Page 1

Bulletin V-8

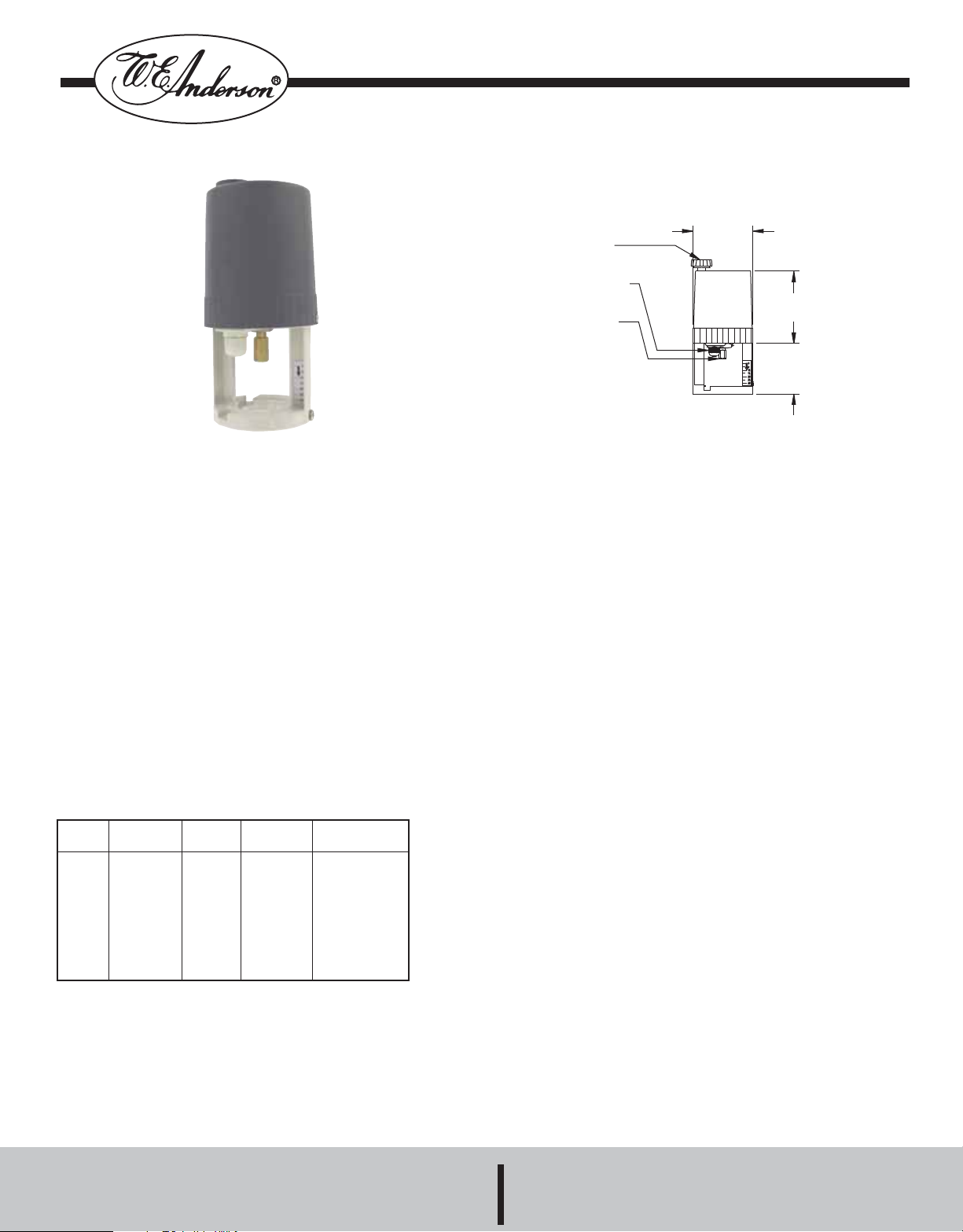

Ø4-1/32

[102.4]

4-57/64

[124.22]

3-15/16

[100]

KNOB

POWER

CONNECT

CONNECTOR

Series EVA2 and EVA3 Electric Actuators

Specifications - Installation and Operating Instructions

The Series EVA2 and EVA3 Electric Actuators are designed to mount

directly onto the Series GV globe valves, creating a complete, low cost,

and compact control valve package. Floating or modulating control inputs

are available, and the 24 VAC synchronic motor includes a magnetic

clutch to protect the motor in stall conditions. Actuators are ruggedly

constructed with a fire-proof ABS housing and robust aluminum bracket.

