Page 1

Bulletin V-6

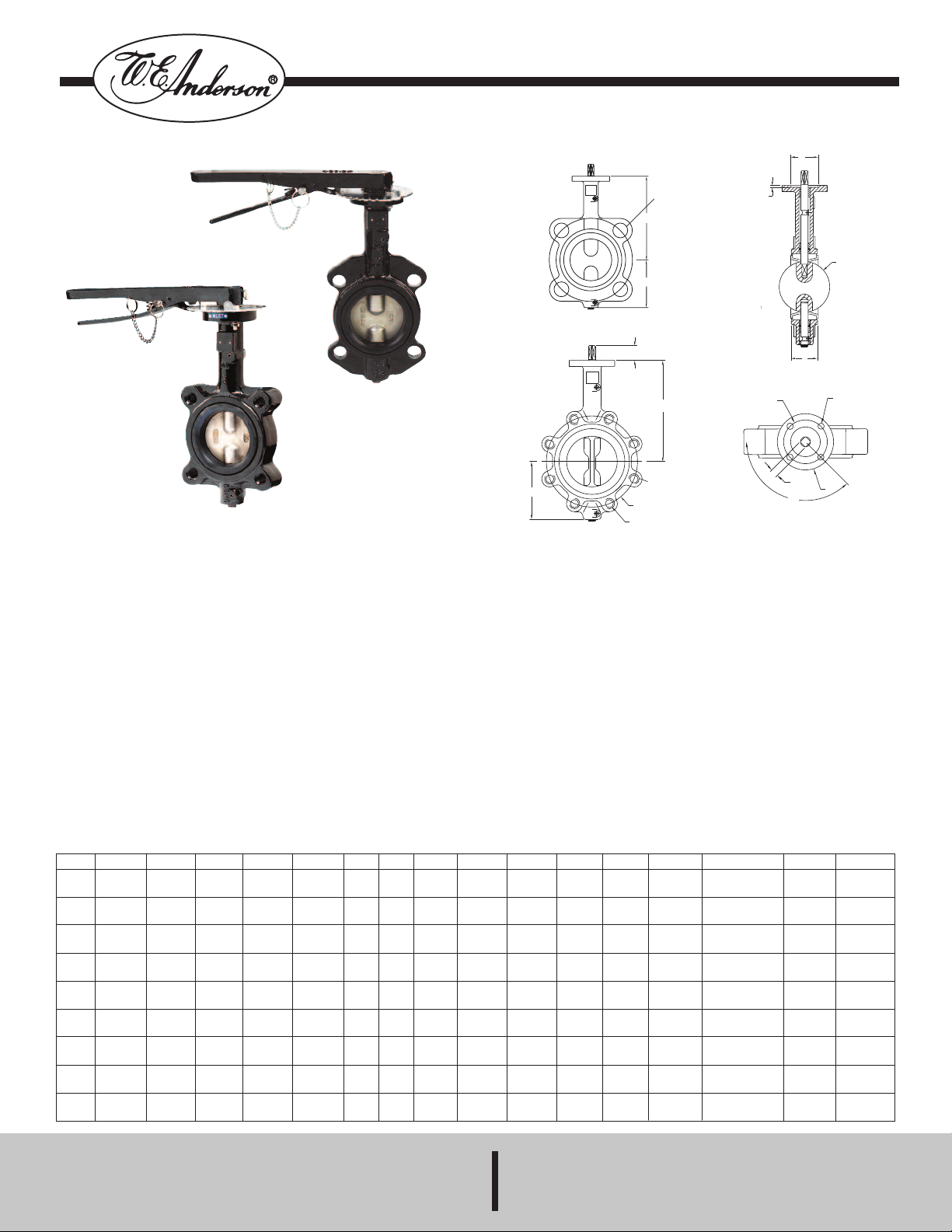

B

A

n = # of holes

h

L

A

B

øD1

BOLT CIRCLE

n = # of holes

M = thread size

øD

C

øg

h

135°

øK

P

øE

ø

d

4

PLCS

Series BFV Butterfly Valves

Specifications - Installation and Operating Instructions

WAFER STYLE

“WF”

WAFER STYLE

LUG STYLE

Series BFV Butterfly Valves are bi-directional allowing control of fluid flow and

sealing in either direction, and are designed for installation between the faces of

125#/150# ANSI flanges. They do not require gaskets; the integral seat serves as

the gasket. The wafer and lug bodies have bolt hole locations for alignment and

attachment with mating flanges.

