Page 1

Series DFMT2 Digital Paddlewheel Flow Transmitter

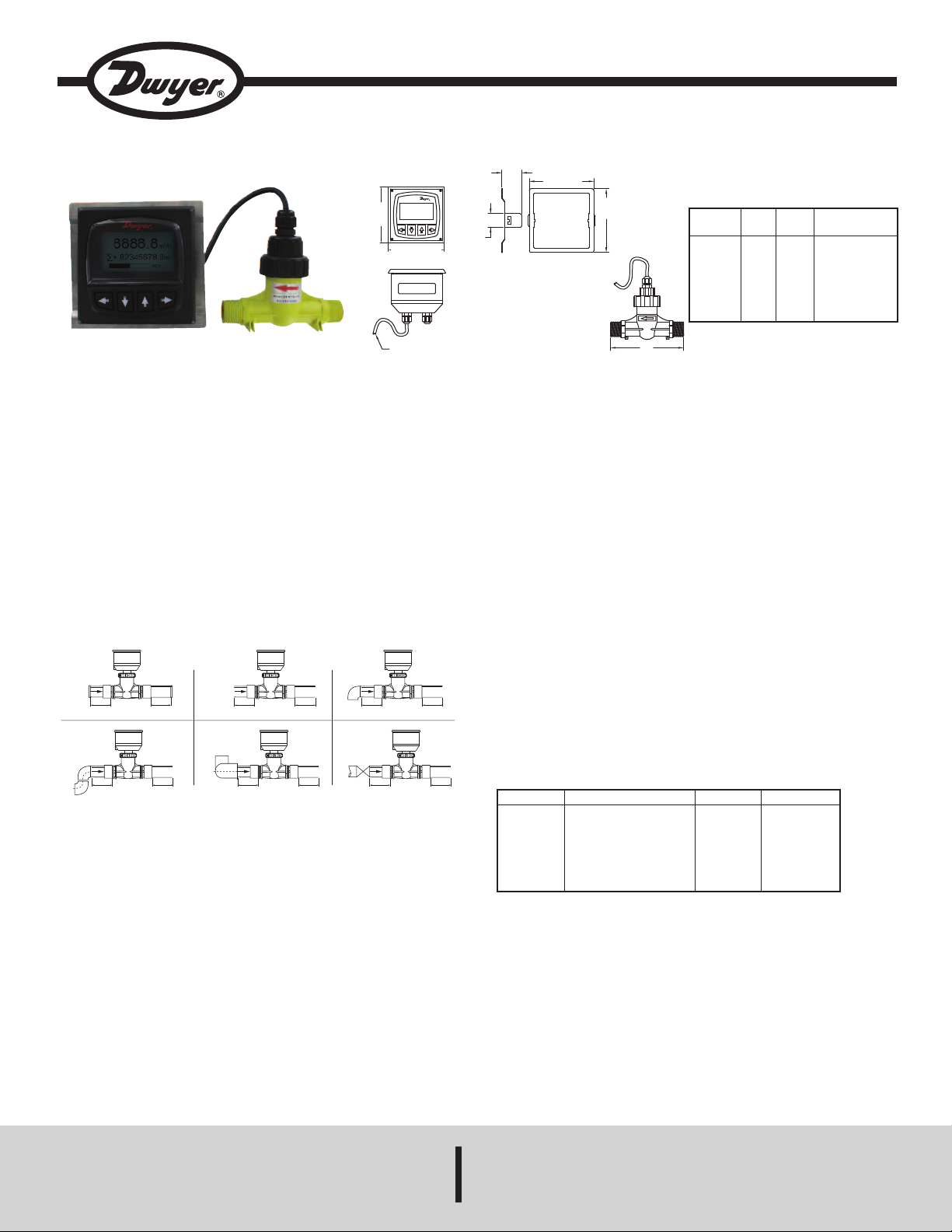

15xI. D. 5xI.D . 20xI. D. 5xI.D .

90°elbow

2x90° elbow

division 2

plane

15xI. D. 5xI.D .

20xI. D. 5 xI .D

pump/valve

40xI. D. 5xI.D .25xI. D. 5xI.D .

