injuries or damages.

An appropriate explosion-proof enclosure or intrinsically safe interface device

must be used for hazardous area applications involving such things as (but not

limited to) ignitable mixtures, combustible dust and flammable materials.

Pressure and temperature limitations shown on individual catalog pages and

drawings for the specified level switches must not be exceeded. These pressures and temperatures take into consideration possible system surge pressures/temperatures and their frequencies.

Selection of materials for compatibility with the media is critical to the life and

operation of Dwyer level switches. Take care in the proper selection of materials

of construction; particularly wetted materials.

Life expectancy of switch contacts varies with applications. Contact Dwyer if

life cycle testing is required.

Ambient temperature changes do affect switch set points, since the specific

gravity of a liquid can vary with temperature.

Level switches have been designed to resist shock and vibration; however,

shock and vibration should be minimized.

Liquid media containing particulate and/or debris should be filtered to ensure

proper operation of Dwyer products.

Electrical entries and mounting points may require liquid/vapor sealing if located in an enclosed tank.

Level switches must not be field repaired.

Physical damaged sustained by the product may render it unserviceable.

DWYER INSTRUMENTS,INC.

P .O.BOX 373 MICHIGAN CITY, INDIANA 46361, U.S.A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Lit-By Fax: 888/891-4963

Single-Station Level Switches

Instruction Bulletin No. 202503

Series Mounting HEX Size

F7-C**

F7-SS3**

F7-BB**

F7-T*

F7-ST**

F7*

F7-PS*

F7-PVC*

F7-SS6**

* Plastics ** Alloys

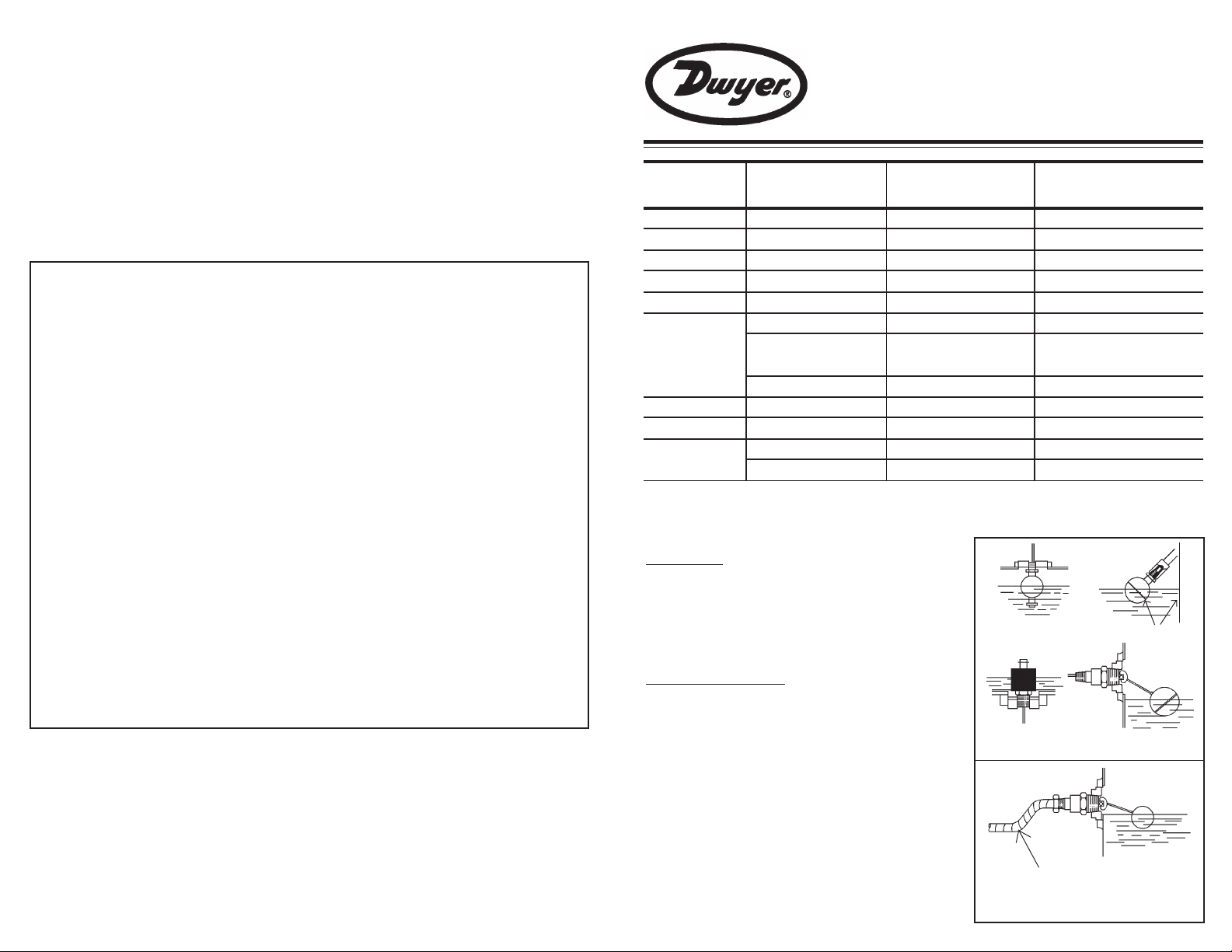

Installation

A standard NPT female boss in tank top, bottom or side is all that is required. Units operate

in any attitude - from the vertical to a 30° inclination - with lead wires up or down. Standard