Prior to installation, close the valve. Spread the flanges apart far enough to allow

the valve to slip easily between the flanges. Insert the valve between the flanges.

Be sure to center the valve and not damage the liner. Allow the flanges to return to

their un-spread state. Install and hand-tighten all flange bolts. Slowly open the

valve, checking for free movement of the disc. If no obstruction is encountered,

leave valve in the open position and tighten all flange bolts. Be certain to keep

flange faces as parallel as possible during and after tightening bolts or studs. After

final tightening, again check the valve for full opening and closing.

Lug style bodies used for dead end service must be installed as marked on the

body (inlet–outlet).

DIMENSIONS [in (mm)]

n, WF

C

1-21/32

(42.07)

1-49/64

(44.85)

1-25/32

(45.24)

2-1/16

(52.39)

2-5/32

(54.77)

2-13/64

(55.96)

2-25/64

(60.72)

2-19/32

(65.88)

3-1/32

(76.99)

øD

2-5/64

(52.78)

2-35/64

(64.69)

3-7/64

(78.98)

4-7/64

(104.38)

4-55/64

(123.43)

6-9/64

(155.97)

7-63/64

(202.80)

9-7/8

(250.83)

11-7/8

(301.63)

3-11/32

3-55/64

4-3/32

(104)

4-27/32

(123)

5-11/32

(136)

5-53/64

(148)

7-5/16

(186)

8-11/32

(212)

9-7/8

(251)

B

(85)

(98)

Size

A

6-11/32

2˝

(161.13)

6-57/64

2-1/2˝

(175.02)

7-9/64

3˝

(181.37)

7-7/8

4˝

(200.03)

8-25/64

5˝

(213.12)

8˝

10˝

(226.22)

10-1/4

(260.31)

11-1/2

8-29/32

6˝

(292.10)

13-9/32

12˝

(337.34)

øD1

4-3/4

(120.65)

5-1/2

(139.70)

6-1/16

(153.99)

7-1/2

(190.50)

8-33/64

(216.30)

9-33/64

(241.70)

11-49/64

(298.85)

14-17/64

(362.35)

17-1/64

(432.20)

4

4

4

4

8

8

8

12

12

W.E. ANDERSON DIV., DWYER

INSTRUMENTS, INC.

P.O. BOX 358 • MICHIGAN CITY, INDIANA 46361 U. S. A.

n, LT

4

4

4

8

8

8

8

12

12

M

5/8

(15.88)

5/8

(15.88)

5/8

(15.88)

5/8

(15.88)

3/4

(19.05)

3/4

(19.05)

3/4

(19.05)

7/8

(22.23)

7/8

(22.23)

LUG STYLE

“LT”

SPECIFICATIONS

VALVE BODY

Service: Compatible liquids, gases,

and steam.

Line Size: 2˝ to 12˝.

Body Style: 2-way, wafer, or lug

butterfly.

End Connections: Flange, to be used

with flanges that are ANSI Class 125

(B16.1) and ANSI Class 150 (B16.5)

dimensions.

Pressure Limit: 225 psi (15.5 bar)

WOG.