2x90° elbow

flange

reducing

C

ABLE LENGTH 197˝ [5 m]

3

-7/8 [100]

3

1/32

[24.61]

4-1/2

[114.30]

A

1

-13/32

[35.72]

4-9/16

[

115.89]

3-7/8

[100]

Specifications - Installation and Operating Instructions

M

ange

emote Mounting Bracket

R

(Stainless Steel)

R

m3/h)

(

0

0

0.3-5.91

0.5-11.36

1.5-23.85

2

.1-2

.2-4.09

-40.88

N

3

1

3/4˝

1˝

1-1/2˝

2

Bulletin F-DFMT2

ress.

P

ale

PT

/8˝

/2˝

˝

MPa)

(

.0

1

.0

1

1.0

0.8

0.8

.8

0

A

-3/4˝ (121 mm)

4

-1/8˝ (130 mm)

5

5-5/8˝ (142 mm)

5-1/2˝ (141 mm)

6-7/8˝ (175 mm)

-7/8˝ (175 mm)

6

he Series DFMT2 Remote Digital Paddlewheel Flow Transmitter is a two

T

piece digital flow transmitter that provides instantaneous, as well as totalizing flow

monitoring. The two piece design allows the user to separate the control panel from

the application, making it ideal for industrial use in reverse osmosis water purifying

systems and any other applications where space is limited. The large backlit

isplay makes navigating through the menu structure simple. The Series DFMT2

d

ses high accuracy, industry proven paddlewheel technology, offers a user

u

electable 4 to 20 mA or pulse output, and has a corrosion resistant PVDF sensor

s

giving it a long operation life. Users can reset the totalizer at any time and set a

security password protecting the system settings from unauthorized changes.

Installation Instructions

The accuracy of these flowmeters can be affected by disturbances such as pumps,

elbows, tees, and valves that are in the flow stream. To reduce the error caused by

these disturbances, pick a section of pipe that is at a distance from any pumps,

bends or valves. The recommended distance away from elbows and pumps is

shown in Figure 1.

Figure 1: Mounting Straight Pipe Runs Required

Mounting Location

To reduce the possibility of causing damage to the Series DFMT2, it is

recommended that the meter be mounted in a full flow pipe. Vertical mounting is

acceptable, provided the liquid is flowing up through the meter, or a sufficient back

pressure exists on the downward flow. On horizontal mountings, it is recommended

that the meter be mounted perpendicular to the pipe. For systems that may have

small air pockets at the top of the pipe, the meter can be mounted up to 45° off the

vertical normal.

SPECIFICATIONS

ervice: Compatible clean liquids.

S

ange: See model chart.

R

etted Materials:

W

Sensor and Impeller: PVDF;

Shaft: Ceramic;

O-Rings: Fluoroelastomer;

Accuracy: ±1.5% FS.

epeatability: ±0.5% FS.

R

Output:

Analog: 4 to 20 mA (750 Ω max. loop resistance);

Pulse: NPN square wave output;

Frequency: 0 to 2 kHz (adjustable);

Pulse width: 0 to 1000 ms (adjustable).

Electrical Connections: Removable screw terminal.

Temperature Limits:

Process: -4 to 194°F (-20 to 90°C);

Ambient: -4 to 149°F(-20 to 65°C).

Pressure Limit: 145 psi (1.0 MPa).

Power Requirements: 12 to 24 VDC.

Power Consumption: 2 W.

Display: 2.38 x 1.25" (60.33 x 31.75 mm) LCD.

Totalizing Display Maximum: 9,999,999,999.

Process Connection: See model chart.

Enclosure Rating: IP65.

Enclosure Material: ABS plastic.

Weight: See model chart.

