Page 1

Series EBV Electric Bin Vibrator

MODEL EBV-3

D

E

A

B

C

Specifications - Installation and Operating Instructions

he Series EBV Electric Bin Vibrator incorporates adjustable force features

T

ithout creating irritating noise. The low amperage draw at 120V reduces power

w

consumption and makes the vibrators useable in any application. The EBV

eliminates drawbacks associated with non-adjustable constant force units. The

conventional fix force units are sized with narrow operating limits and may not

move material from bins or pack material in containers if the moisture content

hanges. The adjustable force feature increases application flexibility; reducing

c

quipment downtime and labor expense. The EBV is capable of running

e

ontinuously at 100% force output without overheating or mechanical damage.

c

Model

EBV-1

EBV-2

BV-3

E

BV-4

E

Max Power

Kw

0.09

.11

0

.21

0

.28

0

Centrifugal Force

Kg

Hp

71

0.12

5

.15

9

0

89

.28

1

0

23

.38

3

0

Lb

156.5

09.4

2

16.7

4

12.1

7

Current

Max Amps

1.03

.3

1

.62

2

.43

3

Weight

Lb

9.3

0.1

1

5.4

1

1.6

2

Bulletin L-EBV

Dimensions - inches (mm)

odel

M

A

BV-1

E

5-1/8

(130)

EBV-2

EBV-3

E

PECIFICATIONS

S

ower Requirements: 120 VAC.

P

Power Consumption: See model

chart.

Temperature Limits: -4 to 104°F (-20

to 40°C).

nclosure: Aluminum.

E

nclosure Rating: IP 66 (NEMA 4X).

E

IBRATION FORCE CALCULATION

V

or Bins and Hoppers:

F

alculate the weight of the material in the transition (sloping part) of the bin or

C

hopper (not the straight wall above the transition). Divide by 10 and the sum left is

the force needed on the vibrator. For example: if your calculated weight is 1000 lb

divided by 10 equals 100, you will need a vibrator producing 100 lb of force.

BV-4

-1/8

5

130)

(

-1/8

5

130)

(

6-7/64

(155)

N

E

junction box.

Rotational Speed: 3600 RPM.

Weight: See model chart.

Approvals: CE.

C

B

8-5/16

5-23/64

(211)

(136)

5

136)

(

6

159)

(

6-23/32

(170)

oise Level: 20 dB.

lectrical Connection: Electrical

-23/64

-17/64

-5/16

8

211)

(

-3/32

9

231)

(

10-23/64

(263)

D

4-11/64

(106)

-11/64

4

106)

(

-11/64

4

106)

(

4-7/16

(113)

E

2-43/64

(68)

2

68)

(

2

68)

(

5-1/8

(130)

