Page 1

Series BTK2 Backflow Prevention Test Kit

Ø

4-25/32

[

Ø121.36]

Ø1-41/64

[Ø41.66]

5

-31/64

[

139.46]

2

[

50.80]

3

[

76.12]

9-39/64

[244.27]

7

-7/16

[

189.07]

3´ HOSE WITH FEMALE COUPLINGS

[SHOWN UNATTACHED]

Specifications - Installation and Operating Instructions

The Model BTK2 Backflow Prevention Test Kit is capable of testing hydronic

systems with test procedures recommended by ASSE, AWWA, CSA, FCCC, HRUSV, and NEWWA. The BTK2 is comprised of three valves and is specially

designed for testing backflow prevention assemblies. The tests can be completed

n almost any area by mounting the unit with the included high performance elastic

i

ord. PTFE-lined brass ball valves simplify the adjustment procedure. The large,

c

asy-to-grip needle valve allows for quick adjustment. The kit includes a 4.5˝

e

diameter diaphragm differential pressure gage (0 to 15 psid), a 1.5˝ diameter in-line

pressure gage (0 to 200 psig), three 3´ long hoses (color-coded), three sets of

brass adapter fittings for hookups to all standard size test cocks, an elastic cord for

hanging/mounting, and a durable polyethylene carrying case.

Note: It is the responsibilty of the tester to ensure that the test procedures are

*

ccepted by the local authorities.

a

Prior to testing any backflow device, the following procedures are recommended:

1. Permission should be obtained from the owner, to shut down the water supply.

This is necessary to ensure, since all testing is accomplished under no-flow

conditions. Concurrent with the request for permission to shut off the water, it is

advisable to point out that while the water is shut off during the test period, any

inadvertent use of water within the building will reduce the water pressure to zero.

In order to address this situation, it is recommended that the owner caution the

inhabitants of the building not to use the water until the backflow test is completed

and the water pressure is restored.

2. Determine the type of device to be tested i.e., double check valve or reduced

pressure principle device.

3. Determine the flow direction.

4. Number the test cocks, bleed them of potential debris, and assemble appropriate

test cock adapters and bushings that may be required.

5. Shut off the downstream (number 2) shut-off valve.

6. Wait several moments prior to hooking up the test kit hoses when testing a

reduced pressure principle device. If water exits the relief valve, in all likelihood, the

first check valve is fouled and it is impractical to proceed with the testing until the

valve is serviced. This waiting period is not necessary when testing double check

valves.

Test personnel are cautioned to be aware and follow local municipal, county, and

state testing requirements and guidelines as may be dictated by local authority.

The following test procedures are guidelines for standard, generally acceptable

test procedures but may be amended, superseded, or modified by local jurisdiction

For field testing of reduced pressure principle backflow preventers and double

check valve assemblies, the BTK2 is utilized. All test equipment should be

periodically checked for calibration.

Bulletin P-BTK2

PECIFICATIONS

S

ressure Limits: 175 psi (12 bar).

P

emperature Limits: 210°F (99°C).

T

Range: 4.5˝ gage: 0 to 15 psid (0 to 1 bar); 1.5˝ gage: 0 to 200 psi (0 to 14 bar).

Accuracy: 4.5˝ gage: ±2% FS; 1.5˝ gage: ±3-2-3% FS.

Wetted Parts:

4.5˝ Gage: Anodized aluminum;

.5˝ Gage Diaphragm: Buna-N;

4

.5˝ Gage: Brass;

1

all Valves: PTFE lined brass;

B

Needle Valve: Brass;

Hose Couplings: Brass;

Adaptors: Brass;

Hose: Rubber.

Size: Case: 9˝ H x 16˝ W x 9˝ D (228 mm H x 406 mm W x 228 mm D).

Weight: 8.9 lb (4 kg).

Pressure Vacuum Breaker

Field testing of a pressure vacuum breaker involves testing both the internal spring

loaded soft seated check valve, as well as testing the spring loaded air inlet valve.

The testing must be performed with the device pressurized and the air inlet closed.

The number 2 shut-off valve must also be closed and the air inlet valve canopy

removed. Perform with Ball Valve C closed.