Features include a visual position indicator and manual override to make

this actuator an excellent choice for any size area, large or small.

FEATURES

• Manual override

• Compact size

• Floating control or selectable 0-10 VDC or 4-20 mA proportional

control

• Reversible direction on proportional models

• Magnetic clutch protects motor in stall conditions

Model

EVA2F

EVA2M

EVA3F

EVA3M

Actuator

Action

Floating

Modulating

Floating

Modulating

Output

Force

225 lb

(1000 N)

225 lb

(1000 N)

337 lb

(1500 N)

337 lb

(1500 N)

Valve

Size

1˝ to 2-1/2˝

1˝ to 2-1/2˝

1˝ to 2-1/2˝

1˝ to 2-1/2˝

Compatible

Valve Models

GV2__ , GV3__

GV2__ , GV3__

GV2__, GV3__

GV2__, GV3__

SPECIFICATIONS

SERIES EVA2, EVA3

Output Force: EVA2: 225 lb (1000 N); EVA3: 337 lb (1500 N).

Power Requirements: 24 VAC.

Power Consumption: EVA2F (EVA3F): 5.5 VA; EVA2M (EVA3M):

7.5 VA.

Cycle Time: EVA2F (EVA2M): 97 sec/in. (3.8 sec/mm); EVA3F

(EVA3M): 164 sec/in. (6.45 sec/mm).

Enclosure Rating: IP40.

Housing Material: Fire-proof ABS plastic (UL94V-0).

Bracket Material: Aluminum.

Operating Temperature: 36 to 131°F (2 to 55°C).

Storage Temperature: -4 to 149°F (-20 to 65°C).

Humidity Limit: <90%, non-condensing.

Electrical Connection: Screw terminal.

Modulating Input: 0 to 10 VDC or 4 to 20 mA.

Weight: EVA2F (EVA3F): 2.43 lb (1.1 kg); EVA2M (EVA3M): 3.31 lb

(1.15 kg).

INSTALLATION

1. Tightly screw the valve connector on the valve body. Please pay

attention to the direction of the connector.

2. Install the actuator bracket on the valve connector.

3. Insert the U-type connector into the bracket, and lock the connector

nut.

4. Lift up the valve stem and put the lock nut and indicator guide onto it,

then rotate the connecting rod of the actuator and let it rotate onto the

valve stem. Use spanner to lock the locknut after adjusted into position.

5. In vertical installations, leave enough head room to unscrew the

actuator prior to servicing the valve body.

W.E. ANDERSON DIV., DWYER INSTRUMENTS, INC.

P.O. BOX 358 • MICHIGAN CITY, INDIANA 46361 U.S.A.

