Page 1

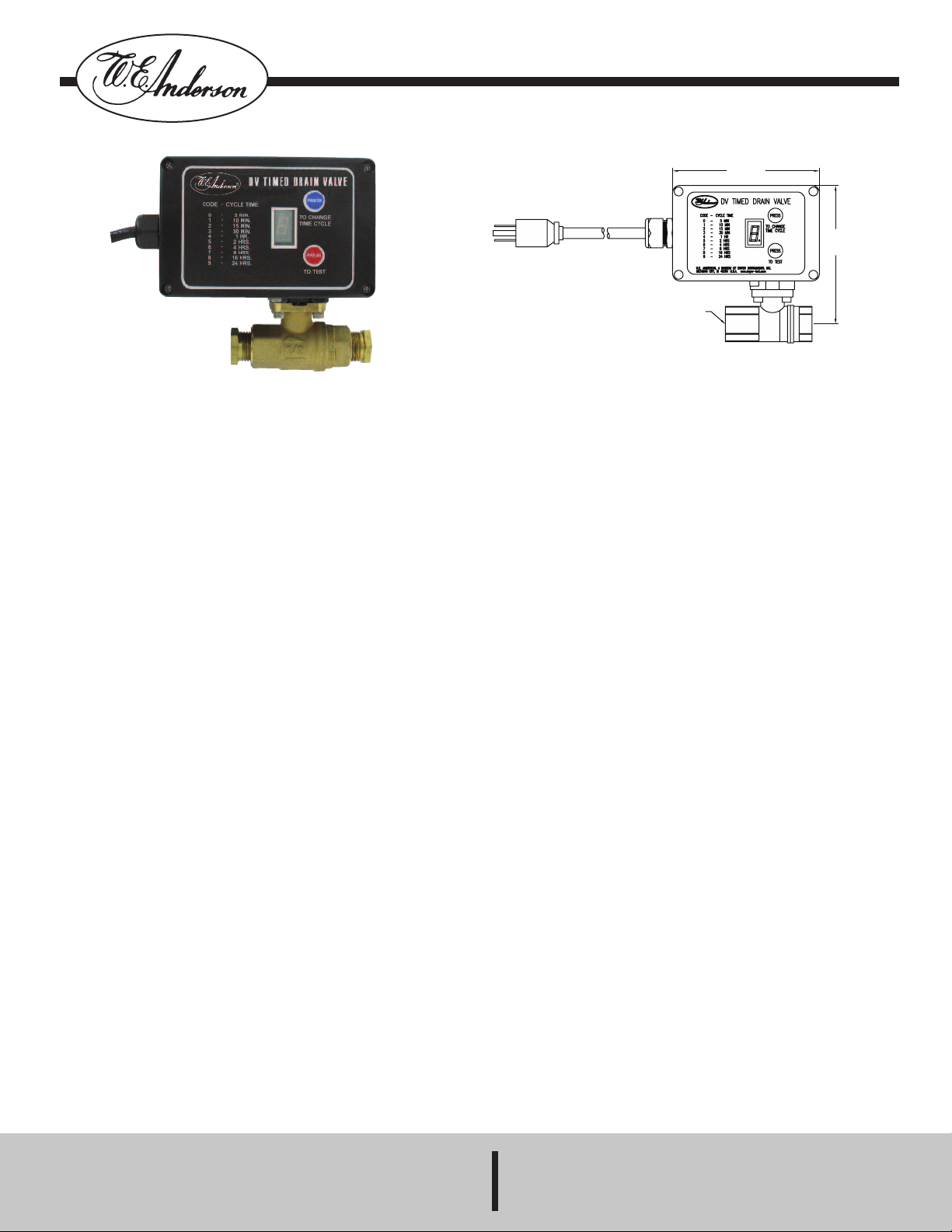

Series DV Timed Automatic Drain Valve

®

5

[

127.00]

1

/2˝, 3/4˝ OR 1˝ NPT

B

OTH ENDS

4

-3/4

[

119.89]

Specifications - Installation and Operating Instructions

Bulletin V-18

Series DV is an automatic drain system designed to eliminate the need

to manually drain water and harmful sediments from your compressed air

system, thereby improving the systems performance. The unit can be

used on receivers, dryers, tanks, and drop legs for sampling and purging

a wide variety of liquids. The Series DV has a heavy-duty motor for

operation under adverse conditions and an adjustable timer to meet

specific user requirements. By design, the Series DV eliminates major

drawbacks of other compressed air draining systems. The valve is brass

for corrosion resistance and it is a full port ball valve giving maximum and

unobstructed flow with no clogging. A test button allows for the unit to be

cycled at any time. It is mountable in any position for easy plumbing, and

trouble free operation.