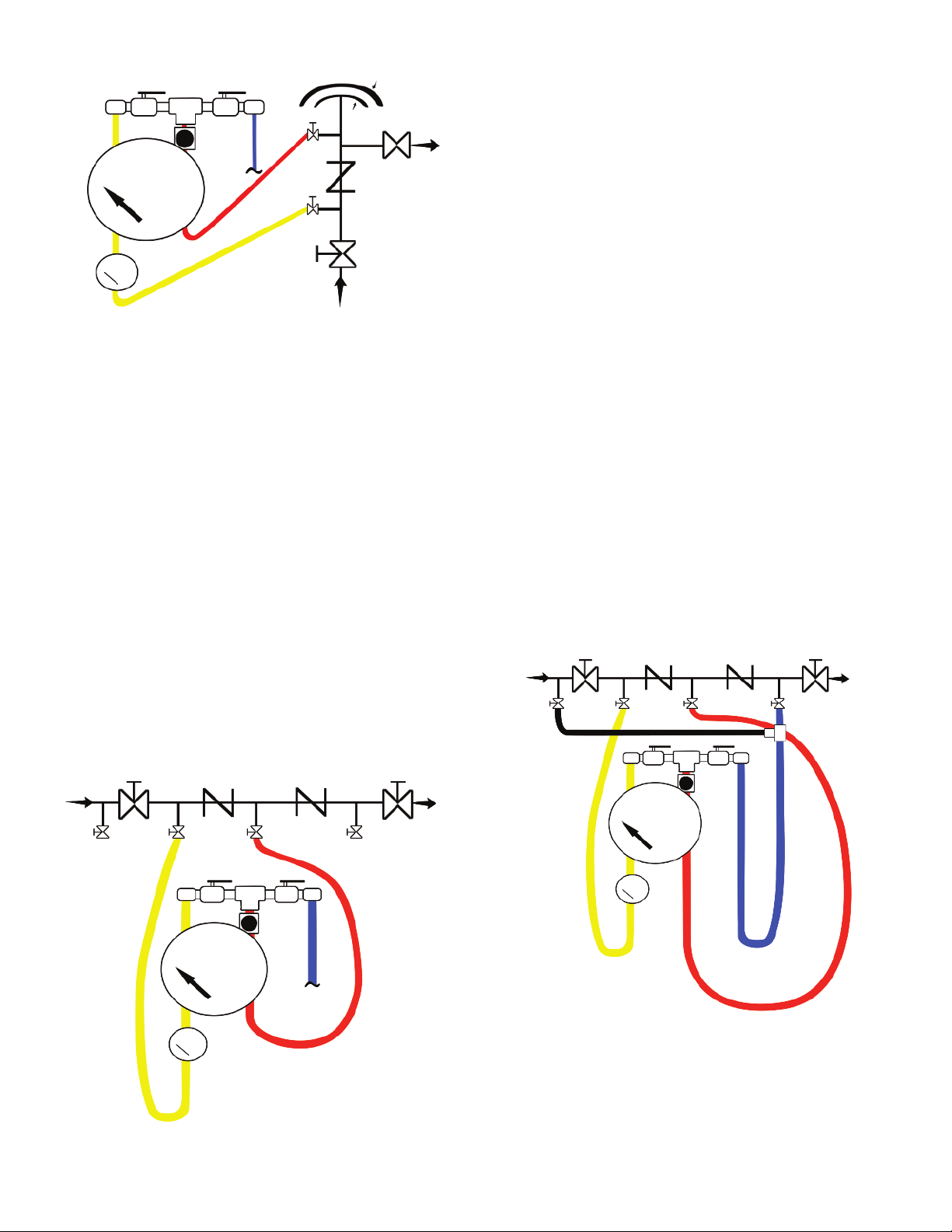

Test 1 - Refer to Figure 1

Test the internal check valve for tightness of 1 psid in the direction of flow using the

following procedure.

1. With the valve body under pressure, (number 2 shut-off valve closed and

number 1 shut-off valve open), bleed test cocks number 1 and number 2.

2. Hook up the high pressure hose (yellow) to number 1 test cock (red) and the low

pressure hose (red) to number 2 test cock.

3. Bleed the high pressure hose and low pressure hose (yellow), in that order, and

close the test kit valves slowly (ball valve A & needle valve B).

4. Record the differential pressure on the gage. A reading of 1 psid is acceptable

to insure a tight check valve.

Test 2

Test the air inlet valve for a breakaway of 1 psid using the following procedure.

1. Connect the high pressure hose (yellow) to test cock number 2, and bleed the

high pressure hose (yellow).

2. Shut off number 1 shut-off valve.

3. Slowly open the needle valve B of the test kit, and observe and record the

pressure when the air inlet poppet opens. This should be a minimum of 1 psid.

