Page 1

Series BGM Bar Graph Meter

X

XXX

TARE

M

ENU

V

ALLEY

>

P

EAK

S

ETPT/

RESET

X

X.X

X

X.X

XX.X

XX.X

XX.X

XX.X

L

1

L2

1-13/32

[35.56]

5-45/64

[144.78]

VERTICAL

2

1/64

[

8.33]

2

1/32

[

16.51]

19/32

[14.99]

5

1/64

[

20.07]

55/64

[21.84]

1

7/64

[

6.92]

21/64

[8.33]

3-51/64

[96.39]

25/32

[19.81]

5

5/64

[

21.72]

Installation and Operating Instructions

orizontal

H

Vertical

The Series BGM Digital Bar Graph Meter is extremely durable and can

replace a wide range of analog meters. The 4-digit display will

significantly reduce the potential for human error in reading by eliminating

errors commonly produced by the viewing angle when reading analog

meters. This series has a key pad that allows for easy access of features

without complex menu structures. With the combined ability to create a

wide range of custom faceplate and the optional NEMA 4X bezel, the

Series BGM can be used in a variety of applications. The LED bar graph

adds a visual indicator of the measured value so that it can be visually

analyzed, preventing accidents or system failures from happening.

POWER SUPPLY SPECIFICATIONS

120 VAC UNITS

Input Voltage Range: 85 to 140 VAC

Input Frequency Range: 47 to 63 Hz

Power Dissipation: < 3 VA

P4 WIRING

P4 - 1 : Neutral Line

P4 - 2 : 120 VAC Hot Line

P4 - 3 : Chassies Ground - Read Cautions

5 TO 12 VDC UNITS

Input Voltage Range: 5 TO 12 VDC

Permissable Ripple: 200 mV Max

Input Current: < 200 mA

Bulletin PC-BGM

PECIFICATIONS

S

Inputs: 0 to ±10 VDC or 4 to 20 mA.

ccuracy: ±0.05% FS.

A

ower Requirements: 120 VAC 50/60 Hz, 5 to 12 VDC, or 10 to 30 VDC model

P

ependent.

d

Power Consumption:

120 VAC: 2.4 W @ 20 mA max;

5 to 12 VDC: 1.2 W @ 100 mA max;

10 to 30 VDC: 1.5 W @ 50 mA max.

Display:

LED Display: 4 red colored digits, 0.3˝ height;

LED Graph: 31 element bar, 0.2˝ W x 3.1˝ L (5.08 mm W x 78.74 mm L).

Decimal Point: 3 positions, user selectable.

Temperature Limits:

Operating: -13 to 176°F (-25 to 80°C);

Storage: -67 to 176°F (-55 to 80°C).

Enclosure Rating: NEMA 1 or NEMA 4X

Electrical Connections: Removable screw terminal blocks.

Outputs: 2 SPST relay outputs (optional).

Switch Rating: 1 A @ 200 V.

Enclosure Material:

Bezel: Black epoxy enameled steel;

Window: Acrylic;

Case and Mounting Bracket: 304 SS.

Time Delay: 0.5 sec.

Weight: 40 oz (1.13 kg).

Wiring Guide

†

, model dependent IP65 front.

P4 WIRING

P4 - 1 : GROUND

P4 - 2 : + DC

P4 - 3 : Chassies Ground - Read Cautions

10 TO 30 VDC UNITS

Rear View

Input Voltage Range: 10 TO 30 VDC

Permissable Ripple: 500 mV Max

Input Current: < 150 mA

P4 WIRING

P4 - 1 : GROUND

P4 - 2 : + DC

P4 - 3 : Chassies Ground - Read Cautions

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

FRONT PANEL CONTROLS

PEAK / ^ (SET)

• Press and hold to view peak value

• To reset the peak value - while holding ‘PEAK’, press ‘SETPT/RESET’

momentarily.

• When in the setpoint or menu mode, this button changes the setting for

a parameter or increments the flashing digit.

SETPT / RESET

• Press momentarily to view/set setpoint 1 - see instructions below to set

a setpoint or scaling value.

• Press again momentarily to view/set setpoint 2 - see instructions below

to set a setpoint or scaling value.

• Press again momentarily to return to the operate mode.

• Press while holding ‘PEAK’, ‘VALLEY’ or ‘TARE’ to reset those values.

TARE

• Press momentarily to zero meter display.

• Display offset (TARE) value is stored until power is removed, menu is

entered or TARE is reset.

• To reset the TARE value - while holding ‘TARE’, press ‘SETPT/RESET’

momentarily.

MENU

• Press to enter the menu/scaling mode.

• Press again to exit the menu/scaling mode.

VALLEY / > (STEP)

• Press and hold to view valley value.

• To reset the valley value - while holding ‘VALLEY’, press

‘SETPT/RESET’ momentarily.

• When in the setpoint or menu mode, this button advances to the next

parameter or to the next digit.