IPS pipe extends units to any intermediate level

in the tank. (Figure 1)

Moisture Protection: When moisture exists in

conduit and extension pipes, the potential for

this moisture to "wick" down the wire leads and

into the switch assembly exists. Should this

happen, the switch will appear to be closed due

to a high resistance path through the moisture.

The following suggestions may help to prevent

this from happening:

1. Pitch conduit away from the level switch when

possible, so that condensation will drip away

from the level switch assembly.

(Figure 2)

1/8" NPT

1/8" NPT

1/4" NPT

1/4" NPT

1/4" NPT

1/8" NPT

1/8" NPT 1/2”

1/8” NPT

1/4" NPT

1/4” NPT

1/8" NPT

3/8" - 24 Str. Thd.

21/32"

1/2"

1/2"

5/8"

5/8"

1/2"

1/2"

5/8"

5/8”

1/2"

3/4"

Float

Diameter

1"

1-1/32"

1-7/8"

2-1/8"

2-1/16"

1"

1-1/4"

(Slosh Shield Version)

1-7/8" (P/N F7-LL)

1-7/8"

1-1/2”

1"

1-1/2"

30°

Max.

- Figure 1 -

Conduit

- Figure 2 -

Page 2

2. When a vertical run of extension pipe is used

to extend a level switch down from the top of the

tank, a non-conductive silicone oil should be

used to fill the vertical run. Alternatively, an ap-

Silicone

Oil

propriate potting may be used to fill the vertical

run to occupy the space in which condensation

will normally form. (Figure 3)

CAUTION

Most of Dwyer level products incorporate a potting cap or are fully potted. Due to the bonding

characteristics of the potting to the wire leads,

there is no way of assuring a water-tight seal at

- Figure 3 -

the potting joint. Our potting cap will resist moisture to some degree, but the precautions mentioned above should be used to assure

moisture doesn't enter the switch and cause a short.

Consult your Dwyer representative for more

suggestions on how to lessen the effects of moisture.

Thread Treatment

1. Sealing: When threading metal threads into a metal coupling, pipe sealant or

®

Teflon

sealing plastic threaded units, a compatible pipe sealant such as No More Leaks

from Permatex

2.

tape is recommended. Due to potential compatibility problems, when

®

is recommended.

Tightening: When threading a plastic level switch into a metal coupling, the

TM

installer should use a suitable wrench and tighten the threads one to one and onehalf additional turns past hand-tight. Over-torquing of the threads will result in

damage to the plastic mounting plug.

