Page 1

Bulletin IN-EDAW

Series EDA Electronic Pressure Controller

Specifications - Installation and Operating Instructions

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, IN 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

ONTENTS

C

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Model Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

nstallation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 – 5

I

npacking and Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

U

lectrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

E

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 18

Front Panel Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Set Points & Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 8

Alternation (Lead/Lag) Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

rogramming Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 11

P

ain Menu Selections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

M

enus and Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12 - 18

M

Security Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Operation Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Output Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14 – 15

Display Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Advanced Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Test Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Failsafe Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Diagnostic Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Page 3

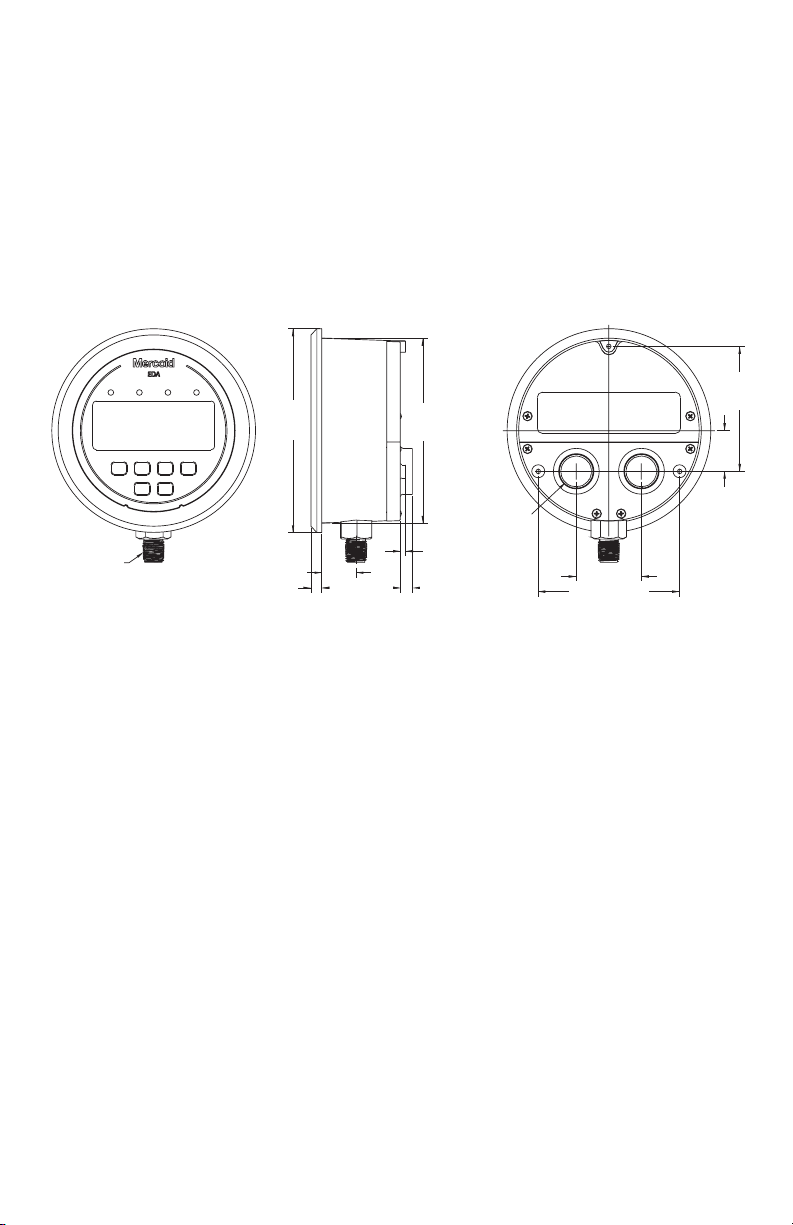

Dimensions

1/4 MALE NPT

WITH 3/4 [19.05]

WRENCHING HEX

9/32 [7.14]

Ø 5

[127.00]

Ø 4-17/32

[115.09]

1

[25.40]

3-1/16

[77.89]

27/32

[21.43]

1-59/64 [26.16]

2X 5/16 [7.93]

3-15/32 [88.11]

1-5/8 [41.28]

[40.88]

3X 1/8 [3.18]

1/2 FEMALE NPT

CONDUIT ENTRY

1

Page 4

SPECIFICATIONS

Service: Compatible liquids and gases.