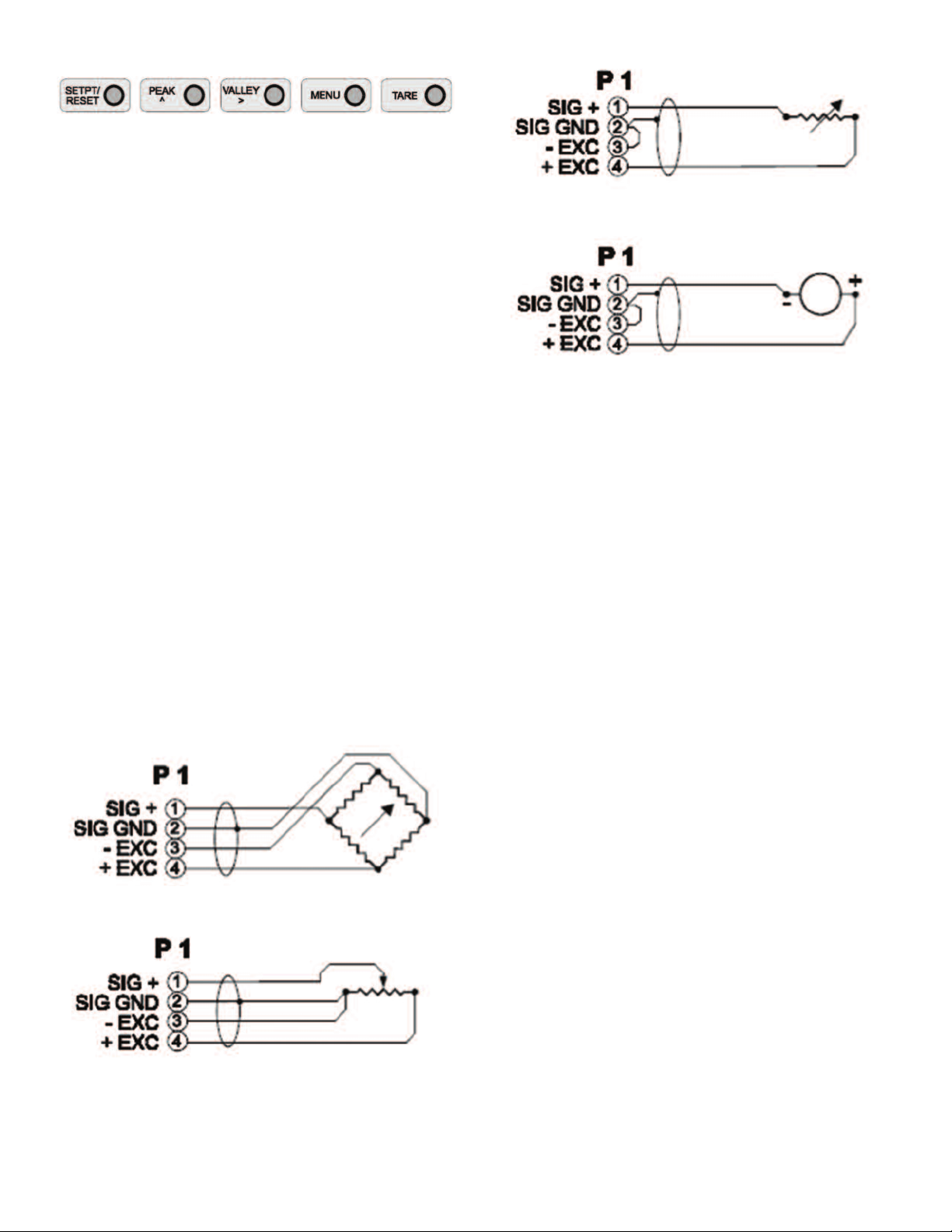

TRANSCONDUCTANCE SENSORS

ie: PH PROBE CURRENT INPUT METERS

2 WIRE LOOP POWERED PROBES

ie: 4-20 mA TEMPERATURE TRANSMITTER

CURRENT INPUT METERS

P2 - REMOTE CONTROL INPUTS

P2 - 1: GROUND RETURN

P2 - 2: TARE

P2 - 3: SETPT / RESET

P2 - 4: PEAK / ^ (SET)

P2 - 5: VALLEY / > (STEP)

P2 - 6: MENU

Above inputs are all active low - short input to ground return or pull to

logic low to activate function; see front panel control section for a

description of each function.

CONNECTOR / PIN DESCRIPTIONS

P1 - SIGNAL INPUT

P1 - 1: SIGNAL INPUT

P1 - 2: SIGNAL RETURN

P1 - 3:+VOLTAGE RETRANSMISSION (OPTIONAL)

P1 - 4: -VOLTAGE RETRANSMISSION (OPTIONAL)

4 WIRE TRANSDUCERS

ie: LOAD CELL VOLTAGE INPUT METERS

3 WIRE TRANSDUCERS

ie: LINEAR POT VOLTAGE INPUT METERS

Installation of a shorting jumper between pins P2-5 and P2-6 disables

the five front panel push buttons.