No More Leaks is a trademark of Permatex® Industrial Corp., a subsidiary

of Loctite Corporation. Teflon is a registered trademark of DuPont Corporation

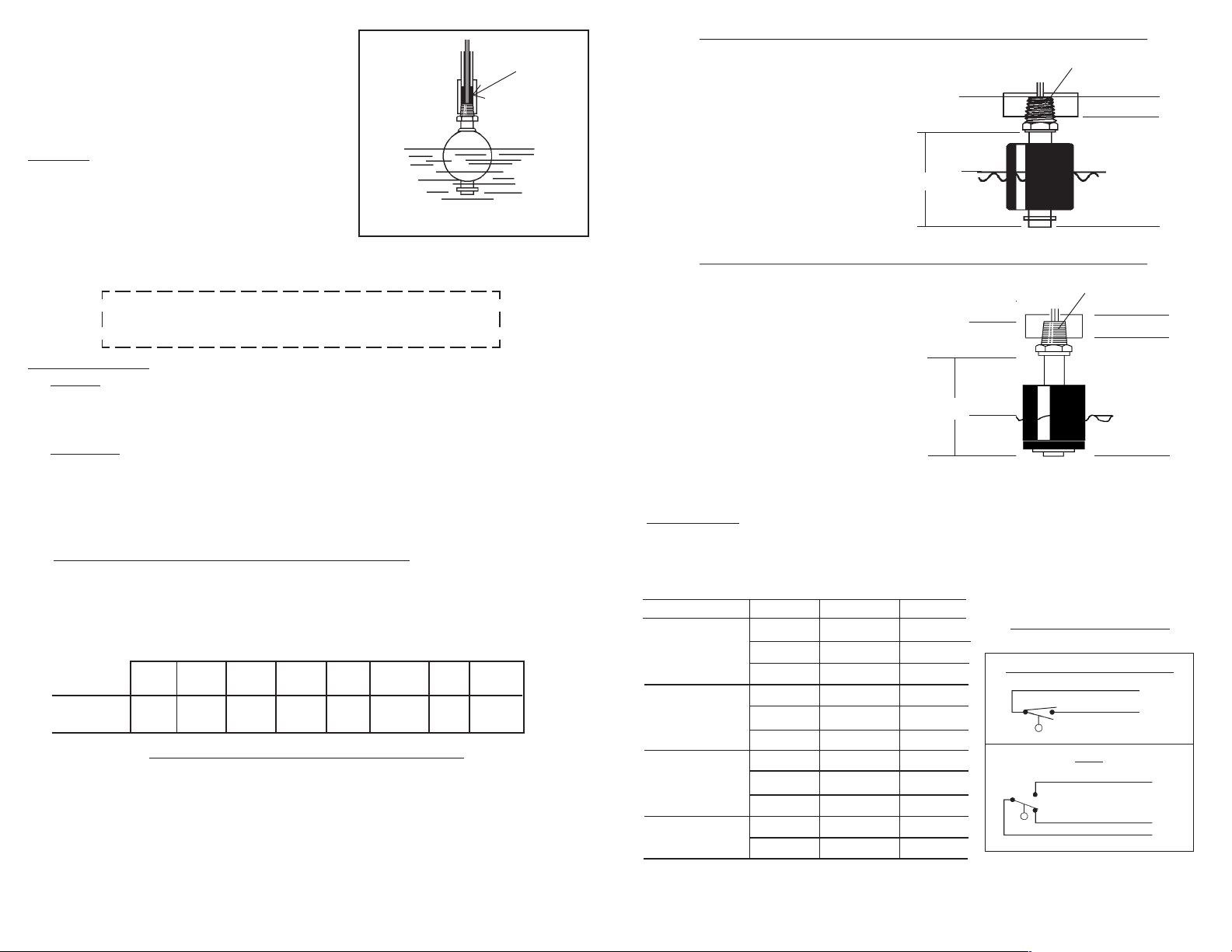

3. The Effect of Thread Engagement on Actuation Points

The length of mounting threads engaged at installation is important in calculating

switch actuation points and the actual length of stem extending into the tank. Use

the chart below to find the thread engagement length (T) for a given NPT size.

Factor the dimension into any calculation of switch actuation levels (L) and overall

length (L0).

1/8"

.27"

1/4"

.39"

NPT 1/2"

T Dim.

.53"

3/4"

.55"

1"

.68"

1-1/4"

.71"

2"

.76"3"1.20"

Definition of Variables Used in Examples

A = Mounting Length

T = Thread Engagement

P = Distance from coupling (bung) top to inside surface of tank or bracket

= Overall length from bottom of mounting

L

0

L = Switch actuation level as measured from inside surface of tank or

bracket to fluid surface

L1 = Switch actuation level, nominal, as measured from bottom of

mounting (based on a liquid specific gravity of 1.0)

1/4” NPT

Internally Mounted F7-BB

L

↓

T

↑

Actual

Tank

Intrusion

↓

↓

T

↑

Actual

Tank

Intrusion

↓

(Standard Length)

F7-BB Series internally mounted

through a 1/4" NPT hole. To

calculate "L" dimension:

L = L

L = 1-3/16" + (21/32" - .39")

+ (A-T)

1

L = 1.46"

Internally Mounted F7-C/F7-SS3

(Standard Length)

F7-C/F7-SS3 internally mounted

through a 1/8" NPT hole. To

calculate "L" dimension:

L = L

+ (A-T)

1

L = .63" + (.56" - .27")

L = .92"

L

0

Fluid

Level

21/32”

1-3/16”

Fluid

Level

L

0

↓

A

↑

↓

9/16”

L

1

↑

L

↓

1/8” NPT

↓

A

↑

=5/8”

↓

Electrical Data

Standard reed switches in Dwyer level switch units are hermetically-sealed, magnetically

actuated, make-and-break type. Switches are SPST or SPDT and are rated in V olt-Amps (V A).

See the chart below for maximum load characteristics of Dwyer level switches. CAUTION:

Contact protection is required for transient or high in-rush current.

VA

10

General Use

20

Pilot Duty

50

General Use

100*

* Not U.L. Recognized ** Limited to 50,000 operations

Volts

0-50

120

100

0-30

120

240

0-50

120

240

120

240

Amps AC

.2

.08

N.A.

.4

.17

.08

0.5

.4

.2

.8**

.4

Amps DC

.13

N.A.

.10

.3

.13

.06

0.5

.4

.2

N.A.

N.A.

Typical Wiring Diagrams

(Circuit Condition Dry)

SPST, Normally Open or Closed

SPDT

COM

N.O.

N.C.

Red

Red

Orange,

Y ellow

or

White

Red

Black

Loading...

Loading...