Page 1

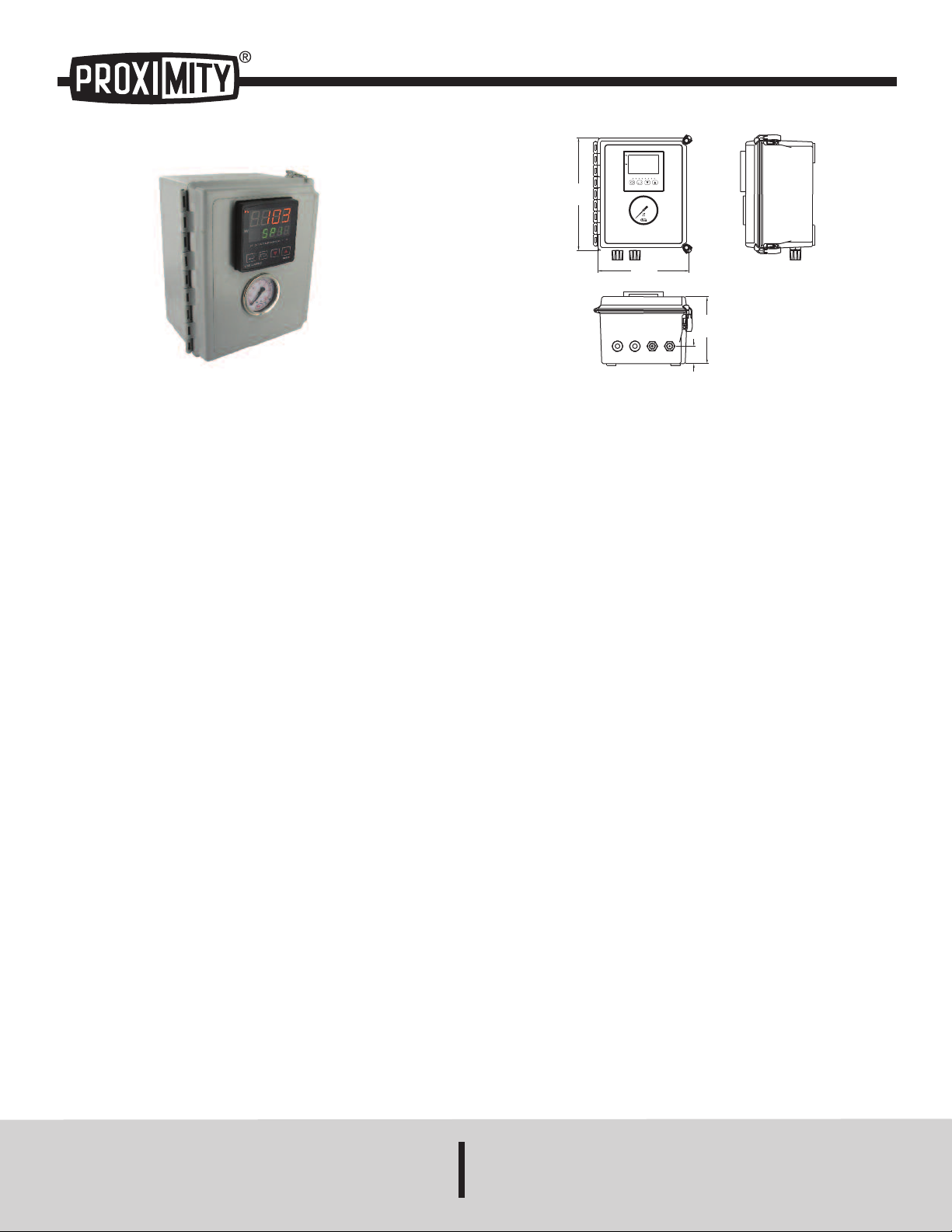

Series EP1000 Electro-pneumatic Controller

OUTPUT SUPPLY

SERIES 4B

LOVE CONTROLS

AT OUT1 OUT2 ALM3ALM1 ALM2

°

F °C

1

0-1/2

[

266.7]

8

-1/5

[

215.9]

6

-1/4

[

158.75]

1

-5/8

[

41.28]

Specifications - Installation and Operating Instructions

Bulletin F-84

The Series EP1000 Electro-pneumatic Controller combines

the highest quality instrumentation in one compact NEMA 4X

enclosure for easy, low cost installation. Simply provide a supply

pressure and voltage with a standard thermocouple, RTD, DC

voltage or DC current input to this unit and a traditional

pneumatic process quickly converts to a state-of-the-art

electronic operation. The versatile microprocessor based

controller incorporates a high level of standard features. Typical

function setup items appear in the control menu only when the

function is selected, so you don’t have to wade through

unnecessary items. Standard features include Self-Tune, fully

adjustable PID and Auto/Manual control.

INSTALLATION

Mounting: Loosen four (4) mounting screws on back of

enclosure and rotate mounting feet to vertical position. Mount

enclosure to a flat surface in a vertical position.

PNEUMATIC CONNECTIONS

CAUTION: Use of a supply gas other than air can create a

hazardous environment because a small amount of the gas

continuously vents to the atmosphere.

Connect a clean dry air supply from 20 to 1000 psig to the port

marked “supply”. Connect the control element to the “output”

port. Output is 0 to 20 psig. Both ports are 1/4˝ NPT. It is

important that the line does not leak. This will affect control

operation.

ELECTRICAL CONNECTIONS

Two (2), 1/2˝ conduit holes are provided for AC power and input

signal connections. Run power and signal leads in separate

conduit. Connect AC power and input signal to terminals shown

on page 5 of controller instruction manual 949-1195. Route wire

carefully and allow proper slack in wires to allow door to open.

Wires can be secured with wire tires.

SPECIFICATIONS

Front Panel Selectable Inputs: Thermocouple, RTD, DC voltage

or DC current.

Supply Pressure:

Minimum: EP1000: 18 psig (1.24 bar);

EP1011: 33 psig (2.28 bar);

Maximum: 100 psig (6.89 bar).

Output:

EP1000: 3 to 15 psig (0.21 to 1.03 bar);

EP1011: 6 to 30 psig (0.41 to 2.07 bar).

Accuracy: ±1.0% of span.

Linearity: ±0.75% of span.

Hysteresis: ±1.0% of span.

Repeatability: ±0.5% of span.

Power Requirements: 100 to 240 VAC, 50/60 Hz.

Temperature Limits: 32 to 122°F (0 to 50°C).

Pressure Connections: 1/4˝ female NPT.

Air Consumption: 0.03 SCFM (0.5 m

Output Capacity:

4.5 SCFM (7.6 m

12 SCFM (20 m

3

/h) at 25 psig (1.72 bar) supply;

3

/h) at 100 psig (6.89 bar) supply.

3

/h) typical.

Enclosure: NEMA 4X.

Weight: 8 lb 1 oz (3.67 kg).

SETTING PROGRAM

The EP1000 has been factory set for a 100 ohm platinum RTD

(DIN 0.00385) input and a range of 0 to 250°F. This can be

easily changed to any other input by following the

“Programming” Instructions in the controller manual. See page 3

to get started. This also describes using all of the additional

features.

©Copyright 2014 Dwyer Instruments, Inc. Printed in U.S.A. 4/14 FR# RP-440935-00 Rev. 4

PROXIMITY CONTROLS

A DIVISION OF DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000

Fax: 219/872-9057

www.dwyer-inst.com

e-mail: info@dwyermail.com

Loading...

Loading...