Wetted Materials: 316L SS.

ousing: Glass filled plastic.

H

ccuracy: ±1% of F.S. including linearity, hysteresis, and repeatability (indicator and transmitter).

A

tability: < ± 2% of F.S. per year.

S

Pressure Limits: Ranges up to 6,000 psi: 1.5 x range; 8,000 psi range: 10,000 psi.

Temperature Limits: Ambient: 20 to 140°F (-6.6 to 60°C); Process: 0 to 176°F (-18 to 80°C).

Compensated Temperature Limits: 32 to 122°F (0 to 50°C).

Thermal Effect: ±0.05% of F.S./°F.

Process Connection: 1/4˝ NPT male, 1/4˝ BSPT male, or 7/16” SAE.

Display: 4-digit backlit LCD (Digits: 0.60˝H x 0.33” W).

Display Update: 600 ms (dampening set to 1).

ower Requirements: 12 to 28 VDC ( ) / AC ( ~ ) 50/60 Hz. (Can work at 8 VDC ( ) for 45 seconds). For T5

P

ption: 14 to 30 VDC ( ) / AC ( ~ ) 50/60 Hz.

o

ower Consumption: 2.5 watts.

P

Electrical Connections: Removable terminal blocks with two 1/2˝ female NPS conduit connections.

Enclosure Rating: Weatherproof type 4X IP65 (IP65 not evaluated by UL). Unit is rated weatherproof but if unit is

panel mounted, panel will not maintain 4X rating.

Warm Up Time: <10 seconds.

Mounting Orientation: Any position.

Weight: 1.18 lbs (535 g).

Installation Category: II (transient over-voltage).

Pollution Degree: 2.

Altitude Limit: 6560 ft (2000 m) max.

Environment: Intended for indoor and outdoor use.

Humidity: 0 to 95% RH up to 104°F (40°C) non-condensing, 10 to 50% at 140°F (60°C) non-condensing.

SWITCH SPECIFICATIONS

Switch Type: 2 SPDT relays.

Electrical Rating: 5A @ 120/240 VAC ( ~ ) 50/60 Hz, 1A @ 28 VDC ( ).

Repeatability: ±1% of FS (switching only).

Set Points: Adjustable 0-100% of FS.

Switch Indication: External LED for each relay on the front panel.

Switch Reset: Manual or automatic.

TRANSMITTER SPECIFICATIONS

Output Signal: 4 – 20 mA, 1 - 6 VDC ( ), 1 - 5 VDC ( ), 0 - 5 VDC ( ), or 0 - 10 VDC ( )(direct or

reverse output selection).

Minimum Excitation: 14 VDC ( ).

Zero and Span Adjustments: Menu scalable within the range.

2

Page 5

Model Number Chart

Example

eries

S

ousing

H

rocess

P

Connection

Electrical

Connection

ange

R

Transmitter

Output

Options

*Not UL listed.

Display

The EDA has two displays: a lower larger display and a smaller upper display. The Home Display is the normal display while the control is in operation if there are no errors or functions active. The Home display will indicate the

process variable at the current condition with the lower display and the selected pressure units for the process variable with the upper display. When programming the unit both displays are also used. The Programming Chart in this

instruction manual indicates what both displays show while programming the unit. For programming descriptions in

this instruction manual the format used is “lower display – upper display”. For example Ctrl – 1SP shows that Ctrl

would be in the lower display and 1SP would be in the upper display.

DA

E

DA

E

W

1

N

1

B

A1

E1

1

0

02

03

04

05

6

0

7

0

08

09

10

11*

12*

T0

T1

T2

T3

T4

T5

EDAW-N1E1-01T0-SST

Electronic Pressure Controller

eatherproof

W

/4˝ NPT male bottom

1

/4˝ BSPT male bottom

1

7/16˝ SAE male bottom

Two 1/2˝ female NPT

conduit connections

0 – 30” Hg vacuum

0 – 20 psi

0 – 60 psi

0 – 100 psi

– 150 psi

0

– 300 psi

0

– 600 psi

0

0 – 1000 psi

0 – 1500 psi

0 – 3000 psi

0 – 6000 psi

0 – 8000 psi

None

4 to 20 mA

1 to 5 VDC

0 to 5 VDC

1 to 6 VDC

0 to 10 VDC

STW

Stainless Steel Tag

NIST

NIST Certificate

23444

Special Cleaning

When the user presses the E key to edit an item’s value the upper display will flash “EDIT” and the lower display will

blink. When the user presses the E key to then save the edit to the value the upper display will flash “SAVE” and

the lower display will stop blinking.