Restore the valve to normal service.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

ir inlet valve canopy

all Valve A

B

educed Pressure Principle Backflow Preventer

R

ield testing of a reduced pressure principle backflow preventer is accomplished

F

Ball Valve C

Needle

Valve B

Low

ressure

P

Hose

Red)

(

igure 1 - Pressure Vacuum Breaker

F

Vent Hose

(Blue)

est cock

T

o. 2

N

igh Pressure

H

Hose (Yellow)

Test cock

o. 1

N

A

Loaded air inlet valve

No. 2 shut-off valve

Check valve

o. 1 shut-off valve

N

utilizing a differential pressure gage such as the BTK2 test kit. The device is tested

for three optional characteristics: i.e., (1) the first check valve is tight and maintains a

minimum of 5 psi differential pressure, (2) the second check valve is tight against

backpressure and (3) the relief valve opens at a minimum of 2 psi below inlet supply

ressure. Testing is performed as follows:

p

tep 1 - Refer to Figure 2

S

Test to ensure that the first check valve is tight and maintains a minimum pressure of

5 psi differential pressure using the following procedure. Perform with Ball Valve C

closed.

1. Verify that number 1 shut-off valve is open. Close number 2 shut-off valve. If there

is no drainage from the relief valve, it is assumed that the first check valve is tight.

2. Close all test kit valves.

3. Connect the high pressure hose (yellow) to test cock number 2.

4. Connect the low pressure hose (red) to test cock number 3.

5. Open test cocks number 2 and number 3.

6. Open high pressure side needle valve B on test kit bleeding the air from the high

pressure hose. Close the high pressure side ball valve A.

7. Open the low pressure side needle valve B on test kit bleeding air from the low

pressure hose (red). Close the low side needle valve B. Record the differential gage

pressure reading. It should be a minimum of 5 psid.

tep 2- Refer to Figure 3

S

est to ensure that the second check valve is tight against backpressure using the

T

ollowing procedure.

f

1. Leaving the hoses hooked up as in the conclusion of Step 1, connect vent hose

(blue) to test cock number 4.

2. Open test cock number 4, the high pressure ball valve A and the bypass hose ball

alve C on the test kit. (This supplies high pressure water downstream of check valve

v

umber 2.) If the differential pressure gage reading drops and water comes out of the

n

elief valve, the second check valve is recorded as leaking. If the differential pressure

r

age reading remains steady, and no water comes out of the relief valve, the second

g

check valve is considered tight.

3. To check the tightness of number 2 shut-off valve, leave the hoses hooked up the

same as at the conclusion of Step 2 (2), and then close test cock number 2. This stops

he supply of any high pressure water downstream of check valve number 2. If the

t

ifferential pressure gage reading holds steady, the number 2 shut-off valve is

d

ecorded as being tight. If the differential pressure gage reading drops to zero, the

r

umber 2 shut-off valve is recorded as leaking.

n

With a leaking number 2 shut-off valve, the device is, in most cases, in a flow

condition and the previous readings taken are invalid. Unless a no-flow condition can

e achieved, either through the operation of an additional shut-off downstream, or the

b

se of a temporary compensating bypass hose, accurate test results will not be

u

chieved.

a

Step 3 Check that the relief valve opens at a minimum pressure of 2 psid below inlet

pressure using the following procedure.

1. With the hoses hooked up the same as at the conclusion of Step 2 (3), slowly open

p the low pressure control needle valve B on the test kit and record the differential

u

ressure gage reading at the point when the water initially starts to drip from the relief

p

alve opening. This pressure reading should not be below 2 psid.

v

This completes the standard field test for a reduced pressure principle backflow

preventer. Before removal of the test equipment, the tester should ensure that they

open number 2 shut-off valve thereby reestablishing flow. Also, the test kit should be

thoroughly drained of all water to prevent freezing by opening needle valve B, and ball

valves A and C.

lve

f va

f

o

t-

.1

sh

ck No

. 1

No

st co

Te

.2

u

ck No

st co

Ch

Te

e

ck va

.1

.3

No

lve

ck No

st co

Te

.2

4

.

No

o

N

lve

ck

ck va

e

Ch

N

st co

Te

ve

l

va

f

f

o

-

t

u

sh

2

.

o

e

valv

No.

ock

c

t

es

T

High Pressure

Hose (Yellow)

off

-

1

hut

No.2

1 s

No.

cock

t

Tes

Ball Valve A

o.1

N

o.3

e

N

k

alv

v

k

hec

C

oc

c

t

Tes

Ball Valve C

Needle

Valve B

k

hec

C

Vent Hose

(Blue)

v

Figure 2 - Reduced Pressure Principle Backflow Preventer

e

alv

o.2

N

Tes

Low Pressure

o.4

N

k

oc

c

No

t

Hose (Red)

lve

f va

f

o

t-

u

sh

.2

Temporary

Bypass Hose

(Black)

High Pressure

Hose (Yellow)

Ball Valve A

Ball Valve C

Needle

Valve B

Vent Hose

(Blue)

Low Pressure

Hose (Red)

Figure 3 - Reduced Pressure Principle Backflow Preventer

Page 3

ouble Check Valve Assemblies

D

ome field test procedures for testing double check valve assemblies require that

S

he number 1 shut-off valve be closed to accomplish the test. This procedure may

t

ntroduce debris such as rust into the valve that will impact against check valve

i

number 1 or number 2 and compromise the sealing quality. This potential problem

should be considered prior to the selection of the appropriate test method.

he following steps are performed utilizing the BTK2 without the need to shut off

T

umber 1 shut-off valve. For the following steps, refer to figure 4.

n

tep 1 - Checking check valve number 1.