Do not apply electrical power to the unit unless the unit is fully assembled

and mounted. Failure to do so could result in personal injury and/or

damage to the unit. Disconnect power source and depressurize the

system before working on the unit. Failure to do so could result in

personal injury. The downstream or discharge side of the ball valve must

be directed to a safe area for collecting water, oil and debris. The

compressed air system is pressurized during operation. Appropriate

precautions are recommended.

CAUTION: It is recommended that eye protection be worn while

servicing the system. Failure to do so could result in personal injury.

WARNING: The motorized drive unit case is not capable of supporting

any loads. Do not attempt to use the unit as a step. This will cause

damage to the unit and could cause personal injury. Do not use in

hazardous locations.

SPECIFICATIONS

Body: 2 – piece.

Line Size: 1/4 to 1˝.

End Connections: Female NPT.

Pressure Limit: 200 psi (13.8 bar).

Wetted Materials:

Body, End Cap: Forged Brass;

Ball, Stem: Chrome Plated Brass;

Seat: RTFE;

Stem Seal: Fluoroelastomer;

Bushings: Brass.

Temperature Limits: 35 to 165°F (2 to 74°C).

Other Materials: Thrust washer: RTFE

Fasteners: Stainless Steel.

Discharge Time: 3.5 seconds non-adjustable.

Discharge Volume Cycle: 1/2˝: 0.92 gal @ 80 psi (valve only);

3/4˝: 1.64 gal @ 80 psi;

1˝: 2.50 gal @ 80 psi.

ACTUATOR

Electric

Power Requirements: 110 VAC, 60 Hz, single phase.

Power Consumption: 2.5 A.

Cycle Time Adjustable: 5 min, 10 min, 15 min, 30 min, 1 hr, 2 hr, 4 hr,

8 hr, 16 hr, 24 hr.

Enclosure Rating: NEMA 4.

Housing Material: Polycarbonate.

Electrical Connection: 18 AWGX3C, 8 ft (24 m) power cord.

CAUTION: Do not use the case as leverage when mounting this unit or

tightening fittings. Use the wrenching flats on the valve body.

W.E. ANDERSON DIV., Phone: 219/879-8000 www.dwyer-inst.com

DWYER INSTRUMENTS, INC. Fax: 219/872-9057 e-mail: info@dwyermail.com

P.O. BOX 358 • MICHIGAN CITY, INDIANA 46360 U.S. A.