3

Page 6

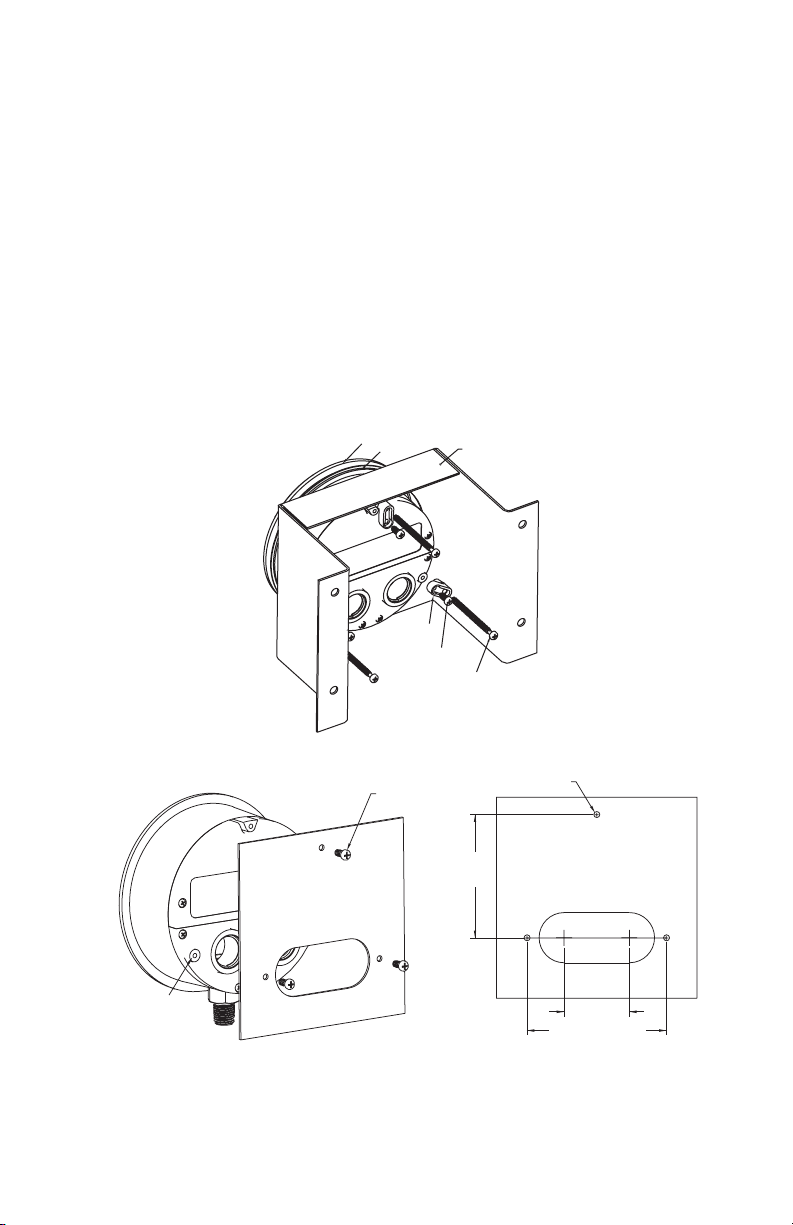

1.0 INSTALLATION

A-370 MOUNTING

BRACKET

EDAW

SEAL

3X MOUNTING

LUG

3X 4-20 X 3/8 SCREWS

3X 6-20 X 2-1/4 SCREWS

3X 4-20 X 3/8

SCREWS

3X ø 1/8 [3.18]

3-1/16

[77.89]

MOUNTING

HOLE DEPTH

3/8 [9.53]

1-5/8

[41.28]

3-15/32 [88.11]

1.1 UNPACKING

emove the EDA from the shipping carton and inspect for damage. If damage is found, notify the carrier immediate-

R

y.