S

1. Verify that the number 1 shut-off valve is open. Shut-off number 2 shut-off valve.

2. Connect the high pressure hose (yellow) to test cock number 2.

3. Connect the low pressure hose (red) to test cock number 3.

. Open test cocks 2 and 3.

4

. Open high pressure side ball valve A on test kit bleeding the air from the high

5

ressure hose (yellow). Close the high pressure side ball valve A.

p

6. Open low pressure side needle valve B on test kit bleeding the air from the low

pressure hose (red). Close the low pressure side needle valve B.

No

k

c

o

c

t

s

e

T

High Pressure

ose (Yellow)

H

e

v

l

a

v

f

f

o

t-

.1

h

s

1

.

No

u

t

s

e

T

.2

No

k

c

o

c

Ch

Ball Valve A

.1

No

.3

e

No

v

l

k

a

c

v

o

k

c

c

t

e

s

e

T

Ball Valve C

Needle

alve B

V

.2

4

No

.

o

e

v

l

N

k

a

c

v

o

k

c

e

e

T

Ch

o

c

N

t

s

e

v

l

a

v

f

f

o

-

t

u

h

s

2

.

Step 2 - Checking check valve number 2.

. Connect the high pressure hose (yellow) to test cock number 3.

1

. Connect the low pressure hose (red) to test cock number 4.

2

. Open test cocks number 3 and 4.

3

4. Open high pressure side ball valve A on test kit bleeding the air from the high

pressure hose (yellow). Close the high pressure side ball valve A.

5. Open low pressure side needle valve B on test kit bleeding the air from the low

pressure hose (red). Close the low pressure side needle valve B.

. Record the differential gage pressure reading. It should be a minimum of 1 psid.

6

. Disconnect the hoses.

7

Check tightness of number 2 shut-off valve, both the check valves must be tight

and holding a minimum of 1 psid using the following procedure. Little or no

fluctuation of inlet supply pressure can be tolerated.

The testing is performed as follows:

1. Connect the high pressure hose (yellow) to number 2 test cock.

2. Connect the low pressure hose (red) to number 3 test cock.

3. Connect the vent hose (blue) to number 4 test cock.

4. Open test cocks numbers 2, 3, and 4.

5. Open high pressure side ball valve A on test kit bleeding the air from the high

pressure hose. Close the high pressure side ball valve A.

6. Open low pressure side needle valve B on test kit, bleeding the air from the low

pressure hose (red). Close the low pressure side needle valve A.

7. The differential gage pressure should read a minimum of 1 psid.

8. Open the high pressure side ball valve A and the bypass hose ball valve C on

the test kit. (This supplies high pressure water downstream of check valve number

2).

9. Close test cock number 2. (This stops the supply of any high pressure water

downstream of number 2 check valve). If the differential pressure gage reading

holds steady, the number 2 shut-off valve is recorded as being tight. If the

differential pressure gage drops to zero, the number 2 shut-off valve is recorded as

leaking.

Vent Hose

(Blue)

Low Pressure

Hose (Red)

igure 4 - Double Check Valve Assemblies

F

With a leaking number 2 shut-off valve, the device is, in most cases, in a flow

condition, and the previous test readings taken are invalid. Unless a no flow

condition can be achieved, either through the operation of an additional shut-off

downstream, or the use of a temporary compensating bypass hose, accurate test

results will not be achieved. This completes the standard field test for a double

check valve assembly. Prior to removal of the test equipment, the tester should

ensure that they open number 2 shut-off valve thereby reestablishing flow. All test

data should be recorded on appropriate forms and the test kit drained of water.

MAINTENANCE/REPAIR

The Model BTK2 requires no routine maintenance, but should be routinely checked

for calibration. The Model BTK2 is not field serviceable and should be returned if

repair is needed. Field repair should not be attempted and may void warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on our website. Contact

customer service to receive a Return Goods Authorization number before shipping

the product back for repair. Be sure to include a brief description of the problem

plus any additional application notes.

Page 4

©Copyright 2012 Dwyer Instruments, Inc. Printed in U.S.A. 10/12 FR# R1-444075-00

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Loading...

Loading...