-43/64

-43/64

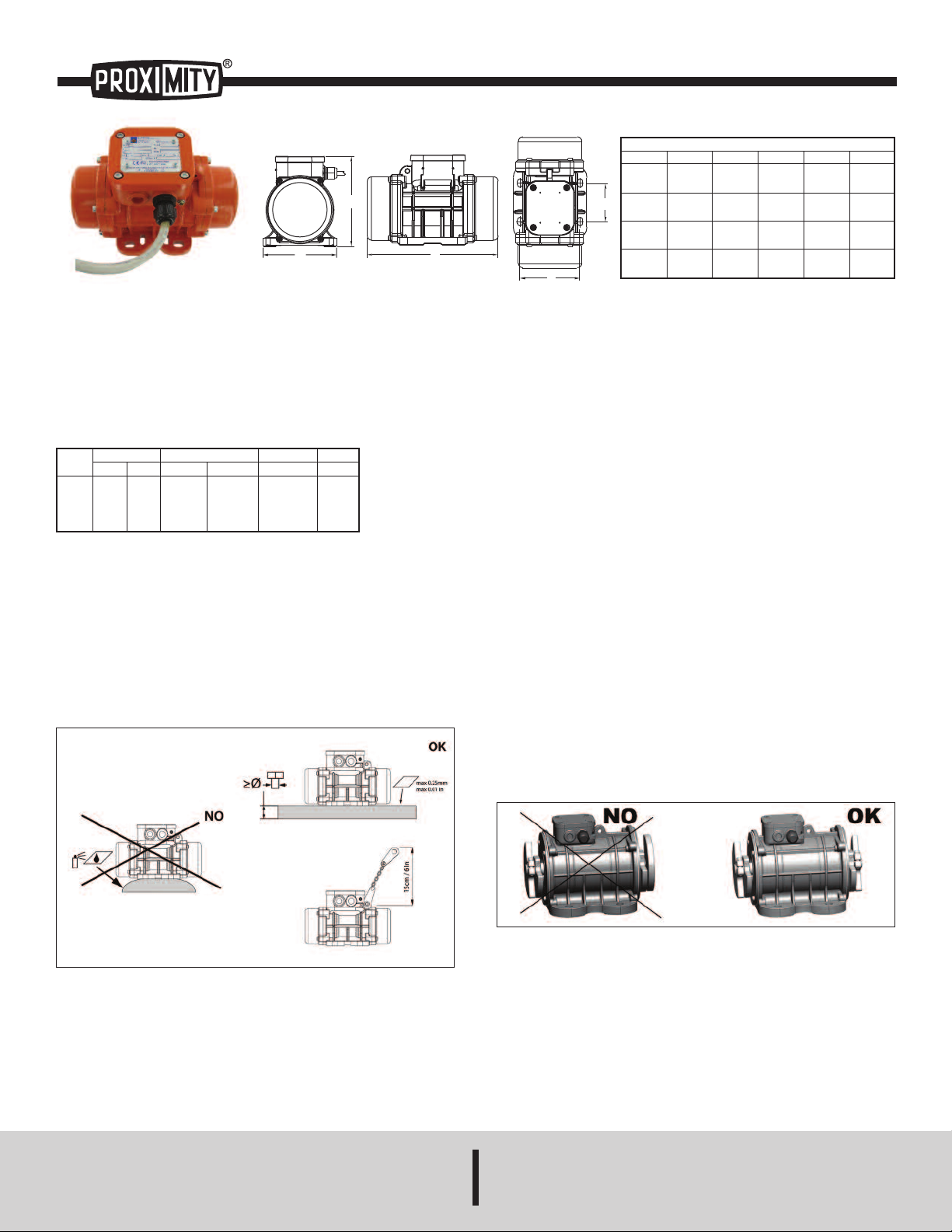

Installation

1. Before installation, especially if the apparatus has been stored in the warehouse,

remove the side covers from the weights and check to make sure the shaft turns

freely.

2. The EBV electric vibrator can be installed in any position. Fix the electric vibrator

on a rigid area to avoid induced vibrations causing breakage or cracks; if this is not

possible, use plates and ribbing for reinforcement.

3. The mounting surface must be level (max 0.25 mm/ max 0.01 in) so that the

vibrator feet rest uniformly and perfectly in contact with the mounting surface, to

avoid internal stresses which can lead to breakage of the vibrator feet.

Figure 1

4. To mount the electric vibrator, use bolts, nuts and flat washers.

5. Remember that most breakdowns are due to incorrect mounting.

6. Anchor the electric vibrator using a chain with a length and cross section suitable

for supporting the electric vibrator with a maximum fall of 15 cm (6 inches), in case

of accidental detachment.

For Screens:

1.When vibrating the screen, multiply the weight of material on the screen by two

and the sum is the force needed on the vibrator.

2. Mounting the vibrator on the screen-frame and vibrating both material and frame,

multiply total weight of material and frame by three to get vibrator force needed.

Vibrating Packing Tables:

Multiply total weight of material and carton by two to get force needed.