Model

DFMT2-10A

DFMT2-15A

DFMT2-20A

DFMT2-25A

DFMT2-40A

DFMT2-50A

Range GPM (m3/h)

0.44 to 7.93 (0.1 to 1.8)

0.88 to 17.61 (0.2 to 4)

1.32 to 26.42 (0.3 to 6)

2.20 to 52.83 (0.5 to 12)

6.61 to 105.67 (1.5 to 24)

8.81 to 176.11 (2 to 40)

Connection

3/8˝ NPT

1/2˝ NPT

3/4˝ NPT

1˝ NPT

1-1/2˝ NPT

2˝ NPT

Weight lb (kg)

1.76 (0.8)

1.81 (0.82)

1.85 (0.84)

1.94 (0.88)

2.20 (1.0)

2.43 (1.1)

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyermail.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

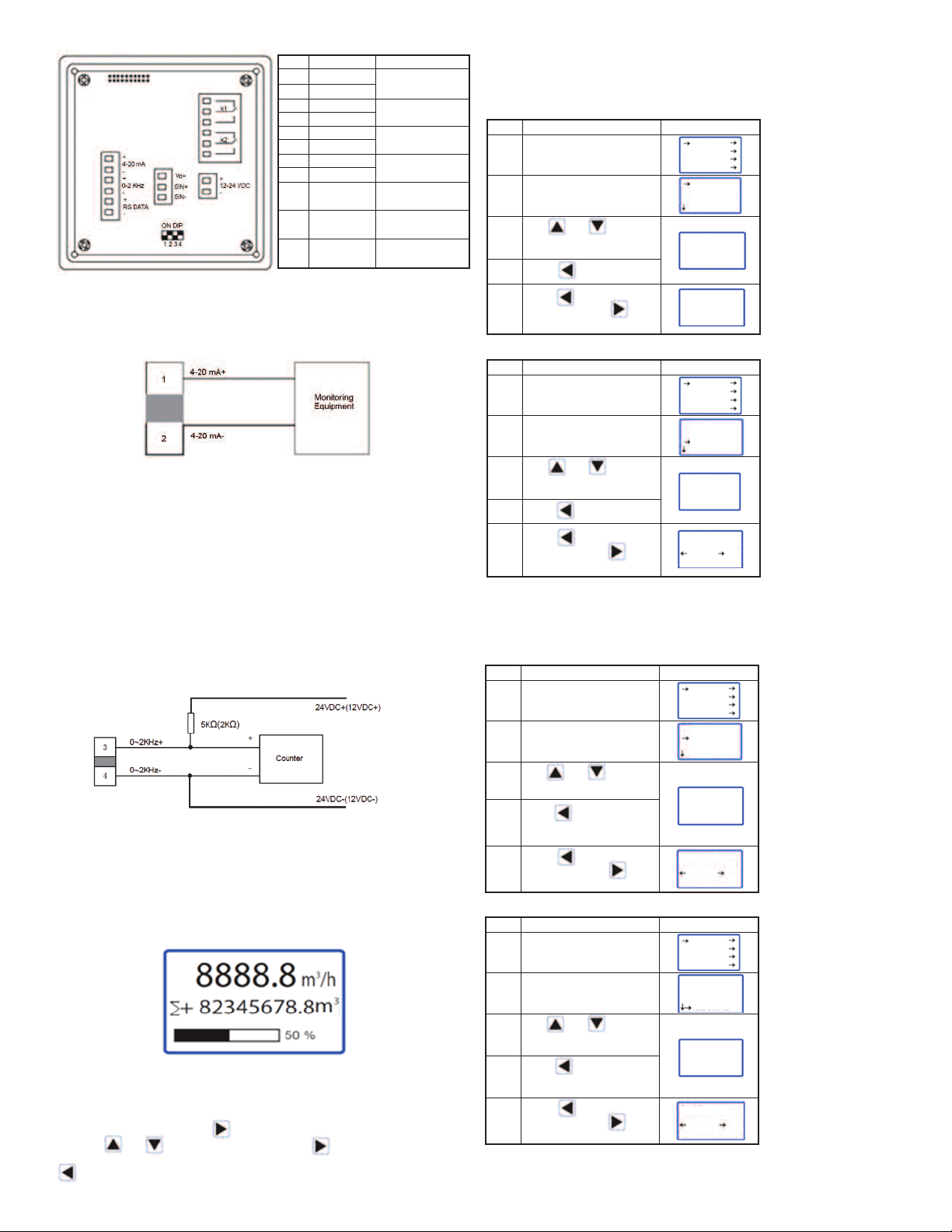

LECTRICAL CONNECTIONS

E

Item

Label

1

4 to 20 mA+

2

4 to 20 mA-

to 2 kHz+

3

0

to 2 kHz-

4

0

S DATA+

5

R

6

RS DATA-

10

1

2

3

4

5

6

7

10

8

11

9

11

7

8

9

12 to 24 V+

12 to 24 V-

o+

V

IN+

S

SIN-

Function

4 to 20 Output

requency/

F

ulse Output

P

S485

R

Communication

Input Power

Terminals

ower to

P

ensor (Blue)