øK

3-1/32

(76.99)

3-1/32

(76.99)

3-1/32

(76.99)

3-35/64

(90.09)

3-35/64

(90.09)

3-35/64

(90.09)

4-59/64

(125.02)

4-59/64

(125.02)

5-33/64

(140.10)

øE

1-31/32

(50.01)

1-31/32

(50.01)

1-31/32

(50.01)

2-49/64

(70.25)

2-49/64

(70.25)

2-49/64

(70.25)

4-1/64

(102)

4-1/64

(102)

4-1/64

(102)

ød

9/32

(7.14)

9/32

(7.14)

9/32

(7.14)

23/64

(9.13)

23/64

(9.13)

23/64

(9.13)

29/64

(11.5)

29/64

(11.5)

29/64

(11.5)

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

h

1-25/64

(35.32)

1-25/64

(35.32)

1-25/64

(35.32)

2-11/64

(55.17)

2-11/64

(55.17)

2-11/64

(55.17)

2-49/64

(70.25)

2-49/64

(70.25)

2-49/64

(70.25)

L

1-17/64

(32.15)

1-17/64

(32.15)

1-17/64

(32.15)

1-17/64

(32.15)

1-17/64

(32.15)

1-17/64

(32.15)

1-1/2

(38)

1-1/2

(38)

1-1/2

(38)

Wetted Materials:

Body Material: Ductile iron.

Disc: 316 SS.

Seat and O-ring: EPDM or PTFE.

Stem: 410 SS.

Temperature Limits: Disc: EPDM: -50

to 250°F (-46 to 121°C). PTFE: 0 to

300°F (-18 to 149°C).

Bearings: Nylatron.

Flow Rate: See Cv chart.

Operator: 2 to 6˝: 10-position locking

hand lever. 8 to 12˝: manual gear.

ISO 5211

P

23/64 x 23/64

(9.13 x 9.13)

23/64 x 23/64

(9.13 x 9.13)

23/64 x 23/64

(9.13 x 9.13)

7/16 x 7/16

(11.11 x 11.11)

9/16 x 9/16

(14.29 x 14.29)

9/16 x 9/16

(14.29 x 14.29)

43/64 x 43/64

(17.07 x 17.07)

7/8 x 7/8

(22.23 x 22.23)

7/8 x 7/8

(22.23 x 22.23)

LO

10-41/64

(270.27)

10-41/64

(270.27)

10-41/64

(270.27)

10-41/64

(270.27)

10-41/64

(270.27)

10-41/64

(270.27)

14-3/16

(360.36)

19-11/16

(500.06)

19-11/16

(500.06)

F05

F05

F05

F07

F07

F07

F10

F10

F10

Page 2

ALVE DISASSEMBLY

LO

F

C

B

A

E

Ø

G

h1

g1

V

1. After removal of valve from the piping system, open the valve fully;

. Remove the handle or actuator;

2

. Remove the stem retaining pins;

3

4. Pull out the upper stem;

5. Pull out the bottom stem;

. Remove the disc from the liner. Do not damage the disc edge;

6

. Remove the liner;

7

8. If the valve has bushings and o-rings, remove by tapping with blunt instrument;

. Inspect all components for wear and replace as required.

9

VALVE ASSEMBLY

1. Clean all reusable parts;

. If valve has bushings and o-rings, tap them carefully;

2

. Apply a lubricant or soapy solution compatible with elastomers to facilitate

3

assembly;

4. Insert liner into body by pressing it into the body evenly;

. Insert disc in open position into liner. Make certain broached end of disc is at

5

the upper stem end of the body;

6. Coat the upper stem with a general purpose lubricant & install into body;

. Install bottom stem;

7

. Install retaining pins to both stems;

8

9. Install the operator;

10. Check assembly by opening & closing the valve several times;

1. Follow installation instructions for reinstalling the valve in the piping system.

1

MAINTENANCE

o regular maintenance or lubrication is required.

N

WARRANTY

The Series BFV Butterfly Valve is warranted from defects in materials and

workmanship for (1) year from the date of purchase. In the unlikely event the valve

should fail, the unit can be returned to the factory for warranty repair if the warranty

period has not expired. Contact our customer service department for an RGA

number and to set up the return.