6. Wire the unit according to the appropriate Wiring Diagram.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

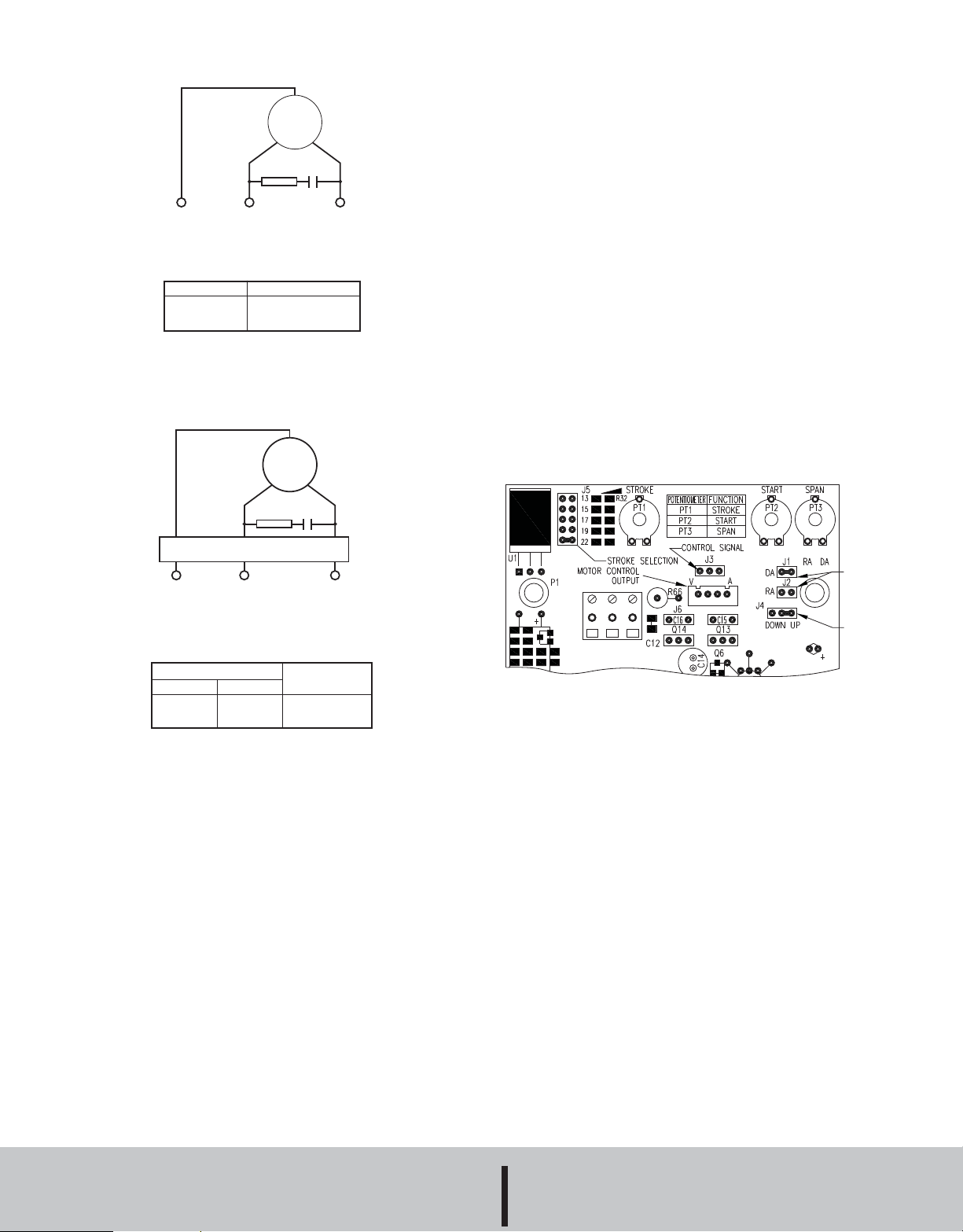

WORKING

STATE

WORKING

DIRECTION

SELECTION

WHEN WITHOUT

CONTROL SIGNAL

1

COM

2

DOWN

3

UP

M

PCB

1

POWER

SUPPLY

24 VAC

2

SUPPLY/

SIGNAL

COM

3 (+)

CONTROL SIGNAL

0-10 VDC OR

4-20 mA DC

M

EVA2F (EVA3F) WIRING DIAGRAM

Terminals

1-2

1-3

EVA2M (EVA3M) WIRING DIAGRAM

Actuator Rod

Down Extend

Up Contract

OPERATION

1. The actuator is driven by a reversible synchronous motor with a

magnetic clutch. The motor can provide stable torsion at stopping

conditions due to the magnetic force created by the motor rotor and the

magnetic clutch. When power is taken away, the motor will stop at its

current position.

2. The signal of the proportional type actuator controls the clockwise or

counter-clockwise rotation of the motor.

3. EVA2M (EVA3M) actuators can be jumper selected for 0.51, 0.59,

0.67 or 0.75 inch valve strokes. Factory stroke setting is 0.75”.

4. The input control signal is jumper selectable between 0-10V or 4-20

mA DC. Factory setting is 0-10V DC input mode.

5. Direct (DA) or Reverse (RA) direction operation is also jumper

selectable. The two states are opposite of each other.

EVA2M (EVA3M) PCB SETTING DIAGRAM

Input Control Signal

DA

Increase

Decrease

Note: Actuator must be protected from dripping water. Damage to

internal elements and motor may occur. Do not cover actuator with

material that does not permit heat exchange.

©Copyright 2009 Dwyer Instruments, Inc. Printed in U.S.A. 12/09 FR# R2-443387-00 Rev.1

W.E. ANDERSON DIV., DWYER INSTRUMENTS, INC.

P.O. BOX 358 • MICHIGAN CITY, INDIANA 46361 U.S.A.

RA

Decrease

Increase

Actuator Rod

Down

Up

MAINTENANCE

The Series EVA2 and EVA3 Electric Actuators are not field serviceable

and should be returned if repair is needed (field repair should not be

attempted and may void warranty). Make sure to cut off power supply

when disconnecting the actuator from the valve. Contact customer

service to receive a return goods authorization number before shipping.

Be sure to include a brief description of the problem plus any relevant

application notes.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...