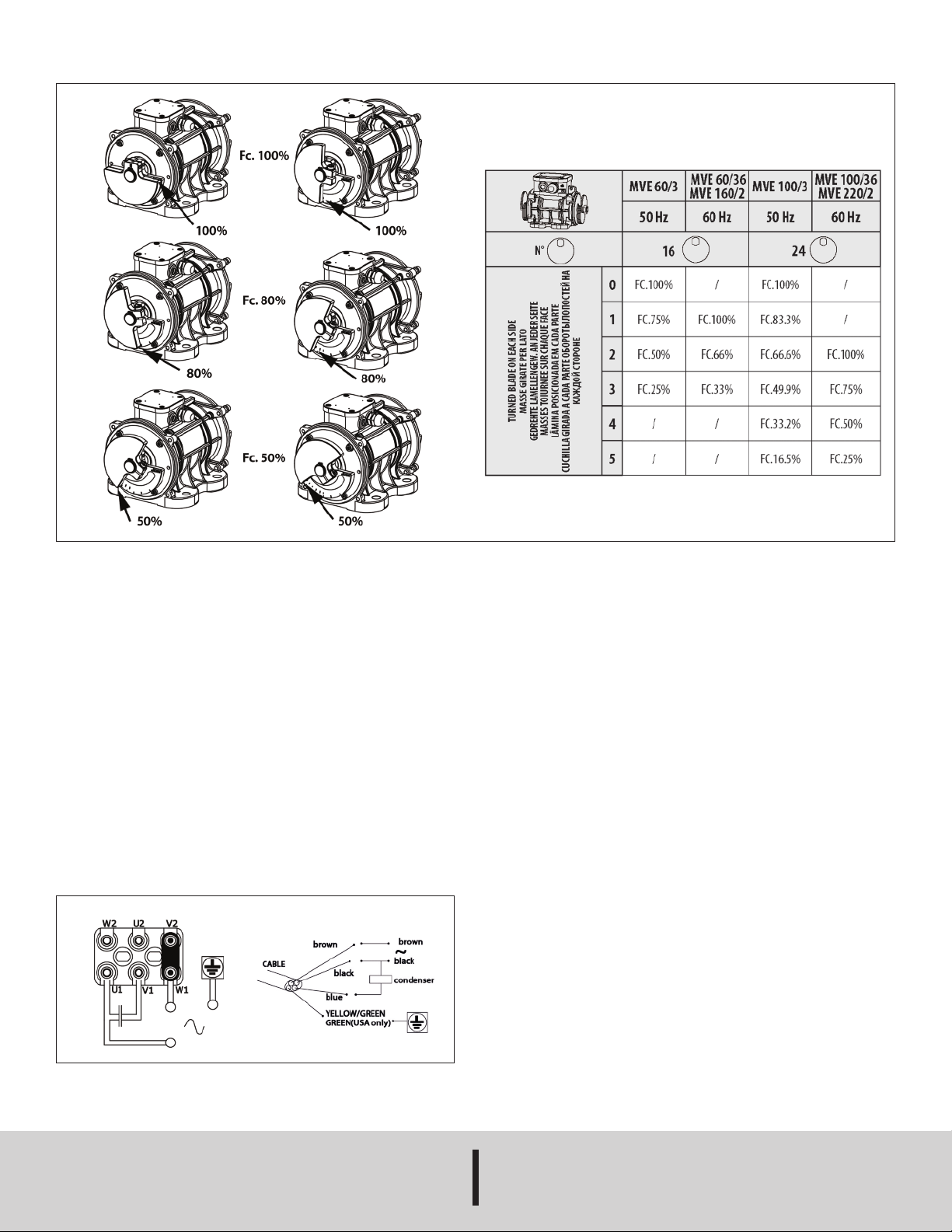

Centrifugal Force Adjustment

1. Remove the side covers.

2. Unscrew the screws used for locking the movable weight.

3. Bring the eccentric weights to the required value indicated in the following

drawings.

Figure 2

4. It is necessary to make sure the weights are adjusted in the same direction at

both ends.

5. Once the weights are brought to the required value, tighten the bolts to hold the

weights in place.

6. After carrying out the operation on both sides, refit the covers using the same

screws and washers taking care to make sure the gaskets are fitted correctly in

their seats.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyermail.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

eight Adjustment

W

Wiring

The power supply mains must be in conformity to the safety standards established

by the competent authorities of the place in which the operations are carried out.

1. Check to make sure the mains voltage is the same as that indicated on the

electric vibrator rating plate.

2. Disconnect the line before carrying out maintenance or while adjusting the

weights. For single phase electric vibrators, wait for at least one minute before

opening the junction box to allow the capacitor to discharge. All repairs or

replacement of components must be carried out exclusively by special personnel.

3. For single phase electric vibrators, it is necessary to check the capacitor to make

sure it corresponds to the rating plate.

4. Use a flexible power cable with 4 wires, one of which is yellow/green (green only

for the U.S.A.) used for grounding. While connecting the electric vibrator to the line,

the yellow-green ground wire must always be longer to prevent it breaking first, in

the event of yielding.

5. Wires used to power the vibrators should be at least 4 mm².

Figure 3

MAINTENANCE

Before carrying out any maintenance or cleaning on the machine, make sure the

conditions are safe.

Cleaning

1. Dust deposits must never exceed a thickness of 5 mm.

2. Use only a damp cloth to remove the dust.

3. Frequency of cleaning depends on the type of product handled by the appliance

in which the electric vibrator is inserted.

4. Do not use high pressure water jets on the electric vibrator.

The EBV is not field serviceable and should be returned if any repair is needed

(field repair should not be attempted and may void warranty). Be sure to include a

brief description of the problem plus any relevant application notes. Contact

customer service to receive a returns good authorization number before shipping.

©Copyright 2014 Dwyer Instruments, Inc. Printed in U.S.A. 8/14 FR# R4-443808-00 Rev. 2

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyermail.com

Loading...

Loading...