P3 - SETPOINT RELAY OUTPUT

Note: This terminal block position will only be present if the meter is

equipped with the corresponding option.

Note: Setpoint relays are rated at 200 VAC/DC @ 1 AMP maximum.

P3 - 1: SETPOINT 1 RELAY

P3 - 2: SETPOINT 1 RELAY

P3 - 3: SETPOINT 2 RELAY

P3 - 4: SETPOINT 2 RELAY

P4 - POWER INPUT

See power supply specifications (page 1) for connection information.

Page 3

Horizontal Version Mounting

Vertical Version Mounting

Page 4

Set-Up Menu

Parameter

Decimal Point

Averaging

Setpoint 1 Active Level

Setpoint 1 Bar Indication

Setpoint 2 Active Level

Setpoint 2 Bar Indication

Bar Direction

Bar Format

Bar Starting Point Scaling

Bar Full Scale Point

CAL Point 1

CAL Point 2

Setting

d_ _0

d_0.0

d0.00

d.000

Av.16

Av.8

Av.4

Av.2

Av.1

S1.no

S1.nc

S1nF

S1Fb

S2.no

S2.nc

S2nF

S2Fb

br.bu

br.td

br.C0

bF.F

bF.d

[ ] [ ] [ ] [ ]

[ ] [ ] [ ] [ ]

CAL1

1234

CAL2

1234

Description

No Decimal Point

O.O

O.OO

O.OOO

4096 Conversions Averaged; 1 Update/Second

2048 Conversions Averaged; 2 Updates/Second

1024 Conversions Averaged; 4 Updates/Second

512 Conversions Averaged; 8 Updates/Second

256 Conversions Averaged; 16 Updates/Second

Setpoint 1 Output will be Normally Open

Setpoint 1 Output will be Normally Closed

Do Not Flash Bar

Flash Bar When Limit 1 Closes

Setpoint 2 Output will be Normally Open

Setpoint 2 Output will be Normally Closed

Do Not Flash Bar

Flash Bar When Limit 2 Closes

Bottom Up

Top Down

Center Zero or Center Reference

Full Bar Display

Moving Dot Display

Enter the Display Value for the Starting Bar LED

Enter the Display Value for the Full Scale Bar LED

Announces CAL 1 Step

Adjust Display to Desired Value for CAL 1 Input

Announces CAL 1 Step

Adjust Display to Desired Value for CAL 2 Input

To Set a Setpoint or Scaling Value

• Press and release the 'peak / ^' button until the flashing digit reaches

the desired value.

• Press the 'valley / >' button to advance to the next digit.

• Repeat until all digits are set.

Note: This meter is equipped with leading zero suppression - blank digits

are assumed to be 0's (they will not flash).

Note: To allow the entry of negative values, the msd (left most digit) will

increment 0 thru 9, -1, -(0).

Calibration Instructions

• The BGM series requires 2 known input signals for calibration / scaling.

These inputs can be of any polarity with respect to each other and should

be as far apart as possible in magnitude.

• Apply the first known input signal to the meter input.

• Simulttaneously press the 'setpt / reset' and 'tare' push buttons to

advance to the CAL 1 value setting step. Adjust the CAL 1 value on the

display until it is at the desired value for the known input. See the

instructions above to set a setpoint or scaling value.

• Simultaneously press both the 'setpt / reset' and 'tare' buttons to enter

this scaling / calibration point. Press the 'valley / >' button to advance to

the CAL 2 value setting step.

• Apply the second known input signal to the meter input.

• Adjust the CAL 2 value on the display until it is at the desired value for

the known input. See the instructions above to set a setpoint or scaling

value.

• Simultaneously press both the 'setpt / reset' and 'tare' buttons to enter

this scaling / calibration point.

CAUTION

your model number to be sure which. Line voltages always present a hazardous

and potentially lethal situation and care should be taken to ensure that power has

been removed from the circuits being wired into.

WIRING - When using stranded wire, inspect the junctions to ensure that all of the

strands are fully inserted into the terminal block, and that the terminal screw has

been tightened, before applying power to the meter.

CHASSIS GROUNDING - If local electrical codes require the case of this unit to be

electrically grounded, make the connection to P4 pin 3. If unsure of code

requirement, make the ground connection. Poor line conditions may cause this

connection to increase noise sensitivity of the meter.

;

POWER WIRING - This meter is designed to be powered from

standard linevoltages, 120 VAC or 240 VAC, not both, check

MAINTENANCE/REPAIR

Upon final installation of the Series BGM, no routine maintenance is

required. The Series BGM is not field serviceable and should be returned

if repair is needed. Field repair should not be attempted and may void

warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on our

website. Contact customer service to receive a Return Goods

Authorization number before shipping the product back for repair. Be

sure to include a brief description of the problem plus any additional

application notes.

©Copyright 2013 Dwyer Instruments, Inc. Printed in U.S.A. 12/13 FR# R2-444135-00

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...