Page 2

INSTALLATION

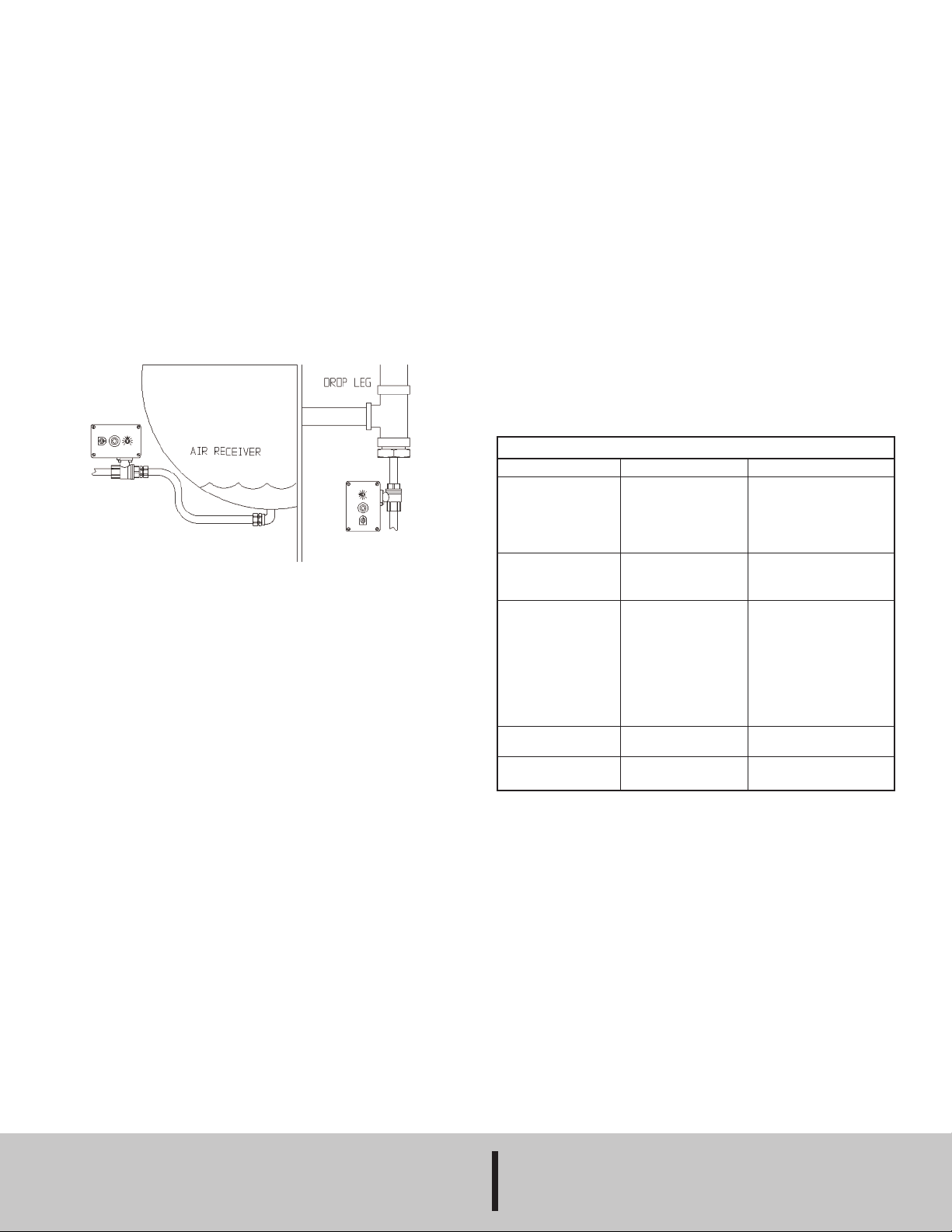

Figures 1 & 2 show typical installations of the drain valve. It is

recommended that the motorized drive be removed from the valve

before piping the valve into your system. Then reinstall the motorized

drive unit to the valve. This can be done using the four screws holding

the valve to the case.

Install the automatic drain valve to the compressed air system at a point

where moisture would tend to collect. Pipe the opposite end of the valve

to your discharge area.

Note: This unit may be mounted in any position with the flow in either

direction. For air receiver applications, (fig. 1) it is recommended copper

tubing be used for all connection of the pressure side of the valve. For

drop leg applications, (fig. 2) install ridged tubing or pipe from the valve

to the lowest practical point of your system.

Fig. 1

Fig. 2

WARNING: Always disconnect power source before working on this unit.

Failure to do so could result in personal injury. The valve is under

pressure. Discharge of compressed gas or fluids will occur during any

cycling of the ball valve when unit is installed in the piping system. Eye

protection is recommended.

OPERATION

Plug the cord set into a proper power source. Set the dial at the desired

frequency of operation. The valve will cycle and the timing sequence will

begin. To change the timing sequence, simply change the code setting

and the timer will reset. The test button may be used to cycle the unit at

any time.

MAINTENANCE

Periodic maintenance is recommended to ensure long, dependable

service from your drain valve. Check power cord for breaks in the outer

jacket or damage to the plug. The case should be kept clean so that label

instructions are legible. The ball valve should be checked for leakage at

the downstream side. The Series DV is not field serviceable and should

be returned if repair is needed (field repair should not be attempted and

may void warranty). Be sure to include a brief description of the problem

plus any relevant application notes. Contact customer service to receive

a return goods authorization number before shipping.

TROUBLESHOOTING CHART

SYMPTOM

Valve does not cycle

Ball valve leaks at

discharge side

Unit cycles but does

not discharge water

and/or air

Valve discharges

mostly air each cycle

Valve discharges all

liquid each cycle

POSSIBLE CAUSE

Proper power is not

reaching unit

Timer set improperly

Excessive seat

damage from debris

No pressure

upstream

Valve or line clogged

with debris

Timer set improperly

Timer set improperly

CORRECTIVE ACTION

Check that power cord is

plugged into the proper

power source. Check

power source. Push test

button. Reset timer.

Push test button to flush

valve. Replace ball

valve.

Check that Pneumatic

system is pressurized.

Disconnect power.

Depressurize pneumatic

system. Remove drain

valve and check for

blockage in the valve

and the line.

Reset timer to longer

intervals

Reset timer to shorter

intervals

©Copyright 2014 Dwyer Instruments, Inc. Printed in U.S.A. 5/14 FR# RV-443450-00 Rev. 2

W.E. ANDERSON DIV., Phone: 219/879-8000 www.dwyer-inst.com

DWYER INSTRUMENTS, INC. Fax: 219/872-9057 e-mail: info@dwyermail.com

P.O. BOX 358 • MICHIGAN CITY, INDIANA 46360 U.S. A.

Loading...

Loading...