S

ommunication to

C

ensor (Red)

S

Communication to

Sensor (Black)

4 to 20 mA Output

The Series DFMT2 can provide a variable current output that is proportional to the

detected flow rate. This output can be used in a range of external interface devices,

nd can be calibrated to suit a particular flow range. The maximum load resistance is

a

50 Ω, including the cables used to connect.

7

Pulse (Frequency) Output

The Series DFMT2 offers a frequency pulsed output that can be configured as a linear

flow proportional frequency output or a standard pulsed output via the unit software.

The maximum pulse output frequency is 5 kHz with a pulse amplitude of 24V and a

aximum load current of 0.2A. The pulse output frequency is adjustable from 100-

m

5000 Hz (please refer to “To Change The Maximum Frequency” under “Pulse Output

Setup”).

When utilizing the unit with a linear proportional frequency output, the liter/pulse

option must be set to 0.0 (please refer to “To Change the Liters/Pulse” under the

“Pulse Output Setup”) and the frequency output signal scaled to the desired range

within the units capability (please refer to “To Set Qmax” under the “Percentage

Range” to scale frequency output signal).

When utilizing the unit as a standard pulsed output (please refer to “Pulse Output

Setup” under the “System Setup Menu”).

RS485 Communication Output (Optional)

The Series DFMT2 features optional RS485 Communication. This must be specified

at time of order and will not function otherwise. The RS data communication option

will remain visible in the unit’s software and on the terminal board but will not be

functional. Please contact factory for RS485 communication output capable units.

USING THE SERIES DFMT2

When first turned on, the Series DFMT2 will initialize, and then it will turn to the

measurement reading screen.

The top number is the instantaneous flow reading, followed by the total amount of

liquid passed. The bottom bar shows the percentage of flow in relation to the

maximum flow rate.

To access the menu, press the key on the keypad. Navigate through the menu

using the and to select a sub menu, and the key to enter a sub menu. To

return to the measurement reading screen, or to return from a sub menu, press the

key.

nit Adjustment

U

he Series DFMT2 can display flow units of L/s, L/min, L/h, m

T

al/s, US gal/min, and US gal/h. The totalization units can be displayed in L, m

g

S gallons.

U

3

/

s, m

3

min, m

/

3

h, US

/

3

and

,

To change flow units:

Steps

Operation Instructions

1

From the menu, select

“Basic”.

elect “PV Units”.

2

S

3

Use and to change

the desired flow units.

ress to select units.

4

P

ress to confirm the

5

P

change, or press to

cancel the change.

o change totalization units:

T

teps

peration Instructions

S

O

rom the menu, select

1

F

Basic”.

“

2

Select “Total Units”.

se and to change

3

U

he desired flow units.

t

4

Press to select units.

5

Press to confirm the

change, or press to

cancel the change.

Display

PV Units

PV Units

isplay

D

Total Units

Total Units

ENT ESC

Basic

System

Calibration

Test

PV Units

PV Decimal

Total Units

Total Decimal

Basic

System

Calibration

Test

PV Units

PV Decimal

Total Units

Total Decimal

m3/h

m3/h

L/h

L/h

L

3

m

L

3

m

Resolution

The Series DFMT2 has a selectable resolution of up to 3 decimal points for both the

flow and totalization units.

To change flow resolution:

Steps

Operation Instructions

1

From the menu, select

“Basic”.

2

Select “PV Decimal”.

3

Use and to change

the desired flow resolution.

4

Press to select

resolution.

5

Press to confirm the

change, or press to

cancel the change.

Display

PV Decimal

PV Decimal

ENT ESC

Basic

System

Calibration

Test

PV Units

PV Decimal

Total Units

Total Decimal

3

3

3

2

To change totalization resolution:

Steps

Operation Instructions

1

From the menu, select

“Basic”.