BREAK TORQUES IN INCH-POUNDS

EPDM Seats

ervice Pressure

S

50 psi

00 psi

1

150 psi

00 psi

2

PTFE Seats

ervice Pressure

S

0 psi

5

100 psi

50 psi

1

200 psi

8

108

1

150

125

1

142

1

-1/2

2

2

126

1

150

1

2

130

1

160

2

44

98

-1/2

45

20

179

1

210

2

195

2

248

3

6

26

2

30

80

3

95

97

3

10

40

Size (inches)

4

5

295

610

10

3

6

335

725

00

4

Size (inches)

4

390

650

30

4

6

443

720

90

4

7

5

6

8

0

40

750

80

7

99

847

40

9

5

6

890

90

40

9

974

95

020

1

1440

490

1

1549

800

1

8

1690

710

1

1770

890

1

1

2466

910

2

3360

890

3

1

3699

365

4

5040

835

5

0

Cv VALUES

EGREE OPENING

Size

10°

0

0

0

0

0.8

20°

.1

5

.2

8

.3

12

.5

7

1

9

2

2

5

4

3

89

4

151

5

234

˝

2

-1/2˝

2

˝

3

˝

4

5˝

6˝

8˝

10˝

2˝

1

v is the number of U.S. GPM of 60°F water that will pass through the valve with a 1 PSI

C

pressure drop.