l

1.2 MOUNTING

The EDA can be pipe, panel, or surface mounted. For pipe mounting thread the unit into a mating female fitting on

the pipe. Use a wrench on the 3/4˝ hex at the base of the housing to tighten the unit to the mating fitting. Do not

hread the unit in by force on the housing. For panel mounting the unit fits into a 4-13/16” (122.24 mm) panel cut out.

t

nsert the unit into the panel opening and secure in place with the machine screws and adaptors provided with the

I

nit as shown in Figure 1 below. Maximum panel thickness is 1/8” (3.5 mm) with supplied screws. For surface mount-

u

ing, panel mount the unit into the A-370 mounting bracket (See the Dwyer catalog or website for ordering details)

also shown in Figure 1. The unit can also be directly surface mounted, as shown in Figure 2, with the proper panel

cutout for the conduit entrances. Support the pressure connection hex with a wrench if attaching a fitting to the unit

in the case of panel or flush mounting so that the pressure connection does not twist. Use a small amount of

plumber’s tape or other suitable sealants to prevent leaks around fitting.

Figure 1: Panel Mounting and Mounting in A-370 Bracket

Figure 2: Surface Mounting

4

Page 7

1.3 ELECTRICAL CONNECTIONS

S

P1

RELAY

5A 250 VAC FOR LOADS USING 120/240 VAC POWER

1A 32 VDC FOR LOADS USING 30 VDC POWER

375 mA 250 VAC

LOAD 1

LOAD 2

LINE

INPUT

12 TO 30 VDC/AC

POWER

S

P2 OR ALARM

RELAY

CAUTION: POWER MUST BE OFF WHILE WIRING CONNECTIONS ARE BEING MADE.

CAUTION: Do not exceed the specified supply voltage rating. Permanent damage not covered by the warranty

ay result.

m

AUTION: To maintain type 4X rating of the enclosure, 1/2 NPT conduit fittings must have a UL type 4X out-

C

oor rating.

d

Note: Installation must be made in accordance with local codes and regulations. When fishing wire through the conduit

onnection do not allow the wire to touch or press on components on the boards. Damage to the circuitry may result.

c

Electrical connections are made to the removable terminal blocks inside the enclosure. Remove the top back cover, do

not remove bottom cover. Feed stripped and tinned leads through the conduit opening and connect them as shown in

Figure 3. The EDA provides two 1/2˝ NPT female ports for conduit connection. The conduit connections must be made

such that condensation is not allowed to enter the sensor housing. If necessary install a conduit breather drain in a sep-

rate conduit body to prevent buildup of moisture. It is recommended that shielded twisted pair wire be used for the

a

ransmitter output option if the potential exists for interference from external noise sources. When replacing top back

t

cover tighten screws to 2 ±.25 in. lbs.

Figure 3: Wiring

An external power supply of 12-28

VDC/AC with minimum current capability

of 200 mA must be used to power the unit.

The power supply connection is not polarity sensitive so the positive and negative

connections may be made to either terminal of CONN9 terminal block.

For voltage output option, connect the voltage receiver (-) to terminal 1 and voltage

receiver (+) to terminal 2 of the CONN10

terminal block. For current output option,

connect the current receiver (-) to terminal

3 and current receiver (+) to terminal 4 of

CONN10 terminal block. DO NOT APPLY

EXTERNAL POWER TO CONN10 TERMINALS - PERMANENT DAMAGE NOT

COVERED BY WARRANTY WILL

RESULT.

Loads can be connected to connectors CONN7 and CONN8 terminal blocks based on the Control settings:

• For single set point mode (CtrL-1SP), connect the Load to SP1 relay (CONN7).

• For two set points mode (CtrL-2SP), connect the Load1 to SP1 relay (CONN7) and

Load2 to SP2 relay (CONN8).

• For single set point and alarm mode (CtrL-SPAL), connect the Load1 to SP1 relay

(CONN7) and Load2 to ALARM relay (CONN8).