2

Select “Total Decimal”.

3

Use and to change

the desired totalization

resolution.

Press to select

4

resolution.

Press to confirm the

5

change, or press to

cancel the change.

Display

Total Decimal

Total Decimal

ENT ESC

Basic

System

Calibration

Test

PV Units

PV Decimal

Total Units

Total Decimal

3

3

3

2

Page 3

amping Factor

D

he Series DFMT2 has the capability to introduce a damping factor allowing the

T

ser to delay the response time of the display and output. This function is used to

u

mooth out a reading of flows that has rapid spikes or dips in the flow rate.

s

To adjust the damping factor:

teps

peration Instructions

S

O

rom the menu, select

1

F

Basic”.

“

2

Select “Damping”.

se , and to

3

U

hange the desired flow

c

esolution.

r

4

Press to select

resolution.

ress to confirm the

5

P

hange, or press to

c

ancel the change.

c

isplay

D

Basic

System

Calibration

Test

PV Decimal

Total Units

Total Decimal

Damping(s)

Damping(s)

Max: 99.9

Min: 0.1

Damping(s)

ENT ESC

02.0

02.0

02.0

03.0

o change low cutoff:

T

teps

peration Instructions

S

O

1

From the menu, select

“System”.

se , , and to

2

U

nput current password.

i

ress to enter password.

P

elect “Signal”.

S

3

Select “Low Cutoff%”

4

se , and to

U

5

nput desired cutoff %.

i

6

Press to select value.

ress to confirm the

7

P

hange, or press to

c

ancel the change.

c

isplay

D

Basic

System

Calibration

Test

Password

New Password

Language

Signal

Pulse Output

Qmax (m3/h)

Low Cutoff%

Low Cutoff%

Max: 9.9

Min: 0.0

Low Cutoff%

ENT ESC

]

*2**

1.0

1.0

1.0

2.0

SYSTEM SETUP MENU

Password Protection

The Series DFMT2 has a system setup menu that is password protected. The

password must be entered each time a user accesses the system setup menu. The

nit is initially setup to have a password of 0200.

u

o change the password:

T

teps

peration Instructions

S

O

1

From the menu, select

“System”.

2

Use , , and to

input current password.

Press to enter password.

Select “New Password”.

3

Use , , and to

4

create the desired

password.

Press to select the

5

isplay

D

Basic

System

Calibration

Test

Password

New Password

Language

Signal

Pulse Output

New Password

*2**

0200

0200

password.

Press to confirm the

6

change, or press to

cancel the change.

New Password

ENT ESC

0200

0300

PERCENTAGE RANGE

The user can configure the percentage of flow display bar to show a specified range

within the products allowable range. The option “Qmax(m

3

/h)” in the system setup

menu allows the user to set a flow rate at which the bar will show 100%. The option

“Low Cutoff%” allows the user to set a flow rate at which the Series DFMT2 to

display zero, and set any outputs to zero.

To set Qmax:

Steps

Operation Instructions

1

From the menu, select

“System”.

2

Use , , and to

input current password.

Press to enter password.

3

Select “Signal”.

4

Select “Qmax(m3/h)”

5

Use , and to

create the desired Qmax.

6

Press to select the

desired value.

Display

Password

Qmax (m3/h)

Max: 99999999

Min: 0.000100

Basic

System

Calibration

Test

New Password

Language

Signal

Pulse Output

Qmax (m3/h)

Low Cutoff%

*2**

100.0

120.0

PULSE OUTPUT SETUP

The Series DFMT2 has a customizable pulse output option. The user can configure

this output’s maximum frequency, the number of liters per pulse, the pulse width,

and whether the pulse level is active low or active high.

o change the maximum frequency:

T

Steps

Operation Instructions

rom the menu, select

1

F

System”.

“

2

Use , , and to

input current password.

Press to enter password.

Select “Pulse Output”.

3

Select “Freq Max(Hz)”.

4

Use , and to

5

input desired frequency

upperlimit.

Press to select value.

6

Press to confirm the

7

change, or press to

cancel the change.