D

30°

40°

12

24

20

37

22

39

6

3

8

7

1

6

33

1

5

9

05

2

188

408

320

694

495

1072

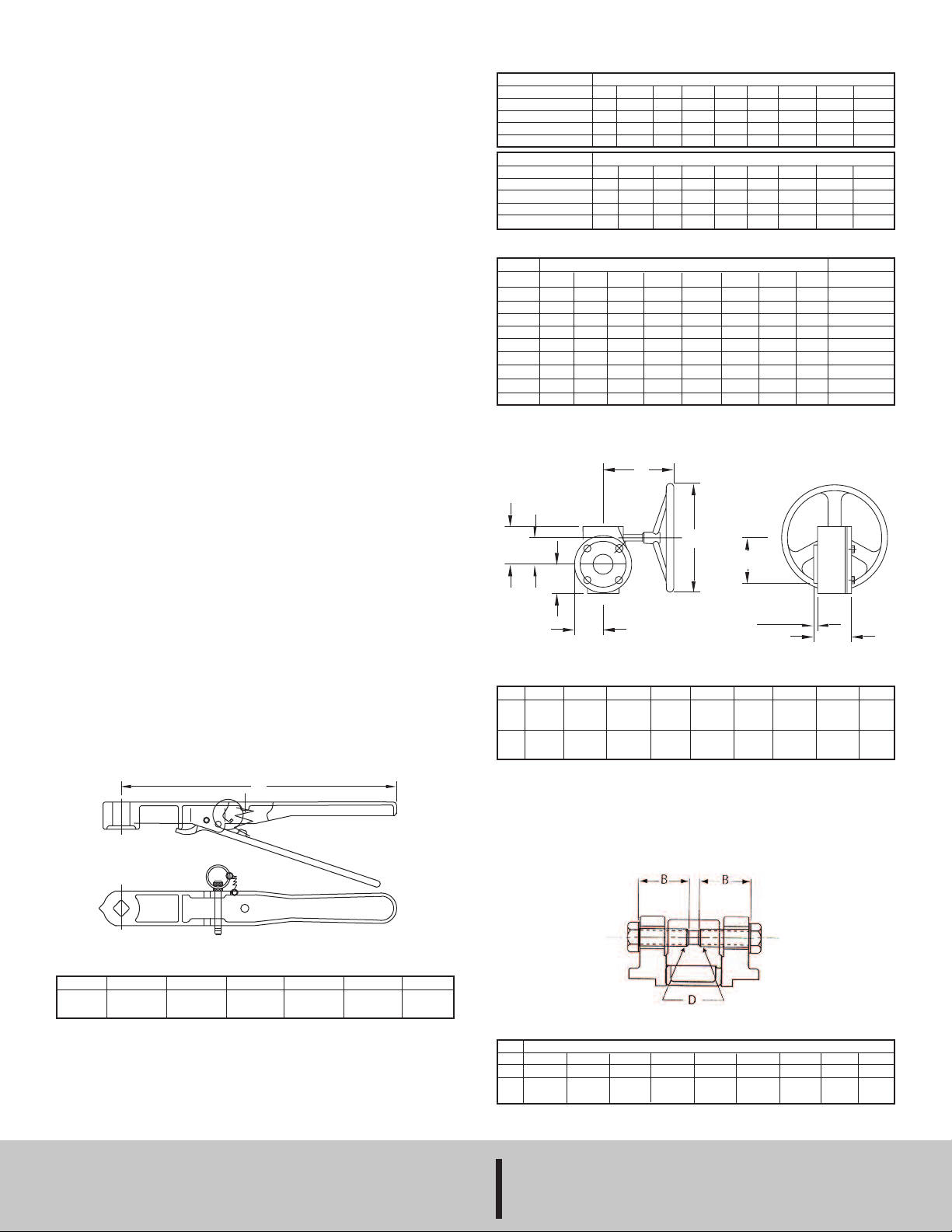

ANUAL GEAR “MG”

M

50°

45

65

70

39

1

37

2

66

3

727

1237

1911

60°

64

98

116

30

2

92

3

05

6

1202

2047

3162

70°

90

144

183

64

3

20

6

58

9

1903

3240

5005

80°

25

1

04

2

75

2

46

5

930

1437

2854

4859

505

7

ULL OPEN

F

3510

4

5560

7

5265

6

8340

1367

1

90°

135

220

302

00

6

022

1

579

1

3136

5340

8250

1

100

558

1

150

2

2

HAND LEVER “HL”

HAND LEVER DIMENSIONS [in (mm)]

Size

LO2˝10-41/64

(270.27)

©Copyright 2011 Dwyer Instruments, Inc. Printed in U.S.A. 9/11 FR# R2-440860-50 Rev.1

2-1/2˝

10-41/64

(270.27)

3˝

10-41/64

(270.27)

4˝

10-41/64

(270.27)

5˝

10-41/64

(270.27)

W.E. ANDERSON DIV., DWYER

INSTRUMENTS, INC.

P.O. BOX 358 • MICHIGAN CITY, INDIANA 46361 U. S. A.

6˝

10-41/64

(270.27)

MANUAL GEAR DIMENSIONS [in (mm)]

Size

A

B

C

E

8˝-

2-61/64

2-31/64

3-63/64

(75)

3-13/64

(81.36)

2

1-1/2

5/8

-11UNC

(63.10)

3-5/32

(80.17)

2-1/2

1-1/2

5/8

-11UNC

10˝

12˝

LUG RECOMMENDED FLANGE BOLT LENGTHS (Fig. 1)

DIM

B

D

(101.20)

4-21/32

(118.27)

3

1-1/2

5/8

-11UNC

2-61/64

(75)

3-13/64

(81.36)

1-3/4

-11UNC

F

9-27/32

(250.03)

8-15/16

(227.01)

FIGURE 1

Valve Size (inches)

5

4

1-3/4

3/4

5/8

-10UNC

3-25/64

(86.12)

3-9/32

(83.34)

-10UNC

G

3/4

6

2

Ø

11-13/16

(300.04)

11-13/16

(300.04)

8

2

3/4

-10UNC

g1

2-49/64

(70.25)

2-49/64

(70.25)

10

2-1/4

7/8

-9UNC

h1

1/8

(3.18)

1/8

(3.18)

12

2-1/2

7/8

-9UNC

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...