Wiring

An external switch or circuit breaker should be added to during the installation as a disconnecting device. The switch

or circuit breaker must meet the requirements of IEC 60947-1 and IEC 60947-3, shall disconnect all current carrying

conductors, and shall not interrupt the protective earth ground. The disconnecting switch or circuit breaker must be

marked or labeled with the symbols “I” for on and “O” for off, per IEC 60417-5007 & IEC 60417-5008 and shall be

marked as “Disconnecting Device”. Do not position the PLS in a space where it is difficult to operate the disconnecting

device that provides power. 300V @ 90°C 18 AWG/0.75 mm

2

wiring with PVC or equivalent insulation with 94-V0 or FV0 flammability rating is recommended for the switch outputs and power. Terminal blocks rated for 16-22 solid or stranded copper conductor. 6 lb in is suggested tightening torque.

WARNING

easy reach of the operator. This disconnect device must include a label indicating its function as a mains disconnect. A

As a permanently installed piece of equipment, a power disconnect switch, circuit breaker, or other

approved disconnect device must be installed in close proximity to the installed board and within

circuit breaker or fuse device is recommended (see Figure 3).

Explanation of Symbols:

Description

Direct current

Alternating current

Protective conductor terminal

On (supply)

Off (supply)

Symbol

Publication

IEC 50417 - 5031

IEC 50417 - 5032

~

IEC 50417 - 5019

IEC 50417 - 5007

IEC 50417 - 5008

5

Page 8

2. OPERATING INSTRUCTIONS

HOME POSITION FUNCTION MAIN MENU FUNCTION

ITEM FUNCTION

Enter into items

Peak/Valley resets

display to present value.

.1 FRONT PANEL & KEY FUNCTIONS

2

Figure 4: Front Panel Functions

Key Functions

6

Page 9

2.2 SET POINTS & ALARMS

The hot key provides direct access to the Set Point and Alarm settings.

The Set Point and Alarm settings that are displayed are based upon the Control (CtrL) menu item.

Setting Set Points and Alarms

Set Point Adjustment

Adjusting the set points is quick and simple. Instead of setting a set point and dead band, simply adjust SP1H,

Set Point 1 High, and SP2H, Set Point 2 High, for the desired relay turn on point, and then adjust SP1L, Set Point

1 Low, and SP2L, Set Point 2 Low, for the desired relay turn off point.

In the above graph, an instrument with a 100 psi range would have the SP1 relay turn ON at 80 psi and OFF at 40

psi. SP1H sets the relay turn ON point, and SP1L sets the relay turn OFF point.

7

Page 10

Relay Action

The relays outputs normally function in the direct acting mode, which means the relays turn ON with an increase in

pressure. SP1 and SP2 may be configured to act as reverse acting relays (refer to the CtrL menu item). When set

for reverse acting, SP1H and SP2H set the relay turn OFF point, and SP1L and SP2L set the relay turn ON point.

The above graph demonstrates direct and reverse action on process (pressure) change.

Alternating (Lead/Lag) Operation

The EDA is designed to easily operate a pair of pumps in an alternating operation to minimize pump wear. The unit

has programmable on and off set points for pump one and two. If the lead/lag feature is turned off then the relays

remain attached to their corresponding set points, SP1H and SP1L control relay 1 (pump 1) and SP2H and SP2L

control relay 2 (pump 2). There is no alternating function.

If lead/lag feature is turned on then the relays will alternate with set points SP1H and SP1L to SP2H and SP2L with

every cycle of set points. The Last relay turned off will be last relay turned on with the next cycle. On the first cycle

on increase of pressure, assuming direct acting, the SP1 relay (pump 1) will come on and then on further increase

of pressure the SP2 relay (pump 2) will come on. On the subsequent decrease of pressure the SP2 relay (pump 2)

will come off and then the SP1 relay (pump 1) will come off. When pressure increases on the next cycle the relay

used on the last cycle for SP2 will now be used for SP1, so that SP1 now controls pump 2 and SP2 now controls

pump 1. Even if SP2 is not used on the pressure cycle the relays still alternate on next cycle.

8

Page 11

.3 PROGRAMMING CHART

HOME

MAIN MENUS

ITEMS SETTINGS

2

MENU MAP

9

Page 12

HOME

M

AIN MENUS ITEMS SETTINGS

CONTROL MODE

SELECTION

ITEMS PRESENT

WHEN “CtrL” SET

TO “1SP”, “2SP”

OR “SPAL”

ITEMS PRESENT

W

HEN “CtrL” SET

T

O “2SP”

ITEMS PRESENT

WHEN “CtrL” SET

TO “SPAL”

10

Page 13

HOME

SEE PAGE 17.