Display

Password

Freq Max(Hz)

Liter/Pulse

PulseWidth(ms)

Pulse Level

Freq Max(Hz)

Max: 5000.0

Min: 100.0

Freq Max(Hz)

ENT ESC

Basic

System

Calibration

Test

New Password

Language

Signal

Pulse Output

4000.0

5000.0

4000.0

5000.0

*2**

To change the liters/pulse:

Steps

Operation Instructions

1

From the menu, select

“System”.

2

Use , , and to

input current password.

Press to enter password.

Select “Pulse Output”.

3

Select “Liter/Pulse”.

4

Use , and to

5

input desired liters per pulse

ratio.

Press to select value.

6

Press to confirm the

7

change, or press to

cancel the change.

Display

Password

Freq Max(Hz)

Liter/Pulse

PulseWidth(ms)

Pulse Level

Liter/Pulse

Max: _____

Min: 0.00055

Liter/Pulse

ENT ESC

Basic

System

Calibration

Test

New Password

Language

Signal

Pulse Output

0.00000

0.01000

4000.0

5000.0

*2**

7

Press to confirm the

change, or press to

cancel the change.

Qmax (m3/h)

ENT ESC

100.0

120.0

Page 4

o change the pulse width:

T

teps

peration Instructions

S

O

rom the menu, select

1

F

“System”.

2

Use , , and to

nput current password.

i

ress to enter password.

P

elect “Pulse Output”.

S

3

Select “PulseWidth(ms)”.

4

se , and to

U

5

nput desired pulse width.

i

6

Press to select value.

7

Press to confirm the

hange, or press to

c

ancel the change.

c

isplay

D

Basic

System

Calibration

Test

Password

New Password

Language

Signal

Pulse Output

Freq Max(Hz)

Liter/Pulse

PulseWidth(ms)

Pulse Level

Pulse Width (ms)

Max: 1000.0

Min: 0.0

Pulse Width (ms)

ENT ESC

*2**

0000.0

0000.0

0000.0

0050.0

o change baud rate:

T

teps

peration Instructions

S

O

rom the menu, select

1

F

System”.

“

2

Use , , and to

input current password.

ress to enter password.

P

elect “RS485 Output”.

S

3

Select “Baudrate”.

4

se , and to

U

5

elect desired baud rate.

s

6

Press to select value.

7

Press to confirm the

change, or press to

ancel the change.

c

isplay

D

Basic

System

Calibration

Test

Password

Signal

ulse Output

P

S485 Output

R

Total Set

RS485 Protocol

Baudrate

Data Bit

Parity

Baudrate

Baudrate

ENT ESC

*2**

9600

19200

9600

4800

PULSE LEVEL

The pulsed output on the Series DFMT2 can be programmed to be active high or

active low.

o change pulse level:

T

Steps

Operation Instructions

rom the menu, select

1

F

System”.

“

2

Use , , and to

input current password.

Press to enter password.

Select “Pulse Output”.

3

Select “Pulse Level”.

4

Use and to select

5

active high or active low.

Press to select value.

6

Press to confirm the

7

change, or press to

cancel the change.

Display

Password

Freq Max(Hz)

Liter/Pulse

PulseWidth(ms)

Pulse Level

Pulse Level

Pulse Level

Basic

System

Calibration

Test

New Password

Language

Signal

Pulse Output

Active L

Active H

Active L

ENT ESC

Active H

*2**

RS485 COMMUNICATIONS OUTPUT (OPTIONAL)

The Series DFMT2 also has a RS485 communications output capability. The user

can alter the protocol, baud rate, parity, stop bit, and the device address. The

RS485 output works on 8 data bits.

To set protocol:

Steps

Operation Instructions

1

From the menu, select

“System”.

2

Use , , and to

input current password.

Press to enter password.

3

Select “RS485 Output”.

4

Select “RS485 Protocol”.

5

Use , and to

select MODBUS.

6

Press to select value.

Display

Password

RS485 Protocol

Basic

System

Calibration

Test

Signal

Pulse Output

RS485 Output

Total Set

RS485 Protocol

Baudrate

Data Bit

Parity

MODBUS-RTU

MODBUS-ASC

*2**

To set parity:

teps

peration Instructions

S

O

rom the menu, select

1

F

“System”.