MAIN MENUS ITEMS SETTINGS

11

Page 14

2.4 MAIN MENU SELECTIONS

enu Selections

M

ress the MENU button to start the menu so that the upper right displays reads MENU. Press the ▼ key to advance

P

to the next menu item. You can press the ▲ key to go back to the previous menu. Press the E key to enter a menu.

SECr Security Menu

O

Out Output Menu

iS Display Menu

d

AdU Advanced Functions Menu

tESt Test Menu

FAIL Failsafe Menu

Menus and Values

SECr Security Menu

SECr When the security item is selected, the present security level is displayed in the upper right hand

Lock out access to set point and alarm settings, or lock out access to all settings.

PEr Operation Menu

elect pressure units, zero the display, and turn the backlight on or off.

S

Select relay mode of operation, alternating function, time delay, and lamp indication.

Monitor and adjust display related settings: Peak, Valley and Dampening.

Modify advanced function parameters: transmitter output scaling, direct or reverse output

setting, calibration, or restoring factory default calibration.

Simulate input over the range without pressure to test switch and transmitter output

function.

Set the relay and transmitter outputs to certain preset values when failsafe conditions occur.

Error codes will show on the display indicating the problem. User chooses if relay is deenergized, energized, or no action taken. With transmitter option, user chooses an output

of 3.6 mA, 22 mA, or no action taken.

display. To change the security level, adjust the number displayed to the password value in the

Password Table, shown below, by pressing the ▲ or ▼ key and then pressing the E key at the desired

security level.

Security Level

Displayed

1

2

3

4

The password values shown in the table cannot be altered, so retain a copy of these pages for future reference.

Access

All menus access

Menu Access

SP/AL Locked

SP/AL Access

Menus Locked

All settings locked

Password

Value to Enter

10

70

90

111

12

Page 15

OPEr Operation Menu

nit Pressure Units

U

Pressure Range vs. Available Units

PSI

-14.70

20.00

60.0

100.0

150.0

300.0

600

1000

1500

3000

6000

8000

ith the display reading Unit - PSI, press the E key. The upper display will blink. Press the ▼ key to

W

hange unit then press E key to save the new unit.

c

PSI Pounds per square inch

FS % of full scale

OZIN Ounces per square inch

MWC Centimeters of water column

C

PA Megapascals

M

AR Bar

B

MBAR Millibar

KPA Kilopascals

FTWC Feet of water column

KGCM Kilograms per square centimeter

MMHG Millimeters of mercury

INWC Inches of water column

INHG Inches of mercury

INHg

KG/CM2

-1.033

1.406

4.22

7.03

10.55

21.09

42.2

70.3

105.5

210.9

422

562

BAR

-1.013

1.379

4.14

6.89

10.34

20.68

41.4

68.9

103.4

206.8

414

551

-29.93

40.7

122.2

203.6

305.4

611

1222

2036

3054

FTWC

-33.94

46.1

138.4

230.7

346.0

692

1384

2307

3460

KPA

-101.4

137.9

414

689

1034

2068

MPA

-0.101

0.1379

0.414

0.689

1.034

2.068

4.14

6.89

10.34

20.68

41.4

55.1

INWC

-407.3

554

1663

2771

MBAR

-1013

1379

CMWC

-1034

1406

MMHg

-761

1035

3105

OZ/IN2

-235.2

320.0

960

1600

2400

% FS

100

100

100

100

100

100

100

100

100

100

100

100

ZERO Auto Zero

Note: DO NOT apply any pressure when performing this function. With the display

reading xx - ZERO, press the E key. The upper display will blink. Press E again to zero the display.

The display will read 0.0 if the zero offset is less than ±5% of full scale.

bCLt Backlight

ON Backlight always on.

OFF Backlight always off.

30 Backlight stays on for 30 minutes.

10 Backlight stays on for 10 minutes.

5 Backlight stays on for 5 minutes.

2 Backlight stays on for 2 minutes.

13

Page 16

Ut Output Menu

O

trL Control Mode

C

SP SP1, Set Point 1, Reverse or Direct Acting

1

1SP Single set point.

2SP Two fully independent set points.

SPAL Single set point and alarm.

IR Direct. Relay turns on with increasing pressure.

D

EV Reverse. Relay turns on with decreasing pressure.

R

DEL1 SP1, Set Point 1, Time Delay

Ed1 SP1, Set Point 1, Lamp

L

The following SP2 function values are only activated when CtrL is set to 2SP:

2SP SP2, Set Point 2, Reverse or Direct Acting

DEL2 SP2, Set Point 2, time delay

LEd2 SP2, Set Point 2, Lamp

LdL9 Relay Alternation (See page 8)

Sets the amount of time a set point condition must be continuously met before the set point condition

is recognized. The DEL1 delay is adjustable from 0-60 seconds.

OFF The SP1 LED on the front panel turns OFF when the SP1 relay turns OFF.

The SP1 LED on the front panel turns ON when the SP1 relay turns ON.

ON The SP1 LED on the front panel turns ON when the SP1 relay turns OFF.

The SP1 LED on the front panel turns OFF when the SP1 relay turns ON.

DIR Direct. Relay turns on with increasing pressure.

REV Reverse. Relay turns on with decreasing pressure.

Sets the amount of time a set point condition must be continuously met before the set point

condition is recognized. The DEL2 delay is adjustable from 0-60 seconds.

OFF The SP2 LED on the front panel turns OFF when the SP2 relay turns OFF.

The SP2 LED on the front panel turns ON when the SP2 relay turns ON.

ON The SP2 LED on the front panel turns ON when the SP2 relay turns OFF.

The SP2 LED on the front panel turns OFF when the SP2 relay turns ON.

OFF There is no alternating function.

ON Relays will alternate with set points SP1H/L and SP2H/L with every cycle of set

points. 2SP control mode only.

14

Page 17

The following alarm function menu items are activated when CtrL is set to SPAL:

ELA Alarm Delay

D

ets the amount of time an alarm condition must be continuously met before the alarm condition is

S

recognized. The alarm delay is adjustable from 0 - 60 seconds.

LEdA Alarm Lamps

AL Alarm Type (see Alarm Adjustment below)

Alarm Adjustment

Alarm settings are dependent upon the selected alarm type. The EDA pressure controller alarm may be configured

as a High Alarm, Low Alarm, or High/Low Alarm. Alarm settings may be set to anywhere within the range of the

instrument. The dead bands of the alarms are fixed at 1% of full scale.

OFF The ALLO LED or ALHI LED on the front panel turns OFF when the alarm relay

N The ALLO LED or ALHI LED on the front panel turns ON when the alarm relay

O

IGH High alarm only.

H

LOW Low alarm only.

HILO For a high and low guard band type alarm. Share the same relay output.

urns OFF. The ALLO LED or ALHI LED on the front panel turns ON when the

t

larm relay turns ON.

a

turns OFF. The ALLO LED or ALHI LED on the front panel turns OFF when the

alarm relay turns ON.

ALrE Alarm Reset

AUTO Automatic reset.

HOLD Manual reset. An alarm is reset by pressing the RST key on the front panel.

ALiH Low Alarm Inhibit

OFF Alarm inhibit is off.

ON Alarm inhibit is on.

Note: If ALiH is selected ON, a low alarm condition is suspended upon power up until the process value passes

through the alarm set point once.

15

Page 18

iS Display Menu

d

PEAK Peak

ALY Valley

V

AMP Dampening

D

AdU Advanced Menu

POL, Process Output Low, and POH, Process Output High are used to scale the transmitter output for a unit with

the output option of 4 to 20 mA, 0-5 VDC, 0-10 VDC, 1-5 VDC, or 1-6 VDC. Below shows with 4 to 20 mA output

option.

POL Process Output Low

POH Process Output High

CAL – ZERO Zero Calibration

The Peak feature stores the highest pressure reading the instrument has measured since

the last reset or power up. At power up PEAK is reset to the present pressure reading. To manually

eset the PEAK value, press the RST (RESET) key while in PEAK.

r

The Valley feature stores the lowest pressure reading the instrument has measured since

the last reset or power up. At power up VALY is reset to the present pressure reading. To manually

reset the VALY value, press the RST (RESET) key while in VALY.

djust from 1-15. Dampening stabilizes the display from instabilities due to things such as vibration

A

nd excessive pressure fluctuations. The dampening setting adjusts the amount of readings that are

a

averaged for each display update. Adjust the dampening value until the display reads a stable value for

the application.