2

Use , , and to

input current password.

ress to enter password.

P

elect “RS485 Output”.

S

3

Select “Parity”.

4

Use , and to

5

select parity type.

Press to select value.

6

Press to confirm the

7

change, or press to

cancel the change.

To set stop bit:

Steps

Operation Instructions

1

From the menu, select

“System”.

2

Use , , and to

input current password.

Press to enter password.

Select “RS485 Output”.

3

Select “Stop Bit”.

4

Use , and to

5

choose the stop bit.

Press to select value.

6

Press to confirm the

7

change, or press to

cancel the change.

isplay

D

Password

Display

Basic

System

Calibration

Test

Signal

ulse Output

P

S485 Output

R

Total Set

RS485 Protocol

Baudrate

Data Bit

Parity

Parity

Parity

ENT ESC

Basic

System

Calibration

Test

Password

Signal

Pulse Output

RS485 Output

Total Set

Data Bit

Parity

Stop Bit

Dev Address

Stop Bit

Stop Bit

ENT ESC

*2**

NONE

EVEN

NONE

EVEN

*2**

1

2

1

2

7

Press to confirm the

change, or press to

cancel the change.

RS485 Protocol

MODBUS-RTU

ENT ESC

MODBUS-ASC

Page 5

o set device address:

T

teps

peration Instructions

S

O

1

From the menu, select

“System”.

se , , and to

2

U

nput current password.

i

ress to enter password.

P

elect “RS485 Output”.

S

3

Select “Dev Address”.

4

se , and to

U

5

nput desired device address.

i

6

Press to select value.

isplay

D

Password

Basic

System

Calibration

Test

Signal

ulse Output

P

S485 Output

R

Total Set

Data Bit

Parity

Stop Bit

Dev Address

Dev Address

o preset totalizer:

T

Steps

Operation Instructions

rom the menu, select

1

F

System”.

“

se , , and to

2

U

*2**

000

101

input current password.

Press to enter password.

Select “Total Set”.

3

elect “Clear Total”.

S

4

Use to select “Yes” or

5

“No”.

ress to select value.

P

6

Display

Basic

System

Calibration

Test

Password

Signal

P

RS485 Output

Total Set

Clear Total

FWD Preset(m3)

FWD Preset(m3)

Max: ______

Min: ______

*2**

ulse Output

000.000000

500.000000

ress to confirm the

7

P

hange, or press to

c

ancel the change.

c

Dev Address

ENT ESC

000

101

CLEAR AND SET TOTALIZER

The Series DFMT2 has a totalizing function that is displayed on the main screen.

This value can be cleared or set to a predetermined value.

o clear totalizer:

T

Steps

Operation Instructions

1

From the menu, select

“System”.

2

Use , , and to

input current password.

Press to enter password.

Select “Total Set”.

3

Select “Clear Total”.

4

Use to select “Yes” or

5

“No”.

Press to select value.

6

Press to confirm the

7

change, or press to

cancel the change.

Display

Basic

System

Calibration

Test

Password

ignal

S

ulse Output

P

R

otal Set

T

Clear Total

FWD Preset(m3)

Clear Total

Clear Total

ENT ESC

*2**

S485 Output

NO

Yes

NO

Yes

7

Press to confirm the

change, or press to

cancel the change.

FWD Preset(m3)

ENT ESC

500.000000

MAINTENANCE/REPAIR

Upon final installation of the Series DFMT2, no routine maintenance is required.

The Series DFMT2 is not field serviceable and should be returned if repair is

needed. Field repair should not be attempted and may void warranty.

ARRANTY/RETURN

W

efer to “Terms and Conditions of Sale” in our catalog and on our website. Contact

R

customer service to receive a Return Goods Authorization number before shipping

the product back for repair. Be sure to include a brief description of the problem

plus any additional application notes.

Page 6

©Copyright 2014 Dwyer Instruments, Inc. Printed in U.S.A. 7/14 FR# R2-444248-00

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyermail.com

Phone: 219/879-8000 www.dwyer-inst.com

Loading...

Loading...