Set to the desired display reading for the 4 mA output. May be set from 2% below

minimum scale up to POH.

Set to the desired display reading for the 20 mA output. May be set from POL to 2% above maximum

scale.

DO NOT apply any pressure when performing this function. With the display

reading CAL - ZERO, press the E key. The upper display will blink. Press the E

key again to complete the zeroing of the instrument or press the MENU key to cancel.

CAL – FS Full-scale Calibration

trAn sets the transmitter output option function for a unit with the output option of 4 to 20 mA, 0-5 VDC, 0-10 VDC,

1-5 VDC, or 1-6 VDC. Below shows with 4 to 20 mA output option.

trAn

DIR Direct Output. 4 mA output at zero, 20 mA output at full scale pressure.

REV Reverse Output. 20 mA output at zero, 4 mA output at full scale pressure.

CAL - DFLT Factory Default Calibration

With the display reading CAL - FS, apply full-scale pressure to the unit, press the E key.

The upper display will blink. Press the E key again to complete the

calibration or press the MENU key to cancel.

With the display reading CAL - DFLT, press the E key. The upper display will blink.

Press E again to restore the original factory calibration values or press the MENU key

to cancel.

16

Page 19

tESt Test Menu

ESt When selected the unit simulates a pressure input over the range to test the programming and output

t

FAIL Failsafe Menu

he Failsafe menu is used to set the relay and transmitter outputs to certain preset values when failsafe conditions

T

ccur. Error codes will show on the display indicating the problem. See Diagnostic Error Messages on the next page.

o

unction. To start an automatic simulated cycling through the pressure range press the E key. This test

f

will run continually until the E key is pressed again. To manually adjust the simulated pressure

press the ▲ or ▼ key to adjust the pressure value. To exit tESt press the MENU key.

rEL Relay Output Failsafe Condition

OUtP sets the transmitter output option failsafe condition for a unit with the output option of 4 to 20 mA, 0-5 VDC,

0-10 VDC, 1-5 VDC, or 1-6 VDC. See below chart of transmitter output action according to output signal type.

OUtP Transmitter Output Failsafe Condition

FrEs Failsafe reset

OPEN The relay is de-energized upon failsafe condition. The NO contacts will be

LSE The relay is energized upon failsafe condition. The NO contacts will be closed,

C

NORM No change applied to the relay upon failsafe condition.

LOW Transmitter output goes to low failsafe condition.

HIGH Transmitter output goes to high failsafe condition.

NORM No change applied to transmitter output upon failsafe condition.

AUTO Automatic reset - Failsafe is reset automatically when the failsafe error condition

HOLD Manual reset - Failsafe is reset when the MENU key is pressed.

opened, and the NC contacts will be closed.

and the NC contacts will be opened.

Output signal

LOW

HIGH

is removed.

4-20 mA

3.6 mA

22 mA

0-5 VDC

-0.125 VDC

5.625 VDC

0-10 VDC

-0.250 VDC

11.250 VDC

1–6 VDC

0.875 VDC

6.625 VDC

1-5 VDC

0.9 VDC

5.5 VDC

17

Page 20

4. DIAGNOSTIC ERROR MESSAGES

Meaning

isplay

D

Err1

Err2

rr3

E

rr4

E

Err5

5. MAINTENANCE/REPAIR

Upon final installation of the Series EDA, inspect and clean with water or damp cloth at regular intervals. The Series

EDA is not field serviceable and should be returned if repair is needed (field repair should not be attempted and may

void warranty.

6. WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on our website. Contact customer service to receive a

Return Goods Authorization number before shipping the product back for repair. Be sure to include a brief description of the problem plus any additional application notes.

ow temperature limit

L

temperature below 0°F has been applied to the sensor

A

igh temperature limit

H

A temperature above 180°F has been applied to the sensor

Sensor failure

The micro-controller is receiving invalid signal from the sensor

Over pressure limit

roof pressure have been exceeded

P

eypad short

K

©Copyright 2013 Dwyer Instruments, Inc.

DWYER INSTRUMENTS, INC.

Printed in U.S.A. 6/13

Phone: 219/879-8000 www.dwyer-inst.com

FR# 76-443725-00 Rev.4

P.O. BOX 373 • MICHIGAN CITY, IN 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...